The fully automatic carton packaging machine is an advanced packaging equipment that integrates automation and intelligence, and is designed to meet the efficient and precise packaging needs of modern enterprises. From carton forming, packing to sealing, the entire process does not require excessive human intervention, which can greatly improve packaging efficiency and reduce labor costs. It is widely used in many industries such as e-commerce, food, medicine, logistics, and daily necessities.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Core advantages of carton packaging machines in the food industry

Accurate and reliable: Equipped with high-precision sensors and intelligent control systems, it can accurately detect the position, size and packaging status of cartons, ensure that the carton is neatly formed and tightly sealed, and the packaging qualification rate is as high as 99.9%, reducing the defective rate and ensuring the quality of product packaging.

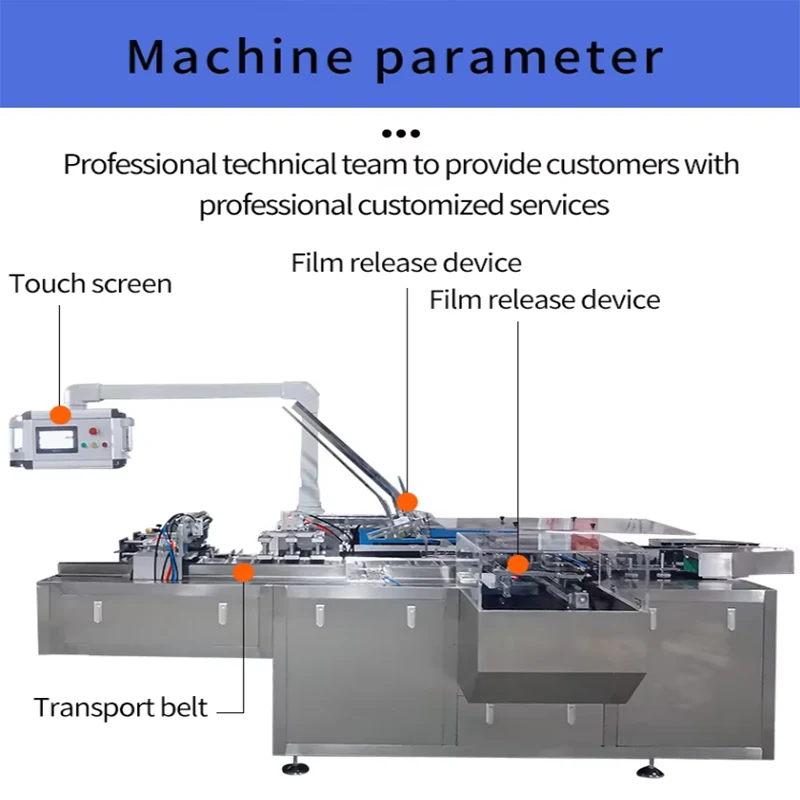

Intelligent and flexible: It supports rapid switching of multiple carton specifications. Through the touch screen human-computer interaction interface, the operator only needs to simply set the parameters, and the equipment can automatically adjust the operation mode to adapt to carton packaging of different sizes and shapes to meet diversified production needs. At the same time, it has a fault self-diagnosis function, which can quickly locate the problem and display the fault information when an abnormality occurs, so that maintenance personnel can handle it in time.

Cost saving: Automated operation reduces the number of manual operations and reduces long-term labor cost investment; the equipment has low energy consumption, optimized mechanical structure and energy-saving design, which effectively reduces power consumption while ensuring efficient operation. In addition, stable and reliable performance reduces the frequency of equipment maintenance and further saves maintenance costs.

Safety and environmental protection: multiple safety protection devices are set up, such as emergency stop buttons, safety light curtains, protective covers, etc., to effectively prevent operators from being injured during the operation of the equipment; the equipment operates with low noise, meets environmental protection standards, and creates a safe and comfortable working environment.

Functional features of fully automatic carton packaging machine

Carton forming: It can automatically complete the suction, unpacking, forming, folding and sealing of carton boards, and quickly convert flat cardboard into three-dimensional cartons. The whole process is smooth and stable.

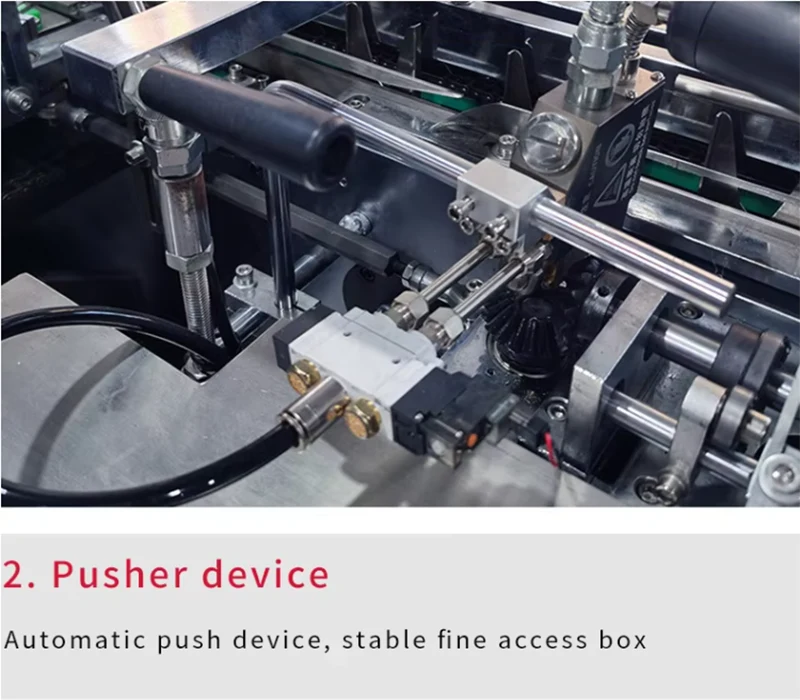

Intelligent packing: With a mechanical arm or automatic conveying device, the product can be accurately grasped, arranged and packed. It can be flexibly adjusted according to product characteristics and packing requirements to meet the packing needs of different products.

Diverse sealing: Supports a variety of sealing methods, such as tape sealing, hot melt adhesive sealing, nailing, etc. Tape sealing is flat and beautiful, hot melt adhesive sealing is firm and reliable, and nailing is suitable for heavy goods packaging, meeting the needs of different customers for sealing effects.

Data management: With data statistics and storage functions, it can record equipment operation status, packaging quantity, production time and other data in real time, which is convenient for enterprises to carry out production management and data analysis, and optimize production processes.

After-sales service

We provide a full range of after-sales service guarantees: equipment installation and commissioning, operator training; quick response to customer issues; regular return visits and equipment maintenance to ensure that the equipment always maintains a good operating state; sufficient supply of spare parts to solve customer worries.

Choosing our fully automatic carton packaging machine means choosing an efficient, intelligent and reliable packaging solution to help enterprises improve their competitiveness and create greater value!

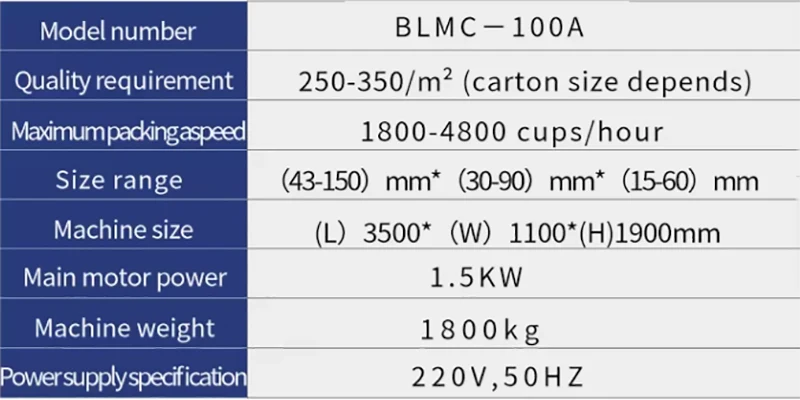

Products Description

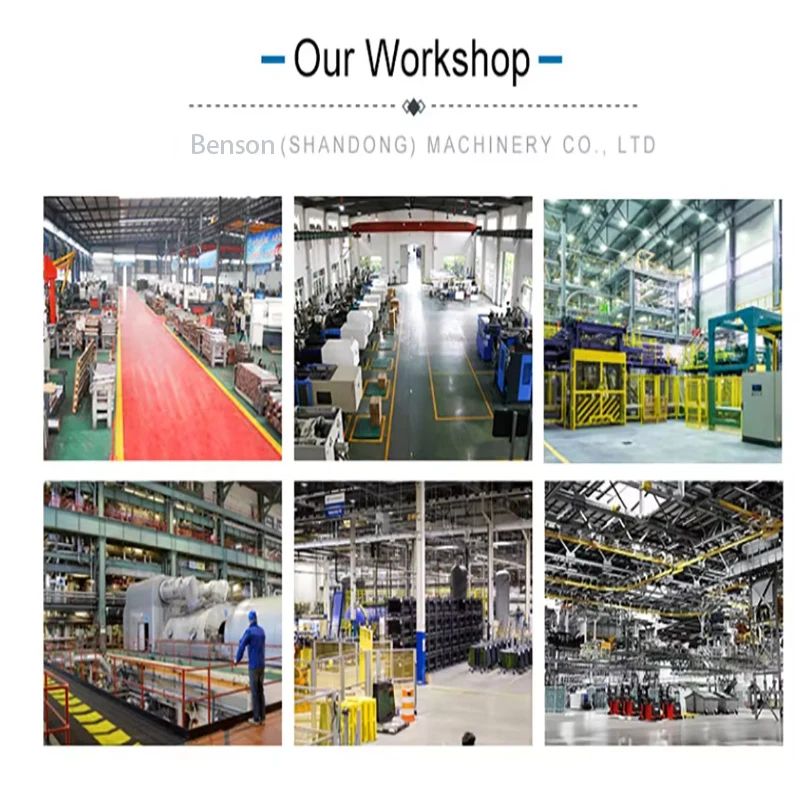

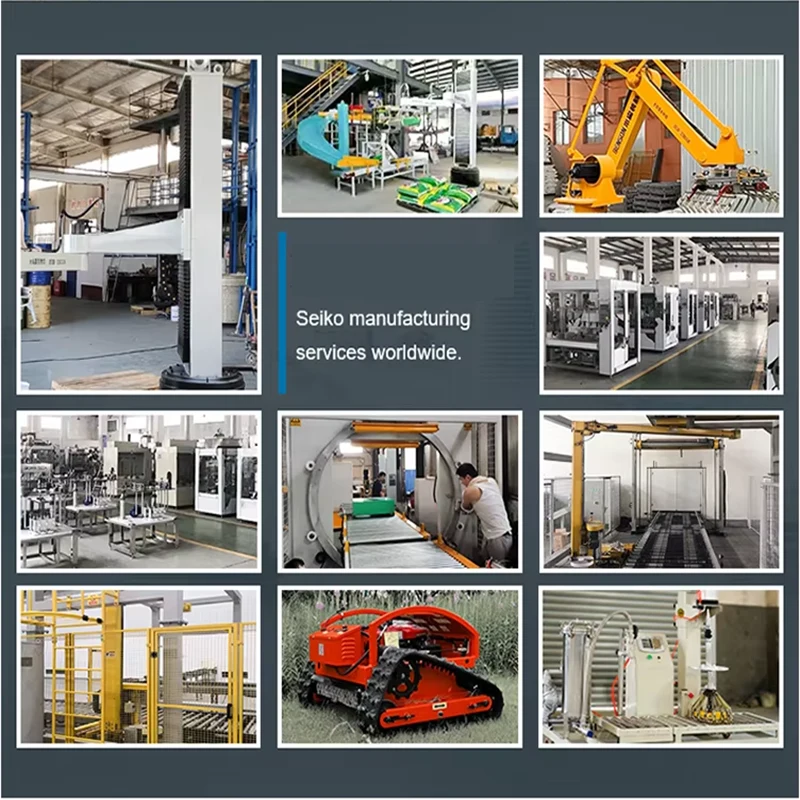

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry