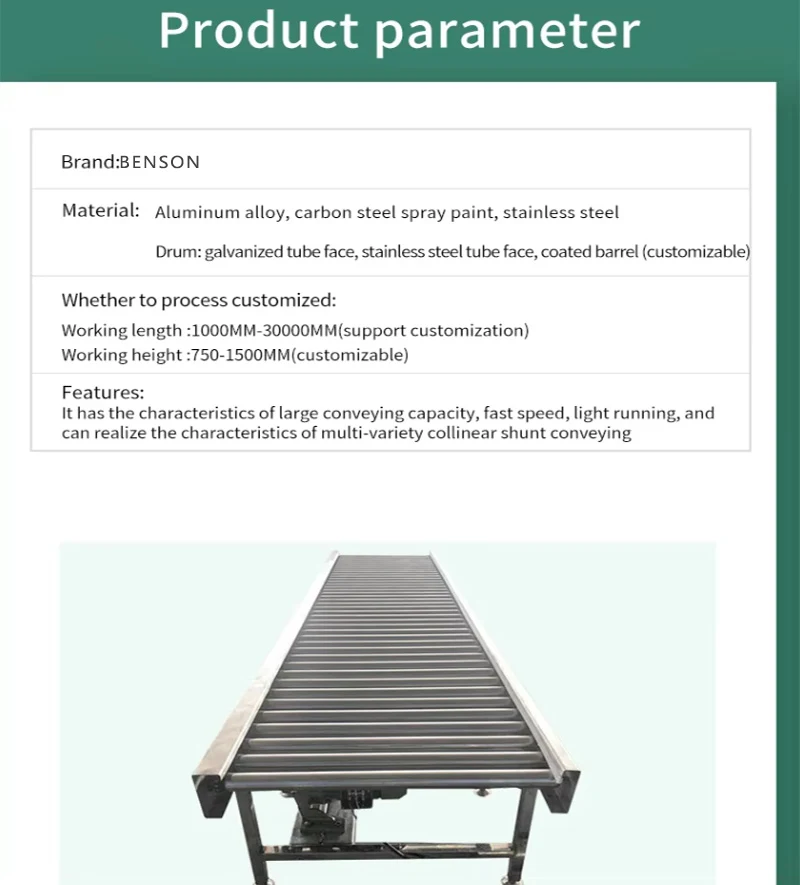

The friction between the rotating roller and the object moves the object forward. The powered roller conveyor is composed of a motor and a reducer, and the roller is driven to rotate by chain drive, belt drive, etc.; the unpowered roller conveyor uses external forces such as gravity and manual push to rotate the roller to drive the goods to move.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

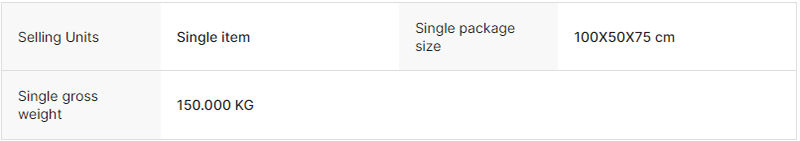

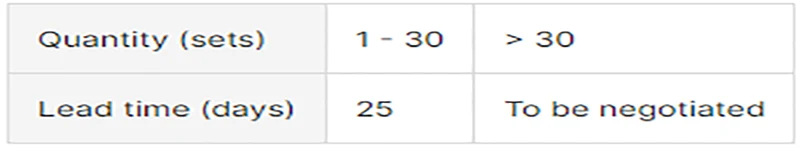

Packaging and delivery

Lead time

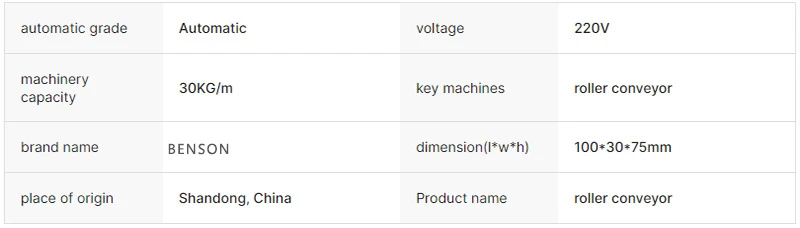

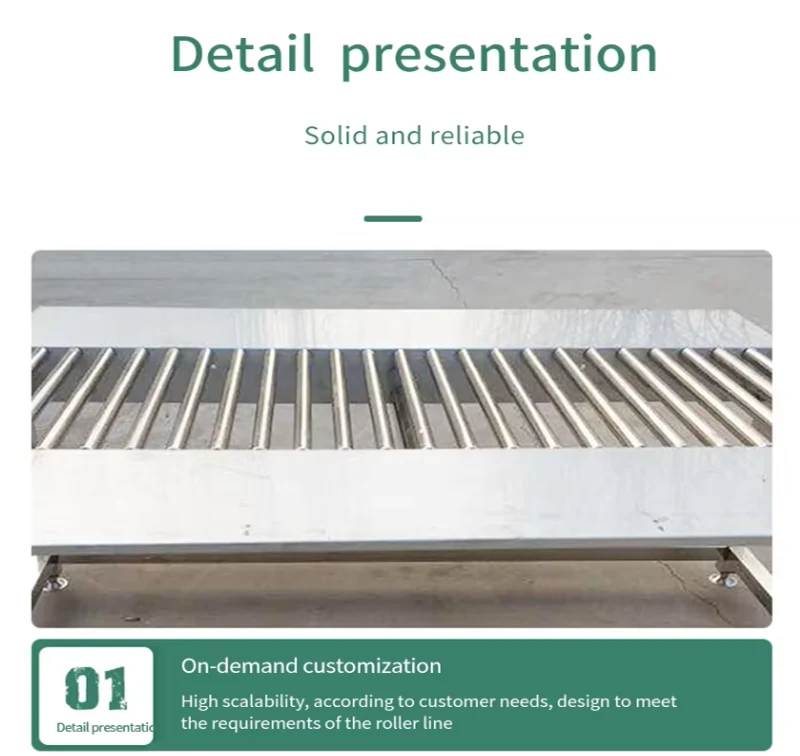

Structural composition of Benson roller conveyors

- Frame: used to support rollers and other components, usually made of carbon steel spraying, stainless steel or aluminum profiles, with sufficient strength and stability.

- Bracket: plays the role of auxiliary support to ensure the stability of the overall structure of theBenson roller conveyor.

- Drive unit: including reduction motor, electric roller, etc., to provide power for the rotation of the roller, and transmit power to the roller through single sprocket, double sprocket, O-belt and other transmission methods.

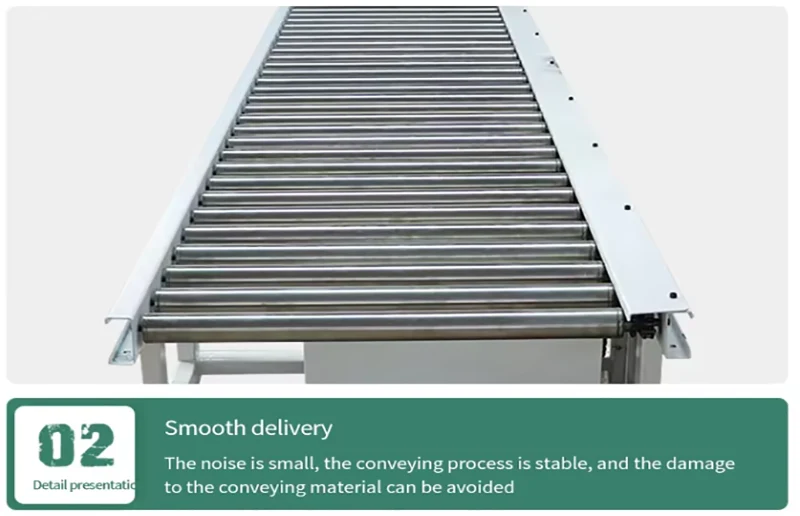

Dimensions of Bensonroller conveyors

- Inner width: standard specifications are 200mm, 300mm, 400mm, 500mm, 1200mm, etc., and special specifications can also be customized according to customer needs.

- Inner radius of turning: standard inner radius of turning is 300mm, 600mm, 900mm, 1200mm, etc., and special specifications can be customized.

- Roller diameter: common diameters of straight rollers are 38mm, 50mm, 60mm, 76mm, 89mm, etc.

Technical parameters of Bensonroller conveyor

- Transmission speed: Generally up to 180m/min, the specific speed can be adjusted according to actual needs through frequency conversion or stepless speed change.

- Maximum load: Multi-V belt pj unit maximum 300kg, multi-V belt pk unit maximum 2000kg, chain according to chain strength, synchronous belt according to synchronous belt core material, O belt unit maximum 30kg.

Classification of Benson roller conveyor

- By driving mode: poweredBenson roller conveyor, which can be driven independently, used in scenes such as automated production lines; unpowered roller conveyor, passive response, suitable for temporary storage, etc.; accumulation type Bensonroller conveyor, with built-in speed regulation and temporary storage functions, used for temporary storage of heavy-loaded materials, etc.

- By layout form: there are horizontal conveyor roller lines, inclined conveyor roller lines, turning roller lines, as well as special layout forms such as straight line, bifurcated, multi-layer, spiral, telescopic, etc., to meet different site and process requirements.

Characteristics ofBenson roller conveyors

- Strong conveying capacity: It can convey single-piece materials with large weight or withstand large impact loads, with large conveying volume and fast speed, and can realize multi-variety co-linear diversion conveying.

- Good connection: BensonRoller conveyors are easy to connect and transition, and multiple roller lines and other conveying equipment or special machines can be used to form a complex logistics conveying system.

- Simple structure: High reliability, easy to use and maintain, only regular cleaning, lubrication and other maintenance are required on a daily basis.

- Strong adaptability: It is suitable for the conveying of various boxes, bags, pallets and other pieces of goods. Bulk materials, small items or irregular items can be placed in pallets or turnover boxes for conveying. Different roller materials and surface treatment methods can be selected according to different conveying environments.

Key points for selectingBenson roller conveyors

- Characteristics of conveyed items: Select appropriate roller length, diameter, spacing, roller material and surface treatment method according to the shape, size, weight, bottom condition, etc. of the items.

- Conveying volume and speed requirements: Select appropriate drive mode, transmission mode and speed regulation mode according to the conveying volume and conveying speed required by the production process.

- Working environment: Consider the temperature, humidity, corrosiveness and other factors of the working environment, and select the appropriate frame material, roller material and surface treatment method.

Application field

Widely used in airports, e-commerce, express delivery, logistics warehouses, food and beverage, 3C, electronics, building materials, chemicals, mining, electricity, grain and other industries, for the transportation, sorting, caching and other links of goods.

Products Description

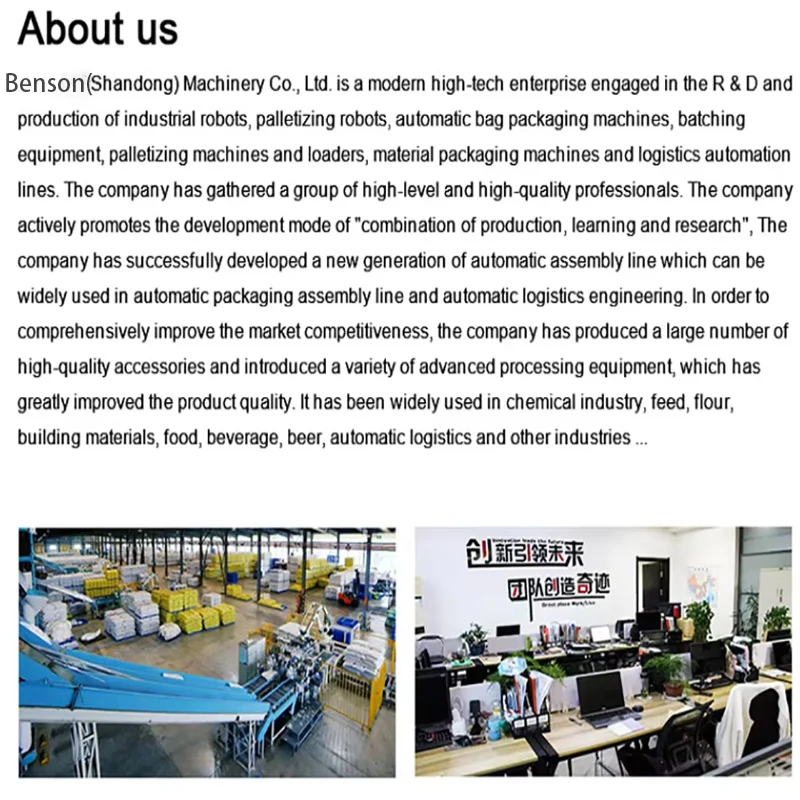

Company Profile

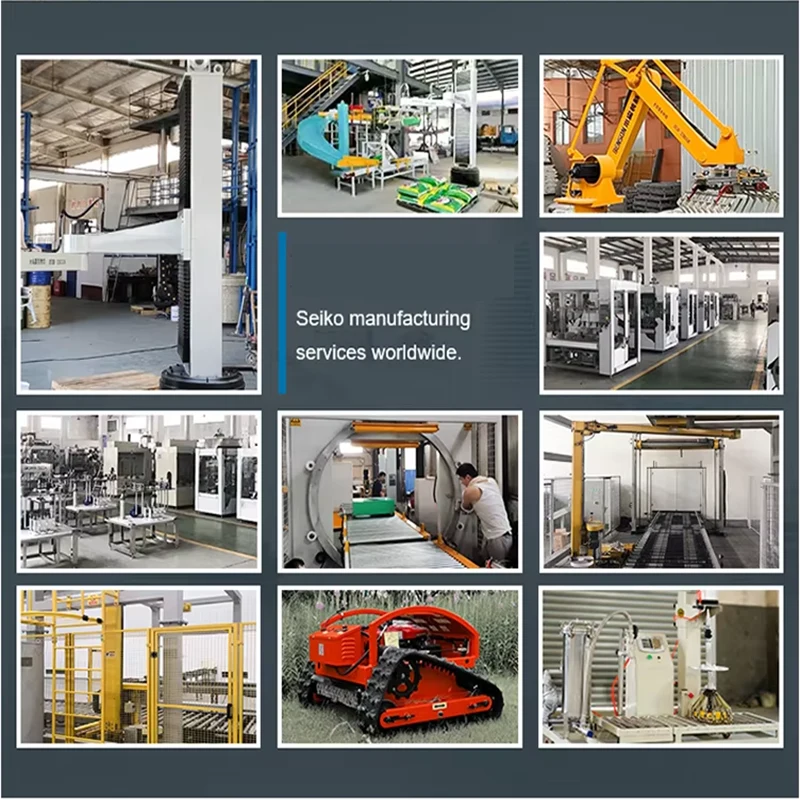

Benson (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Benson (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry