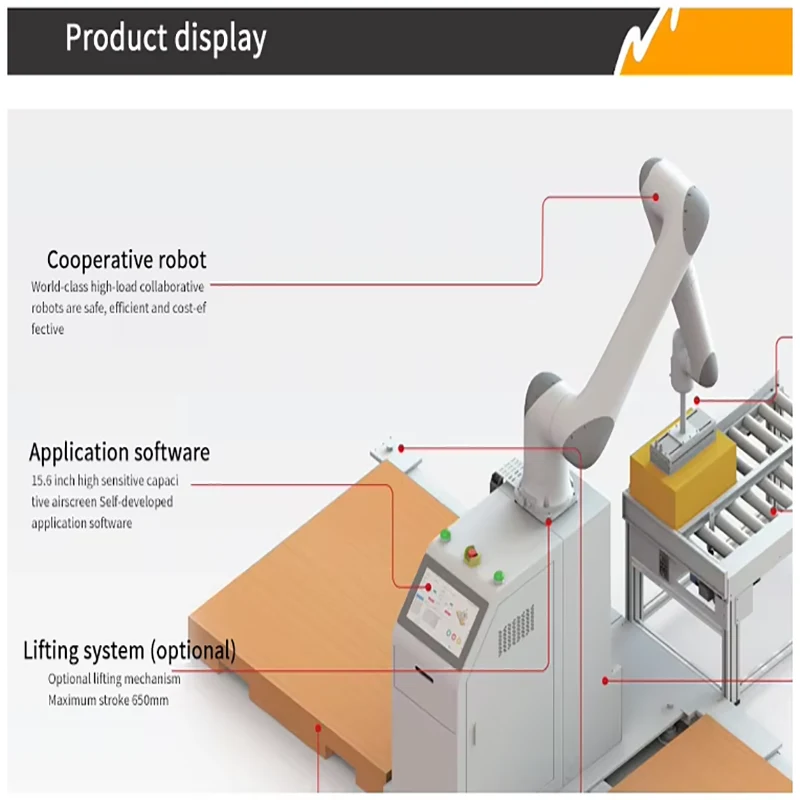

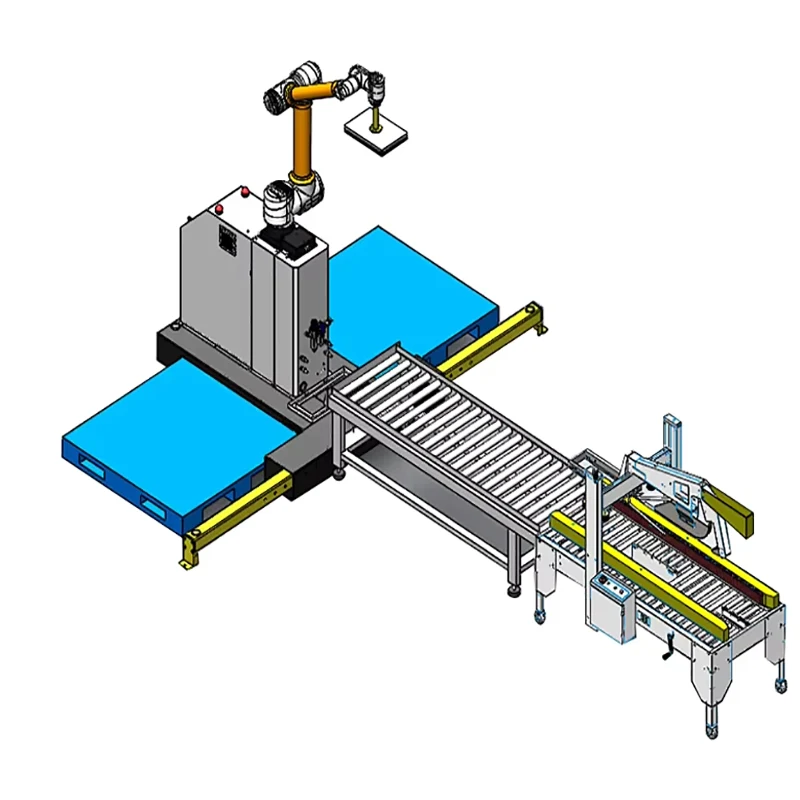

- Product handling and palletizing of automated packaging industrial collaborative robots: can accurately carry products on the production line to the designated location, such as carrying packaged products from the conveyor line to the pallet for palletizing, and can flexibly adjust the action and pallet type according to different product sizes, weights and palletizing requirements.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

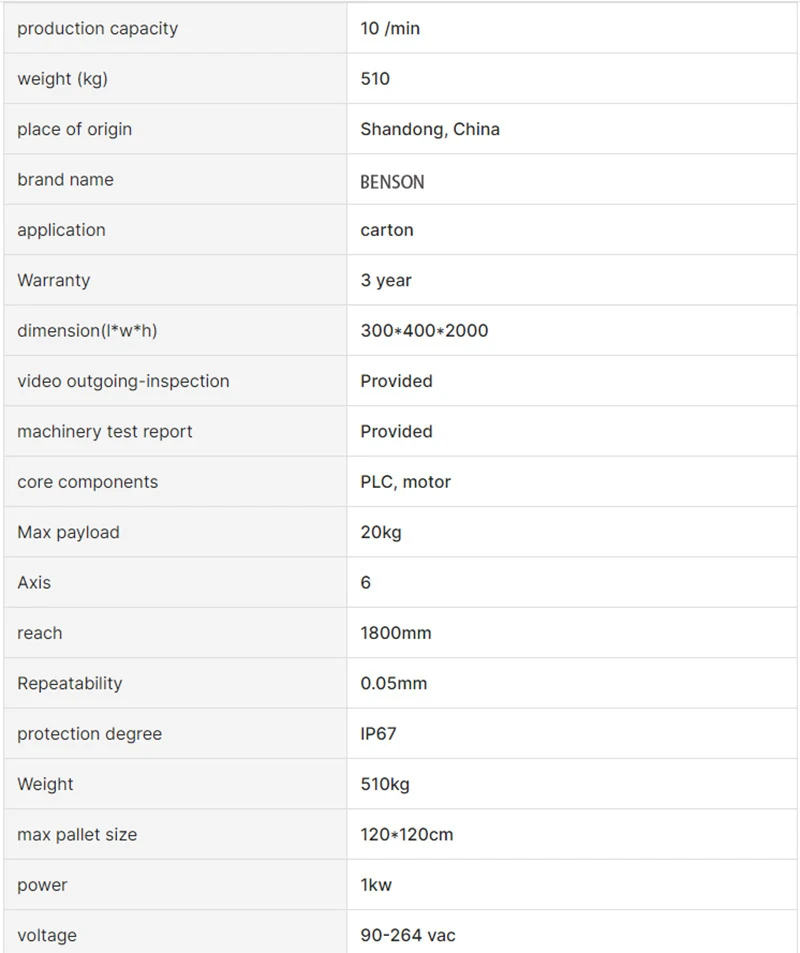

Features of IP67-protected industrial collaborative robots

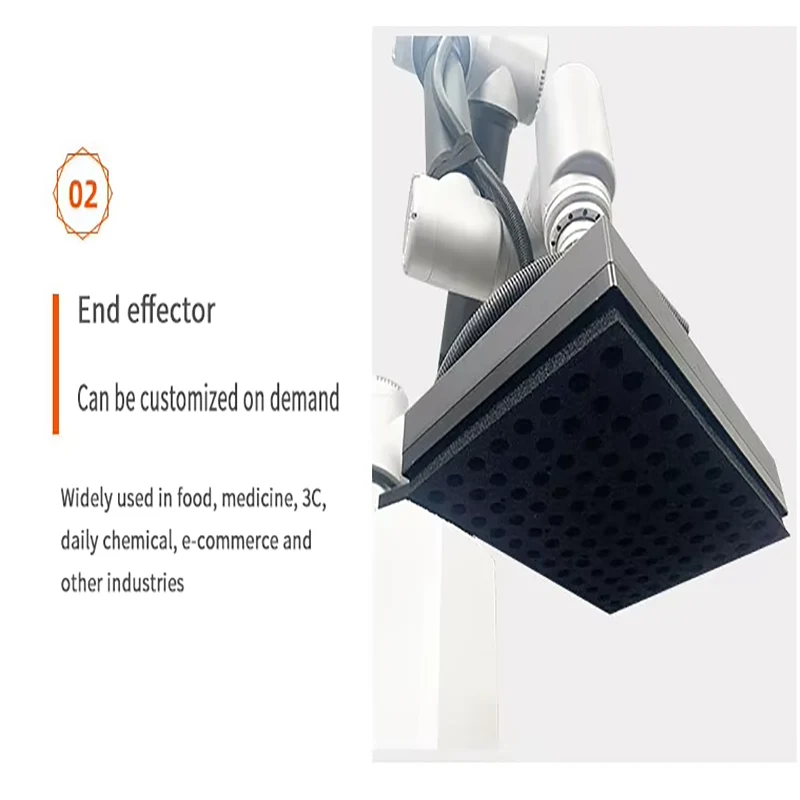

- Safe collaboration: With advanced sensor technology, it can actively sense the surrounding environment. When an accidental collision occurs with personnel, it can stop running in time to ensure the safety of human-machine coexistence, without the need for isolation measures such as guardrails.

- Easy to use: Graphic programming and manual guidance are usually used, without the need for complex traditional robot programming knowledge. Users can let the robot complete tasks through simple dragging, setting and other operations, which lowers the threshold for use.

- Intelligent and efficient: The integrated intelligent vision system can quickly identify the position, shape and posture of the product, and realize accurate grasping, placement and packaging operations. It can also work with other automated equipment to improve the efficiency of the entire packaging production line.

Functions of IP67-protected industrial collaborative robots

- Material sorting and packaging: Use visual recognition technology to sort materials of different types and specifications, and then accurately load them into corresponding packaging containers, such as sorting candies of different flavors into different packaging bags.

- Labeling and coding: Labels can be accurately pasted on products or packages, and coding operations can be performed, such as printing product name, specifications, production date, shelf life and other information, to ensure that the label is accurately pasted and the coding is clear.

- Packaging quality inspection: Equipped with detection sensors and visual systems, the packaged products are quality inspected, such as whether the packaging is intact, whether the labels are pasted correctly, whether the product quantity is accurate, etc., and unqualified products are removed in time.

Application scenarios of IP67 protective industrial collaborative robots

- Food and beverage industry: used for food sorting, packaging, and palletizing, such as the automated packaging process of candy, biscuits, beverages and other products.

- Pharmaceutical industry: can complete the boxing, labeling, and palletizing of drugs to ensure the accuracy and safety of drug packaging.

- Electronic and electrical industry: suitable for the packaging of electronic products, such as shell packaging, accessory packaging, and finished product palletizing of mobile phones, computers and other products.

- Daily chemical industry: on the packaging production line of daily chemical products such as shampoo, shower gel, and cosmetics, the tasks of product handling, packaging, and palletizing are realized.

Products Description

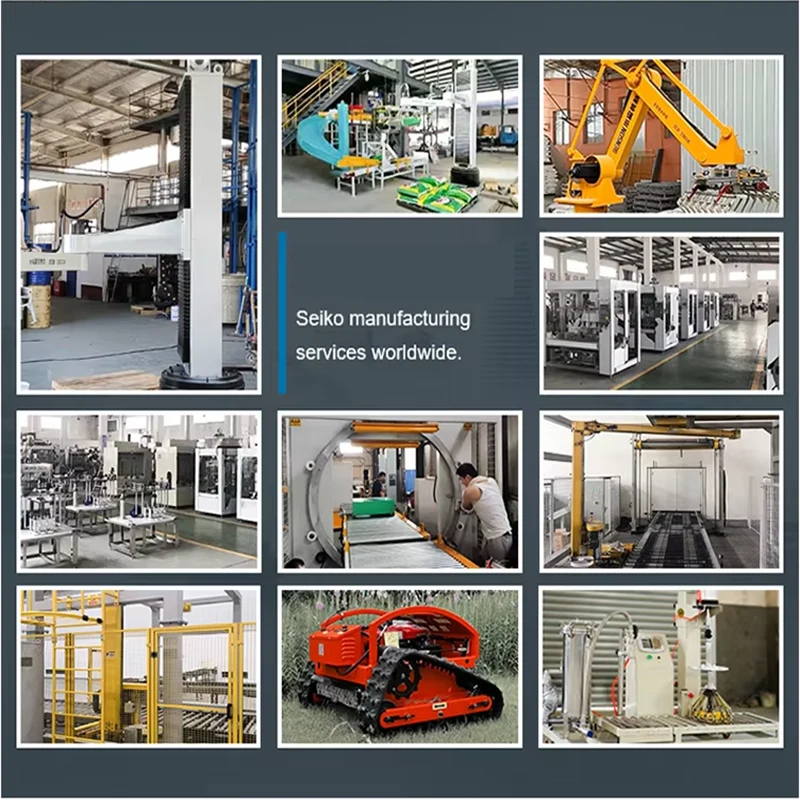

Company Profile

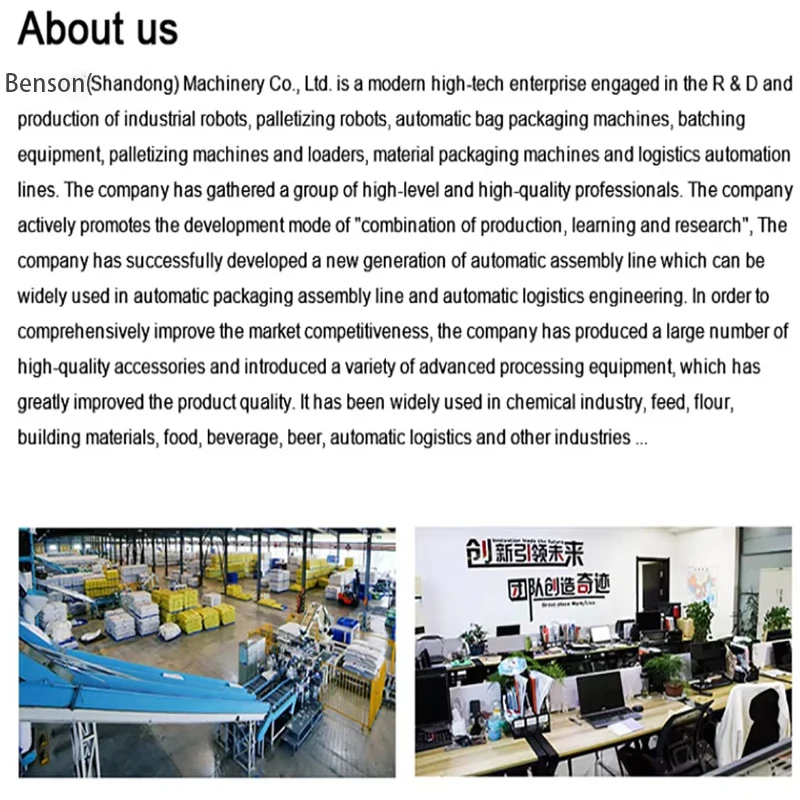

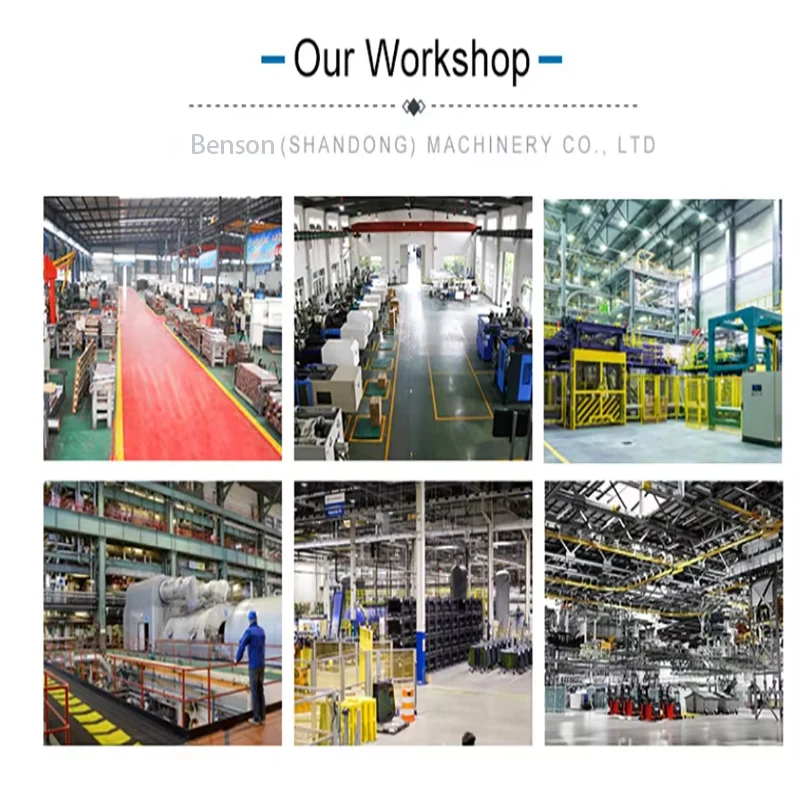

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry