U-shaped ring conveyor is a modern industrial conveying equipment that integrates efficiency, flexibility and intelligence. With its unique U-shaped closed-loop design, it breaks the limitations of traditional linear conveying and is widely used in food and beverage, electronic appliances, pharmaceutical chemicals, automotive parts and other industries, providing reliable guarantees for enterprises to achieve automated production upgrades.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

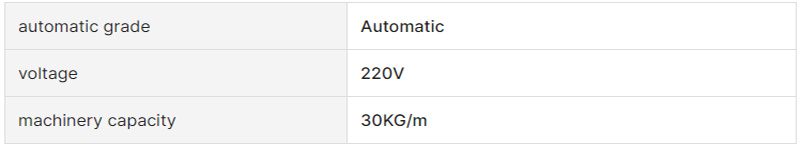

U-shaped ring conveyor core parameter configuration

Project Technical parameters

1.Conveying form: chain/belt/plate chain (optional), supporting single-track/double-track parallel design

2.Track material: carbon steel spraying, stainless steel 304/316, aluminum alloy (food grade material optional)

3.Conveying speed: 0.1-30m/min (frequency control, accuracy ±0.5m/min)

4.Maximum load: single load 5kg-2000kg (customizable heavy load solution)

5.Turning radius: 300mm-2000mm (suitable for narrow space and large-sized materials)

6.Drive system: servo motor + precision reducer (response speed <0.3 seconds, positioning accuracy ±1mm)

7.Control mode: PLC programmable control, touch screen human-computer interaction, remote Internet of Things monitoring (support Modbus protocol)

U-shaped ring conveyor core function modules

1. Intelligent positioning system: equipped with photoelectric sensors and servo positioning mechanisms to achieve ±1mm precise docking of materials and support multi-station synchronous operation.

2. Flexible expansion design: modular track structure, which can be quickly spliced to extend or add branch lines to support later production line upgrades and renovations.

3. Safety protection system: emergency stop button, overload protection, anti-collision warning device, in line with CE/ISO safety standards.

4. Data integration interface: reserved MES/ERP system docking port, support real-time collection and analysis of production data.

Outstanding advantages of U-shaped ring conveyor

High space utilization: U-shaped layout can realize long-distance transportation in a limited space, effectively saving workshop floor space, especially suitable for production environment with compact site.

Flexible customization: Support non-standard customization, and adjust the track length, width, conveying speed and turning radius according to actual needs to adapt to diversified production processes.

Efficient and stable operation: Adopt high-strength wear-resistant materials and precision transmission components, stable operation and low noise, with continuous 24-hour uninterrupted operation capability and long maintenance cycle.

Strong intelligent integration: Support seamless connection with intelligent equipment such as PLC, sensors, AGV trolleys, realize automatic sorting, positioning, detection and other functions, and help factories upgrade to intelligence.

Typical application scenarios of U-shaped ring conveyor

- Food and beverage industry: used for the whole process of filling, labeling and packaging of bottled/boxed products to meet clean production standards.

- Electronic and electrical manufacturing: adapted to the assembly, testing, aging and other processes of precision parts to ensure accurate positioning of materials and anti-static requirements.

- Pharmaceutical industry: in compliance with GMP specifications, to achieve aseptic transportation and traceability management of drugs and medical devices.

- Automotive parts assembly: carrying heavy workpieces in circulation, supporting multi-station synchronous operation, and improving assembly efficiency and quality.

Customized solutions for U-shaped ring conveyors

- Industry-specific configuration:

- Food industry: all stainless steel material + detachable and cleanable design, in line with HACCP standards;

- Electronics industry: anti-static belt + suspended track to avoid product damage;

- Automobile industry: heavy-duty chain + high-rigidity frame to meet the transportation of large parts.

- Special function customization:

- Lifting connection: integrated vertical lifting mechanism to achieve three-dimensional linkage of multi-layer production lines;

- Automatic sorting: equipped with a visual recognition system to support dynamic classification and diversion of materials.

Service guarantee system

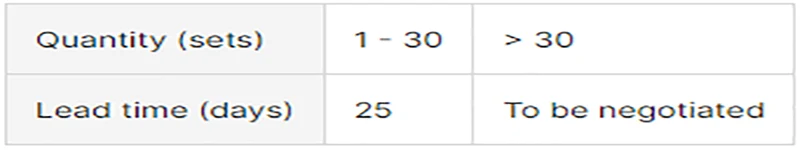

Full-cycle service: free on-site survey → 3D solution design → 25-day fast delivery → 24-hour after-sales response.

Quality commitment: 1-year warranty for core components, lifelong maintenance, regular inspection and system upgrade services.

Choosing our U-shaped ring conveyor means choosing a more efficient, smarter and more reliable production solution! The professional team provides one-stop services from solution design, production and installation to after-sales maintenance, helping enterprises reduce costs and increase efficiency, and seize the industry's first opportunity.

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry