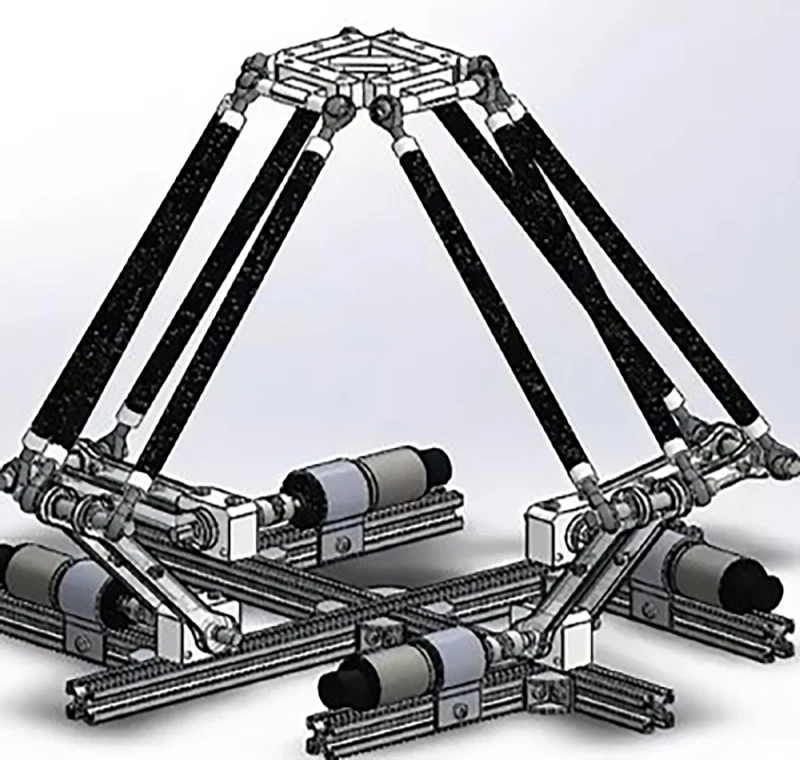

The parallel robot with visual dynamic tracking is an advanced automated device that integrates machine vision technology and the structure of a parallel robot. A parallel robot is a multi-link robotic arm system with multiple parallel brackets and couplings, usually fixed on a common base and driven by motors. The visual system gives it "eyes", enabling it to obtain real-time information such as the position, posture, and shape of the target object.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

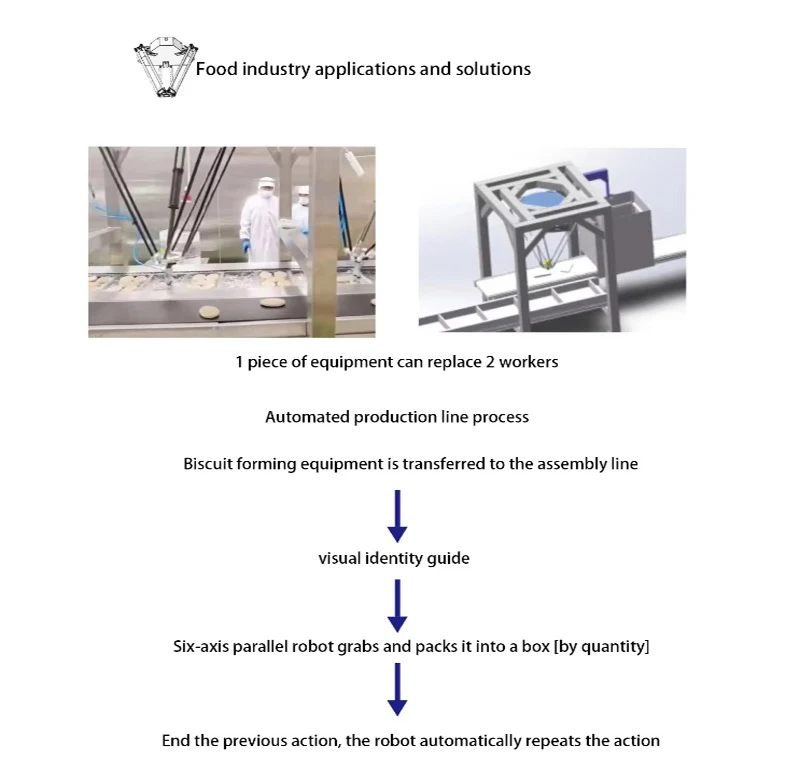

Product descriptions from the supplier

Video Description

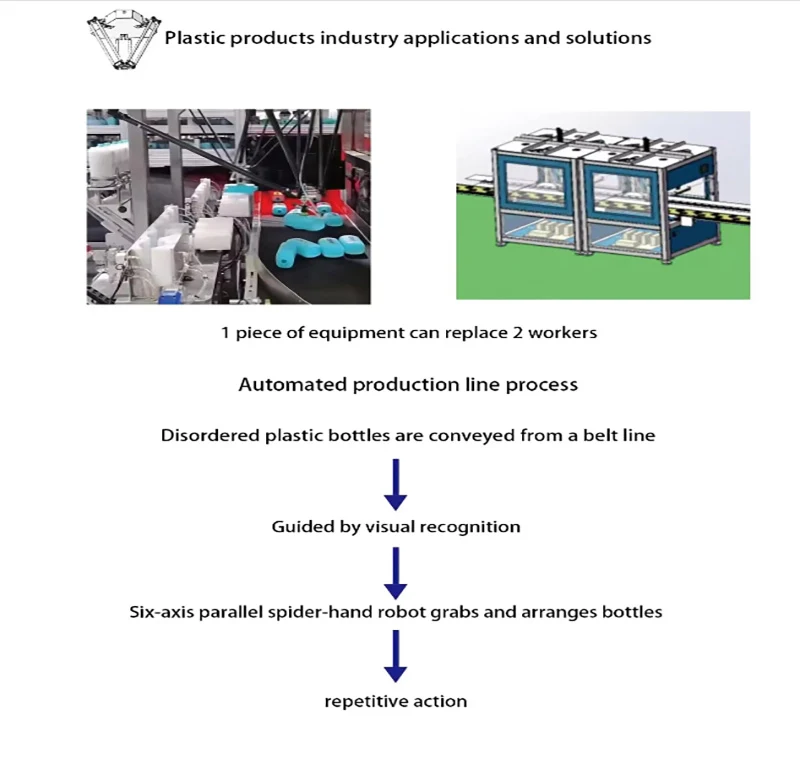

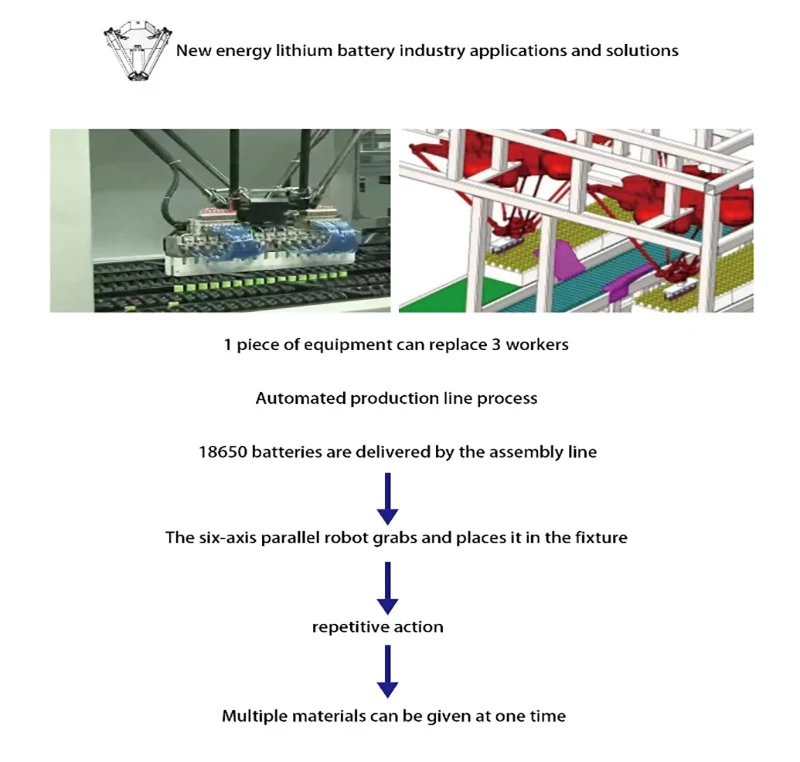

Vision - based dynamic - tracking parallel robotOn this basis, the robot can continuously track dynamic targets, adjust its own motion trajectory and operation actions in real-time according to visual feedback, and achieve precise grasping, sorting, assembly, gluing and other operations on moving targets. For example, in the food boxing industry, it can track the food moving on the conveyor belt for boxing; in the manufacturing of electronic products, it can accurately grasp and assemble high-speed moving components.

Vision - based dynamic - tracking parallel robotAdvantages

1. High speed and high precision: The structure of the parallel robot itself has characteristics such as small mass of moving parts and high structural stiffness, which can achieve rapid movement and accurate positioning. Combined with visual dynamic tracking, it can accurately capture and process dynamic targets during high-speed movement. For instance, it can quickly and precisely sort and package products on a high-speed packaging line.

2. Strong flexibility and adaptability: It can flexibly adjust the tracking strategy and operation mode according to different application scenarios and the characteristics of the target object. It can adapt to the production needs of diversified products. For example, in small-batch and multi-category production, it can quickly switch processes to complete the handling of different materials.

3. Anti-interference ability: The visual system can obtain rich environmental information, identify and track the target through algorithms, effectively eliminate external interference, and stably lock and track the target in a complex environment.

4. Improved production efficiency: Realizing automated dynamic tracking operations, reducing manual intervention, and enabling continuous and efficient work, which greatly improves the production speed and capacity. For example, in the deep processing of agricultural products, the parallel robot combined with the visual dynamic grasping system can cut 80 potatoes per minute.

5. Cost reduction: Long-term use can reduce labor costs, and precise operation can reduce the defective rate, thus reducing the production cost as a whole.

Product Description

Product Inquiry