A valve bag filling machine is specialized equipment designed for filling various powdery, granular, or small-particle materials into valve bags. It operates by connecting to the bag's valve opening, allowing materials to be precisely and efficiently introduced into the bag under controlled conditions, such as through gravity, pneumatic pressure, or mechanical force. The machine can automatically complete a series of operations including material metering, filling, and bag sealing, greatly

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

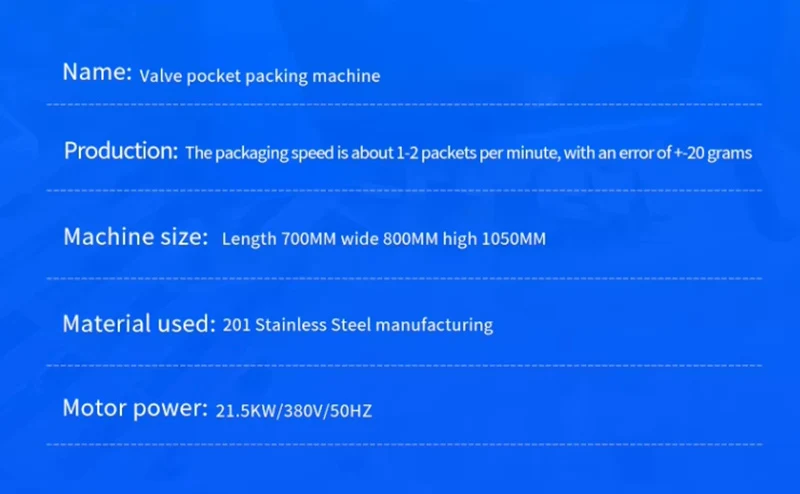

Valve bag filling machineAdvantages

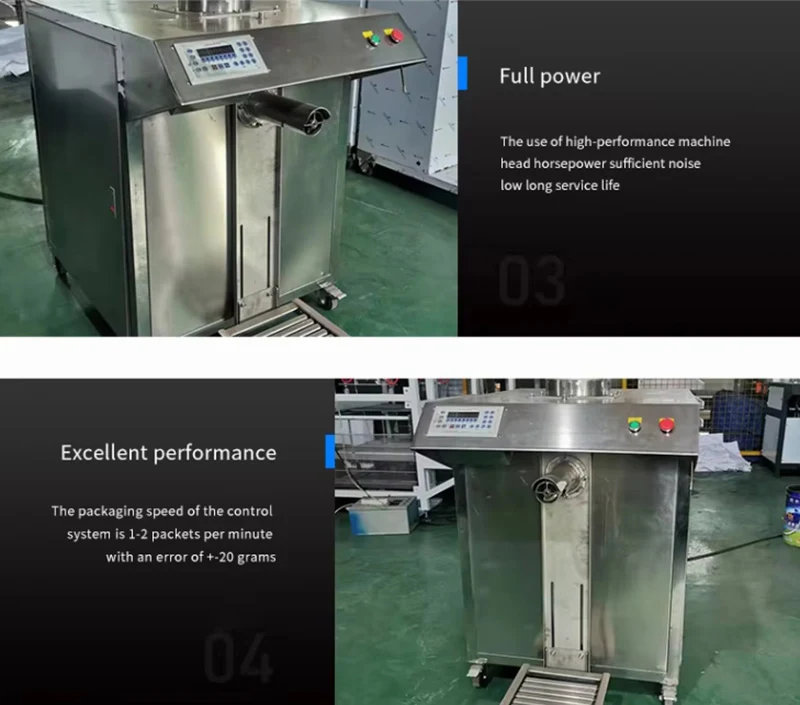

1. High Efficiency: Significantly reduces the time and labor required for bag filling, enabling mass production and meeting high-volume packaging demands. For example, in large-scale industrial production, it can fill dozens or even hundreds of bags per hour.

2. Accurate Filling: Equipped with advanced metering systems, it can achieve precise control of the filling amount, minimizing material waste and ensuring consistent product weight in each bag. Deviation can often be controlled within a very small range, like ±0.5% of the target weight.

3. Versatility: Adaptable to different types of valve bags and a wide variety of materials, including cement, flour, chemical powders, feed grains, and more. It can handle materials with different physical properties, such as varying particle sizes, flowabilities, and densities.

4. Reduced Labor Intensity: Minimizes manual handling of materials, thereby decreasing the physical burden on workers and reducing the risk of occupational diseases caused by long-term exposure to dusty or harmful substances.

5. Enhanced Hygiene: With a closed-filling process, it effectively prevents material spillage and external contamination, maintaining the quality and purity of the filled products, which is crucial for food, pharmaceutical, and high-purity chemical industrie

6. Cost Savings: Although it requires an initial investment, in the long run, the increased efficiency, reduced material waste, and lower labor costs lead to overall cost savings for the enterprise.

Valve bag filling machineApplications

1. Construction Industry: Widely used for filling cement, lime, dry mortar, and other building materials into valve bags, ensuring convenient transportation and storage on construction sites.

2. Food Industry: Applied to fill flour, sugar, salt, starch, and various food additives, meeting strict hygiene and accuracy requirements for food packaging.

3. Chemical Industry: Used to package chemical powders, fertilizers, pesticides, and other products, guaranteeing the safe and efficient delivery of potentially hazardous or valuable chemicals.

4. Feed Industry: Ideal for filling animal feeds, ensuring accurate portioning and maintaining the nutritional balance of the feed during packaging.

5. Mineral Industry: Suitable for filling powdered or granular minerals, such as talc, bentonite, and other non-metallic minerals, facilitating their marketing and use.

Valve bag filling machineFeatures

1. Automated Operation: Incorporates intelligent control systems, such as PLC (Programmable Logic Controller) and touchscreen interfaces, enabling easy operation, parameter adjustment, and monitoring of the filling process. Some models can even be integrated with production management systems for real-time data collection and analysis.

2. Adjustable Filling Parameters: Allows users to flexibly set parameters like filling speed, filling volume, and bag clamping force according to different production needs, ensuring optimal performance for various materials and bag specifications.

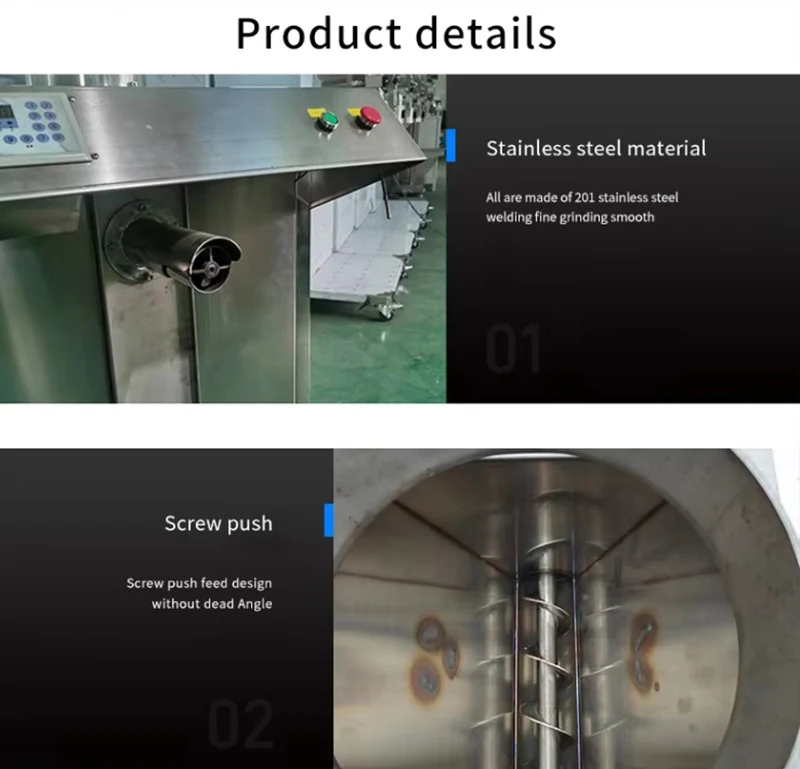

3. Robust Structure: Built with high-quality materials and sturdy mechanical components, it has excellent durability and stability, capable of withstanding continuous operation in harsh industrial environments.

4. Dust Collection Design: Many valve bag filling machines are equipped with integrated dust collection devices to capture and filter dust generated during the filling process, improving the working environment and complying with environmental protection regulations.

5. Quick Bag Changeover: Designed for fast and easy bag size and type changeovers, reducing downtime between different production batches and enhancing production flexibility.

6. Safety Features: Equipped with various safety devices, such as emergency stop buttons, protective enclosures, and interlock systems, to prevent accidents and ensure the safety of operators and equipment.

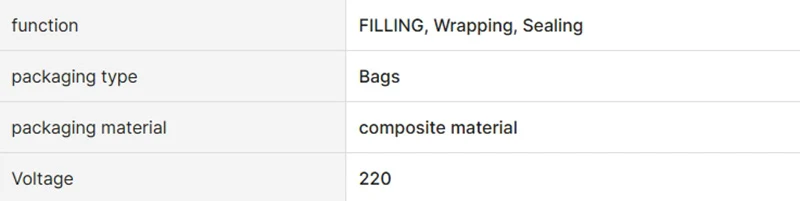

Products Description

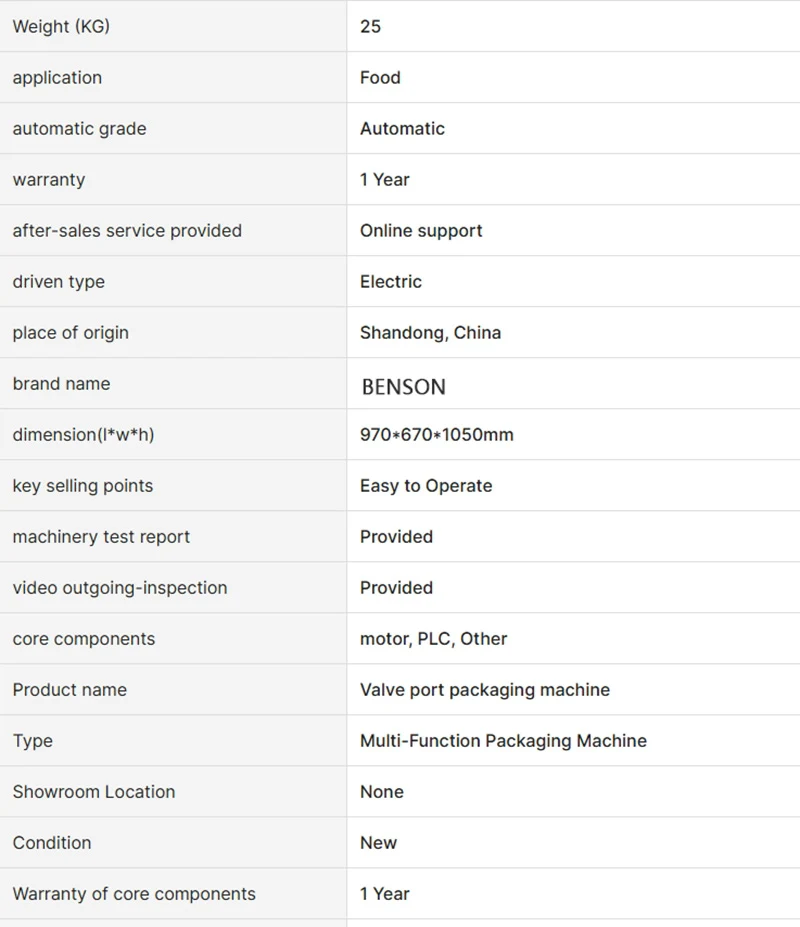

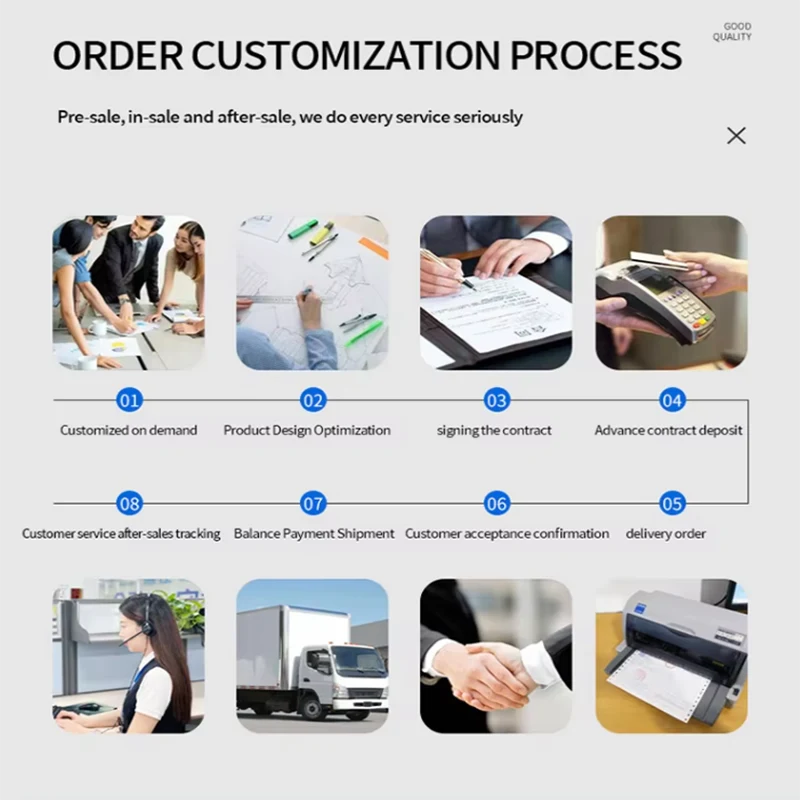

Product Inquiry