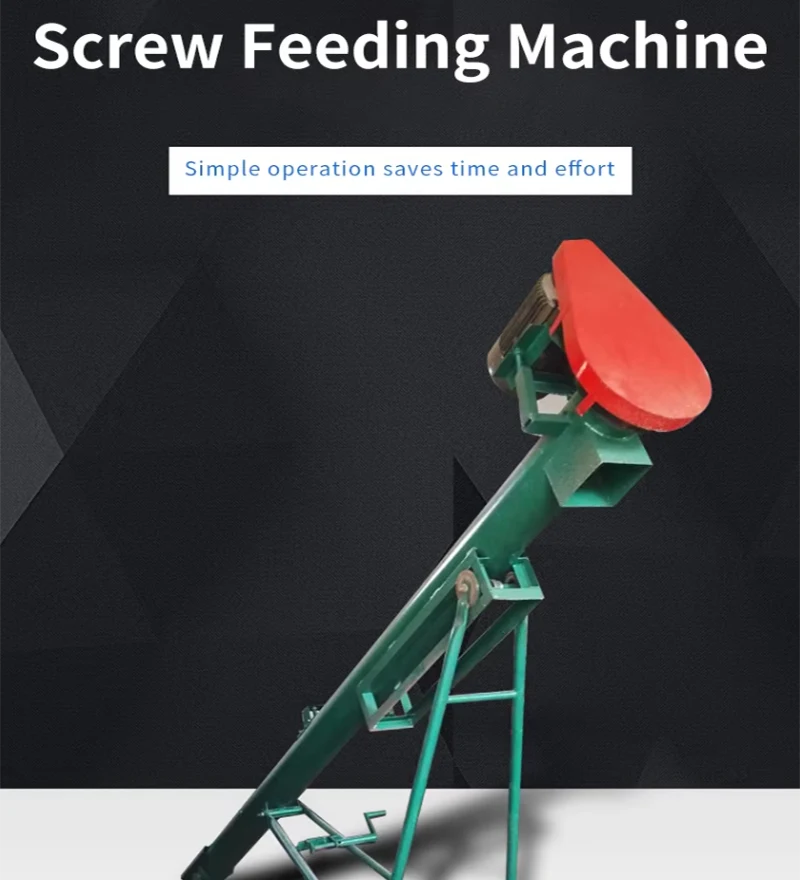

Screw feeder, also known as spiral feeder, is a continuous device that pushes materials along pipes or troughs through the rotation of spiral blades. It uses the volumetric conveying principle to achieve quantitative feeding and precise conveying of powdered, granular, and small block materials. It is widely used in chemical, food, building materials, environmental protection and other industries, especially for material conveying and batching in closed environments.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

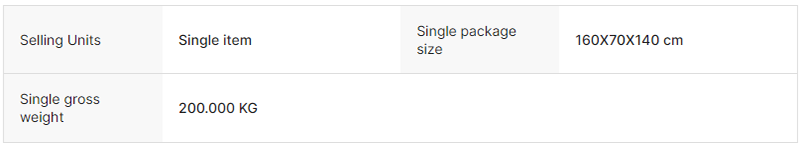

Packaging and delivery

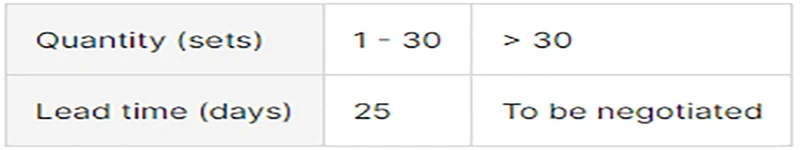

Lead time

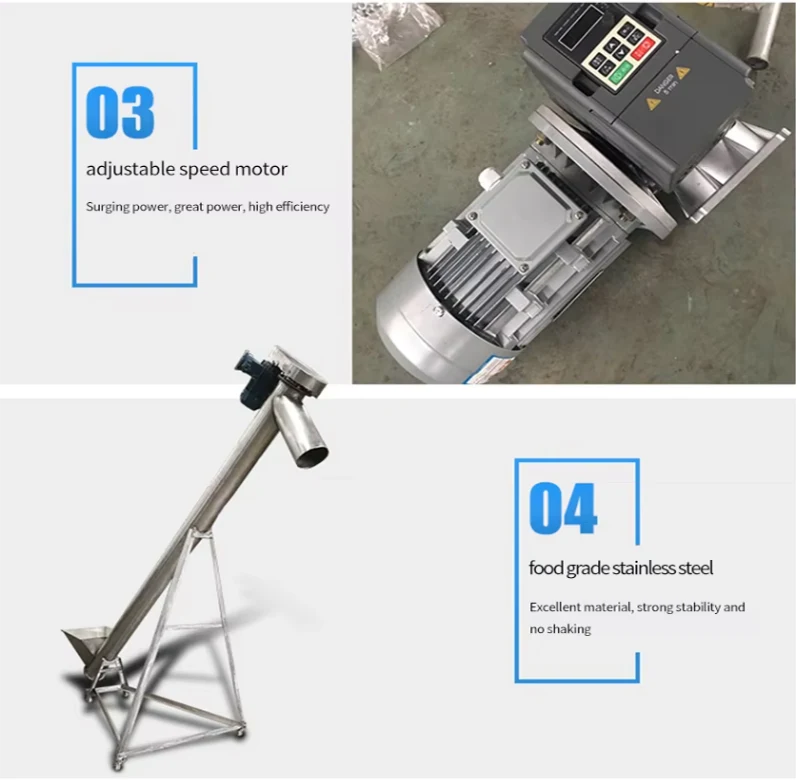

Screw feeder conveyor - precise conveying, efficient production

1.Core structure and configuration of screw feeder conveyor

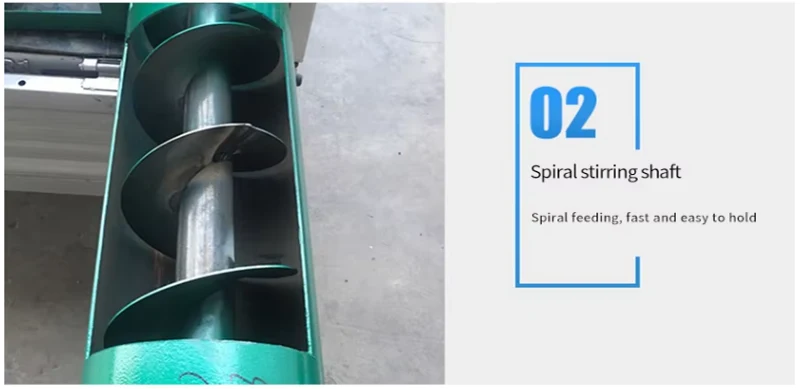

- Screw shaft: Made of high-quality carbon steel or stainless steel, single-head, double-head or variable pitch spiral blades can be selected according to the characteristics of the material to ensure uniform material delivery; the shaft core is thickened to improve torsional strength and wear resistance.

- U-shaped trough/tubular shell: The U-shaped trough is suitable for open conveying, which is easy to observe and clean; the tubular shell has strong sealing, can prevent dust and pollution, and supports negative pressure or positive pressure conveying.

2. Screw feeder conveyor drive device: Equipped with high-efficiency energy-saving motor and cycloid pinwheel reducer, it has strong power; it supports variable frequency speed regulation to achieve flexible flow control of 0.1-10m³/h.

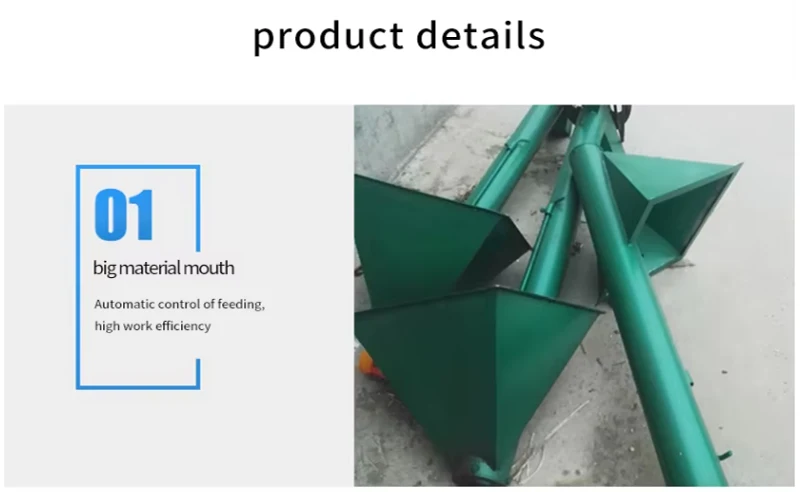

3. Inlet and outlet design: The inlet can be customized with flange connection, gravity drop or pneumatic sealing structure; the outlet supports multi-directional diversion design to adapt to different process requirements.

4. Safety protection components: equipped with overload protection device, anti-blocking sensor, sealed bearing and dust cover to ensure safe operation of the equipment and reduce maintenance frequency.

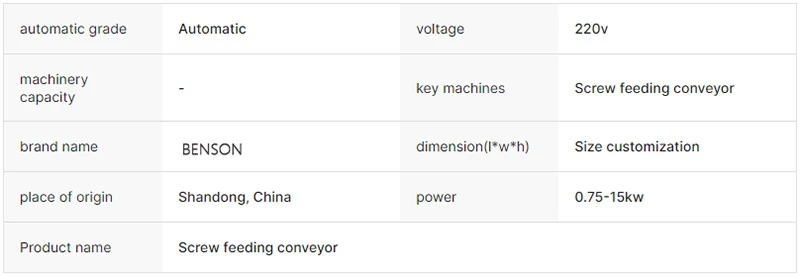

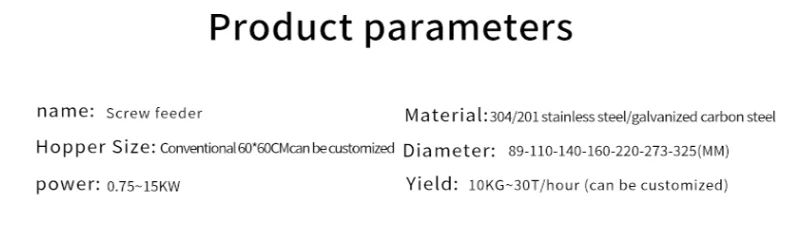

Performance parameters of screw feeder conveyor

Item Parameter range

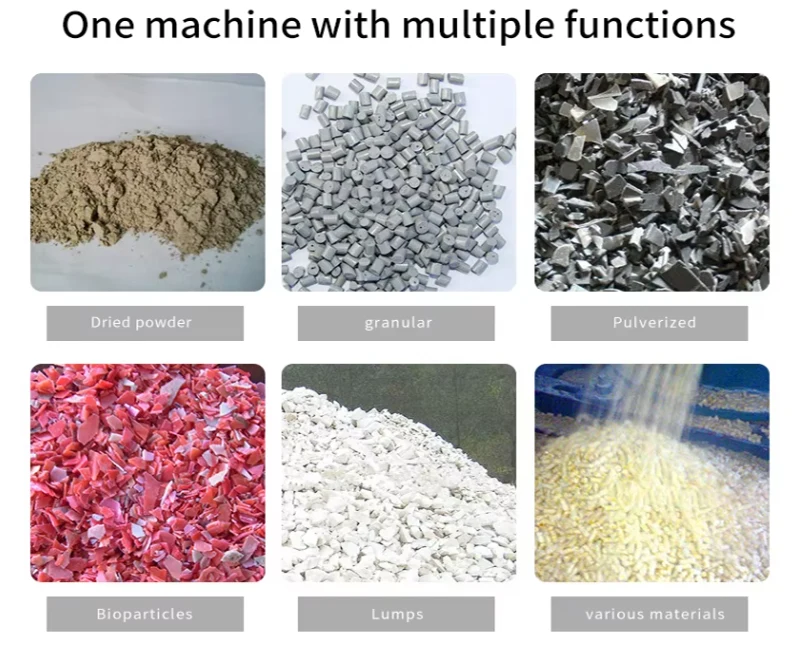

Conveying material type Powder (such as cement, flour), granular (such as feed, plastic particles), small block (such as coal, gravel)

Conveying capacity 0.5-50m³/h (depending on the model and material characteristics)

Conveying length Conventional ≤15 meters (customizable extension)

Conveying angle Horizontal or ≤20° tilt (customizable for special working conditions)

Working voltage 380V/50Hz (support overseas voltage customization)

Ambient temperature -20℃-80℃ (high temperature resistant type can reach 300℃)

Product advantages of screw feeder conveyor

1. Precise quantitative: Through variable frequency speed regulation and stable push of spiral blades, uniform and continuous feeding of materials is achieved, with an error rate of ≤±2%, meeting the needs of high-precision batching.

2. Strong sealing: The fully enclosed pipeline design effectively prevents dust spillage and material contamination, and is suitable for the transportation of toxic, flammable or high-purity materials (such as medicines and chemical raw materials).

3. Flexible adaptation: The blade pitch, trough material (stainless steel/wear-resistant alloy) and discharge port layout can be customized according to the characteristics of the material, and it is compatible with special materials such as corrosive and sticky materials.

4. Screw feeder conveyor is low-consumption and durable: The no-return idling design reduces energy consumption, the wear-resistant material and self-cleaning structure extend the service life, and the maintenance cost is reduced by 40%.

5. Space-friendly: The structure is compact and occupies a small area. It can be flexibly embedded in the production line to achieve a combination of horizontal, inclined or vertical transportation.

6. Strongly adaptable transportation: For sticky and corrosive materials, wear-resistant alloy blades and corrosion-resistant troughs can be customized; for materials with poor fluidity, a stirring function can be added to ensure smooth transportation.

Application scenarios of screw feeder conveyors

- Chemical industry: conveying powdered fertilizers, plastic particles, catalysts and other materials to meet the needs of continuous production.

- Food and medicine: high-precision conveying of flour, powdered sugar, and pharmaceutical particles in compliance with GMP hygiene standards.

- Building materials industry: closed conveying of powdered materials such as cement and gypsum powder to reduce dust pollution.

- Environmental protection field: quantitative conveying and treatment of sludge and waste residue in waste incineration plants and sewage treatment plants.

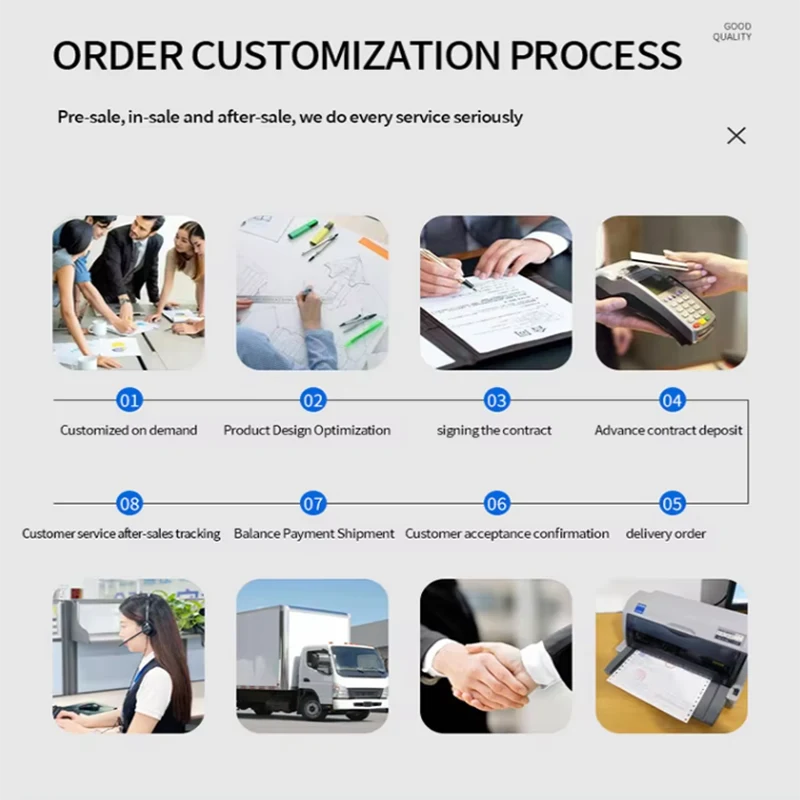

One-stop service guarantee

- Customized solution: provide one-stop service from selection and design to installation and commissioning to ensure perfect matching of equipment and working conditions.

- Quick response: 7×24 hours after-sales support, original accessories delivered within 48 hours, reducing downtime losses.

- Regular maintenance: professional team provides annual inspection and system optimization services to ensure long-term stable operation of equipment.

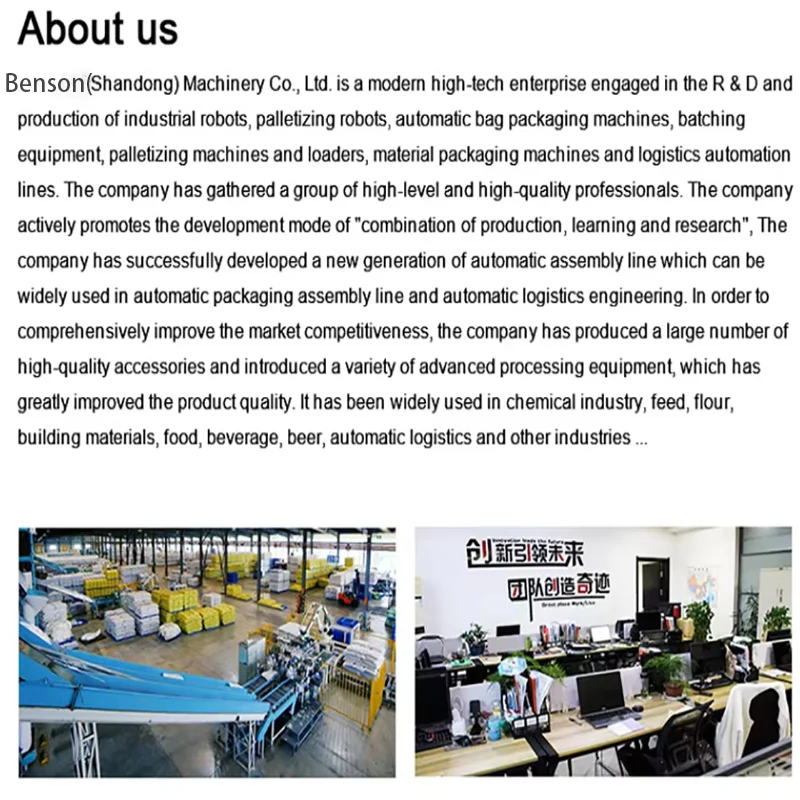

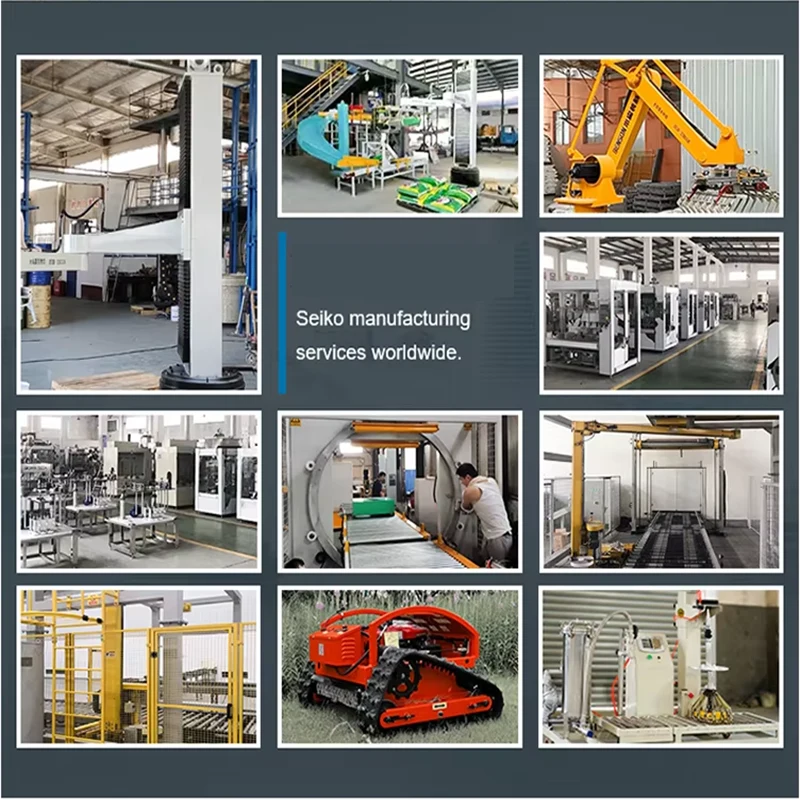

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, automated assembly lines, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry