The unmanned cassava starch unpacking robot operates precisely with a mechanical arm, achieving the automation and dust-free unpacking of raw materials. The intelligent large bag laundry liquid unpacking robot is equipped with a sensing system to safely and efficiently complete the unsealing of liquid packaging and material flow guidance. The automatic bagged peanut unpacking robot focuses on food scenarios and ensures intact unpacking of peanut kernels through flexible gripping technology,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Unmanned intelligent tapioca starch unpacking and destacking robotadvantage:

1. Fully automatic bagged peanut unpacking robot Efficient operation: 24 hours of continuous operation, the speed of unpacking and palletising far exceeds that of manual labour, which greatly improves production efficiency.

2. Reduce costs: reduce manpower input, avoid manual operation errors and losses, and save operating costs for long-term use.

3. Accurate and reliable: accurate positioning, regular palletising, to ensure the integrity of tapioca starch packaging and stacking safety.

4. Safety and environmental protection: the whole process of automatic operation reduces the risk of dust contact and reduces the potential safety hazards of manual handling.

5. Flexible adaptation: The operation mode can be flexibly adjusted according to the production needs and adapted to different specifications of starch packaging.

The equipment has a simple structure and reliable performance.Workers can quickly

get started after simple training. The palletizing process is fully automated without manual intervention.

It can completely replace manual palletizing, reduce production costs, and simplify management processes

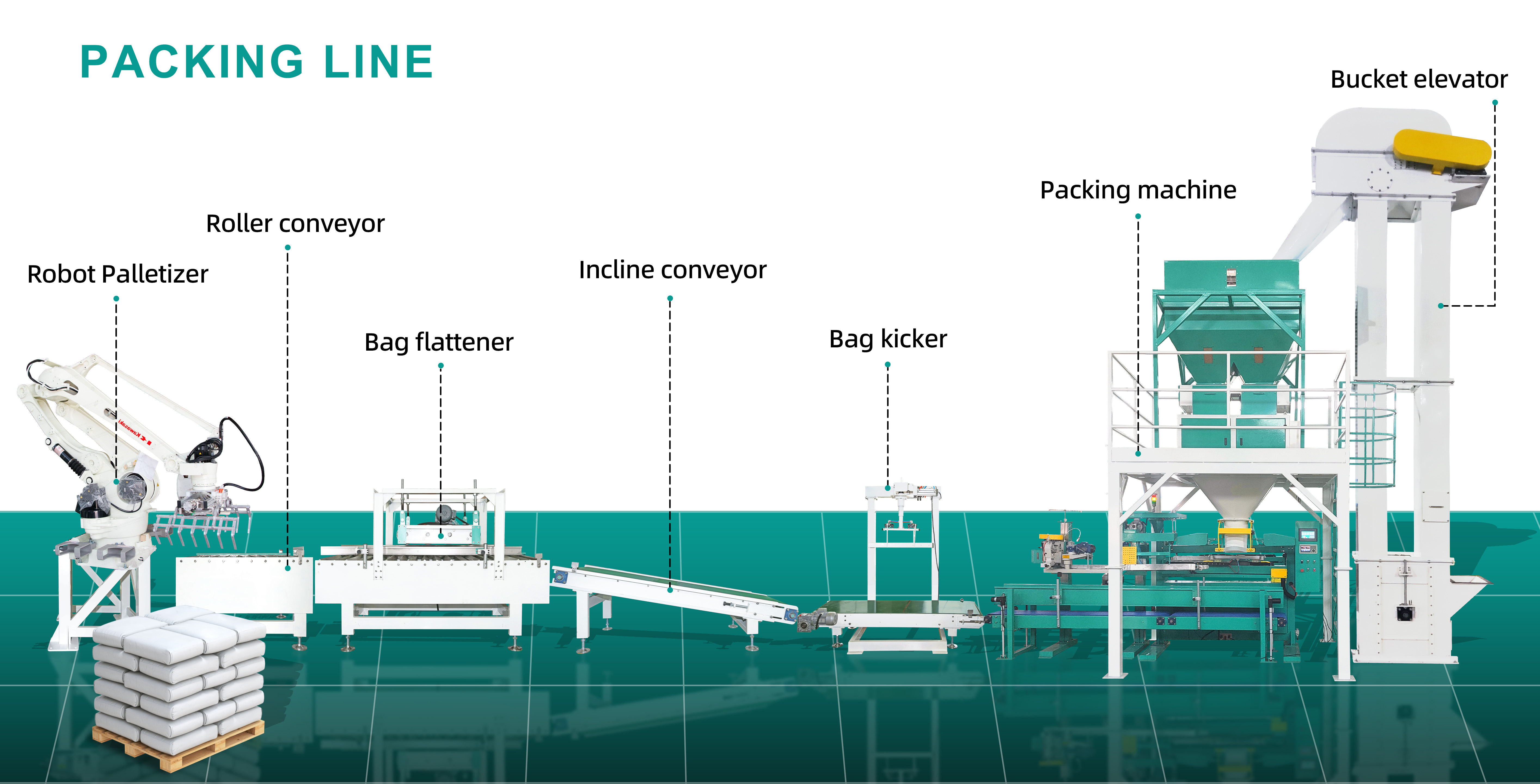

Standing bags are transported to this position, and through the detection of photoelectric switches,

it is judged whether the bag has reached the position of pushing the bag.

After arriving, the cylinder works and kicks the bag down to a horizontal state and transports it to the Incline Conveyor.

The Incline conveyor is mainly used for the transportation of the product. Inclined conveying makes the material inside the bag flat, ready for the next step of shaping and at the same time play the role of cache packing bags .

The bag is conveyed to the Roller Conveyor, the sensors on both sides will detect the bag, stop the conveying and link the palletizer to grab the bag.

Company Profile

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

Company Qualifications

Exhibition

PACKAGING & DELIVERY

FAQ

Q1: May I know how long it takes to get the machine after transfer?

A1: Usually, if the machine you need is a standard type, we can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the product warranty period?

A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the container?

A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other suppliers, you can ask other suppliers to send the products to our factory (Tai’an City, Shandong Province). We help you pack all your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

Product Inquiry