The water-cooled pneumatic sealing machine is a packaging device that combines a water-cooling system and pneumatic drive technology. Its core structure includes a water-cooling system and a pneumatic working unit. The water-cooling system circulates cooling water to effectively remove the heat generated during the sealing process, preventing the performance degradation of the equipment due to overheating, and ensuring the stability of the sealing temperature and the long-term reliable operation

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

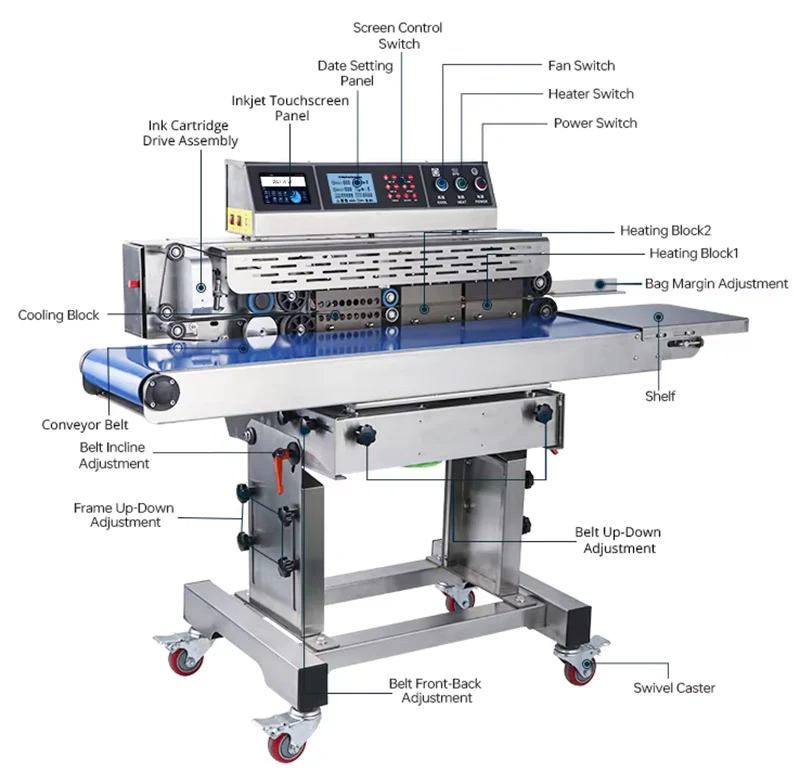

This equipment is usually equipped with adjustable temperature, pressure and time control devices. Users can flexibly adjust the sealing parameters according to different packaging materials (such as plastic films, aluminum foils, etc.) and packaging requirements to achieve the best sealing effect.

Water-cooled pneumatic sealing machine Advantages

1. High efficiency and stability: The pneumatic drive makes the sealing action rapid, greatly improving production efficiency and meeting the needs of large-scale production; the water-cooling system ensures the stable performance of the equipment during long-term continuous operation and reduces the probability of failures.

2. High-quality sealing effect: Precise control of temperature, pressure and time can make the sealed part tight and firm, effectively preventing problems such as leakage and oxidation, improving the packaging quality and extending the product's shelf life.

3. Wide applicability: It can adapt to a variety of packaging materials, such as common plastic films like polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), as well as composite packaging materials, meeting the diverse packaging needs of different industries.

4. Energy conservation and environmental protection: Compared with the traditional air-cooling method, the water-cooling system has higher heat dissipation efficiency and lower energy consumption; compared with the electric drive, the pneumatic drive is more efficient in energy utilization, reducing energy consumption and conforming to the concept of green production.

5. Simple operation and maintenance: The operation interface of the equipment is simple and intuitive, and operators can get started after simple training; the structural design is reasonable, and all components are easy to disassemble and maintain, reducing maintenance costs and downtime.

Water-cooled pneumatic sealing machineApplication Fields

1. Food industry: It is used for the packaging and sealing of various foods, such as snacks, cooked foods, frozen foods, liquid beverages, etc. It ensures the sealing of food packaging, prevents microbial contamination and oxidation deterioration, extends the shelf life of food, and maintains the flavor and quality of food at the same time.

2. Pharmaceutical industry: It is used for the packaging and sealing of pharmaceuticals, medical devices, health products, etc., meeting the strict requirements of pharmaceutical products for packaging sealing, sterility and safety, ensuring the quality and effectiveness of pharmaceuticals, and preventing pharmaceuticals from being contaminated during storage and transportation.

3. Daily chemical industry: It is suitable for the packaging and sealing of cosmetics, detergents, cleaning products, etc., ensuring the integrity and sealing of products before use, avoiding product leakage or volatilization, and enhancing the market image and user experience of products.

4. Electronics industry: It is used for the moisture-proof and dust-proof packaging of electronic components and electronic products, preventing static electricity and moisture from damaging electronic components, and ensuring the stability and reliability of electronic products during transportation and storage.

5. Chemical industry: It is used for the packaging and sealing of chemical raw materials, coatings, adhesives and other products, preventing the leakage and volatilization of chemical products, ensuring the safety during production and transportation, and meeting environmental protection requirements at the same time.

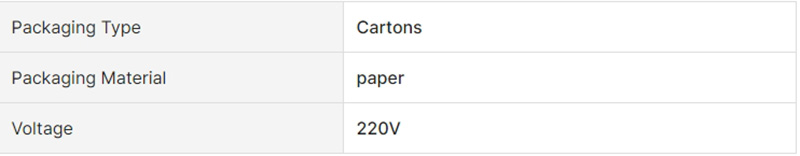

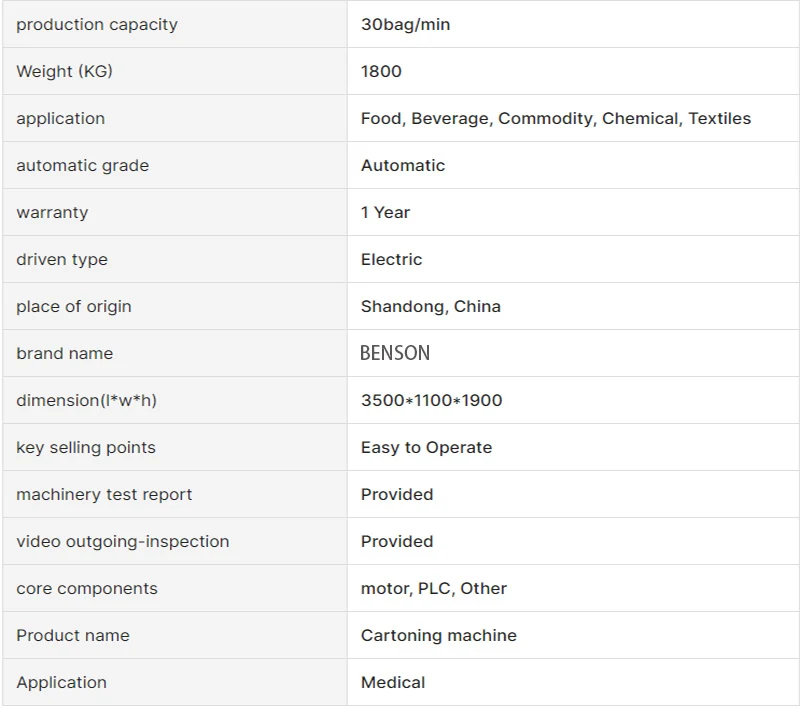

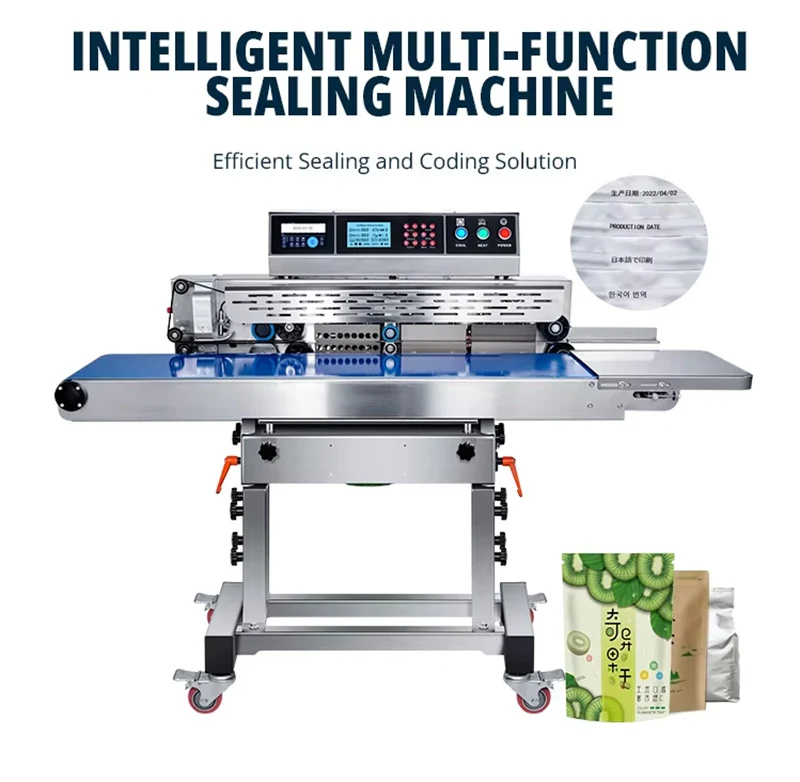

Products Description

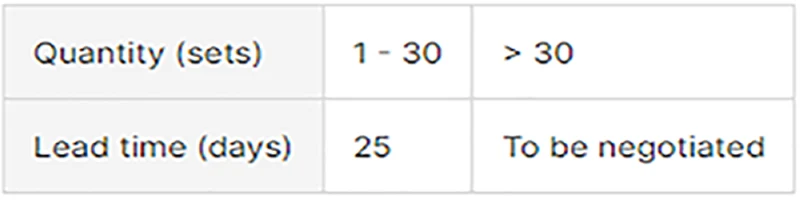

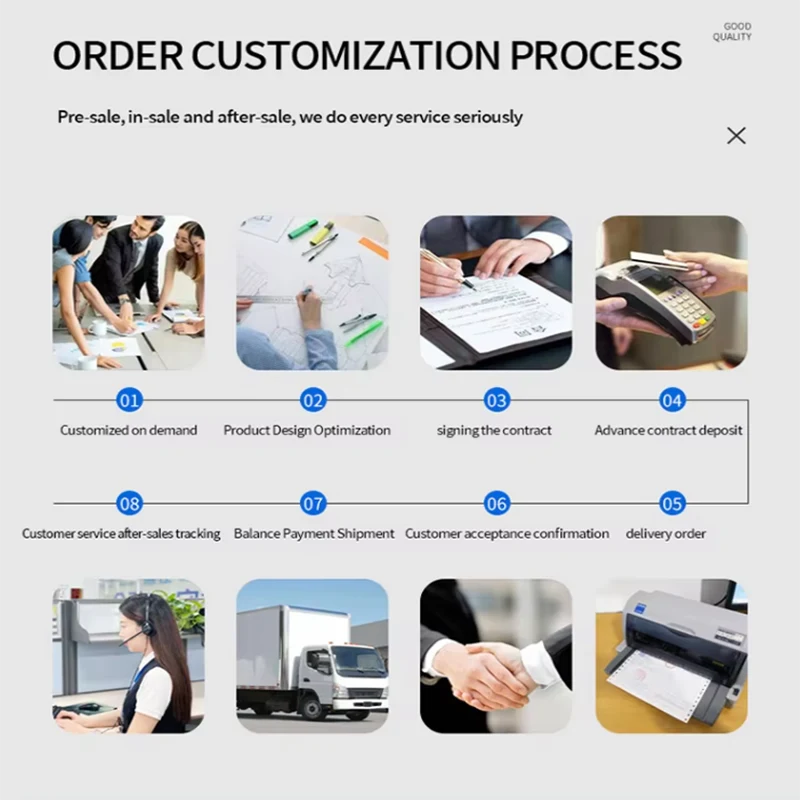

Product Inquiry