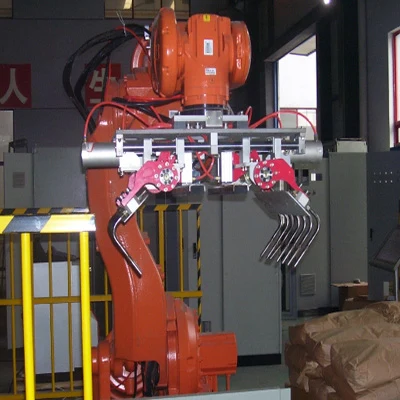

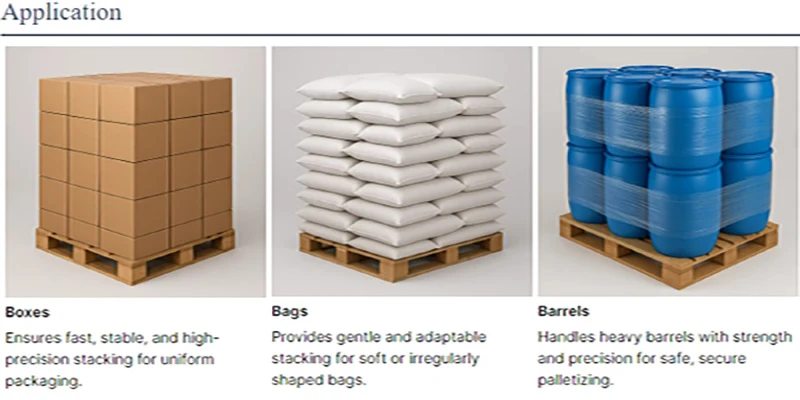

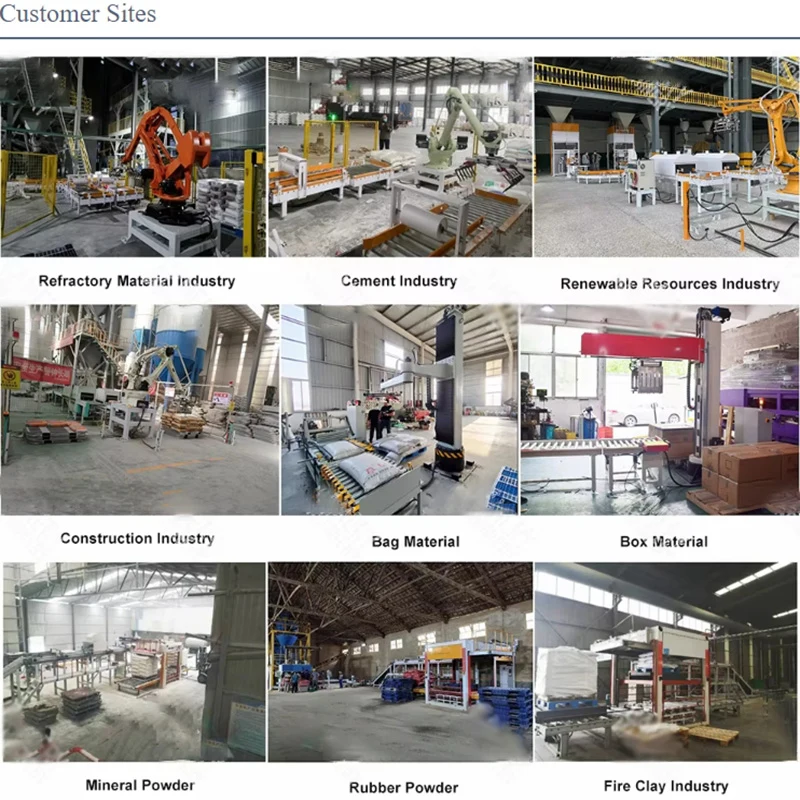

The column palletizer is a compact, space-saving automated palletizing machine. Guided by a column rail system, the robotic arm moves efficiently along both horizontal and vertical axes, allowing for precise picking and orderly stacking of various materials such as cartons, woven bags, and packaging sacks. This equipment supports multiple stacking patterns and pre-set multi-layer programs, making it suitable for industries like chemicals, building materials, grain, and animal feed.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

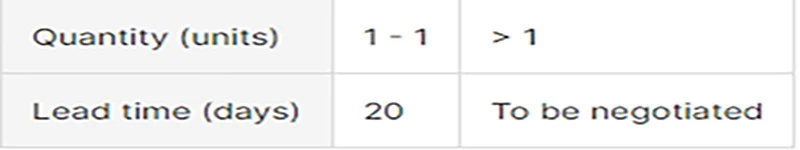

Lead time

Advantages of column stacking machine:

1. Increase productivity and reduce labor costs.

2. Minimize human error and ensure accurate stacking.

3. Wide range of applications, suitable for a variety of industries and material types.

4. Seamless integration with conveyor and packaging lines.

5. Low energy consumption and low operating cost.

6. Long service life and minimum maintenance requirements.

6. Long service life with minimal maintenance requirements.

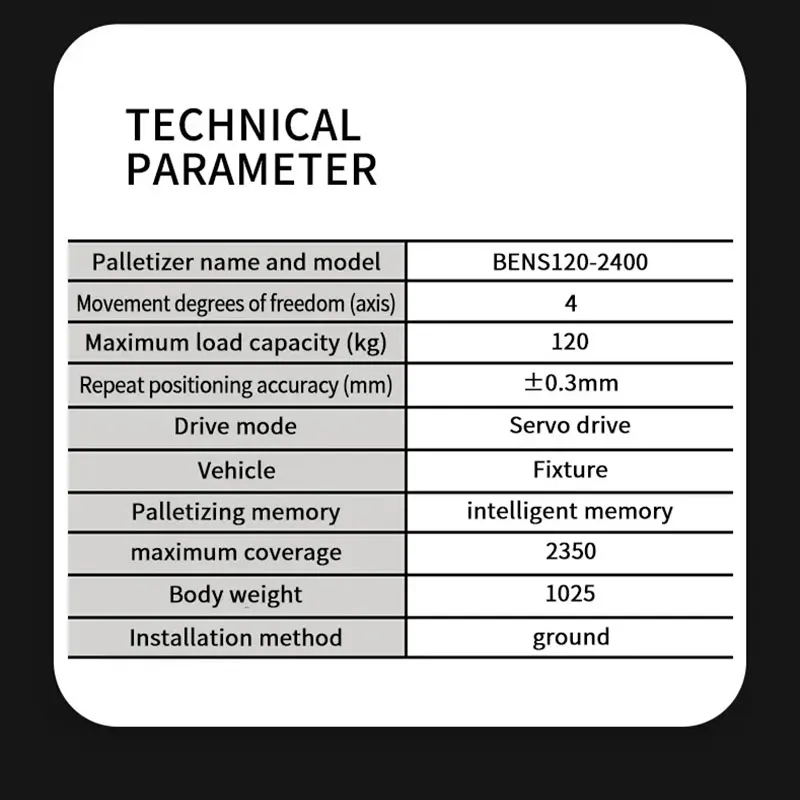

Specification

Single column robot palletizer | |||

Overall size | 2800*2800*1000mm | Palletizing level | 1-12 layer |

Packing capacity | 400-500 packages/hour | bleed pressure | 0.6 to 1.0 MPa |

source | 380V 50Hz 3 phase | Take position | 2 pairs |

power | 5kw-8kw | Bagged | 5 / 6 / 7 / 8 flowers |

1. Increased productivity: Vertical palletizers eliminate the manual labor required to stack product units. They are more efficient, able to handle heavier loads, and complete tasks faster. They also avoid fatigue and injury. With proper maintenance, these palletizers can operate reliably 24/7, reducing any potential bottlenecks in the packaging line

2. Better product handling:Vertical palletizers As automated machines, column-type palletizers have pre-programmed movements and are designed to operate without damaging the products. Unlike humans, they do not need to constantly make decisions, which makes them less prone to errors and results in better product handling.

3. Enhance workplace safety: When properly designed, pillar stacker machines can eliminate the risks associated with manual labor in the workplace. Manual stacking can lead to falls, slips, trips, and crushing injuries. The repeated stretching and stacking of products can also cause muscle strains, potentially leading to lower back injuries and permanent health issues for workers.

4. Reduce operating costs: Column palletizers In most applications, especially in large packaging systems, the cost-benefit analysis of purchasing a palletizer will produce positive results. Operating costs can be saved by increasing throughput, reducing product waste and reducing labor costs.

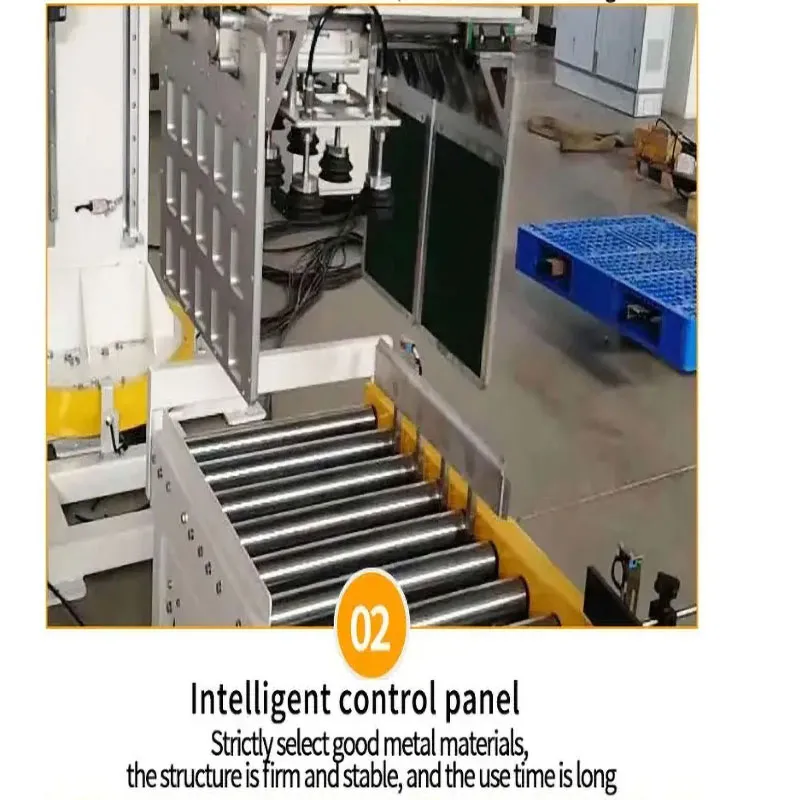

The control center of the system, housing PLC and electrical components. Includes bilingual touchscreen for easy operation.

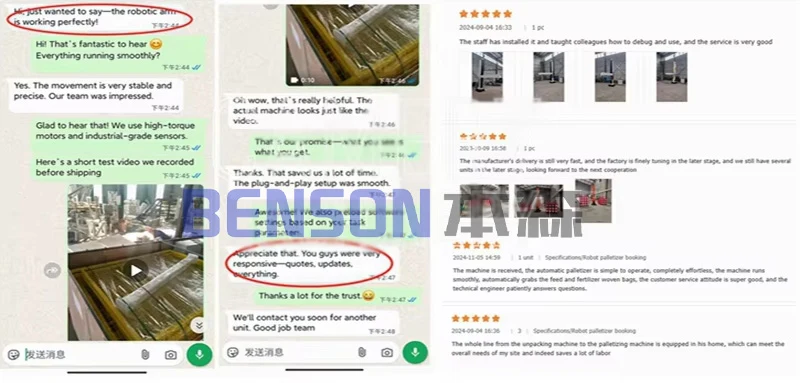

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

Product Inquiry