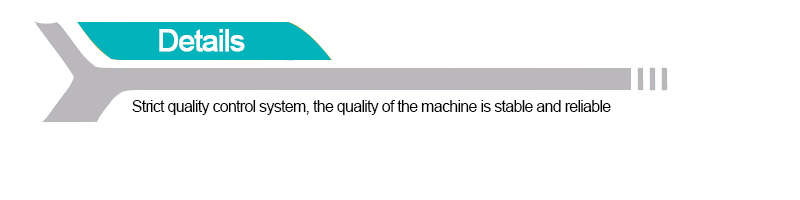

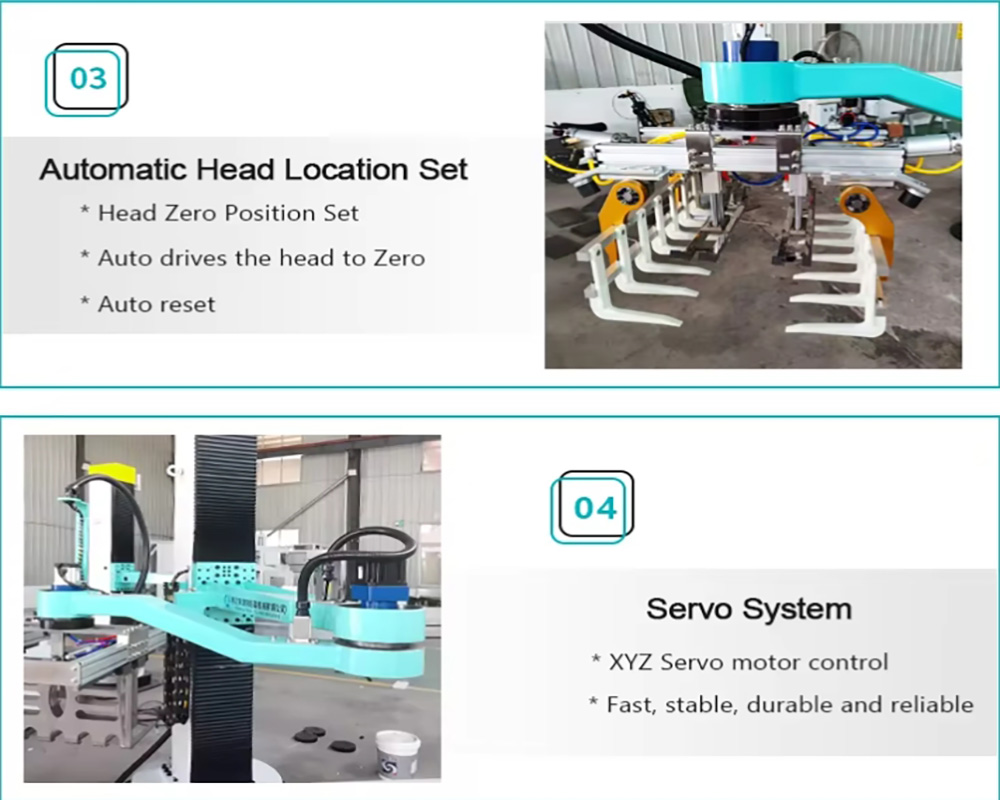

50kg Cement Bagged Palletizing Robot During the production, cartons or packs be transported by conveyor to the carton arrangement system, the arrangement system will arrange cartons in a certain order, after arrangement, the gripper will catch the complete layer of the cartons and move them into the gripper, the single column will lift the gripper and move horizontally to put the complete layer carton on the pallet; repeat above actions until the complete pallet is finished. This series Palletizer Machine mainly use for automatically palletizing of kinds of Carton Box,PE Film Shrink Wrapped Cases according to program setup pattern to finished palletizing products on the pallet one by one layer. This kind machine suitable for process of water,beverage,oil,etc production line, and also suitable for bottles,cans,etc products case packing work in other industries.

This Benson Automation Bagged Wheat Flour Palletizing Robot Manufacturer Series Palletizer Machine could independent finish products feeding,grouping arrange,empty pallet feeding, whole layer palletizing and full pallet feeding out works in continuously and automatically.

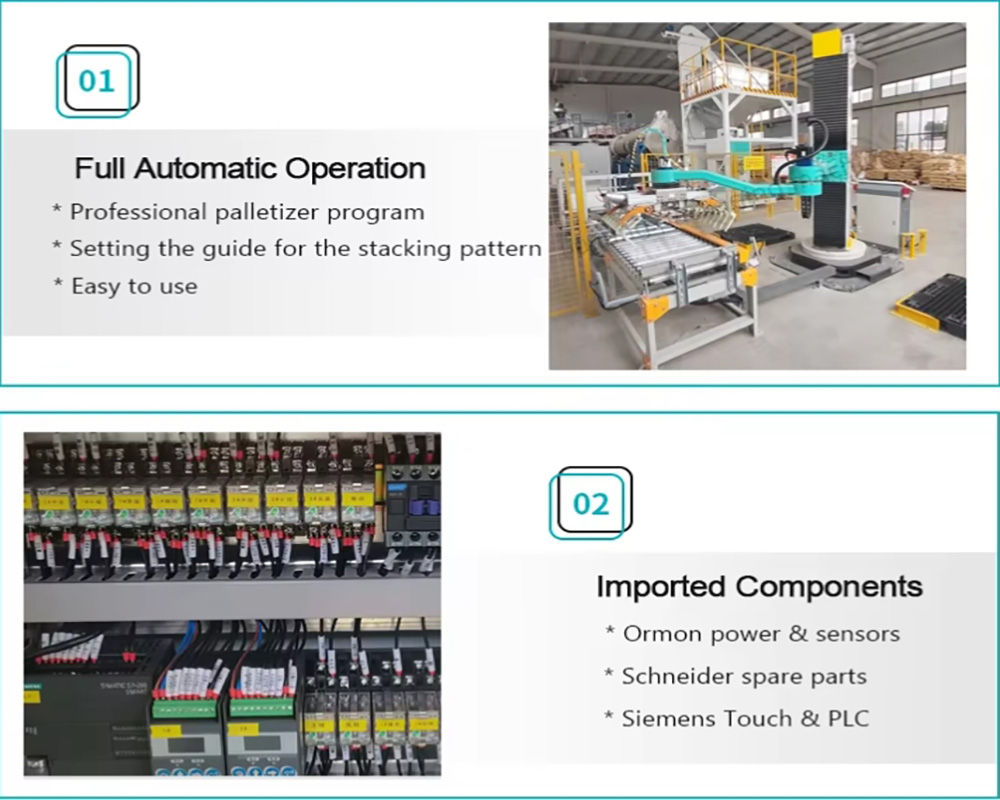

Also could according to client’s different products special requirement to improve design for achieved palletizing works.Such as change to Single Case Grasp Head or Whole Layer Cases Grasp Head, Optional match with Empty Pallet storage and dispenser device with main palletizer working together.

| |

| |

|

15-50 Kg / bag or customized needs

|

|

1-5, 5-25, 25-50 Kg/bag, customized needs

|

|

5/6/7/8/9/10 bags per layer or customized

1,9layer/50packages:6bags/layer*8layer+2bags*1layer=50bags

2,9layer/54packages:6bags/layer*9layer=54bags

3,10layer/50packages:5bags/layer*10layer=50bags

|

Voltage |

AC220V/AC380V/50HZ or customized needs

|

| |

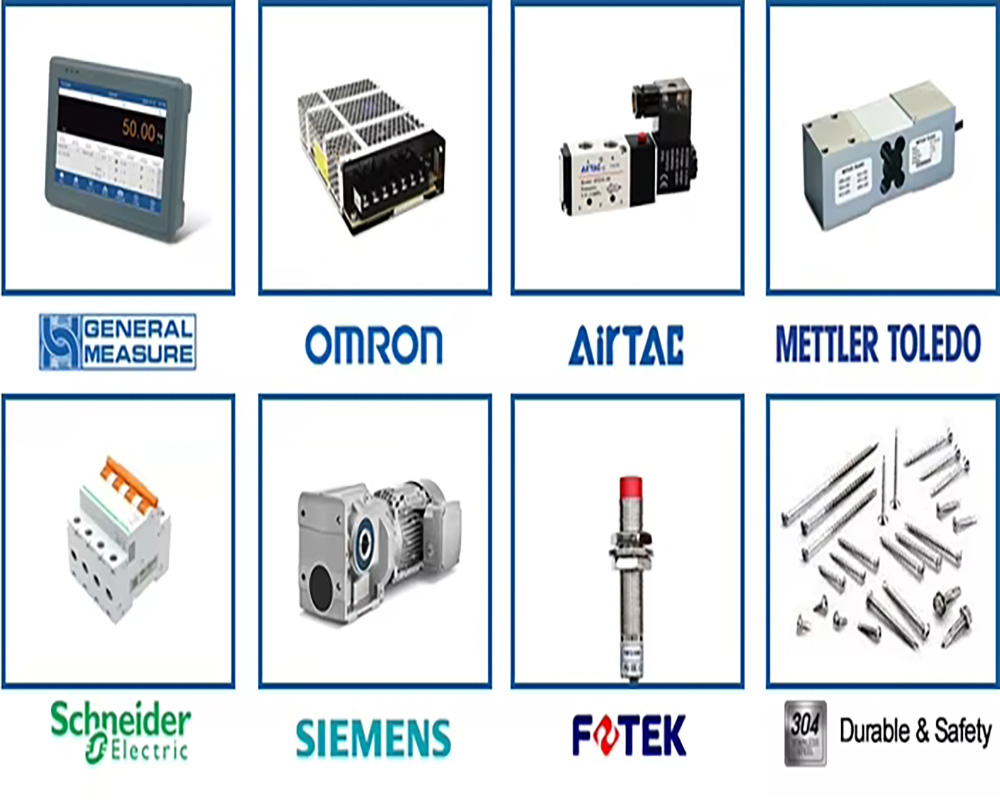

1). New controller with high precision, working stable, can display the total weight, number of package, easy operation.2). The adaptive software, having the function of automatic control parameters setting, automatic drop revising, over-weight warning and auto-diagnosis.

3). Wide packing range, high precision, it can match well with conveyor and sewing machine.

4). Products using imported sensor, pneumatic actuator, easy maintenance and non-pollution.

5). The main material body is carbon steel, with painted plastic. And material contact part is stainless iron, corrosion resistance, long service life.

6). communication interface can be offered if need, realization of data communication with PC.

COMPANY PROFILE

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

Company Qualifications

Exhibition

Customer site

PACKAGING & DELIVERY

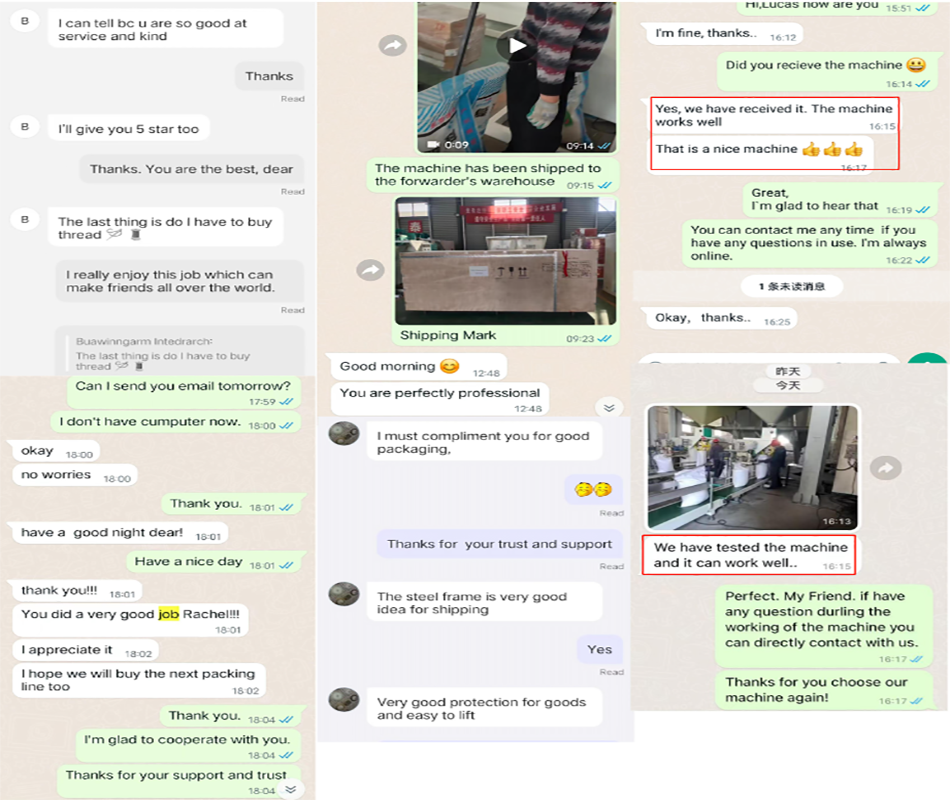

Customer feedback

FAQ

Product Inquiry