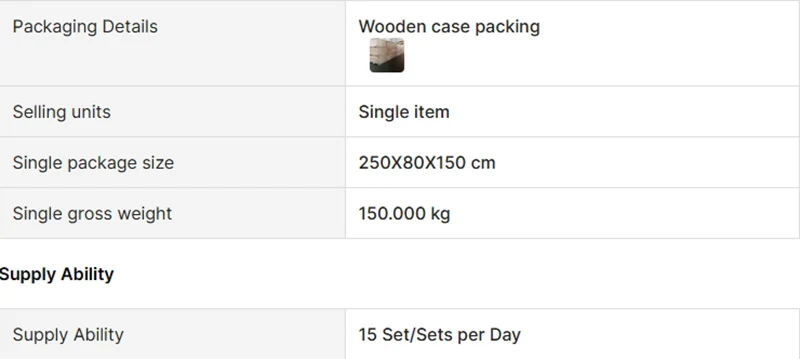

The top-level vertical powder packaging machine is a high-performance, advanced packaging equipment specifically designed for powder materials. It integrates cutting-edge technology and innovative design, featuring a vertical structure that enables efficient and stable operation. The machine can automatically complete a series of processes including metering, filling, sealing, and coding, significantly improving packaging efficiency while ensuring high precision and consistency in packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

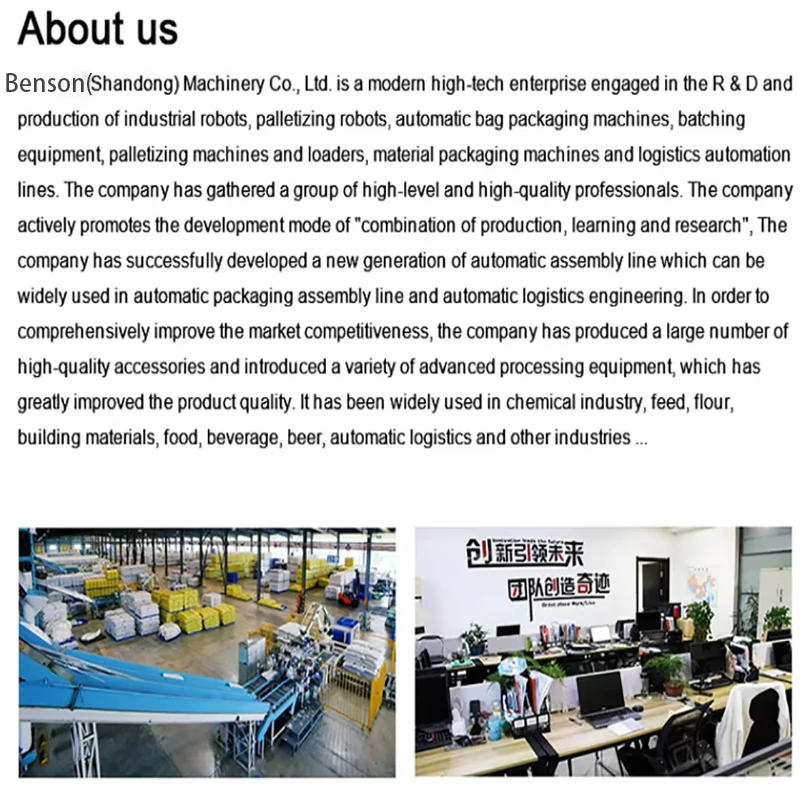

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Top-level vertical powder packaging machineAdvantages

1. High Precision: Utilizes advanced metering systems, such as screw or auger feeding mechanisms, to accurately measure powder quantities, minimizing errors and ensuring each package contains the exact specified amount of powder. This is crucial for products where dosage accuracy matters, like pharmaceuticals and food additives.

2. High Efficiency: With a high-speed operation capacity, it can handle a large volume of powder packaging within a short time. Its automated processes reduce the need for manual intervention, speeding up production lines and increasing overall productivity.

3. Versatility: Adaptable to a wide variety of powder products, from fine flour and milk powder to industrial powders like cement and chemical powders. It can adjust to different packaging sizes and specifications, meeting diverse customer requirements.

4. Reliability and Durability: Constructed with high-quality materials and components, the machine is designed to withstand continuous operation in industrial environments. Minimal breakdowns and long service life ensure stable production and lower maintenance costs in the long run.

5. User-friendly Operation: Equipped with an intuitive control panel, operators can easily set parameters, monitor the production process, and troubleshoot issues. It also offers features like automatic alarm systems for abnormal situations, enhancing operational safety.

Top-level vertical powder packaging machineApplications

1. Food Industry: Widely used for packaging various food powders, including instant coffee, spices, powdered drinks, and baby formula. It ensures product hygiene and extends shelf life through proper sealing.

2. Pharmaceutical Industry: Ideal for packaging pharmaceutical powders, such as powdered medications, herbal extracts, and nutritional supplements. The machine meets strict hygiene and precision requirements in the pharmaceutical sector to ensure product quality and safety.

3. Cosmetics Industry: Used to package cosmetic powders like face powder, body powder, and bath salts, providing accurate packaging and maintaining product quality with excellent sealing performance.

4. Chemical and Industrial Sector: Suitable for packaging industrial powders, such as pesticides, fertilizers, pigments, and cement, meeting the large-scale and efficient packaging needs of these industries.

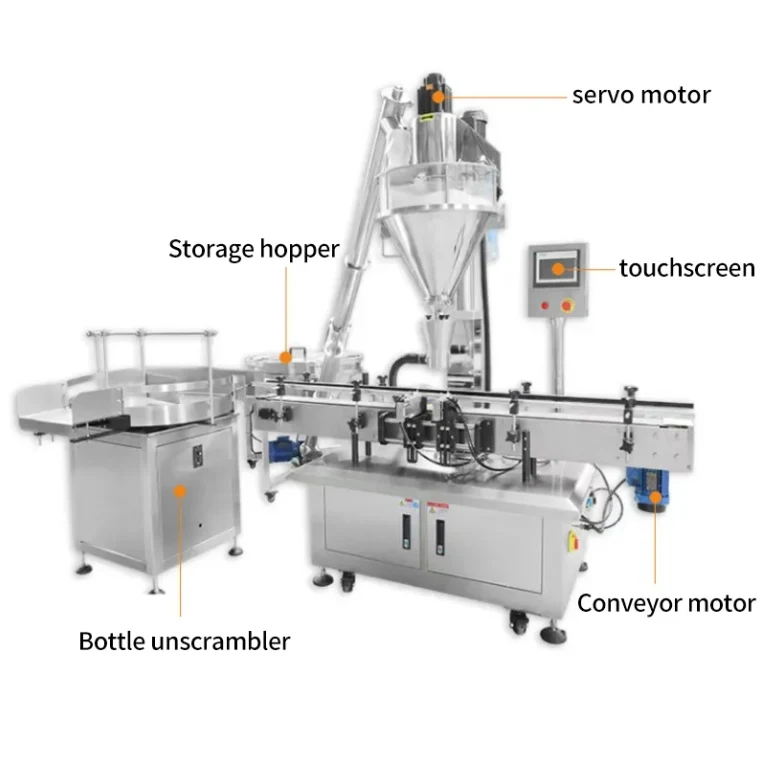

Top-level vertical powder packaging machineFeatures

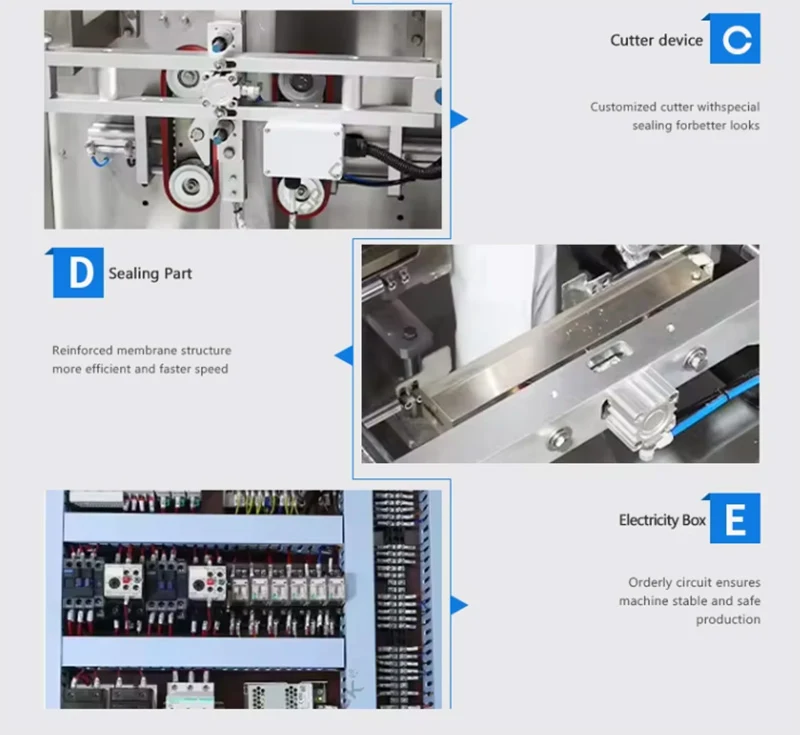

1. Intelligent Control: Integrated with PLC (Programmable Logic Controller) systems and touch-screen interfaces, allowing for precise control and easy customization of packaging parameters. Real-time monitoring and data recording functions help optimize production processes.

2. Sealing Technology: Adopts advanced heat-sealing or ultrasonic sealing methods to ensure strong, airtight seals, preventing powder leakage and contamination. Different sealing patterns can be adjusted according to packaging materials.

3. Dust-free Design: Incorporates dust collection and suppression mechanisms to maintain a clean working environment, especially important when handling fine powders to protect operators' health and prevent cross-contamination.

4. Easy Maintenance: Designed with modular structures, key components can be easily disassembled and replaced, facilitating regular maintenance and reducing downtime for repairs.

5. Customizability: Can be customized with additional functions, such as nitrogen filling for products that require an inert gas environment to extend shelf life, or multi-lane packaging for increased production capacity.

Products Description

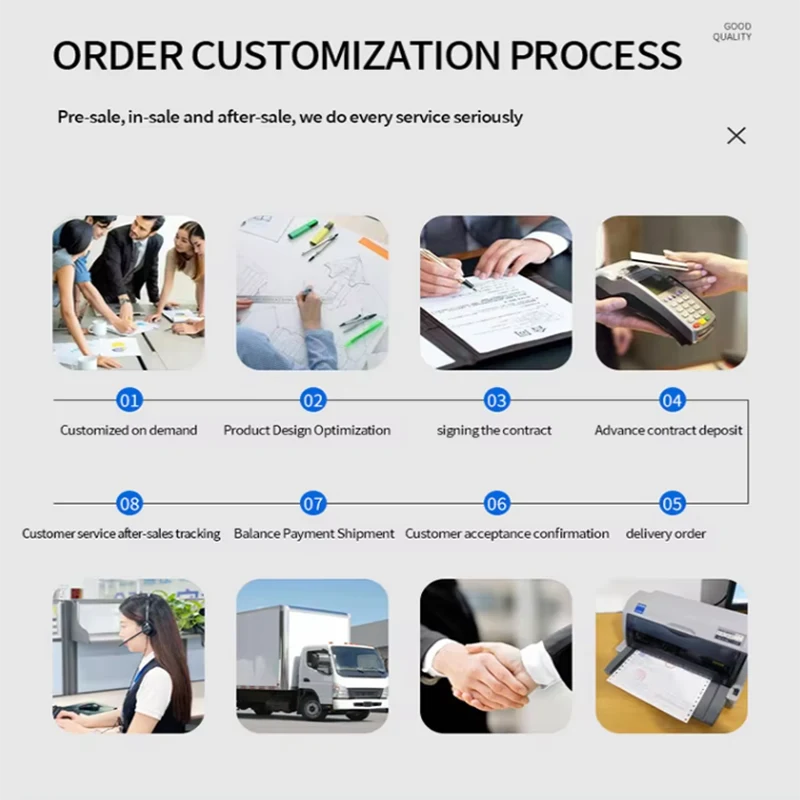

Product Inquiry