A valve bag dry powder mortar packaging machine is specialized equipment designed for automatic packaging of dry powder mortar materials into valve bags. It integrates functions of material metering, filling, and bagging, suitable for powdery mixtures like cement, sand, additives, etc. The machine typically consists of a feeding system, precision metering device, valve bag clamping mechanism, vibration/dense packing unit, and control system.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Valve bag dry powder mortar packaging machineThe process involves:

1. Feeding dry powder mortar into the metering hopper via screw conveyor or gravity;

2. Accurately measuring the preset weight through a load cell system;

3. Filling the material into valve bags via the filling port (valve bags self-seal during filling);

4. Optional vibration or compaction to ensure dense packing and reduce air content.

Valve bag dry powder mortar packaging machineAdvantages

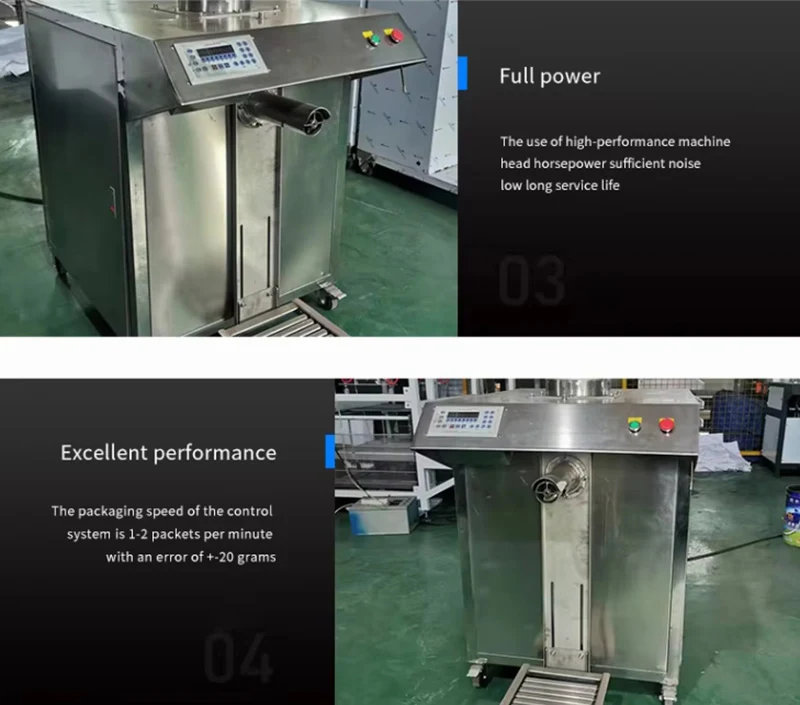

1. High Automation:Fully automatic operation from feeding to bagging reduces labor dependency and improves production efficiency, suitable for 24/7 continuous operation.

2. Precision:Adopts electronic weighing systems with error rates ≤±0.2%, ensuring consistent batch weights and meeting industry standards for mortar quality.

3. Valve Bag Convenience:Valve bags enable dust-free filling (self-sealing during material entry), reducing powder leakage and improving workplace hygiene.

4. Cost-Effective:Minimizes material waste through precise metering and eliminates manual sealing labor, lowering long-term operational costs.

5. Adaptability: mortar formulations (e.g., masonry, plastering, thermal insulation mortar) and bag sizes (20-50kg common).

Valve bag dry powder mortar packaging machineApplications

- Construction Industry:Mainly used for packaging dry powder mortar products, including:

- Masonry mortar

- Plastering mortar

- Tile adhesive

- Waterproof mortar

- Precast Concrete Industry: pre-mixed dry materials for concrete block production.

- Industrial Maintenance:small-batch packaging of specialized repair mortars.

Valve bag dry powder mortar packaging machineCharacteristics

1. Dust Control:Closed filling system with optional dust collection ports to comply with environmental and safety regulations.

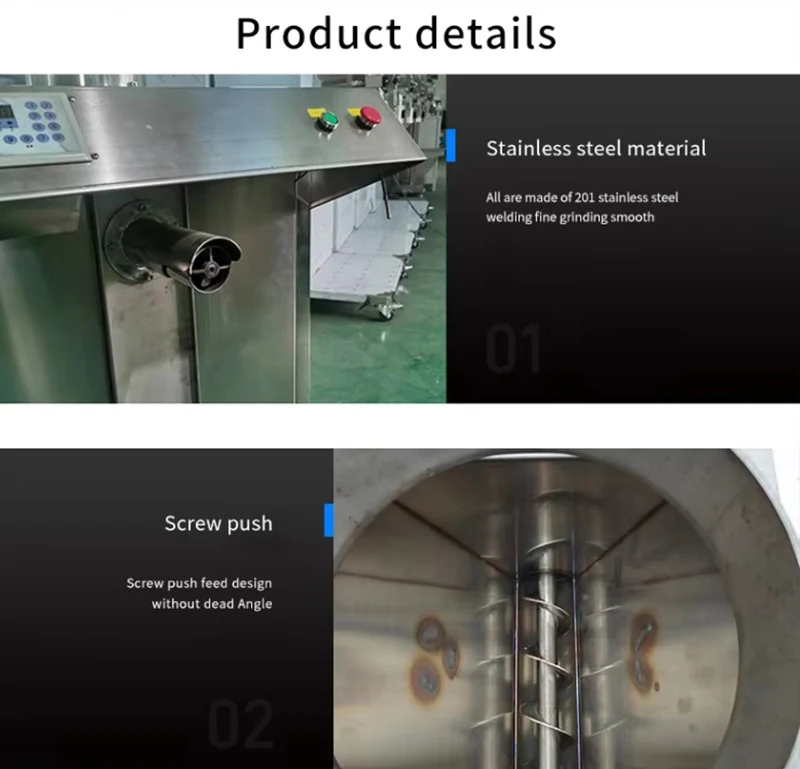

2. Sturdy Structure:Constructed with anti-corrosive steel (e.g., SS304 for contact parts) to withstand abrasive mortar materials and ensure long service life.

3. Intuitive Operation:PLC control panel with HMI touchscreen for easy parameter setting (weight, filling speed, vibration time) and real-time production monitoring.

4. Quick Changeover:Tool-free adjustments for different bag sizes and material types, reducing downtime during product switching.

5. Safety Features:Includes emergency stop, overload protection, and safety interlocks to prevent operator injury and equipment damage.

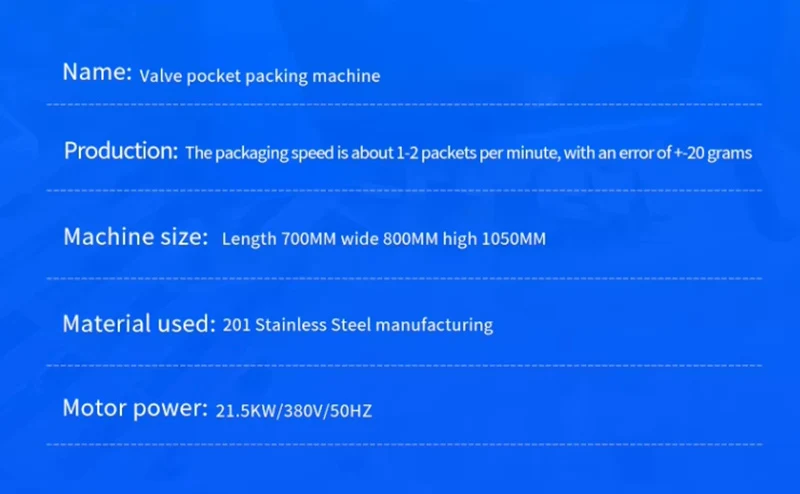

Products Description

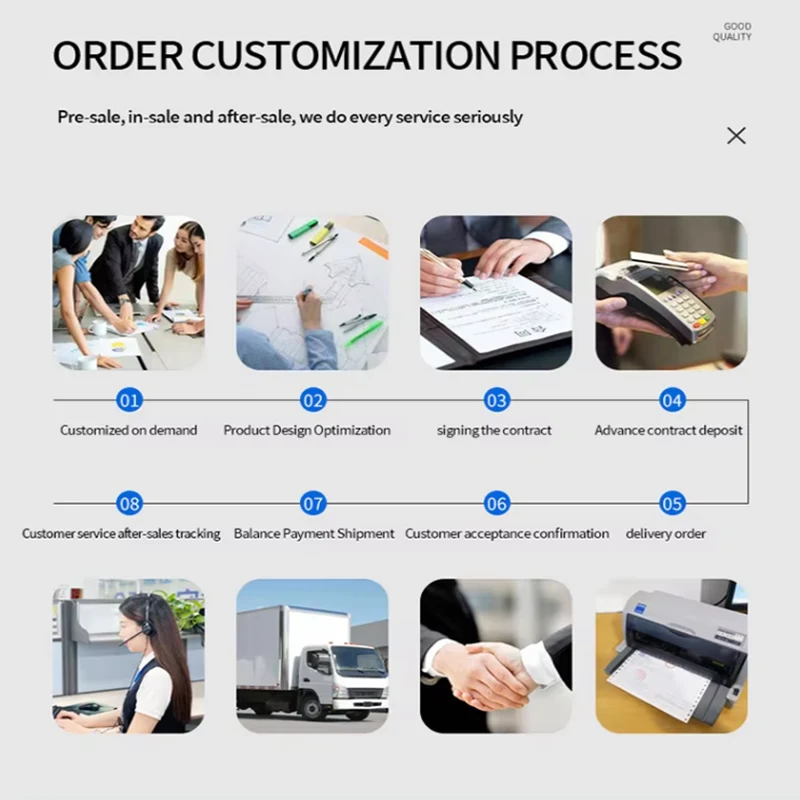

Product Inquiry