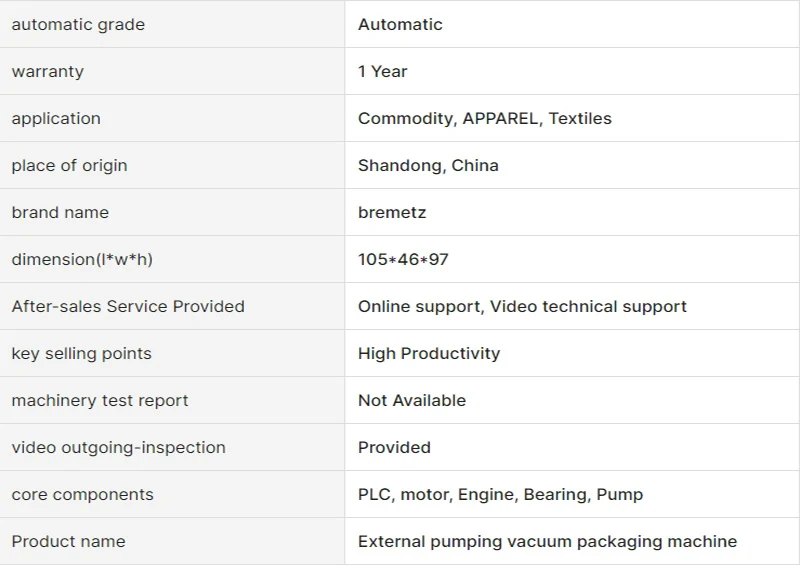

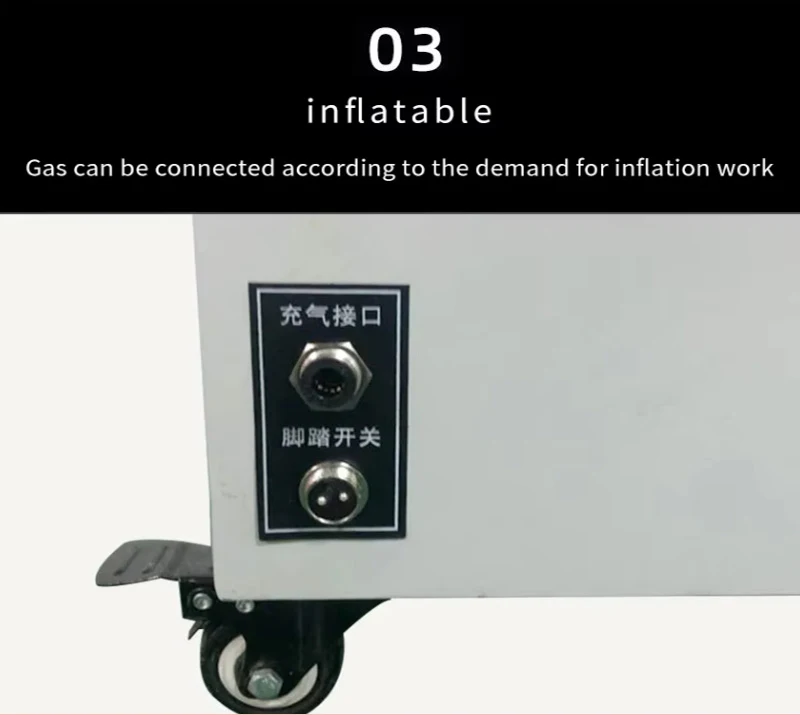

Description: The vertical vacuum sealing machine is a professional packaging equipment. It adopts a vertical structure in its design, which saves floor space and is convenient for operation and maintenance. This equipment is equipped with a high-efficiency vacuum pump, which can quickly extract the air inside the packaging to create a vacuum environment, and then carry out the sealing process. The operation interface of the machine is intuitive and easy to control, and it can adapt to packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The vertical vacuum sealing machine has the following remarkable features:

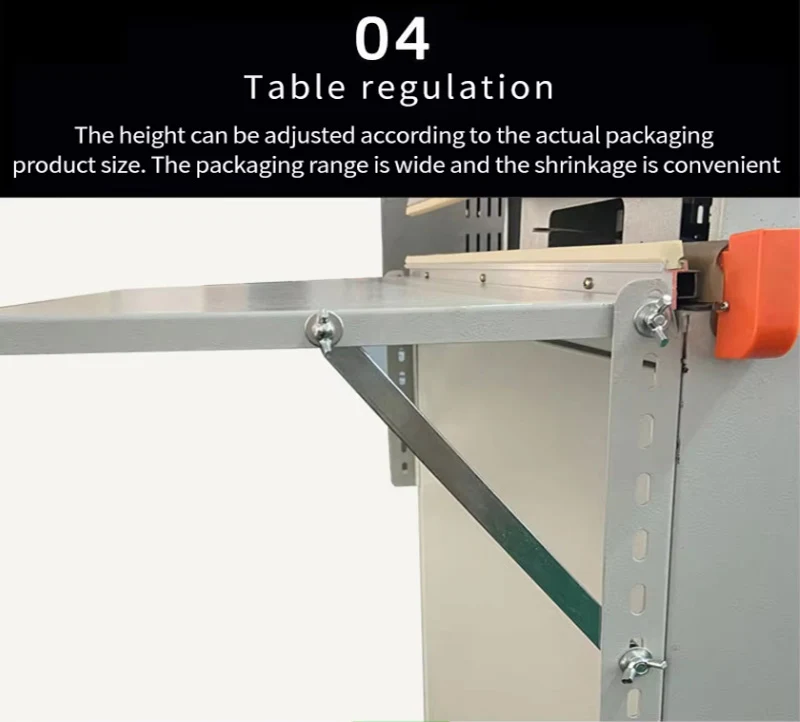

1. Space-saving: With a vertical design, it occupies a relatively small floor area. For places with limited space, such as small processing factories and the back kitchens of shops, the vertical structure makes it easy to be flexibly placed at different positions on the production line or in the working area. It can effectively utilize the vertical space and does not take up too much floor space.

2. High-efficiency vacuum pumping: Equipped with a high-efficiency vacuum pump, it can reach a high degree of vacuum in a relatively short time. It can quickly extract the air inside the packaging to create a vacuum environment, effectively extending the shelf life of products and preventing products from deteriorating due to oxidation, mildew, and the growth of bacteria.

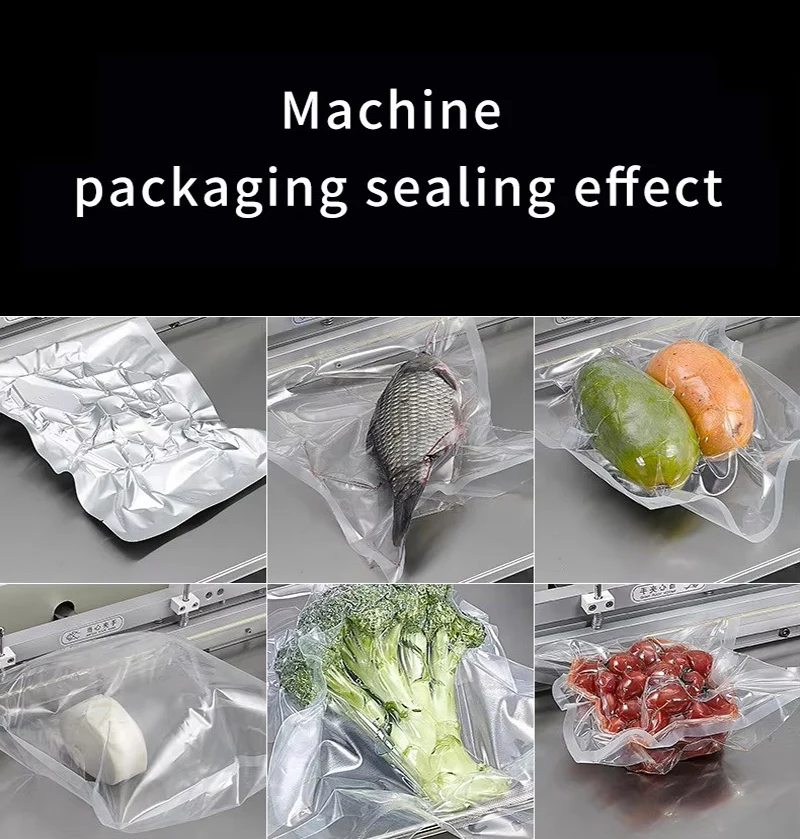

3. Reliable sealing quality: The sealing is firm and has strong airtightness, which can effectively prevent air, moisture, etc. from entering the packaging and protect the product quality. The sealing part is flat and tight, and can withstand a certain amount of tensile force and pressure, ensuring that the product is not affected by external factors during transportation and storage.

4. Easy operation: It has a user-friendly operation interface, and the operation steps are simple and easy to understand. Operators can use it skillfully after simple training, reducing the difficulty of manual operation and the error rate. Some vertical vacuum sealing machines also have automation functions, such as automatic vacuum pumping and automatic sealing, which further improves work efficiency.

5. Wide application range: It can handle various packaging materials of different specifications and materials, such as plastic bags, aluminum foil bags, composite packaging bags, etc., meeting the packaging needs of different products. Whether it is solid, liquid, powdery or granular products, it can carry out effective vacuum sealing packaging, and is widely used in many industries such as food, medicine, electronics, and daily chemicals.

6. Easy maintenance: The equipment has a compact structure, and the main components are easy to disassemble and replace, making the daily maintenance simple. Regular cleaning, maintenance, and the replacement of vulnerable parts are relatively convenient, which can reduce the downtime of the equipment, improve production efficiency, and reduce maintenance costs.

7. Continuous operation: Some vertical vacuum sealing machines can achieve continuous operation, which is suitable for the needs of large-scale production. It can continuously carry out vacuum sealing for products, greatly increasing the product packaging speed, meeting the production requirements of enterprises, and saving labor and time costs.

8. High safety performance: It is equipped with a variety of safety protection devices, such as leakage protection and overheating protection, to ensure the personal safety of operators and the normal operation of the equipment. At the same time, the equipment operates stably with relatively low noise, creating good conditions for the working environment.

Products Description

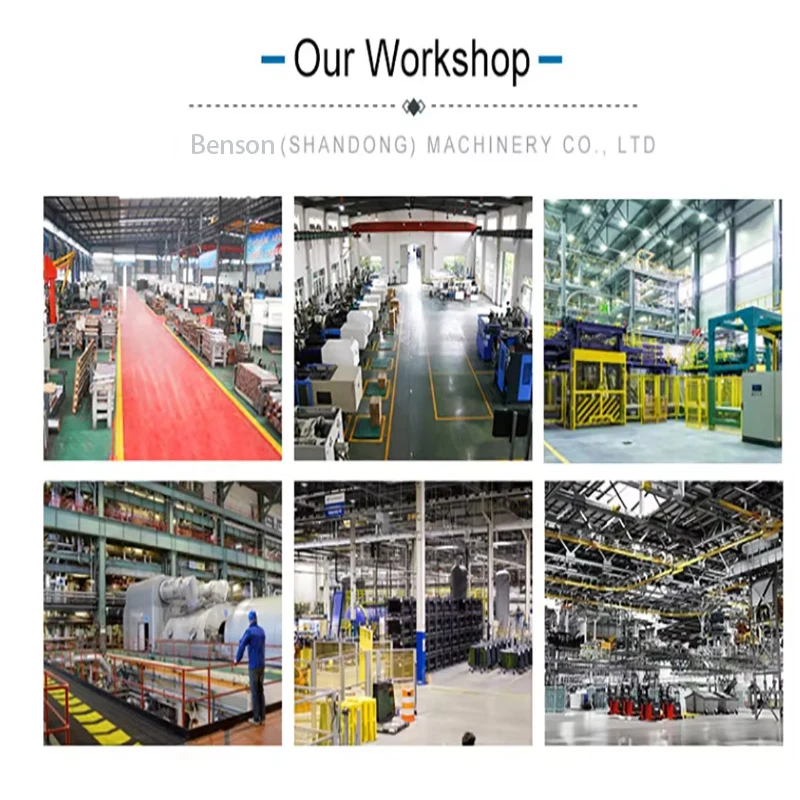

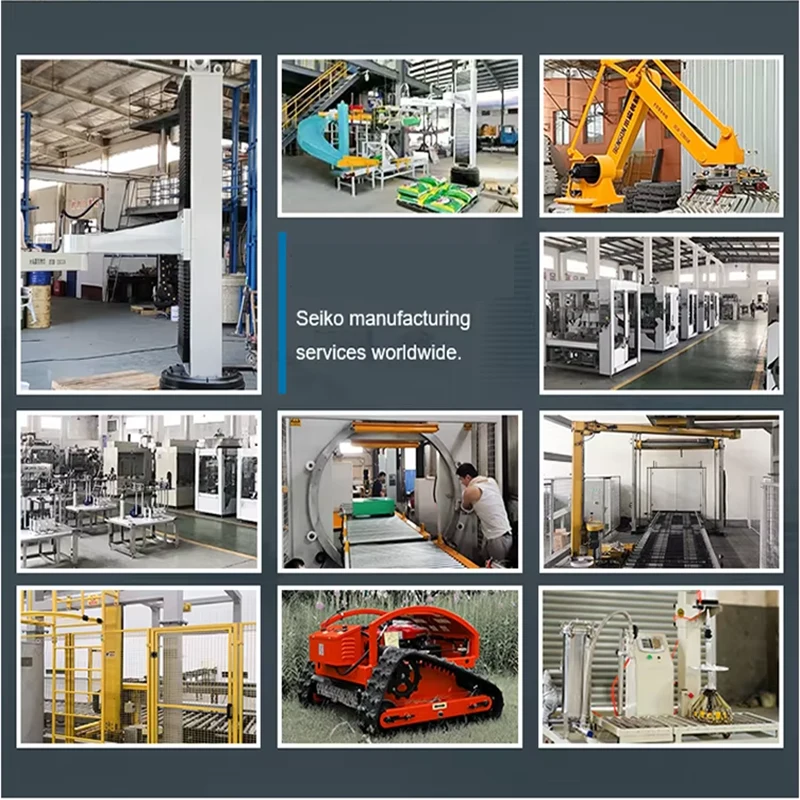

BENSON (Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service

Product Inquiry