The fully automatic carton palletizer is an automated device that combines high efficiency and intelligence. Relying on advanced robotic palletizing technology and intelligent control systems, it is equipped with high-precision sensors and a vision recognition system, enabling it to accurately locate the position and size of cartons. During actual operation, cartons are automatically fed through a conveyor belt. The robotic arm, in conjunction with a specially designed gripper, quickly grabs

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

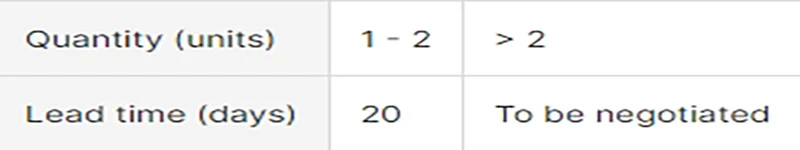

Lead time

Products Description

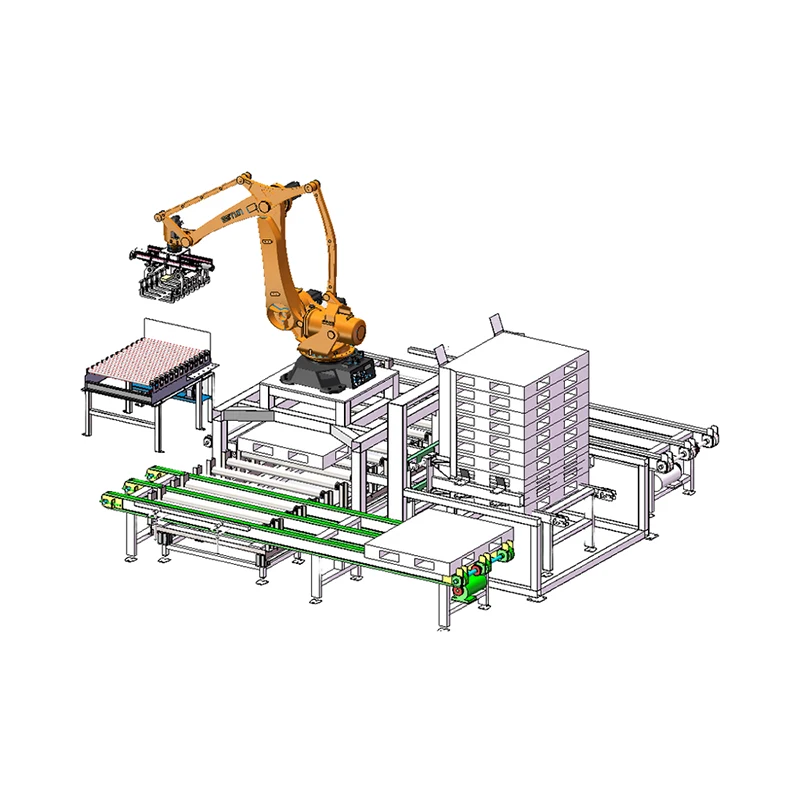

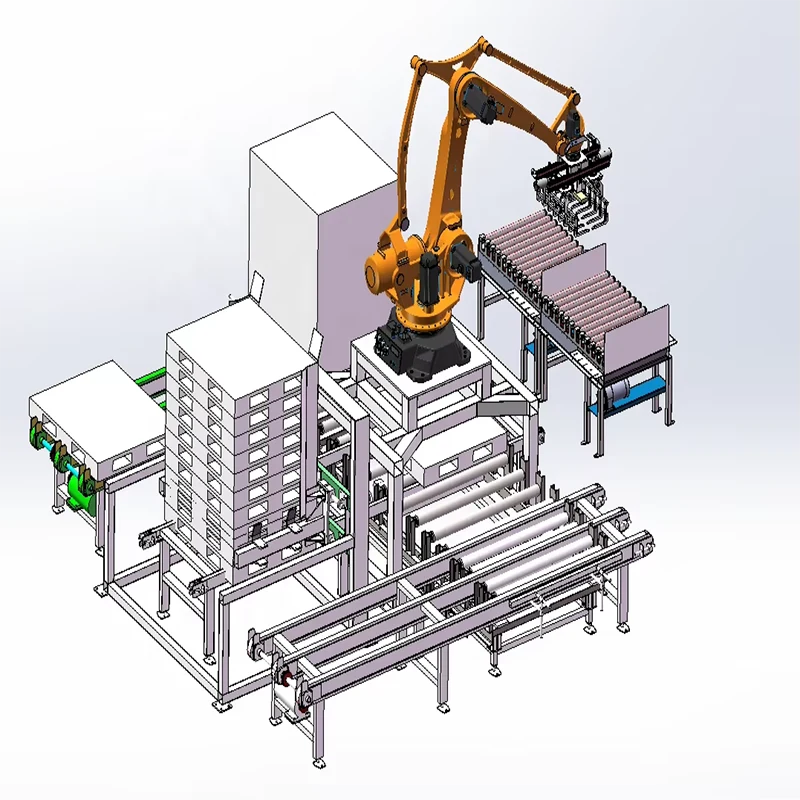

Fully automatic carton palletizer

The fully automatic carton palletizer is a modern logistics equipment integrating high efficiency, intelligence, and stability. Through the advanced PLC control system and visual recognition technology, it realizes the full - process automated operation of cartons from transportation, grasping to precise stacking. It is equipped with high - speed servo motors and precision transmission components, capable of handling 10 - 20 cases of goods per minute. With flexible suction cups or mechanical grippers, it can adapt to cartons of different weights from 5 - 50 kg and complete diversified stacking patterns such as cross - shaped and row - shaped with a high precision of ±5mm. The equipment supports flexible programming and can quickly switch different product palletizing schemes. At the same time, it has intelligent fault diagnosis and data monitoring functions, effectively reducing downtime. With its safety protection design and low - noise energy - saving features, this palletizer is widely used in industries such as food, medicine, and electronics, significantly improving production efficiency and reducing labor costs. It is an ideal choice for enterprises to achieve the upgrading of automated warehousing and logistics.

Working process of the fully automatic carton palletizer:

1.Carton Transportation: The cartons that have been packaged on the production line are transported to the area to be processed of the palletizer at a stable speed along the set route through conveying equipment such as belt conveyors and roller conveyors. During the transportation process, the speed of the conveying equipment is matched with the working rhythm of the palletizer to ensure the orderly supply of cartons.

2.Detection and Positioning: After the cartons reach the designated position, photoelectric sensors, laser sensors, or vision recognition systems start to work. The sensors detect information such as the size, position, attitude, and presence of the cartons. The vision recognition system accurately calculates the position and angle data of the cartons by taking images and using image processing algorithms, and then transmits this information to the control system of the palletizer in real - time to prepare for the subsequent grabbing.

3.Grabbing and Handling:fully automatic carton palletizer The control system controls the actions of the robotic arm or gripper according to the detected carton information. If a suction - cup - type gripper is used, a negative pressure is generated by a vacuum generator to make the suction cup adhere to the surface of the carton. Then, the robotic arm steadily grabs and lifts the carton according to the preset trajectory. If a mechanical jaw - type gripper is used, the opening and closing of the jaws are driven by an air cylinder or an electric push rod to precisely clamp both sides of the carton to complete the grabbing action. After grabbing, the robotic arm transports the carton to the designated position above the pallet.

4.Palletizing Formation:fully automatic carton palletizer The robotic arm accurately places the cartons on the pallet. According to the pre - set pallet pattern (such as the number of cartons arranged per layer, the number of layers, etc.), the cartons are stacked layer by layer. During the stacking process, after each layer of cartons is placed, the robotic arm will perform position calibration and height adjustment to ensure that the cartons are stacked neatly and the pallet pattern is stable. At the same time, some palletizers will gently press the cartons during the palletizing process to make the pallet pattern more compact.

5. Pallet Replacement: When the number of cartons stacked on a pallet reaches the set number of layers, the palletizer sends a signal. A forklift or an automatic guided vehicle (AGV) moves the full - stacked pallet away, and at the same time, transports an empty pallet to the palletizing position. The palletizer then continues the palletizing operation for the next pallet. In this way, the continuous and uninterrupted fully automatic palletizing work is realized through circulation.

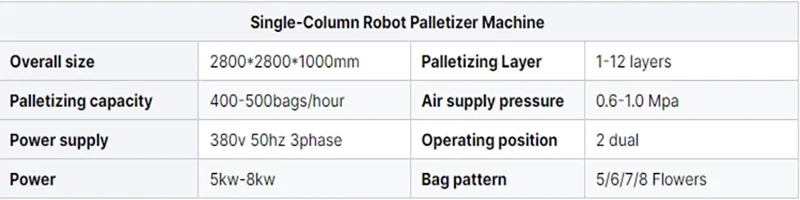

Specification

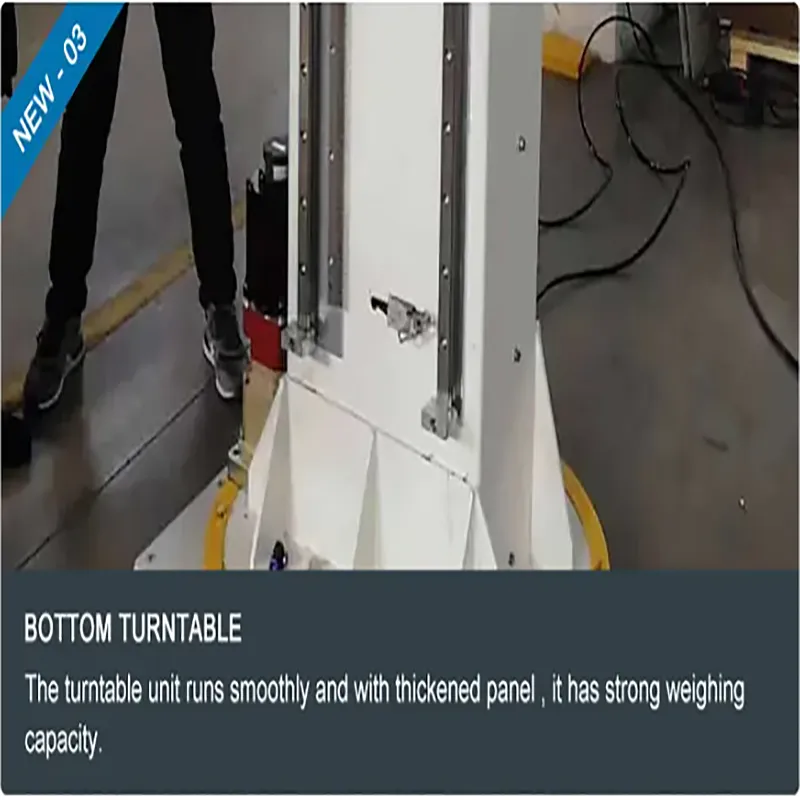

The main features of the fully automatic carton palletizer:

1.High degree of automation: fully automatic carton palletizer It can automatically complete the whole process of cartons from transportation, detection and positioning, grasping and handling to palletizing formation and pallet replacement without human intervention. This greatly reduces labor costs and improves production efficiency, making it suitable for large - scale production scenarios.

2.High palletizing accuracy: It adopts advanced sensors and vision recognition systems, which can accurately detect information such as the position, size and posture of cartons. Combined with high - precision robotic arms and control systems, it can accurately place cartons on pallets, achieving high - precision palletizing with neat and stable stack patterns.

3.Strong adaptability:fully automatic carton palletizer It can be programmed to adapt to the palletizing requirements of cartons with different sizes, shapes and weights. At the same time, according to different stack pattern requirements, it can flexibly adjust parameters such as palletizing methods and the number of layers, and can also be connected to various types of packaging production lines.

4.High work efficiency: It has a fast work rhythm and can complete a large number of carton palletizing operations in a short time. The running speeds of its conveying equipment and robotic arms can be adjusted according to production needs, and the connections between various links are tight, reducing waiting time.

5.Good stability: fully automatic carton palletizer The equipment is made of high - quality materials and advanced manufacturing processes. Key components are carefully designed and strictly tested, with high reliability and stability. It can operate continuously for a long time, reducing the probability of equipment failure and downtime, and ensuring the continuity of production.

6.High safety: It is equipped with a variety of safety protection devices, such as light curtain sensors, safety fences, emergency stop buttons, etc., which can effectively prevent human misoperation and accidents, and ensure the safety of operators and equipment.

7.Space - saving: The overall structure is compactly designed with a small footprint, and it can operate efficiently in a limited production space. At the same time, its layout is reasonable, facilitating the installation, debugging and maintenance of the equipment.

8.Data monitoring and management: Some full - automatic carton palletizers have data monitoring and management functions. They can real - time monitor information such as the operating status and production data of the equipment, record and analyze it, making it convenient for managers to promptly understand the production situation, carry out optimized scheduling and fault diagnosis.

The palletizer features an interchangeable gripper—clamp, suction, or fork—suitable for various materials and shapes.

This ensuressecure, damage-free handling and precise placement, enhancing flexibility and efficiency across different product lines and packaging types.

The control cabinet contains all electrical and control components, including PLCs, motor drives, and safety relays.

It ensures reliable, safe operation with easy access for maintenance and built-in protection against electrical faults.

The palletizer includes an intuitive teach pendant for easy programming and control. Operators can quickly set pallet patterns, adjust positions,

and moninor status, enabling efficient operation and fast changeovers without technical complexity.

Handles material transfer and placement with precision; easily integrates into existing packaging systems for streamlined

operations.

Advantages of the fully automatic carton palletizer:

1. High - efficiency automation: It can automatically complete the whole process of carton transportation, positioning and palletizing with

out human intevention. This greatly improves production efficiency, reduces labor costs, and is especially suitable for large - scale production.

2. Precise palletizing: With the help of advanced sensors and vision recognition systems, it can accurately detect the position, size and pos

ture of cartons. Combined with high - precision robotic arms and control systems, it can achieve accurate placement of cartons, resulting in neat and stable pallet patterns.

3. Flexible adaptability:fully automatic carton palletizer Through programming, it can adapt to the palletizing of cartons with different si

zes, shapes and weights. It can also flexibly adjust parameters such as palletizing methods and the number of layers according to different pallet pattern requirements, and can seamlessly connect with a variety of packaging production lines.

4. High work efficiency:It has a fast working rhythm and can complete a large number of carton palletizing operations in a short time. The running speedsof the conveying equipment and robotic arms can be adjusted as needed, and all links are closely connected to reduce waiting time.

5. Stable and reliable:fully automatic carton palletizer It uses high - quality materials and advanced manufacturing processes. Key components are carefully designed and strictly tested, ensuring high reliability and stability. It can operate continuously for a long time, reducing the probability of failure and ensuring production continuity.

6. Safety guarantee: It is equipped with a variety of safety protection devices such as light curtain sensors, safety fences and emergency

stop buttons, effectively preventing human misoperation and accidents, and ensuring the safety of operators and equipment.

7. Space - saving: The overall structure is compact, with a small footprint. It can operate efficiently in a limited production space, and has

areasonable layout, which is convenient for equipment installation, debugging and maintenance.

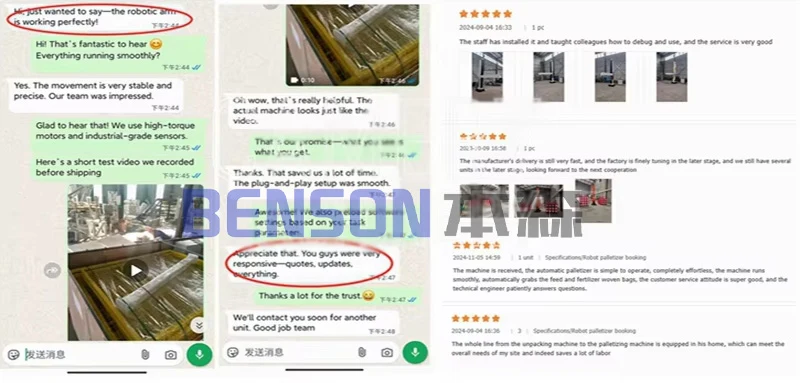

Company Profile

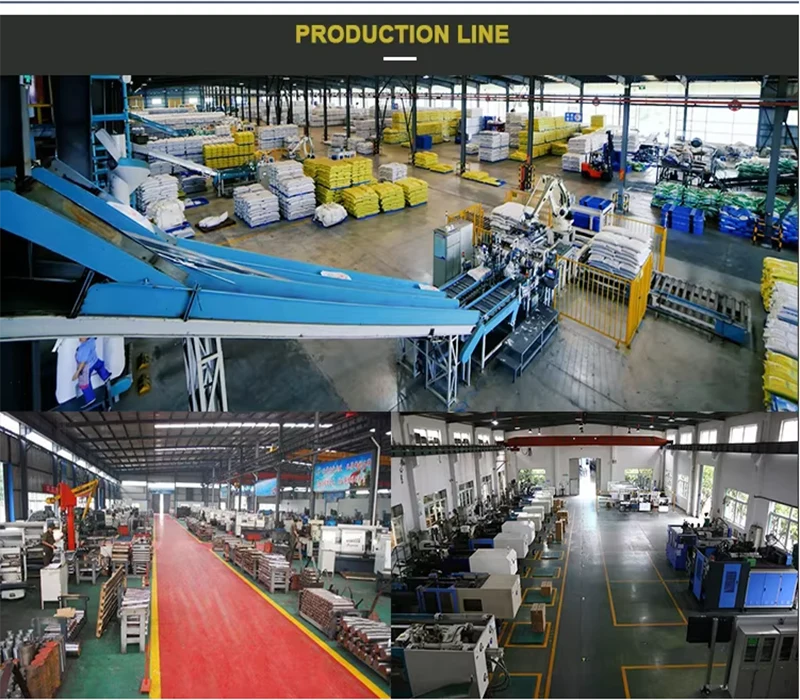

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales.

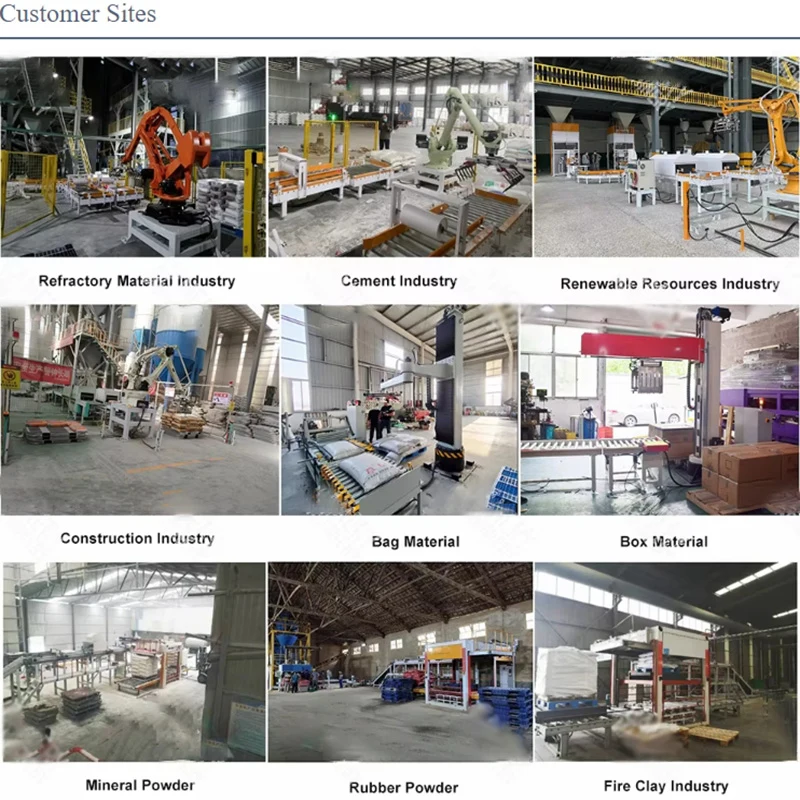

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Camery has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Camery has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

Product Inquiry