This high - level food palletizer takes intelligent and high - efficiency as its core advantages. It adopts an advanced servo motor drive system, running accurately and stably with strong power. It can quickly and orderly stack various bagged and boxed foods neatly, and its palletizing efficiency far exceeds that of manual work. It has a high degree of automation. The whole process from grasping, handling to palletizing requires little human intervention, effectively reducing labor costs

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Lead time

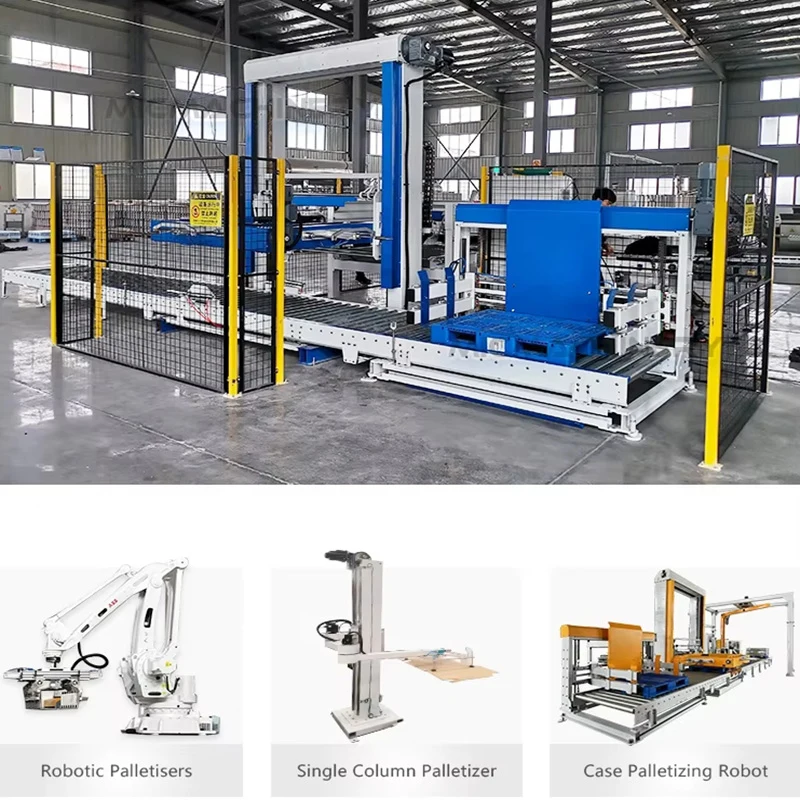

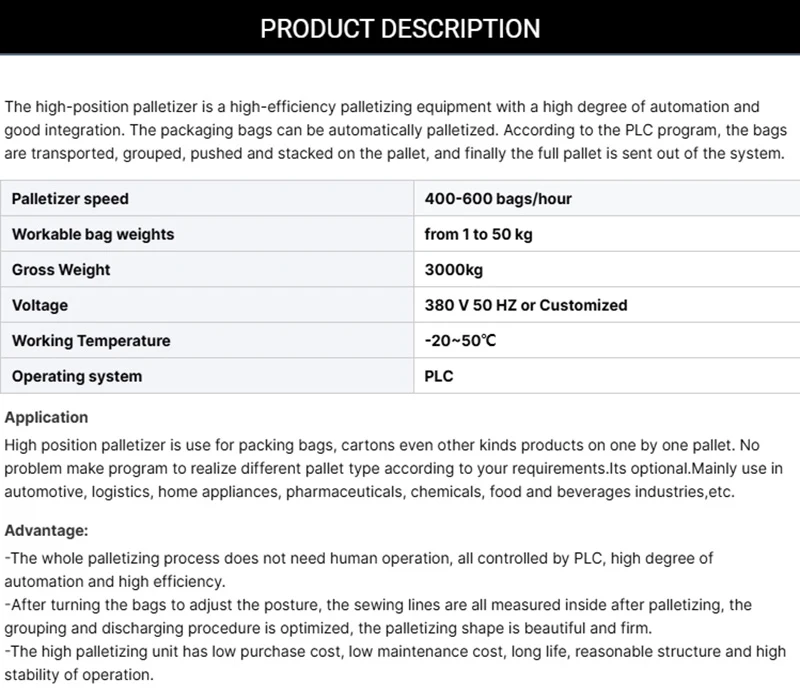

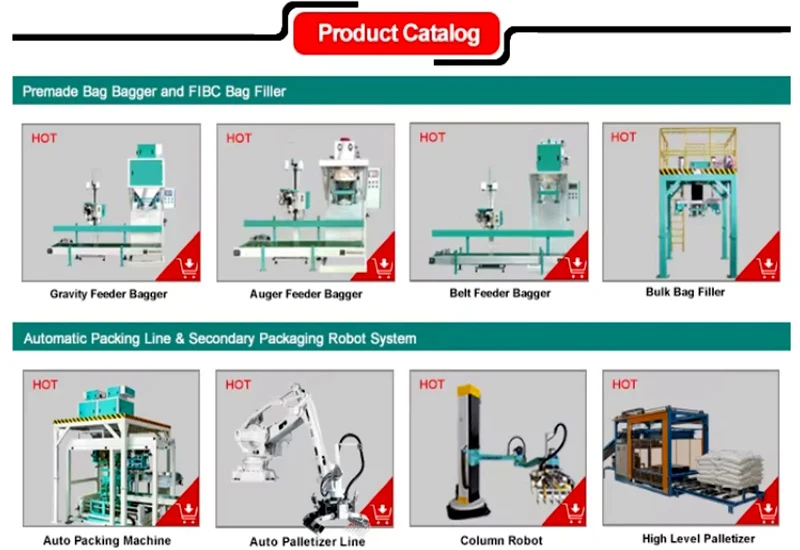

Products Description

The high - level food palletizer is a key equipment in the automated food production process. It can accurately and efficiently stack various types of food such as bagged, boxed, and bottled foods into a neat and stable stack shape according to the preset arrangement and number of layers. This equipment is equipped with advanced sensors and an intelligent control system, which can quickly identify food packaging of different specifications. During high - speed operation, it ensures that the grabbing, handling, and palletizing actions are gentle and stable, avoiding damage to the food such as extrusion and collision. At the same time, it has a high degree of flexibility and compatibility, can be seamlessly connected to the food production line, and can achieve 24 - hour continuous operation. This Food high - level palletizer greatly improves the warehousing and logistics efficiency of food production enterprises, effectively reduces labor costs and labor intensity, and ensures the standardization, normalization, and intelligence of food production.

The working process of Benson Food's high - level palletizer:

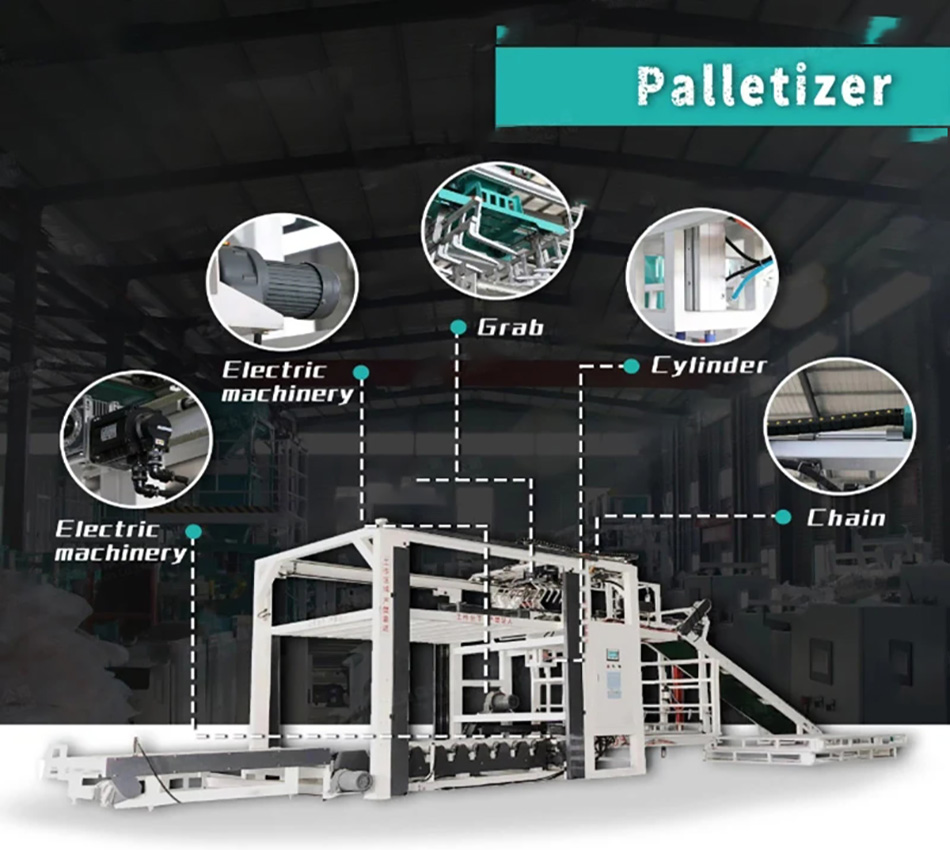

1. Food Conveying: Various types of packaged foods on the production line, such as bagged, boxed, and bottled foods, are conveyed to the gripping station of the high - level palletizer through conveying equipment like belt conveyors and chain - plate conveyors at a stable speed and direction. During this process, the conveying system will conduct preliminary sorting and arranging of the foods to ensure that the foods entering the gripping station are in accurate positions and have consistent spacing.

2. Detection and Identification:Food high - level palletizerdriven by servo motorWhen the foods reach the gripping station, the detection devices equipped on the high - level palletizer, such as photoelectric sensors and visual recognition systems, start to work. The photoelectric sensors detect the arrival of the foods, and the visual recognition systems quickly identify information such as the specifications, shapes, and packaging types of the foods, and then transmit the data to the control system. This enables the control system to formulate appropriate gripping and palletizing strategies according to the preset programs.

3. Gripping Action: Based on the information detected and identified, the control system drives the robotic arm to move the corresponding gripping devices (such as vacuum suction cups, clamping grippers, etc.) to the appropriate positions. For different types of foods, the gripping devices will adopt different gripping methods.

4. Gripping Methods: For bagged foods, the vacuum suction cups will adhere to the surface of the bags and lift them using vacuum suction force. For boxed and bottled foods, the clamping grippers will steadily clamp them from both sides to ensure that the foods do not fall or get damaged during the gripping process.

5. Handling and Transferring: After the gripping device successfully grabs the food, the robotic arm, driven by the servo motor, transports the food to the designated palletizing area along the planned path. During the handling process, the robotic arm will precisely control the movement speed and acceleration according to the instructions of the control system to avoid the food from shaking or colliding due to excessive speed or sudden stops and turns.

6. Palletizing Arrangement: After reaching the palletizing area, the robotic arm accurately places the foods on the pallet according to the preset arrangement methods (such as row - column type, staggered type, etc.) and the number of layers. After each placement, the robotic arm will return to the gripping station for the next grab. At the same time, the pallet conveying system will appropriately lower a certain height according to the increase in the number of palletizing layers to ensure that the foods are always in the appropriate placement position and guarantee the stability of the entire pallet shape. with high - efficiency palletizing to improve production efficiency. Manufacturer: Shandong Bensen

7. Palletizing Completion and Output: When the foods on the pallet are palletized according to the preset requirements, Food high - level palletizerthe pallet conveying system transports the full pallet to the discharge port. Subsequently, a forklift or an automated guided vehicle (AGV) will transport the palletized pallets to the warehouse storage area or the subsequent logistics transportation link. At the same time, the empty - pallet conveying system will supply new empty pallets to the palletizing station to prepare for the next round of palletizing operations.

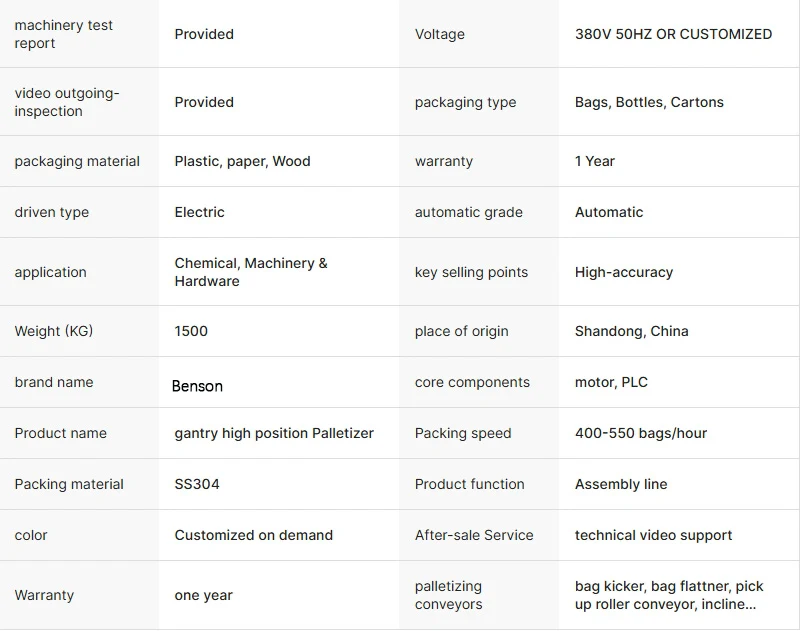

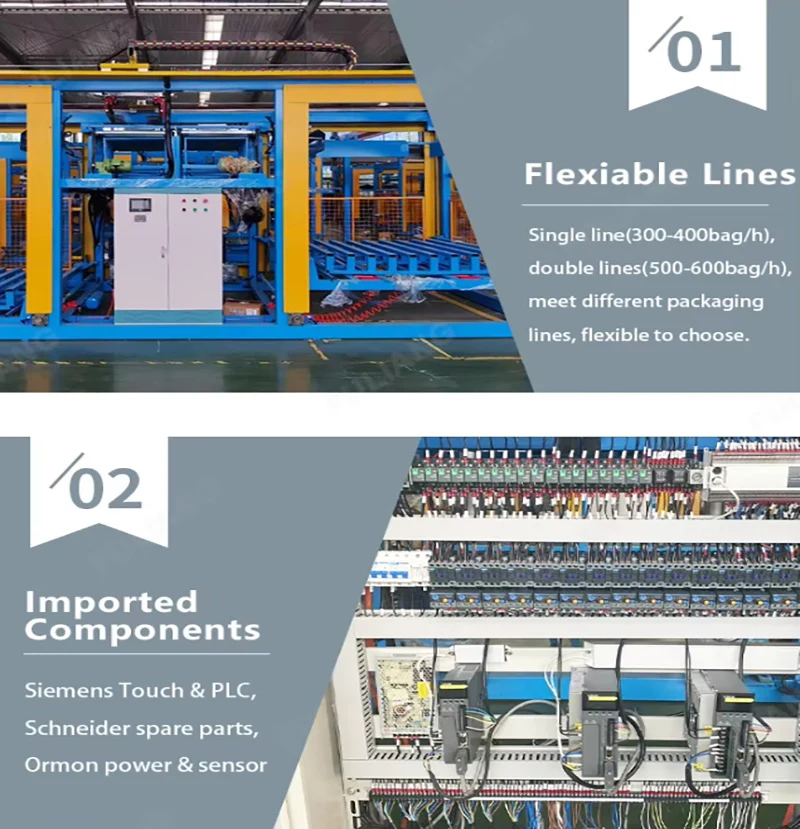

Specification

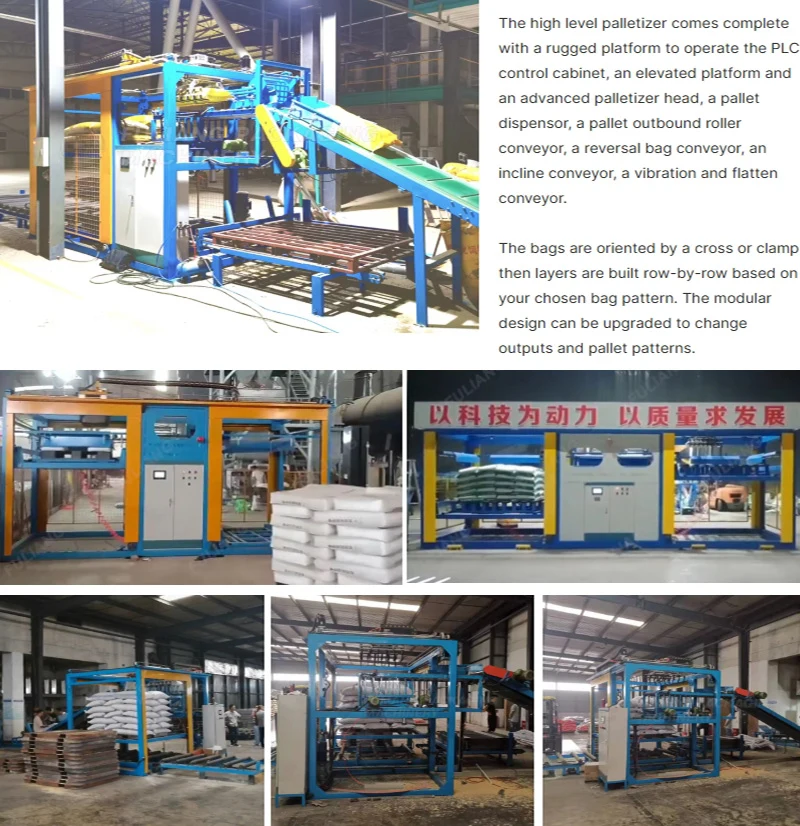

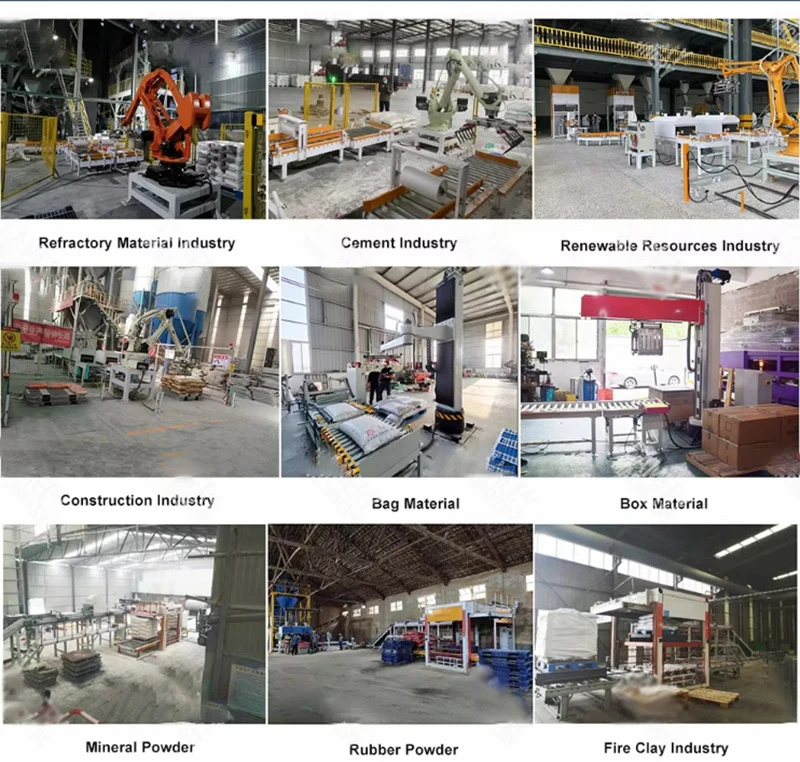

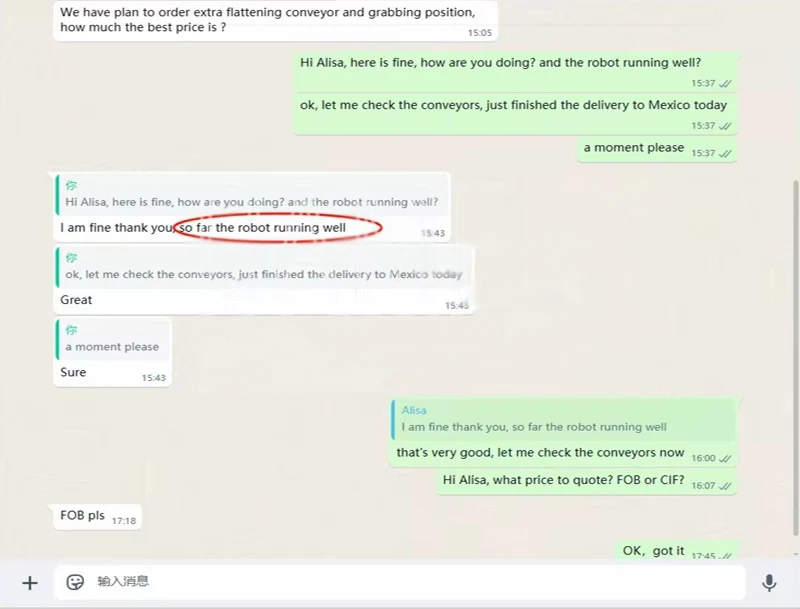

Customer Sites

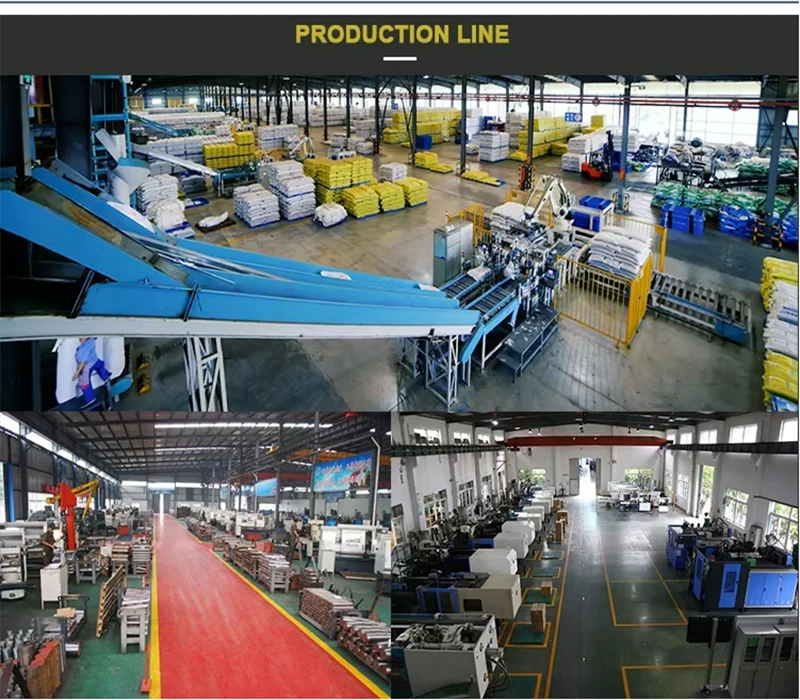

Company Profile

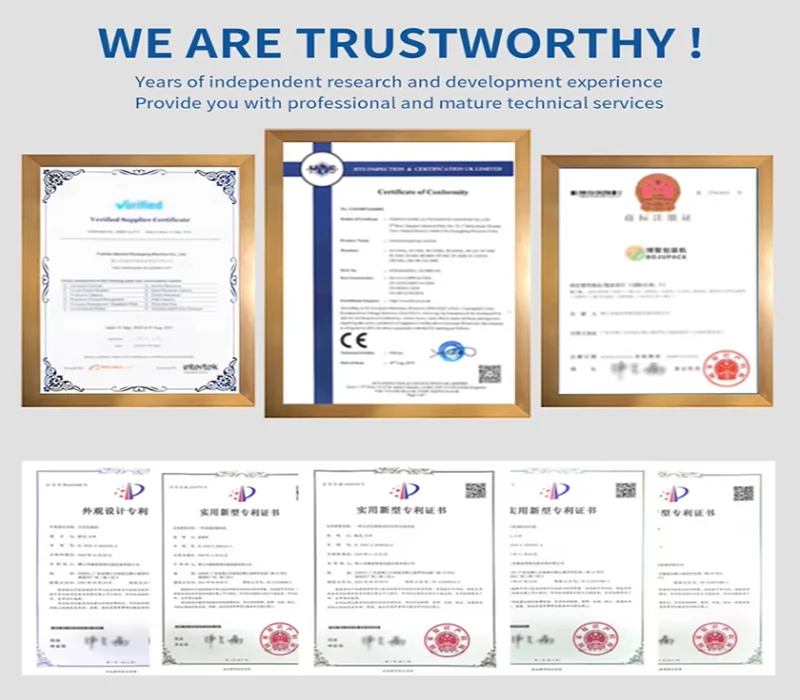

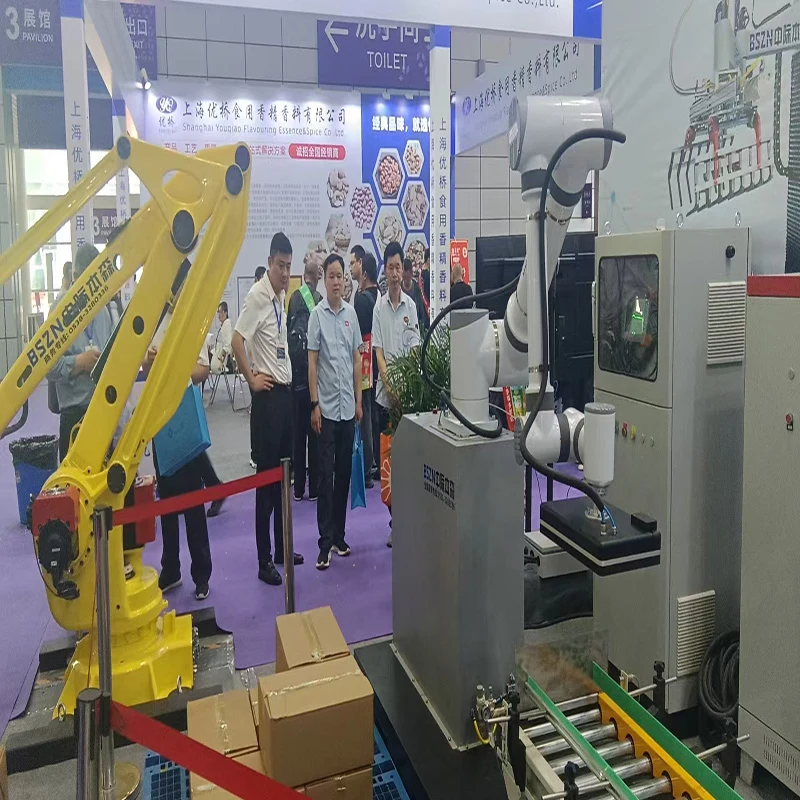

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales. Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client. Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service

Exhibition

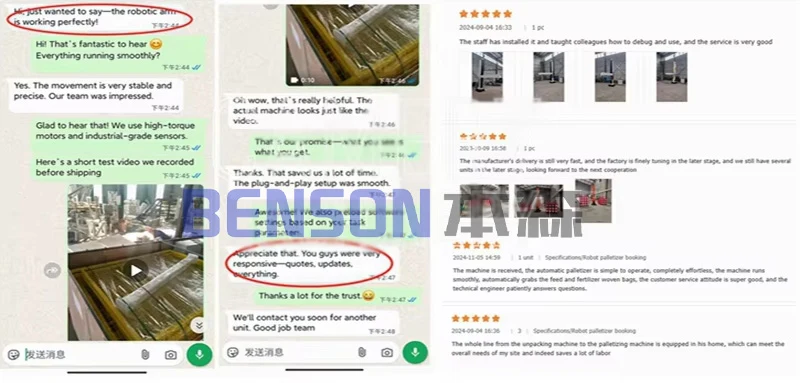

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

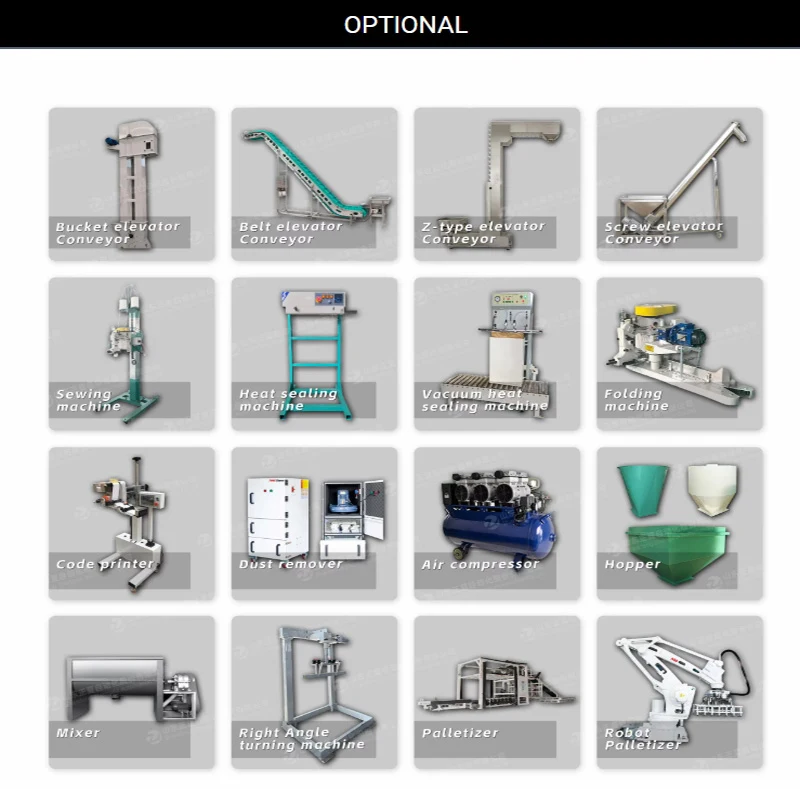

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry