The automatic column-type palletizer, as an important equipment in the field of industrial automation, takes the column as the core supporting structure, and is equipped with a flexibly movable manipulator and an intelligent control system to achieve automated material palletizing operations. Its main structure is composed of a sturdy column, which provides a stable base for the movement of the manipulator. The manipulator flexibly extends and rotates in three-dimensional space through precise

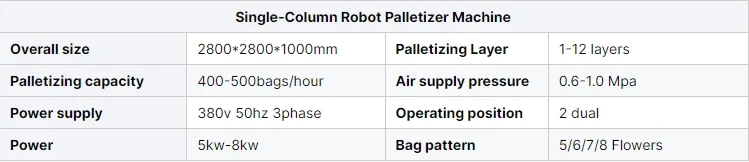

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

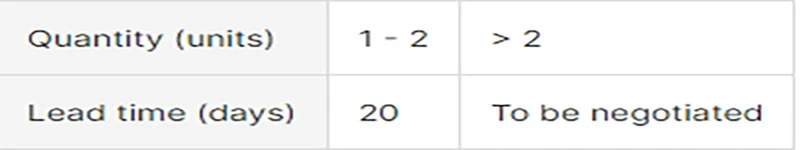

Products Description

The column palletizer is a compact, space-saving automated palletizing machine. Guided by a column rail system, the robotic arm moves efficiently along both horizontal and vertical axes, allowing for precise picking and orderly stacking of various materials such as cartons, woven bags, and packaging sacks. This equipment supports multiple stacking patterns and pre-set multi-layer programs, making it suitable for industries like chemicals, building materials, grain, and animal feed. With stable operation, high efficiency, and easy maintenance, it is an ideal choice for medium- to high-speed production lines.

6. Pallet Exchange: Once the pallet is full, it is conveyed out, and a new pallet is automatically positioned.

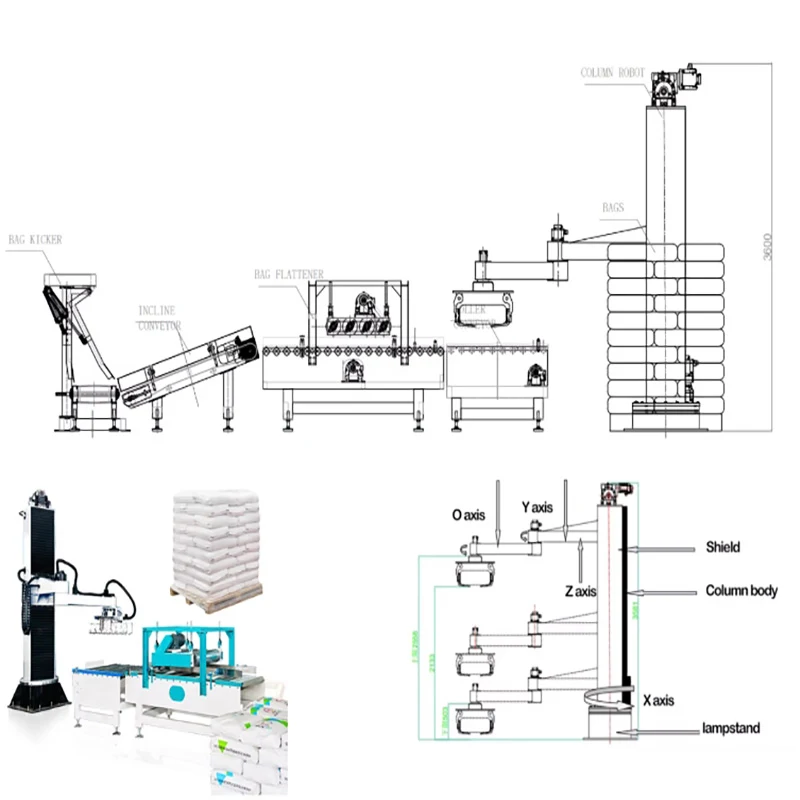

Specification

By boosting productivity and minimizing product damage and labor costs, palletizers provide long-term savings, making them a cost-effective solution—especially in high-volume packaging environments.

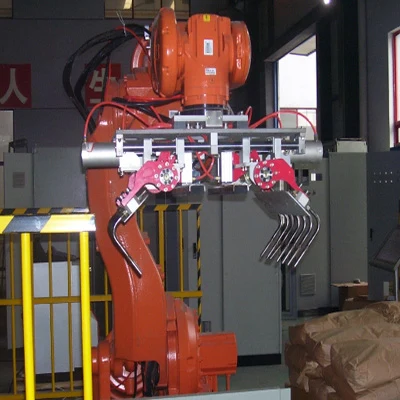

Gripper

The palletizer features an interchangeable gripper—clamp, suction, or fork—suitable for various materials and shapes. This ensuressecure, damage-free handling and precise placement, enhancing flexibility and efficiency across different product lines and packaging types.

The control cabinet contains all electrical and control components, including PLCs, motor drives, and safety relays. It ensures reliable, safe operation with easy access for maintenance and built-in protection against electrical faults.

The palletizer includes an intuitive teach pendant for easy programming and control. Operators can quickly set pallet patterns, adjust positions, and monitor status, enabling efficient operation and fast changeovers without technical complexity。

Handles material transfer and placement with precision; easily integrates into existing packaging systems for streamlined

operations.

6.Seamless Integration: Easily connects with upstream and downstream packaging equipment.

Company Profile

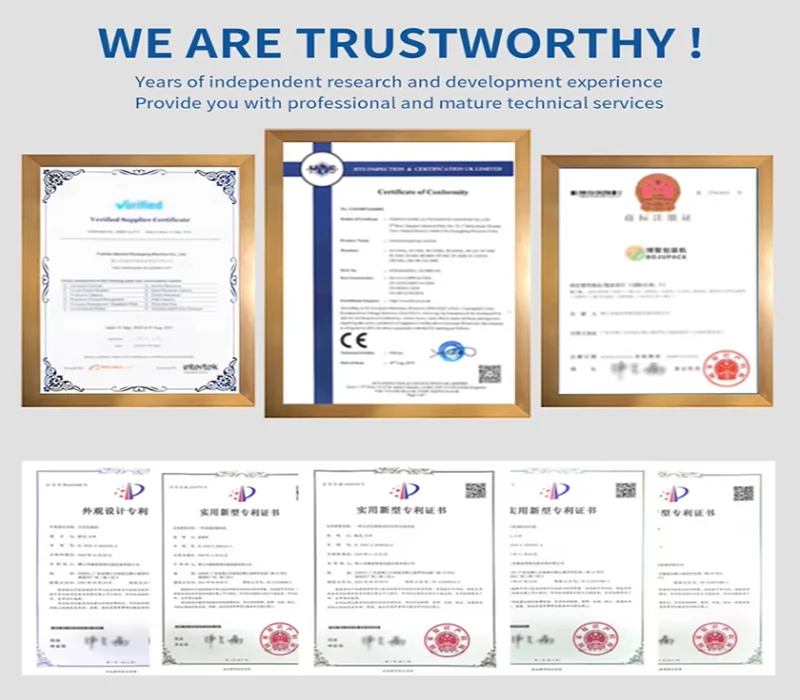

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales.

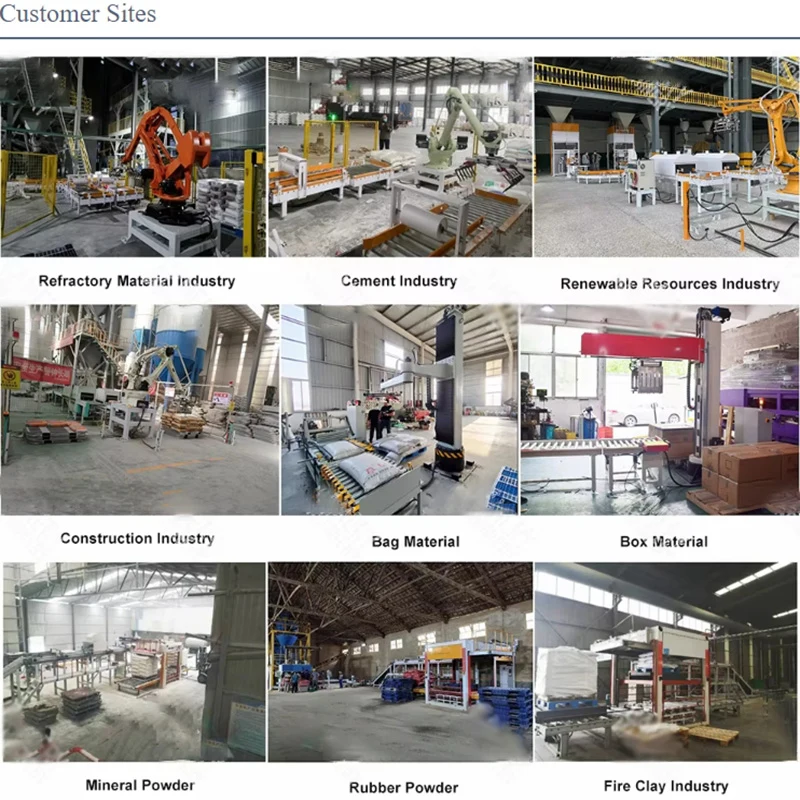

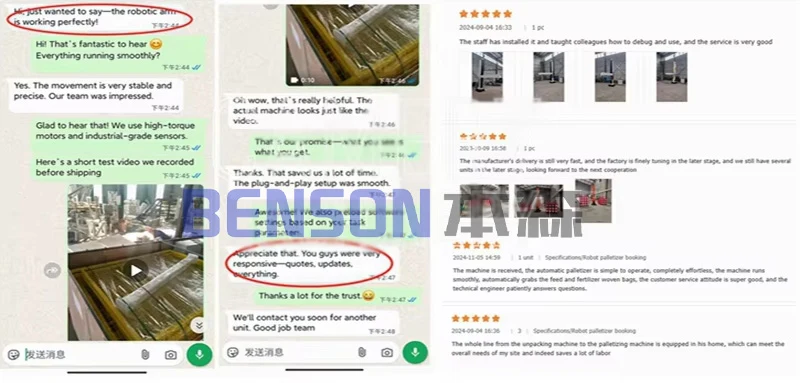

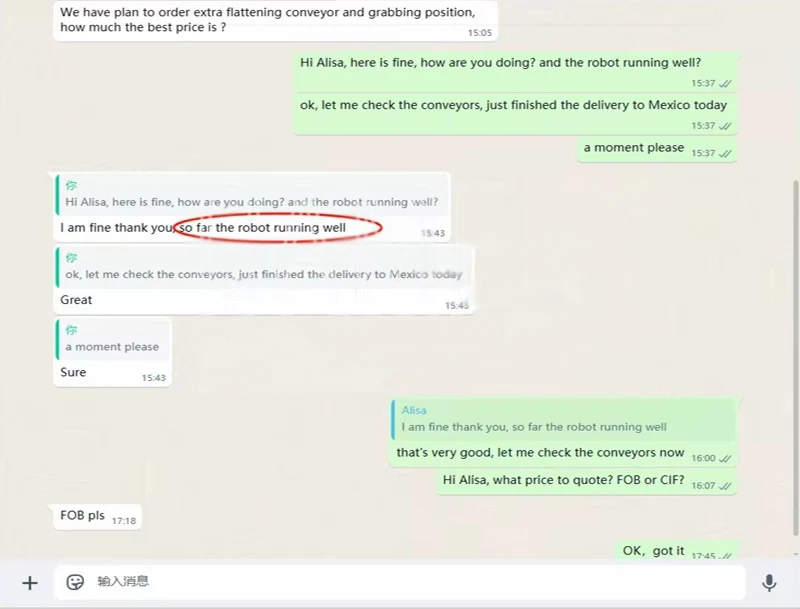

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Camery has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

Product Inquiry