Spiral gantry conveyor: efficient material conveying solution

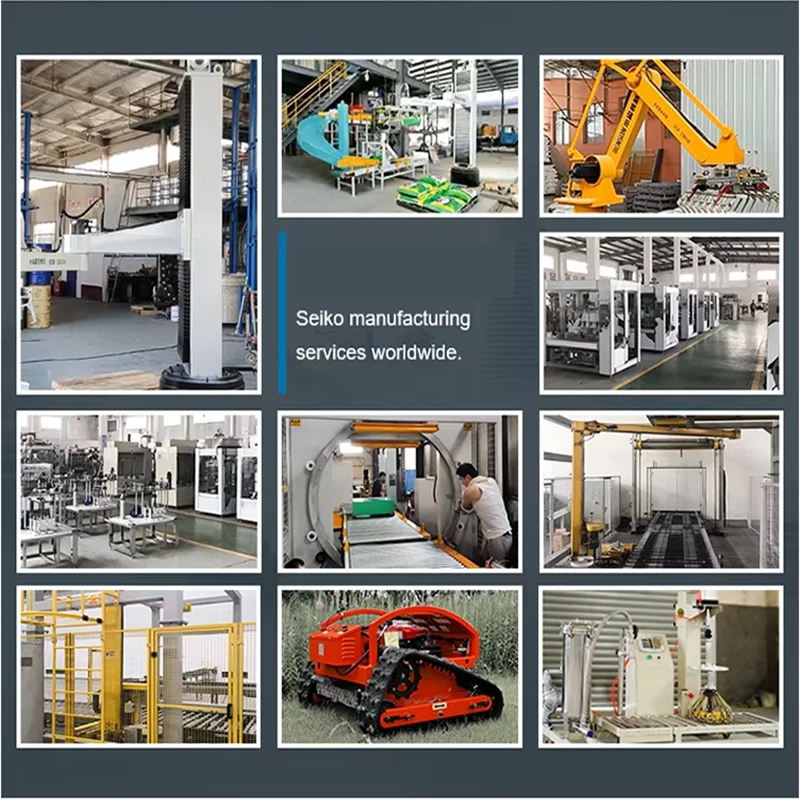

Spiral gantry conveyor is a professional conveying equipment that combines the advantages of spiral conveying and gantry structure. It is widely used in many fields such as industrial production, logistics warehousing, etc., providing reliable guarantee for the efficient transmission of various materials.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

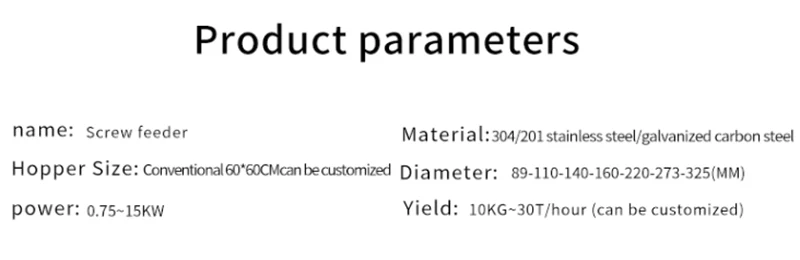

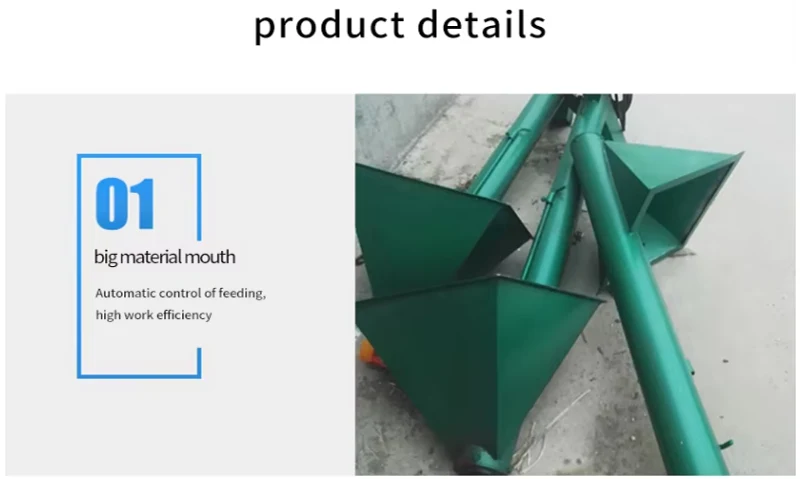

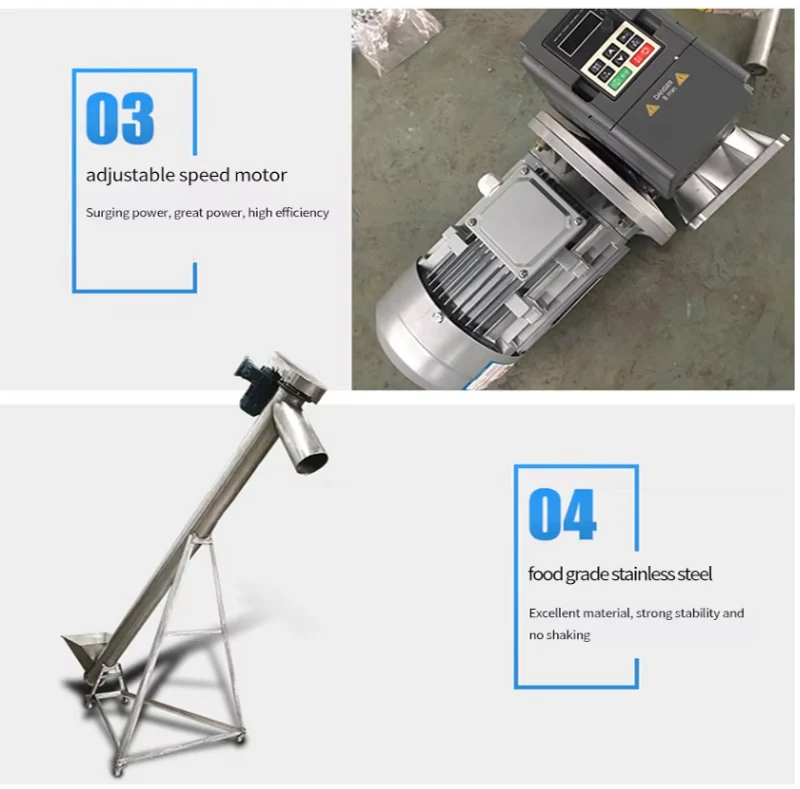

Structural composition of spiral gantry conveyor

- Spiral conveying part: It is composed of spiral blades, spiral shafts, bearings, etc. According to the characteristics of the conveyed materials and process requirements, the spiral blades have different forms such as solid type, belt type, and blade type; the spiral shaft provides support and power transmission; the bearing ensures the stable rotation of the spiral shaft.

- Gantry structure: It includes a sturdy frame, columns and beams. The gantry frame provides stable support for the equipment and can be designed into different heights and spans according to actual needs to adapt to diverse sites and operating requirements.

- Driving device: It is generally composed of electric motors, reducers, etc., which provide power for the rotation of spiral blades. The power can be reasonably selected according to factors such as conveying volume and conveying distance.

- Feeding and discharging device: The feed port is responsible for introducing materials into the screw conveyor, and the discharge port sends the materials out. Some equipment can also be equipped with a feed adjustment device to control the feed flow rate.

Product advantages of spiral gantry conveyor

Efficient space utilization

The gantry structure enables the equipment to cross obstacles or transport materials at a higher spatial position, making full use of vertical and horizontal space, especially suitable for working environments with narrow sites or space restrictions.

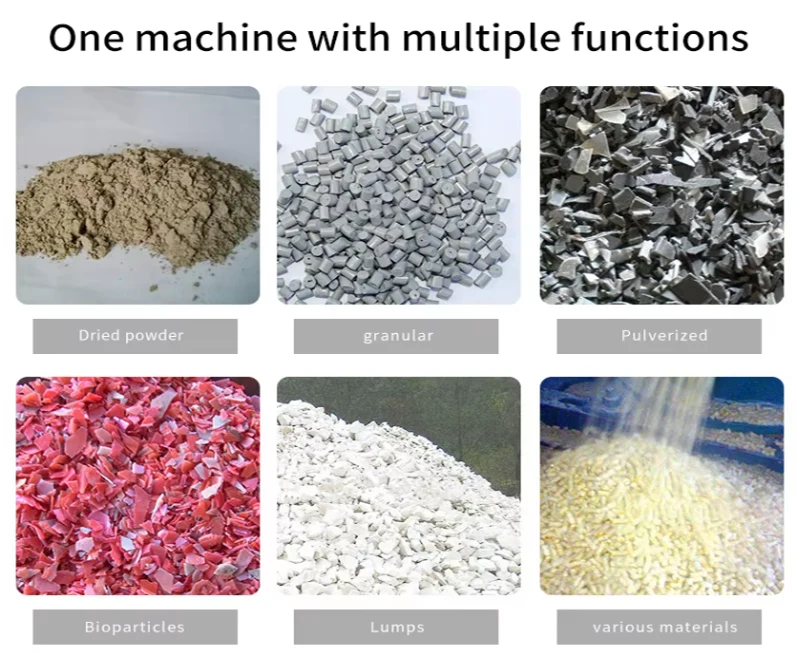

Spiral gantry conveyor has strong conveying capacity

It can continuously and stably transport various forms of materials such as powder, granules, and small blocks. By adjusting the speed, pitch, and diameter of the spiral blades, it can flexibly match different conveying volume requirements, and the hourly conveying volume can reach several tons to tens of tons.

Flexible conveying distance

According to actual production needs, it can be designed as a shorter distance of local conveying, or a longer distance of continuous conveying, to meet the material transmission requirements of production operations of different scales.

Spiral gantry conveyor has good sealing performance

The fully enclosed conveying structure effectively prevents material leakage and dust flying, which not only improves the working environment, but also prevents materials from being damp and contaminated. It is particularly suitable for industries with high requirements for sanitary conditions and material quality.

Stable and reliable operation

The structural design is reasonable, and the key components are made of high-quality materials. After strict processing technology and quality inspection, it has good wear resistance and fatigue resistance, stable operation, low failure rate and long service life.

Easy maintenance

The modular design makes the installation, disassembly and maintenance of the equipment more convenient. Daily maintenance mainly focuses on regular inspection of spiral blade wear, bearing lubrication status and drive device operation status, etc., and the maintenance cost is low.

Application field

Industrial production

- Chemical industry: used for conveying various chemical raw materials, additives, finished particles, such as fertilizers, plastic particles, chemical powders, etc.

- Food industry: suitable for conveying food raw materials, semi-finished products and finished products, such as grains, candies, nuts, etc., in line with food hygiene and safety standards.

- Building materials industry: can convey powdered and granular building materials such as cement, sand, gravel, lime, etc., and are widely used in mixing stations, cement plants and other places.

- Metallurgical mines: used to convey ores, mineral powders, coke and other materials to meet the material transportation needs in mining, mineral processing and metallurgical production.

Logistics warehousing

In logistics centers, warehouses and other places, it is used for sorting, handling and stacking of goods, realizing efficient transportation of goods between different workstations and floors, and improving logistics turnover efficiency.

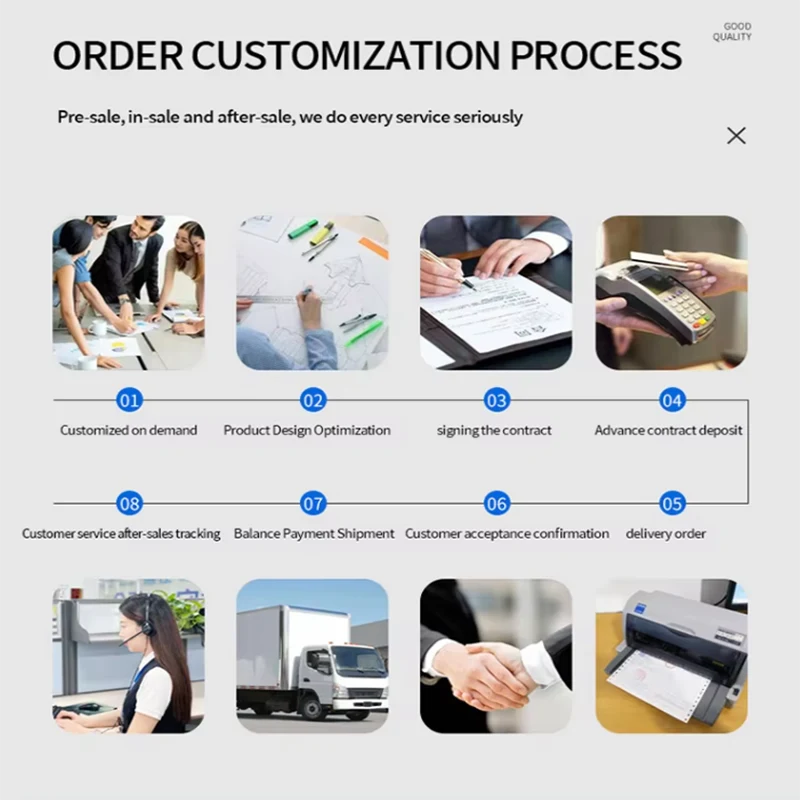

Our spiral gantry conveyor can provide customized design and manufacturing services according to the specific needs of customers. From program planning, equipment production to installation and commissioning, and after-sales maintenance, we provide you with a one-stop solution to help enterprises improve production and logistics efficiency.

Products Description

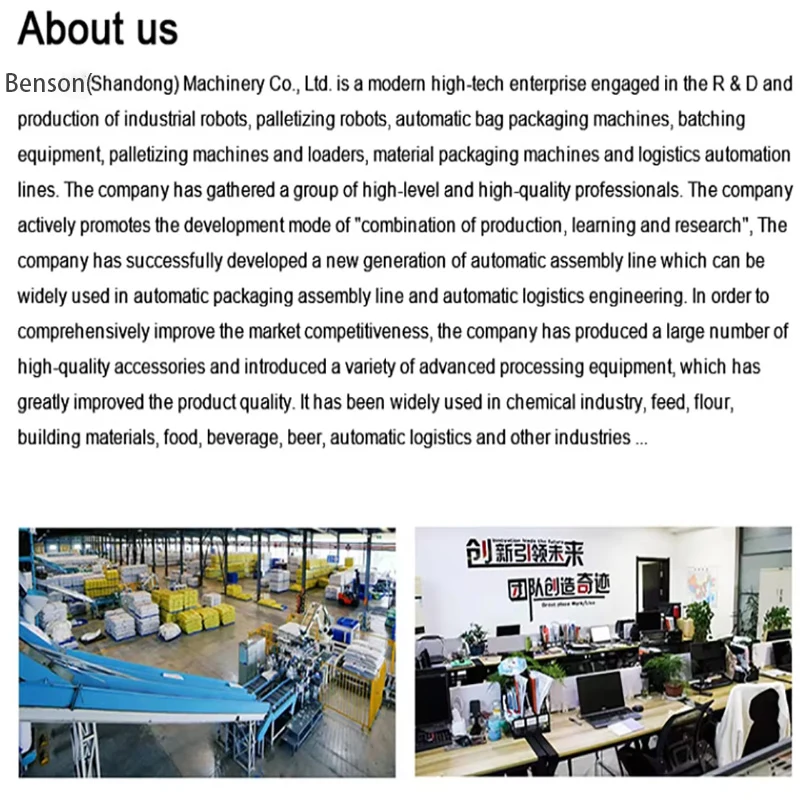

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry