The gantry - type high - level palletizer, with its stable and robust structure, has excellent high - load - bearing capacity and performs outstandingly in the field of heavy - object palletizing. Its unique gantry - type architecture endows the equipment with a wide working range, enabling it to flexibly complete various palletizing tasks within a large space. Through an advanced automated control system, precise and efficient palletizing operations can be achieved, greatly improving production

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Lead time

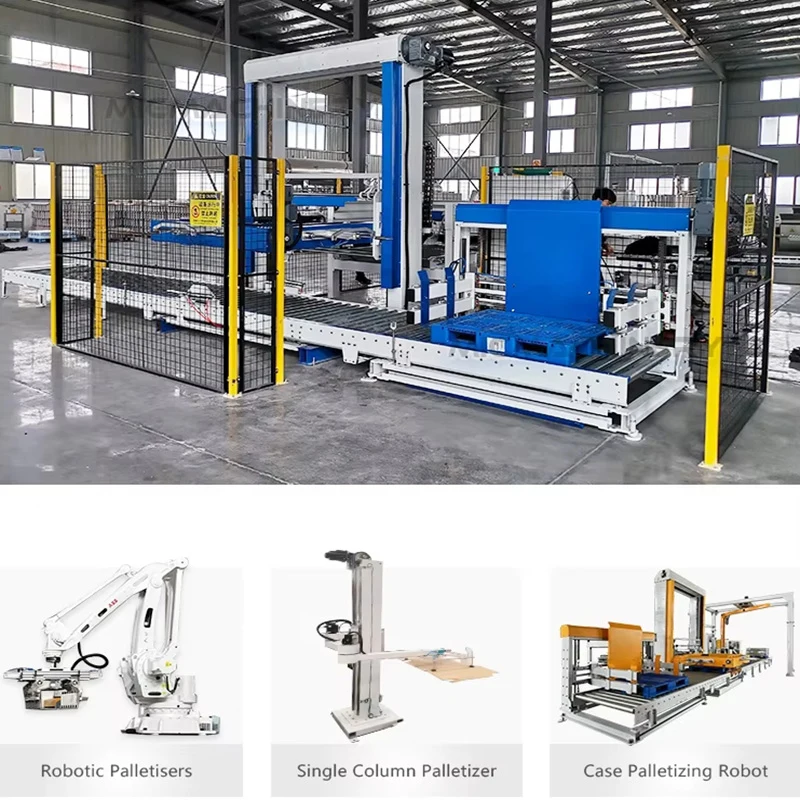

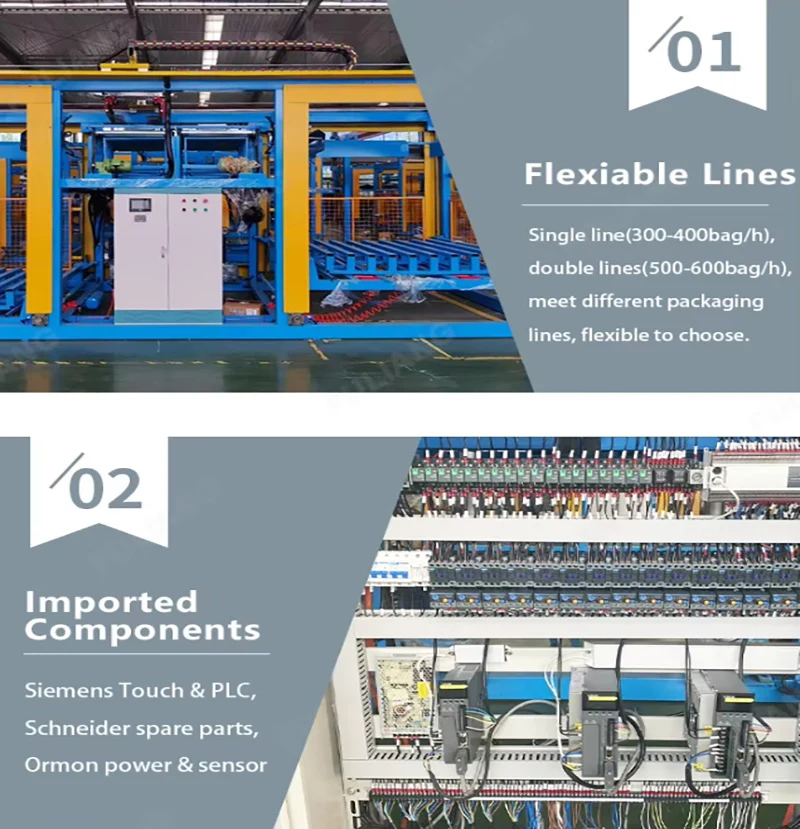

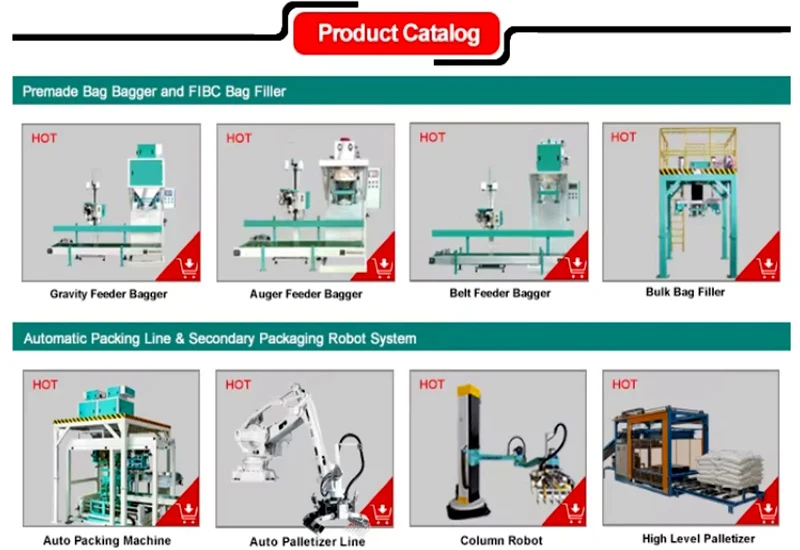

Products Description

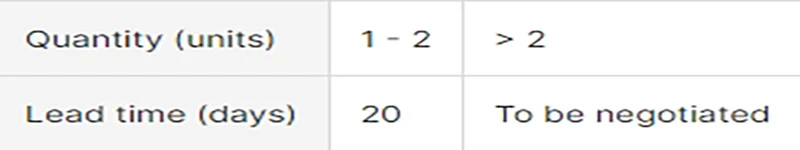

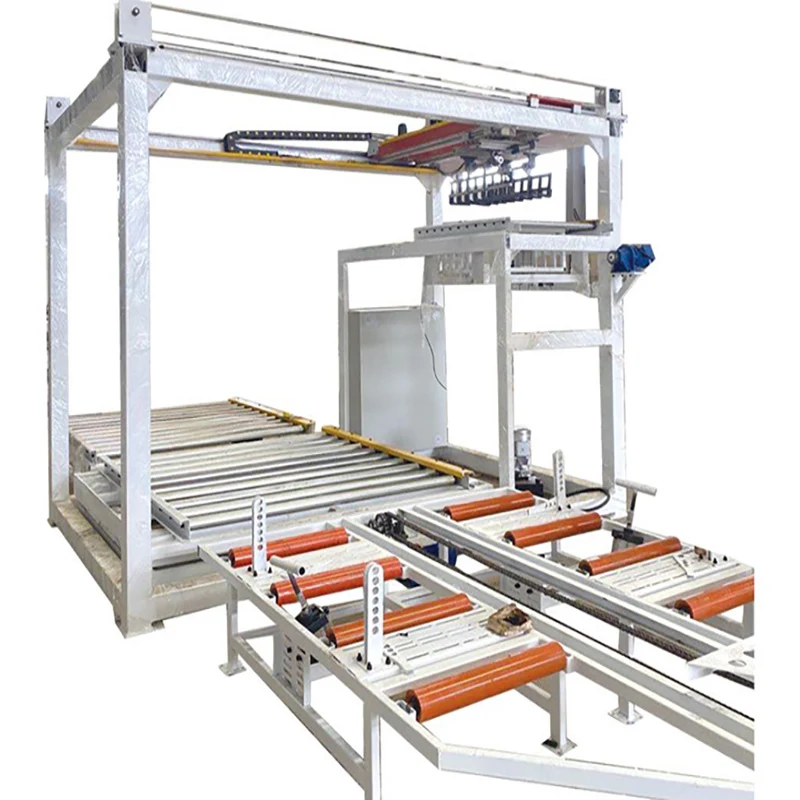

Gantry high - level palletizer

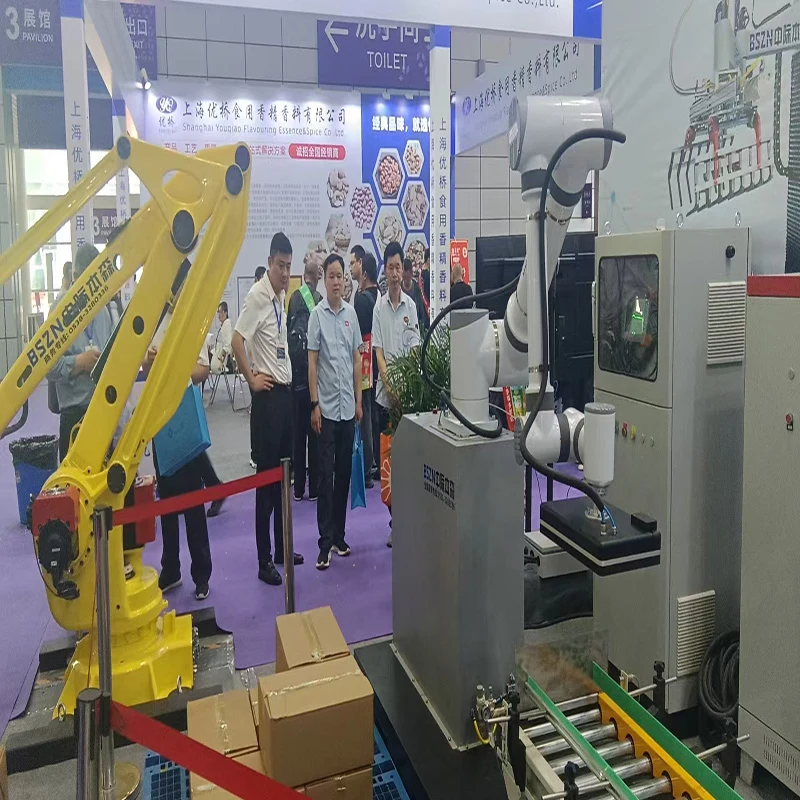

As a core equipment in the field of industrial automation, the gantry - type high - level palletizer, with its unique frame - type structure design, builds a stable and high - load operating foundation.Benson gantry palletizer, It can easily handle the tasks of grasping and stacking heavy goods weighing several tons. Its iconic gantry cross - beam, combined with a multi - axis linkage system, not only endows the equipment with a wide operating range covering the three - dimensional space of length, width, and height, but also enables it to shuttle flexibly in complex production line layouts, achieving efficient operation in multiple workstations and multiple areas. Relying on advanced servo - drive technology and an intelligent control system, the equipment can quickly switch operation modes according to product specifications and pallet - type requirements, precisely control the grasping angle and stacking position, ensuring that the pallet shape is neat and stable. In practical applications, whether it is boxed products in the food and beverage industry, heavy - duty plates in the building materials industry, or large - tonnage packaging in the chemical industry, Gantry high - level palletizerthe gantry - type high - level palletizer can operate at an efficiency of dozens of pieces per minute, replacing traditional manual operations, significantly reducing labor costs and safety hazards, and becoming an indispensable automated tool in modern intelligent manufacturing production lines. fully automatic palletizer, saves labor and supports customization.

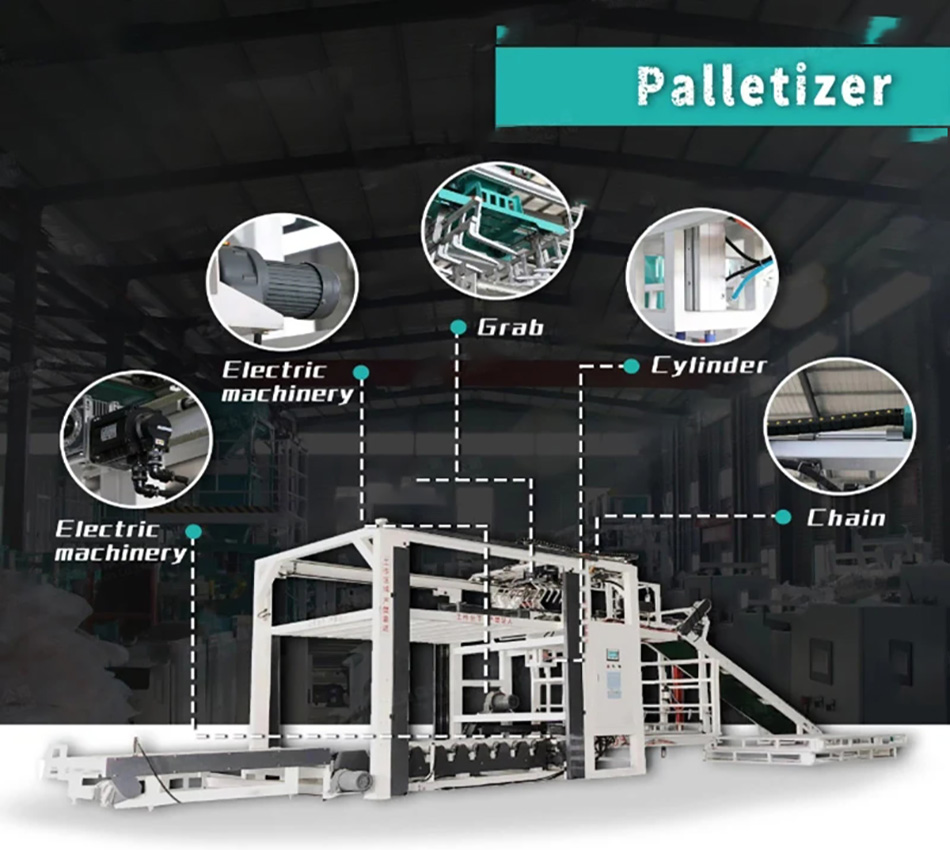

Working process of gantry high - level palletizer:

The working process of the gantry - type high - level palletizer closely revolves around four major links: cargo transportation, gripping, handling, and palletizing, and achieves efficient and orderly operations through an automated system:

1. Cargo transportation: The goods to be palletized are transported to the designated position by the production line or conveying equipment (such as belt conveyors, roller conveyors). After the positioning sensor on the conveyor detects that the goods are in place, it triggers the subsequent operations.

2. Information identification and processing:gantry high - level palletizer The vision recognition system or sensor group scans and analyzes information such as the specifications, dimensions, and positions of the goods, and transmits the data to the control system. Based on the preset palletizing program and stack pattern parameters, the control system calculates the optimal paths and postures for gripping and stacking.

3. Gripping the goods: The robotic arm on the gantry (usually equipped with special grippers, such as clamping - type, vacuum - suction - cup - type, fork - tooth - type) moves above the goods along the X, Y, and Z axes driven by the servo motor. It precisely adjusts the position and angle through the control system, and then activates the gripper to firmly grip the goods.

4. Handling and stacking:Benson gantry palletizer,After gripping the goods, the robotic arm moves smoothly within the gantry frame along the planned path and transports the goods to the target pallet or shelf area. After reaching the designated position, the robotic arm descends precisely and stacks the goods steadily according to the stack pattern (such as row - type, staggered - type). Subsequently, the gripper releases, completing one palletizing action.

5. Cyclic operation: After completing one palletizing, the robotic arm returns to the initial position and waits for the gripping instruction of the next good. This process repeats. When the goods on the pallet are stacked to the set number of layers or quantity, the conveying system moves out the full - stack pallet and simultaneously sends in an empty pallet to continue the subsequent palletizing operations. The entire process, coordinated by the intelligent control system, realizes unmanned, high - precision, and high - efficiency automated palletizing tasks.saves labor and supports customization.

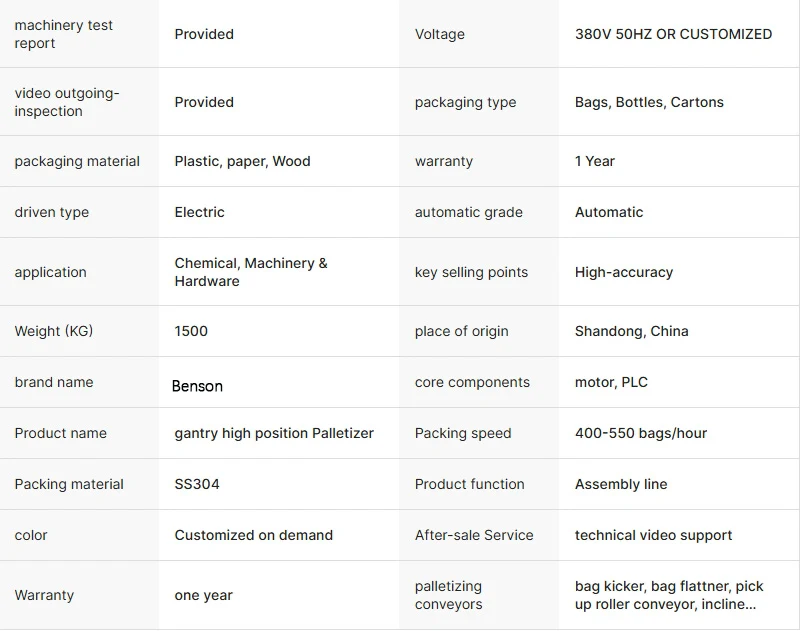

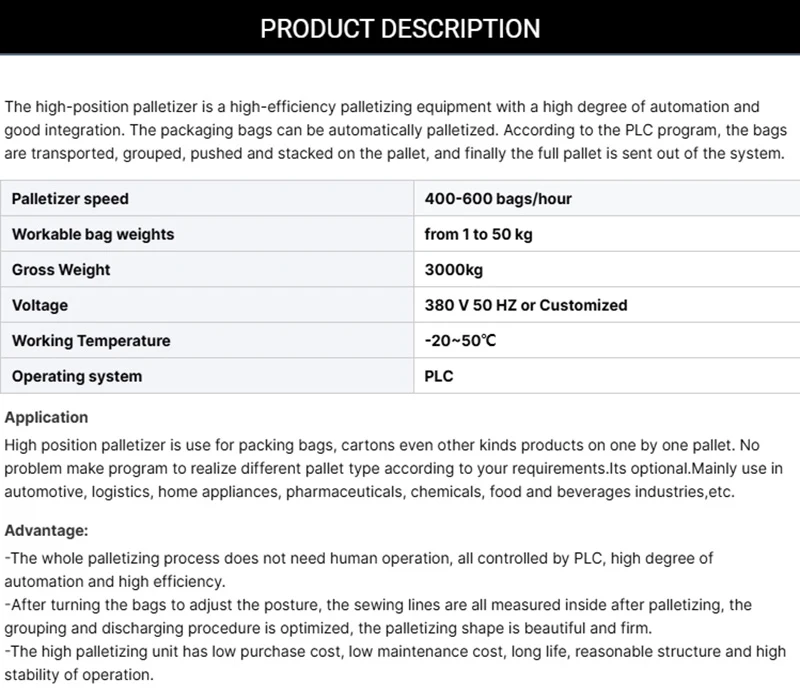

Specification

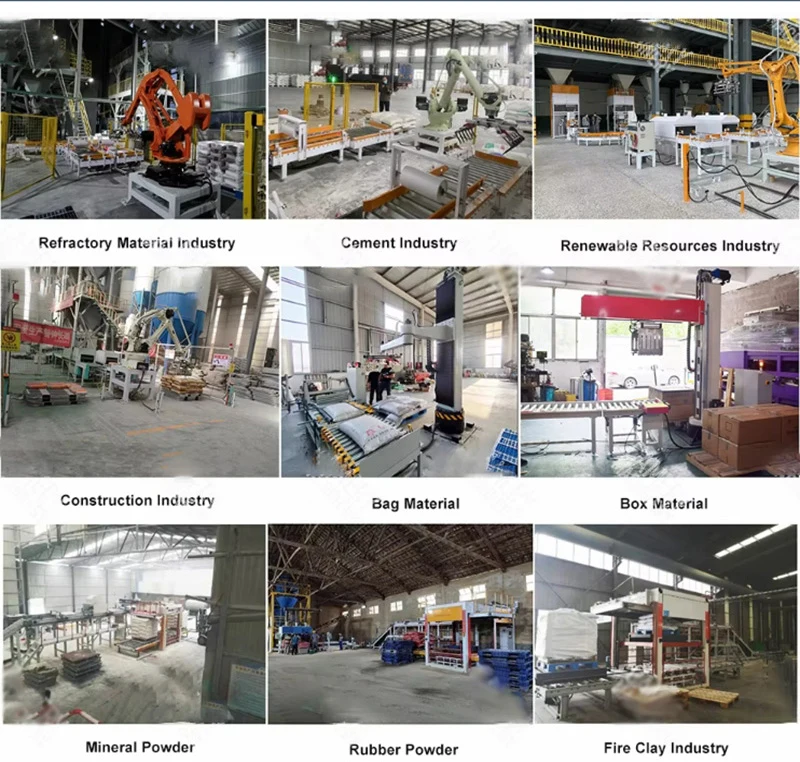

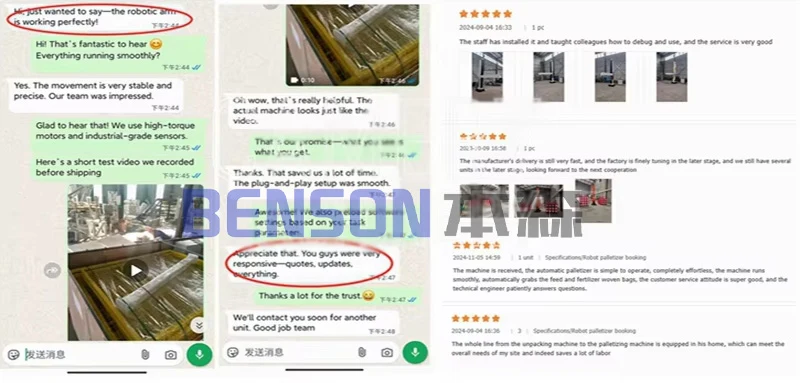

Customer Sites

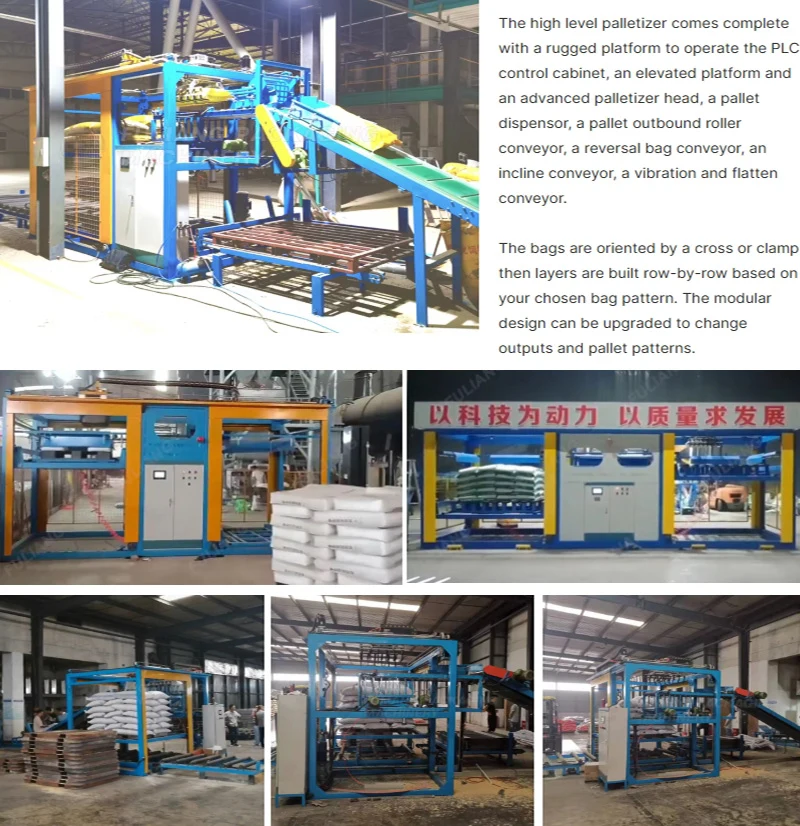

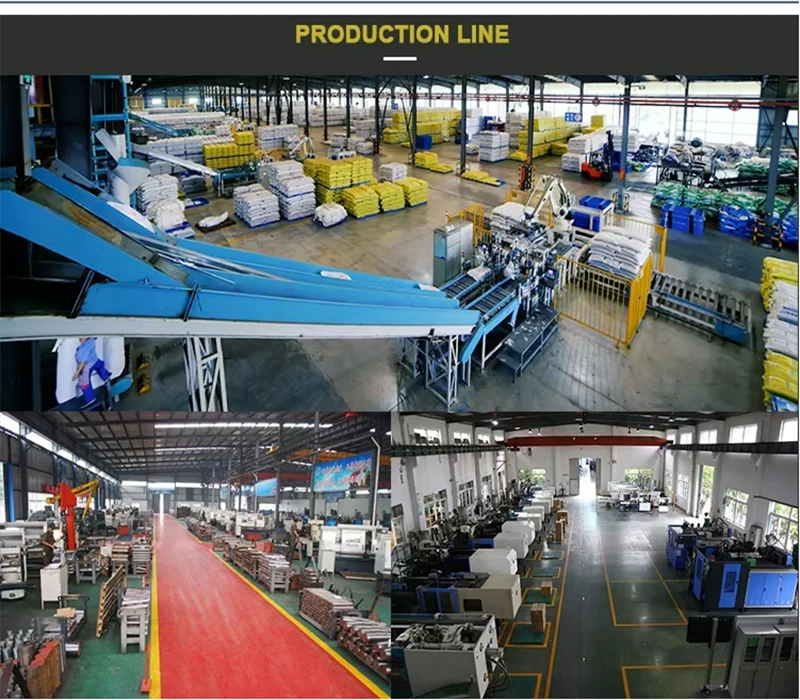

Company Profile

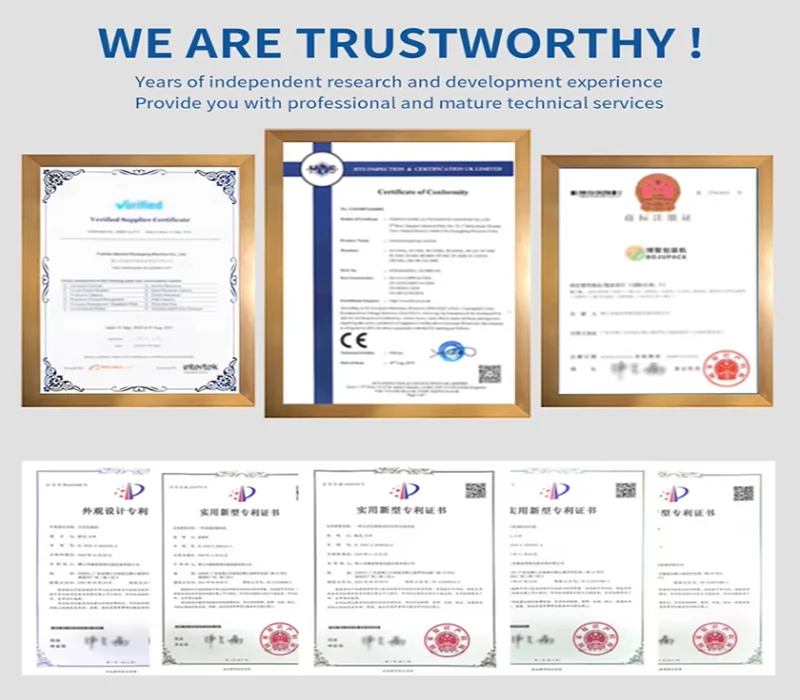

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales. Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client. Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

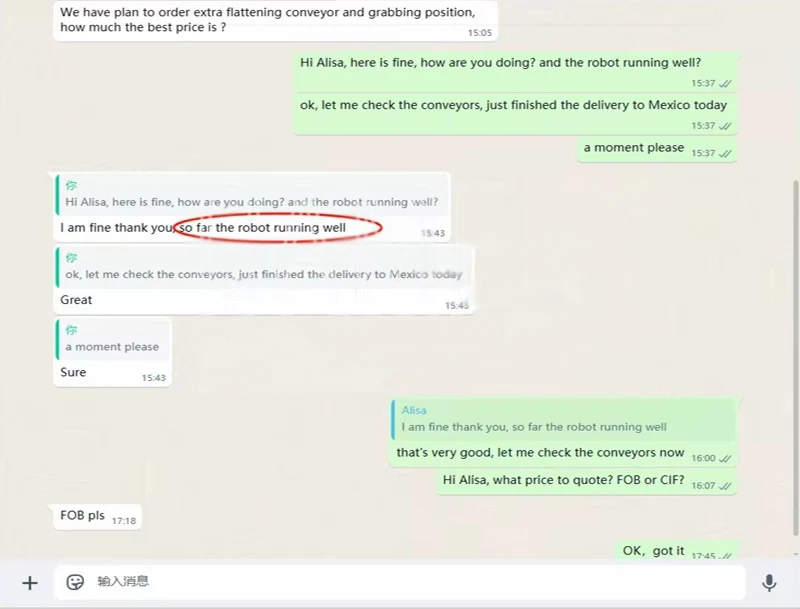

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

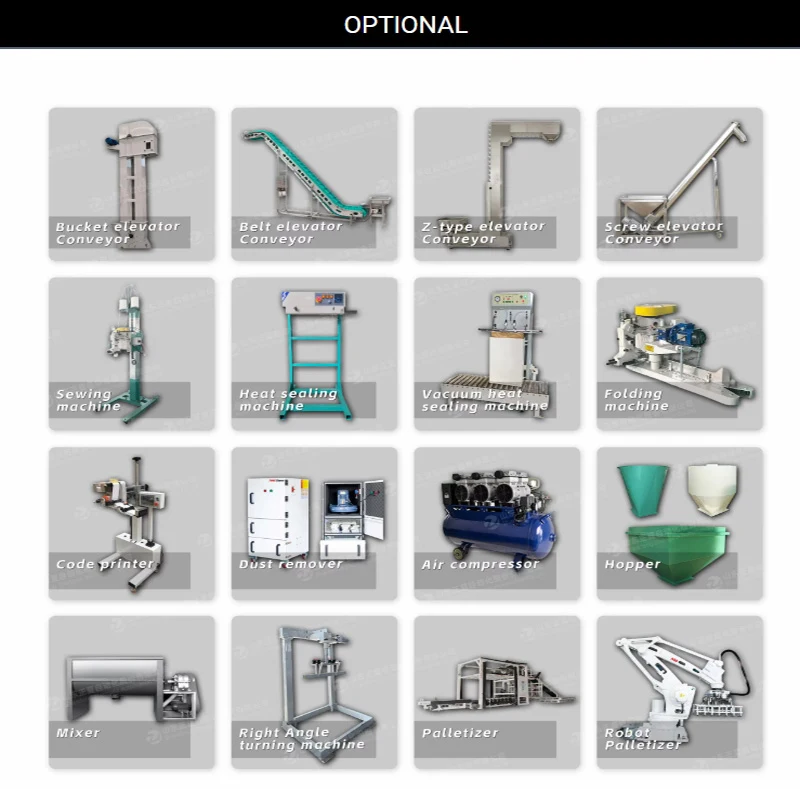

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry