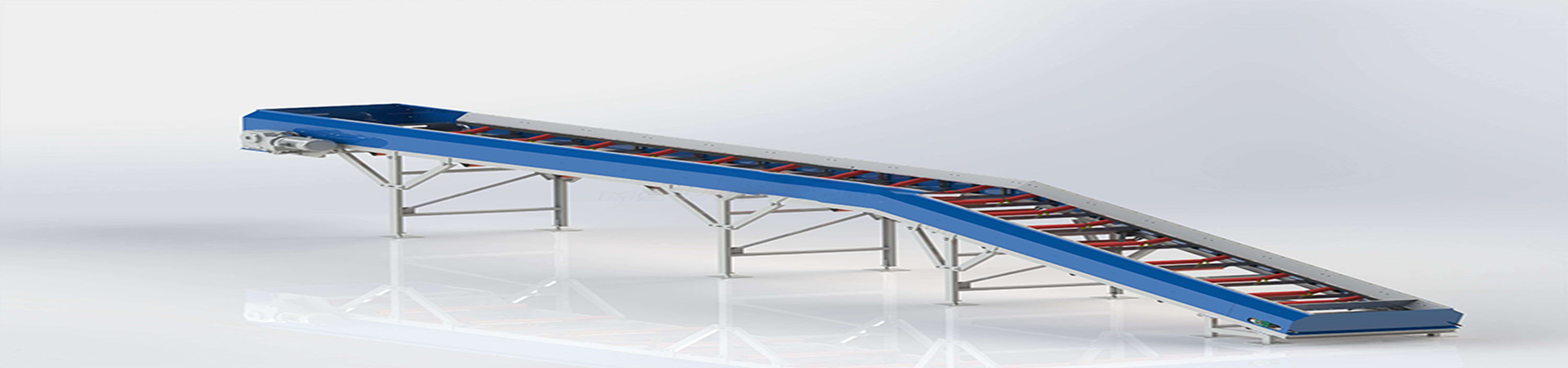

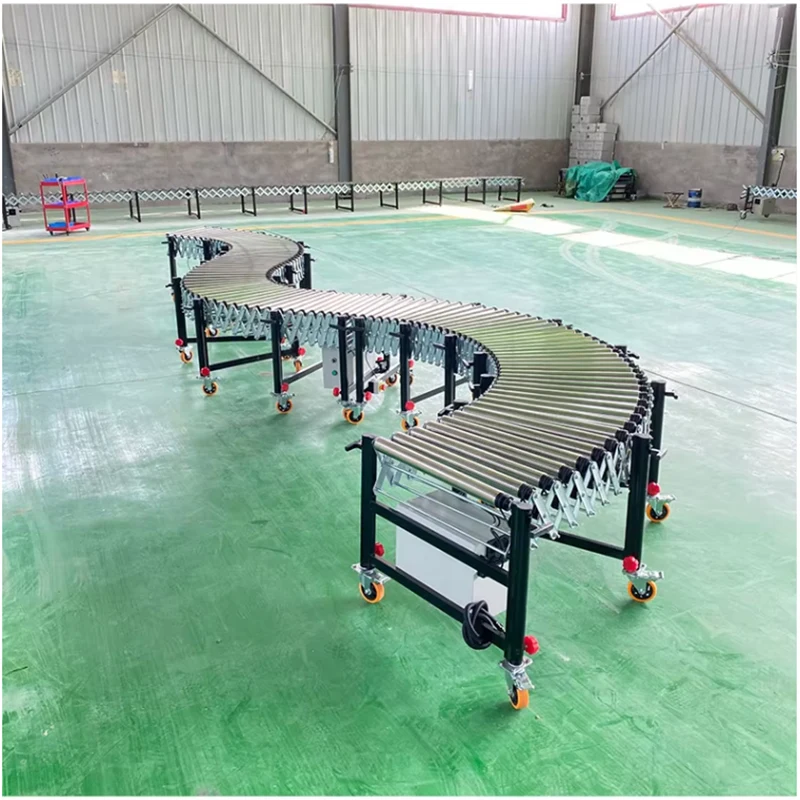

The automated pallet roller conveyor is a modern material conveying equipment that integrates high efficiency, intelligence and stability. It is widely used in many industries such as logistics warehousing, e-commerce sorting, food processing, and machinery manufacturing.It drives the roller to rotate through a motor to achieve automated transportation of pallets and goods. It can be seamlessly connected with other automated equipment to build a complete automated production line and warehousing

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Products Description

Core advantages of roller conveyor for express sorting pallets

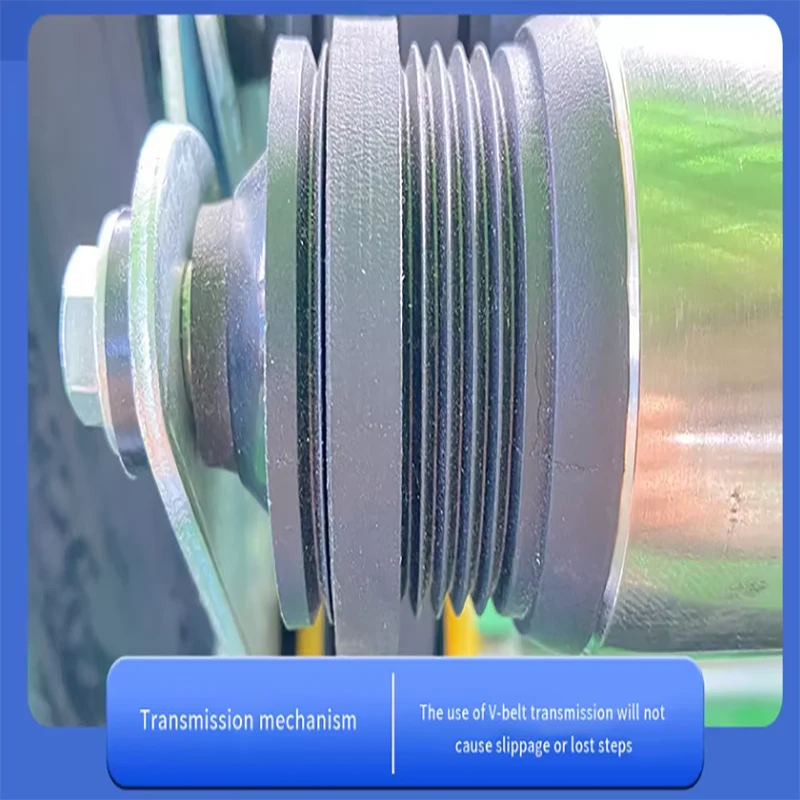

Efficient conveying: high-performance motors and high-quality rollers are used, the conveying speed is stable and adjustable, the maximum conveying speed can reach [X] meters/minute, and [X] pallets can be processed per hour, which can meet the needs of large-scale and high-intensity material transportation.

Intelligent control: equipped with advanced PLC control system and sensor device, it can realize automatic start and stop, speed regulation, sorting, counting and other functions. It supports docking with information systems such as WMS (warehouse management system) and MES (manufacturing execution system) to realize full-process automatic monitoring and management, and grasp the equipment operation status and cargo transportation information in real time.

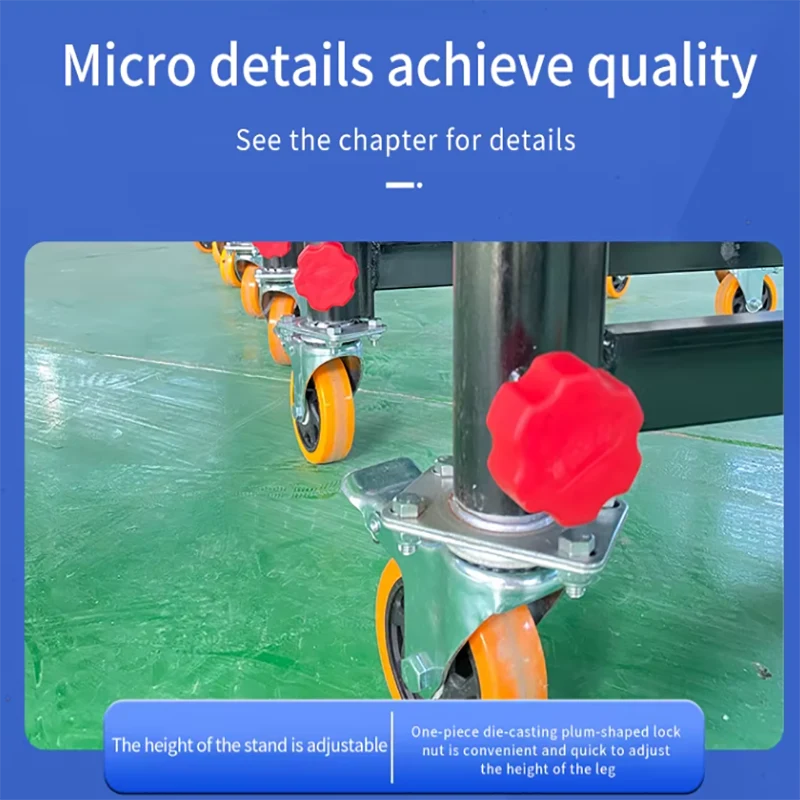

Flexible customization: personalized design can be carried out according to the customer's site layout, conveying requirements, cargo size, etc. Parameters such as roller spacing, conveying length, conveying height, and bend angle can be customized to adapt to different types of pallets (such as wooden pallets, plastic pallets, metal pallets, etc.) and cargo.

Stable and reliable: The body is welded with high-strength steel, the surface is treated with anti-corrosion, the roller is made of wear-resistant and impact-resistant high-quality materials, and key components such as motors and bearings are all internationally renowned brands, ensuring long-term stable operation of the equipment, a service life of more than [X] years, low failure rate, and easy maintenance.

Safety and environmental protection: Multiple safety protection devices are set up, such as emergency stop buttons, photoelectric protection devices, guardrails, etc., to effectively prevent accidental injuries to operators and cargo falling. The equipment operates with low noise, meets environmental protection standards, and creates a safe and comfortable working environment for enterprises.

Application scenarios of automated pallet roller conveyors

Logistics warehousing: In the warehouse warehousing, storage, sorting, and outbound links, the rapid handling and precise delivery of pallet goods are realized, and the utilization rate of storage space and cargo turnover efficiency are improved.

E-commerce sorting: With the automatic sorting system, parcels are efficiently sorted and transported, and goods at different destinations are quickly sorted and sorted to meet the processing needs of massive orders in the e-commerce industry.

Food processing: Suitable for material transportation on food production lines. Stainless steel meets food hygiene standards, can effectively avoid cargo contamination and ensure food safety.

Machinery manufacturing: In the production workshop, realize the automated transportation of parts and finished products, and work with other processing equipment, assembly lines, etc. to improve the level of production automation.

Express delivery: In the express distribution center, quickly transport and sort packages, improve express processing speed, shorten delivery time, and improve customer satisfaction.

After-sales service

Installation and commissioning: Professional technical teams provide on-site installation and commissioning services to ensure that the equipment is installed in place and operates normally, and provide free training for operators to enable them to master equipment operation and daily maintenance skills.

Warranty service: The product provides a one-year warranty period. If non-human quality problems occur during the warranty period, free repairs, replacement of parts and other services are provided.

Regular maintenance: Provide customers with regular equipment inspection and maintenance services to promptly discover and solve potential problems, extend the service life of the equipment, and ensure stable operation of the equipment.

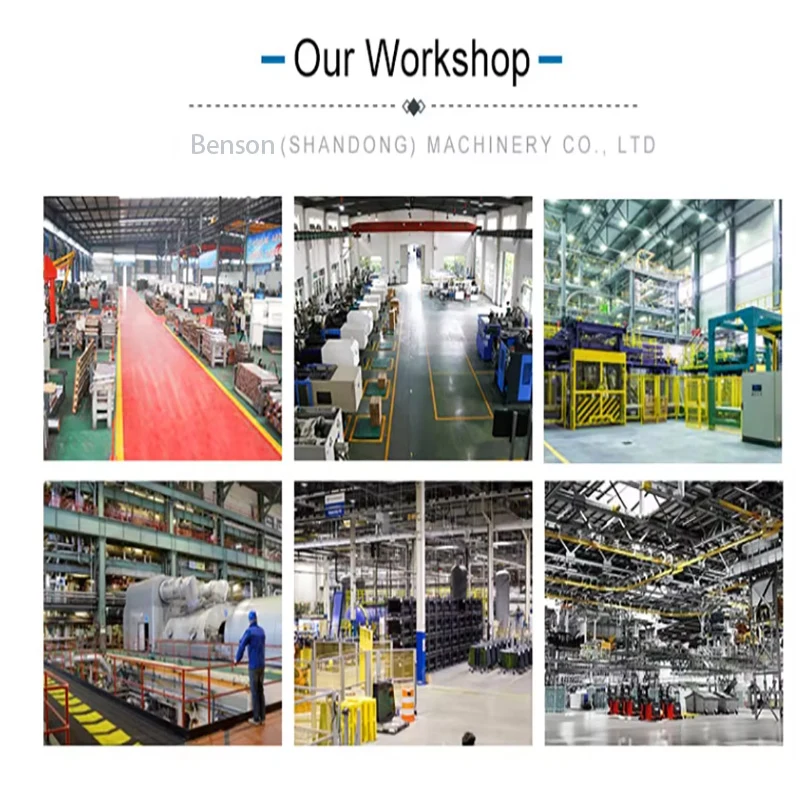

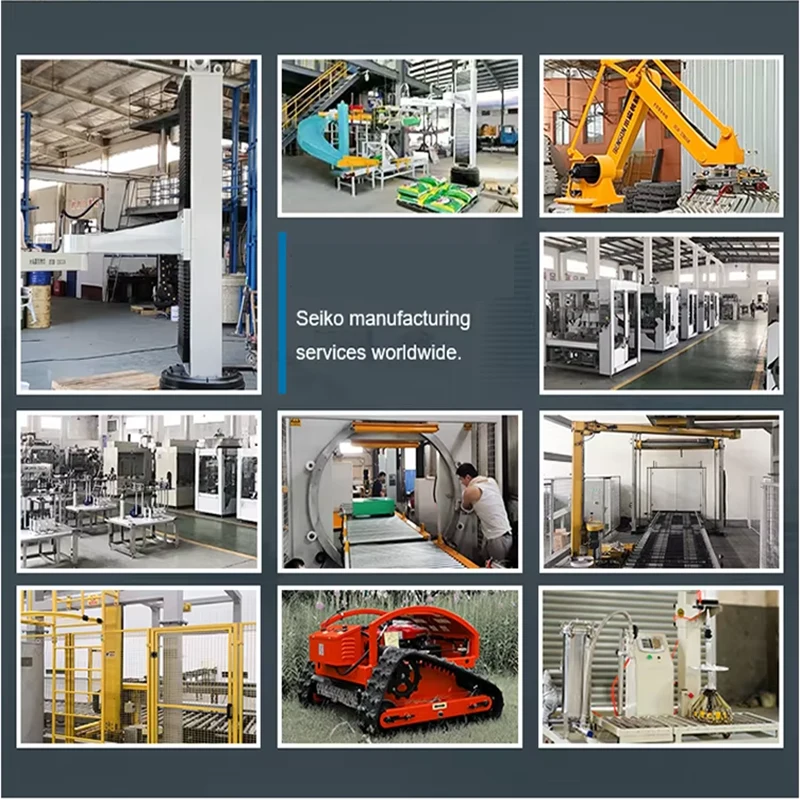

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry