As a key equipment in the field of modern industrial automation, the intelligent collaborative robot arm is leading the transformation of production methods with its excellent performance and innovative design. It integrates advanced sensing technology, intelligent control algorithms and precision mechanical manufacturing processes, has high flexibility, safety and ease of use, can work closely with human workers, and play a key role in a variety of complex production scenarios.

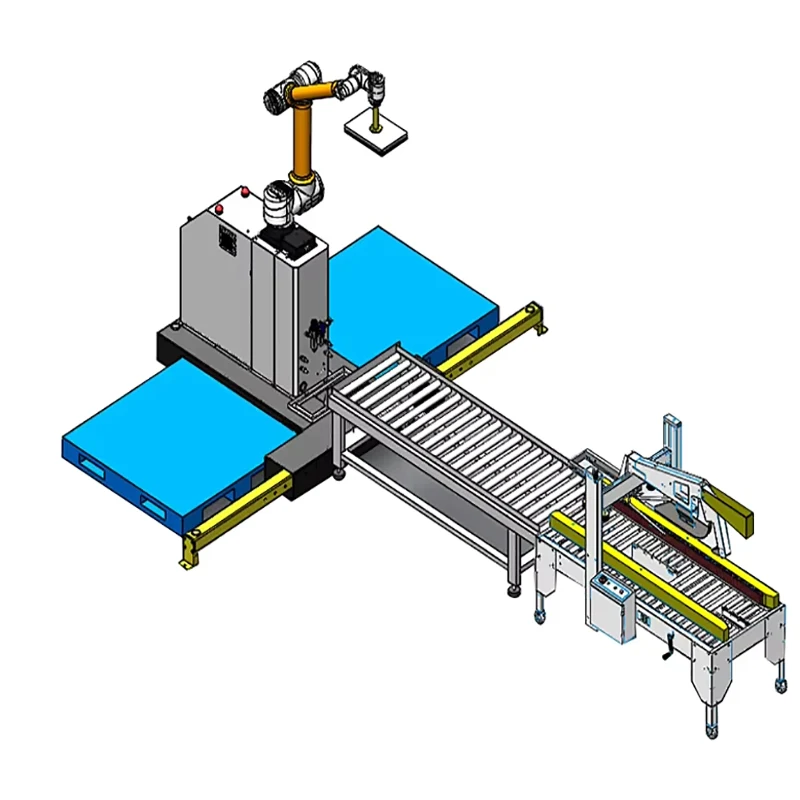

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

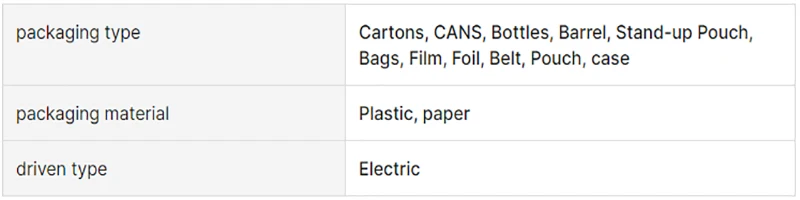

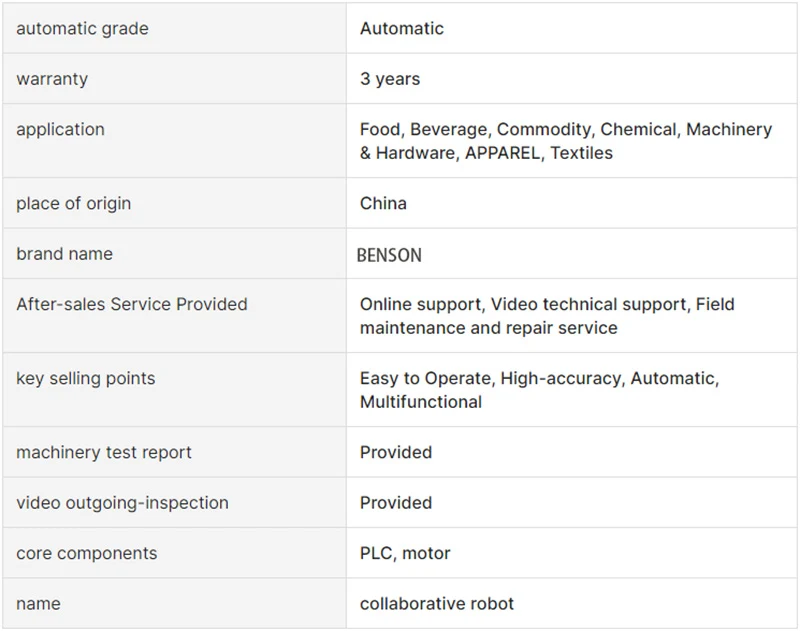

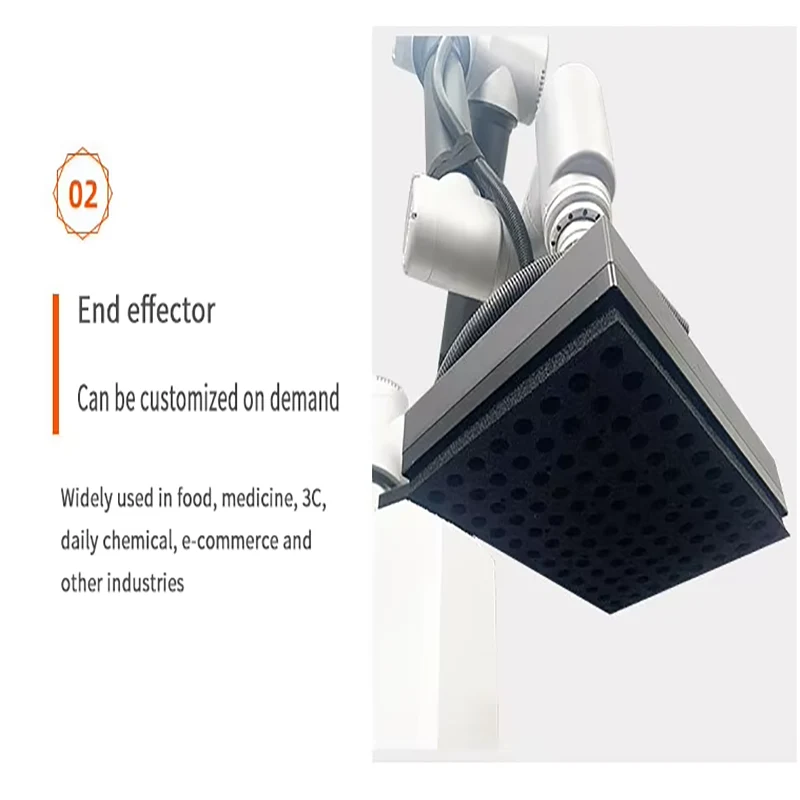

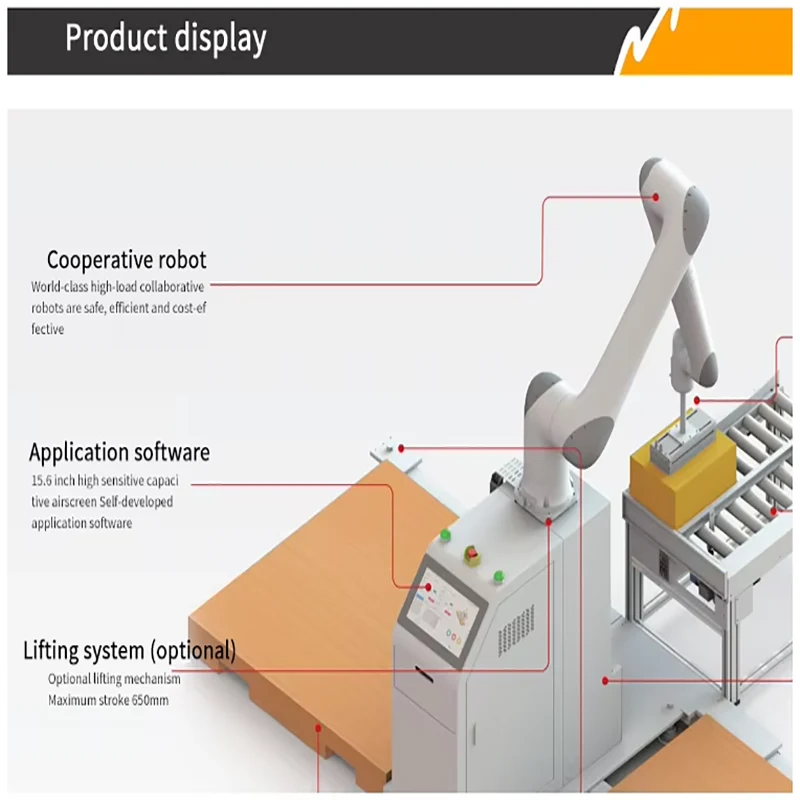

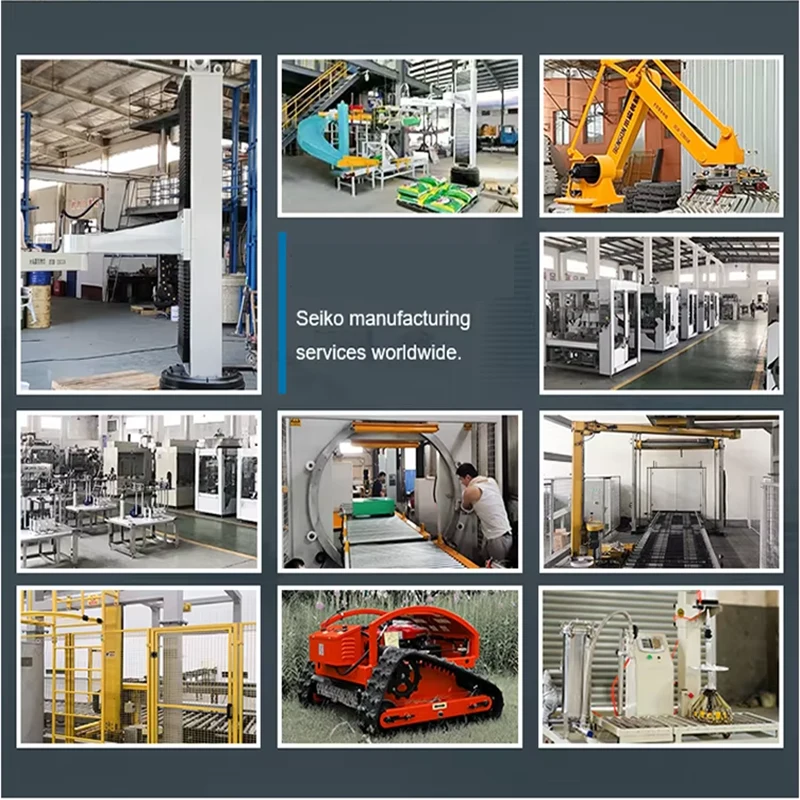

Feature highlights: This collaborative robot arm is designed for industrial applications such as packaging, palletizing and handling in the food, beverage, textile and other industries. It features automatic operation, high precision and versatility, and offers 500W and 1000W power options. It is suitable for plastic, film, bottle and bag packaging, and provides a three-year warranty and comprehensive after-sales services such as on-site repairs, online support and video technical guidance. Its advanced electric drive system ensures reliable performance.

As a key equipment in the field of modern industrial automation, the intelligent collaborative robot arm is leading the transformation of production methods with its excellent performance and innovative design. It integrates advanced sensing technology, intelligent control algorithms and precision mechanical manufacturing processes, has high flexibility, safety and ease of use, can work closely with human workers, and play a key role in a variety of complex production scenarios. The following is a detailed introduction for you:

Design structure: adopts a lightweight and compact design concept, and the overall structure is sturdy and durable. The fuselage material is made of high-strength, corrosion-resistant aviation aluminum alloy, which effectively reduces its own weight while ensuring the strength of the robot arm, making it more flexible and convenient to move. The joint part uses high-precision harmonic reducers and advanced servo motors, combined with an optimized transmission system, to achieve precise movement and smooth operation of the robot arm, ensuring stability even in complex operations. For example, in the precision assembly of 3C products, the robot arm can easily complete the grasping and installation of tiny parts with its flexible joint design, and will not affect the assembly accuracy due to vibration or jitter.

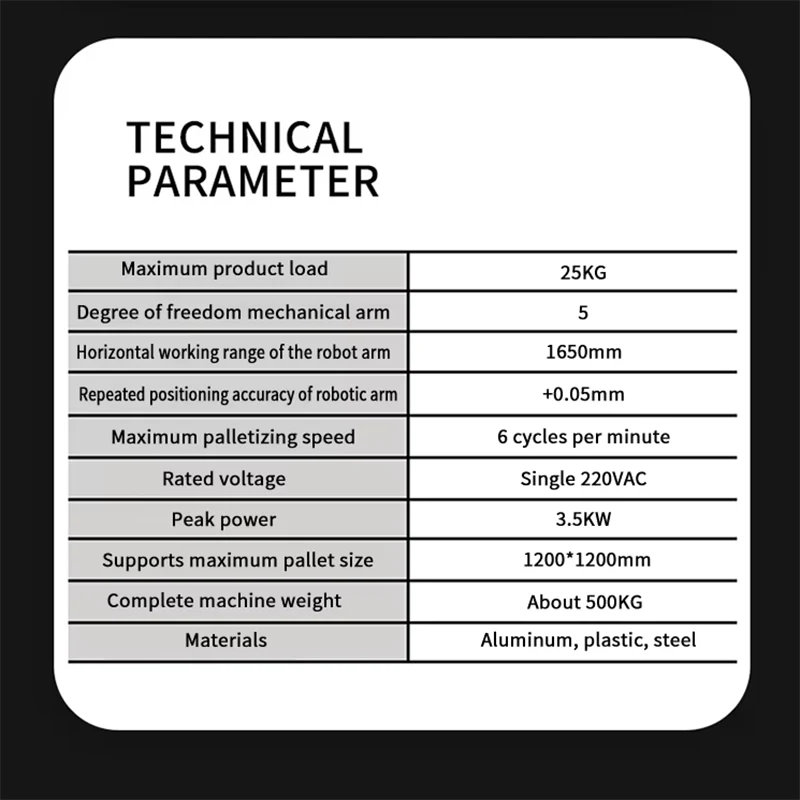

Movement performance: It has a multi-degree-of-freedom joint configuration, usually 6 axes or more, which can achieve all-round and multi-angle flexible movement, simulate various movements of human arms, and adapt to complex working environments and diverse task requirements. The working radius covers a wide range, up to [X] mm, and can meet the operation requirements of working areas of different sizes. The repeat positioning accuracy is extremely high, up to ±0.02mm or even higher, which makes it perform well in precision machining, assembly and other work with strict precision requirements. Taking the precision assembly of automotive parts as an example, the robot arm can accurately install the parts to the specified position, effectively improving the assembly quality and production efficiency.

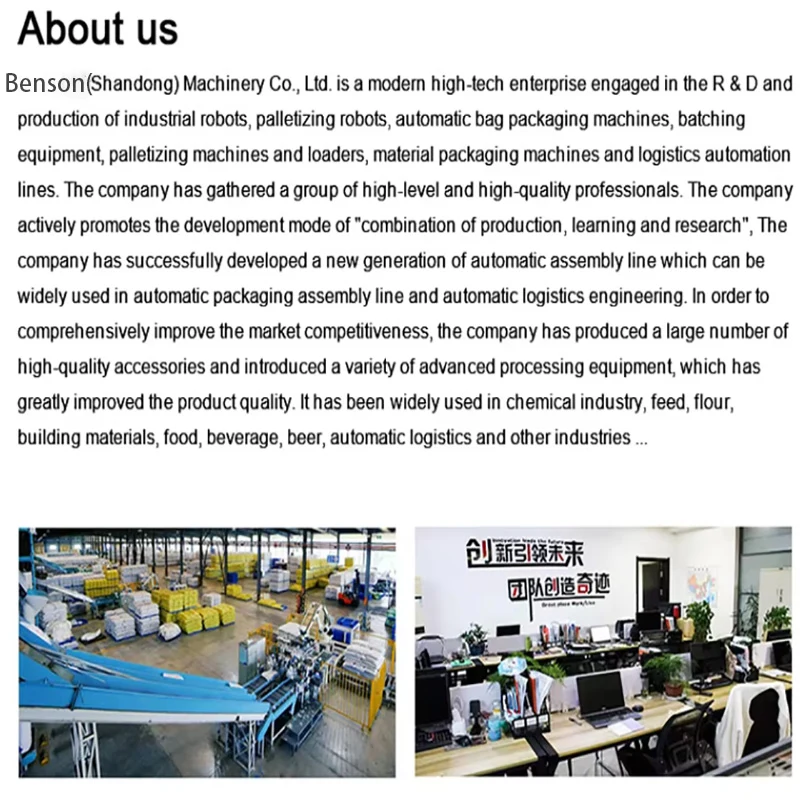

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

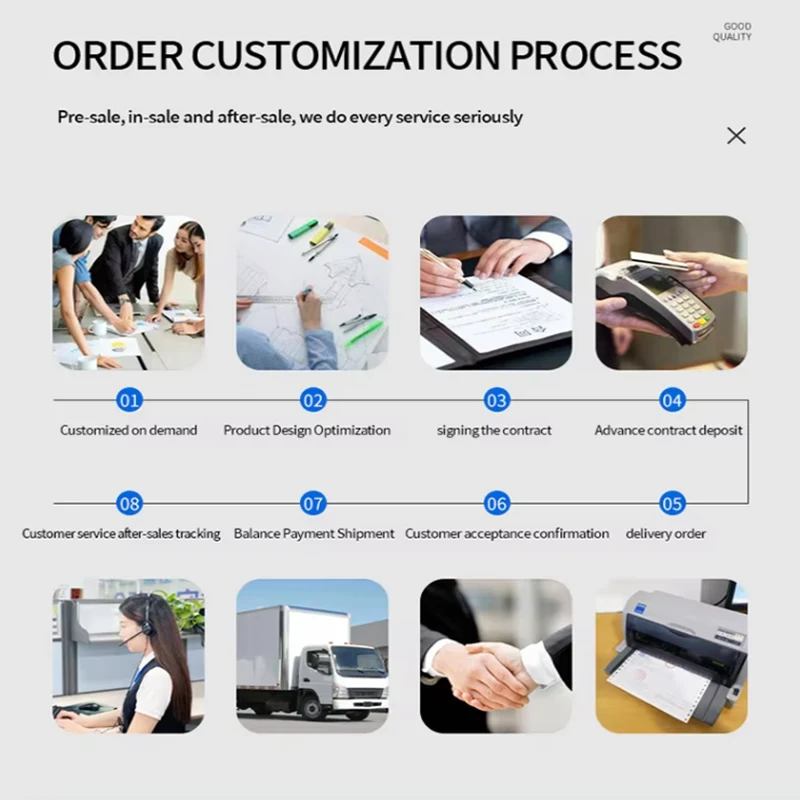

Product Inquiry