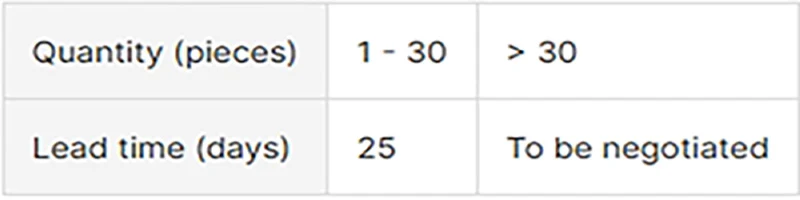

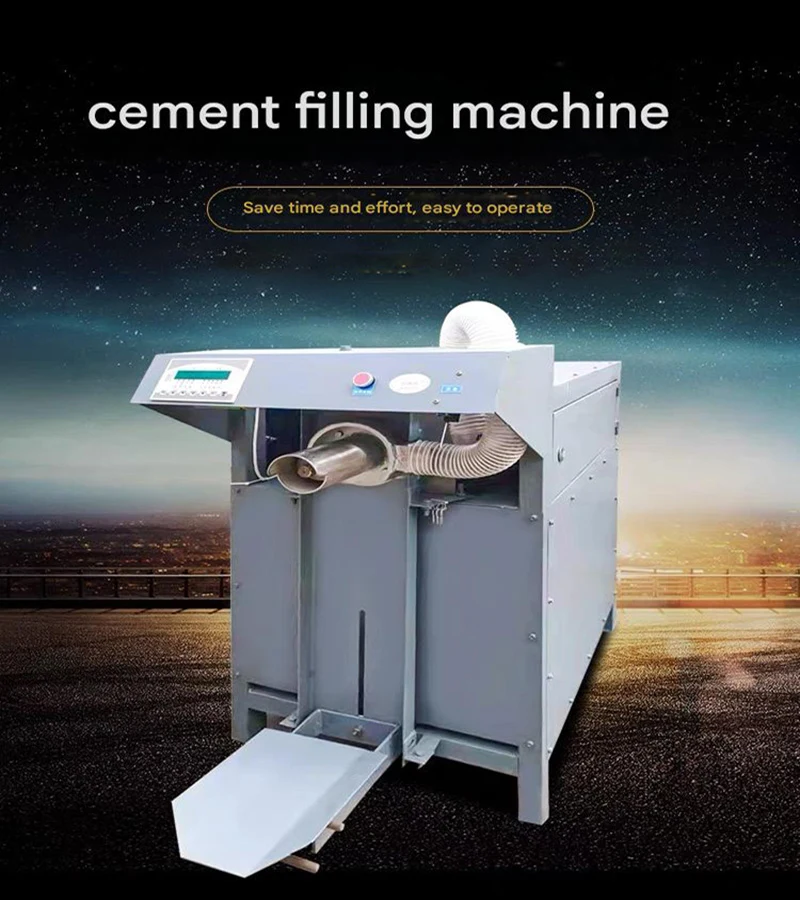

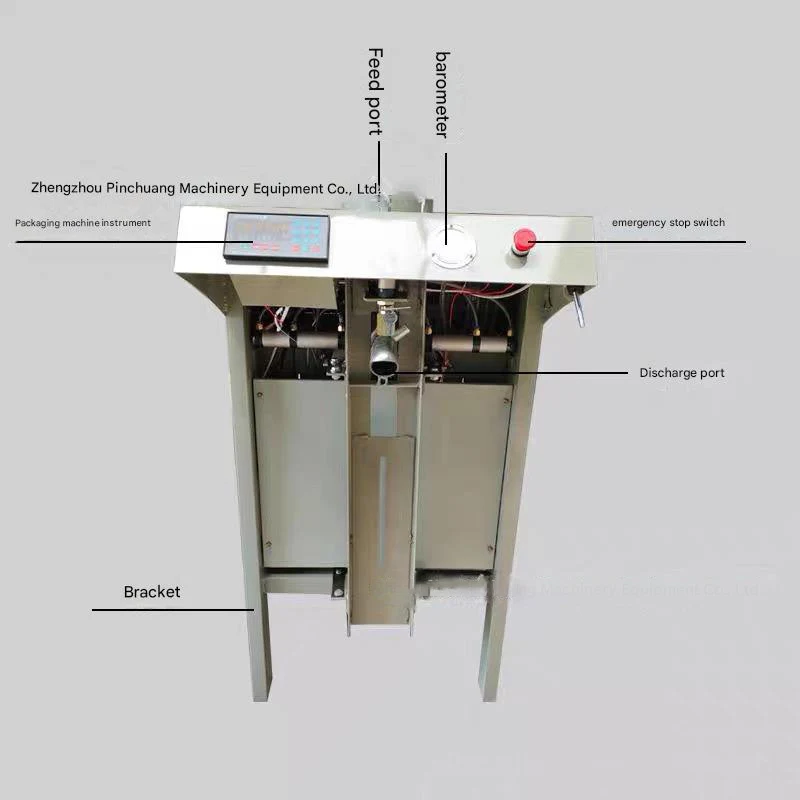

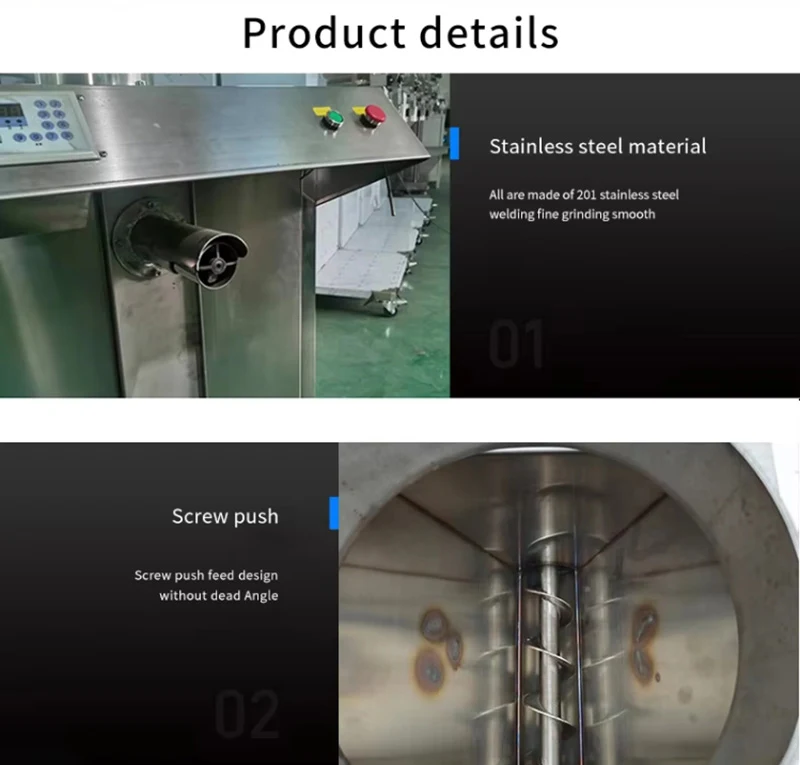

The small particle dry powder packaging machine is a mechanical device specialized in automated packaging of powdery materials with small particle size and good fluidity. Integrating mechanical, electronic, and pneumatic technologies, it consists of core components such as a material conveying system, metering device, bag-making system (for bag packaging), sealing unit, and electrical control system. The material conveying system steadily transports dry powder to the metering device,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

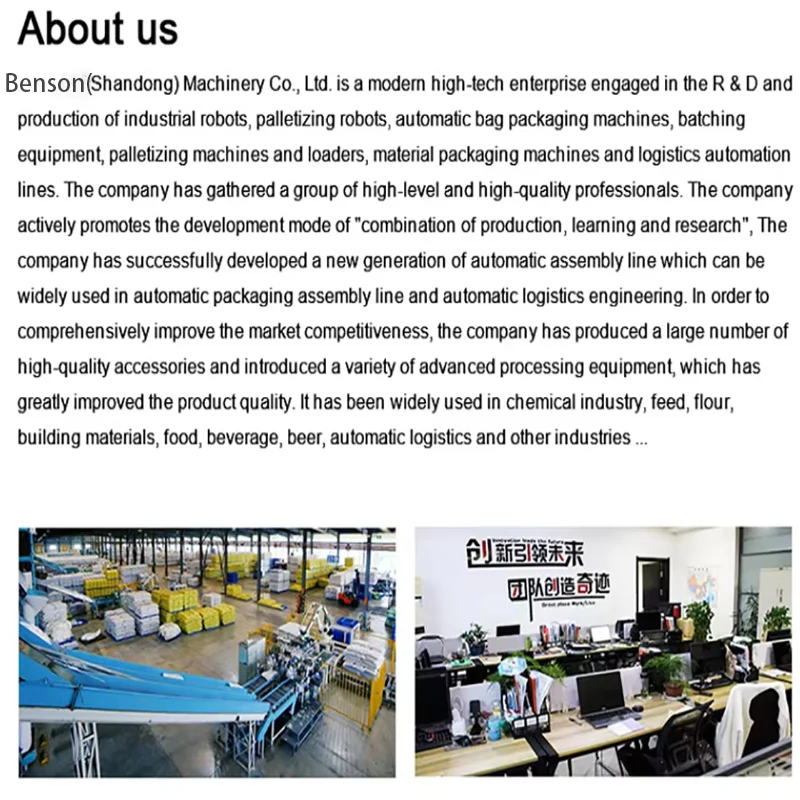

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

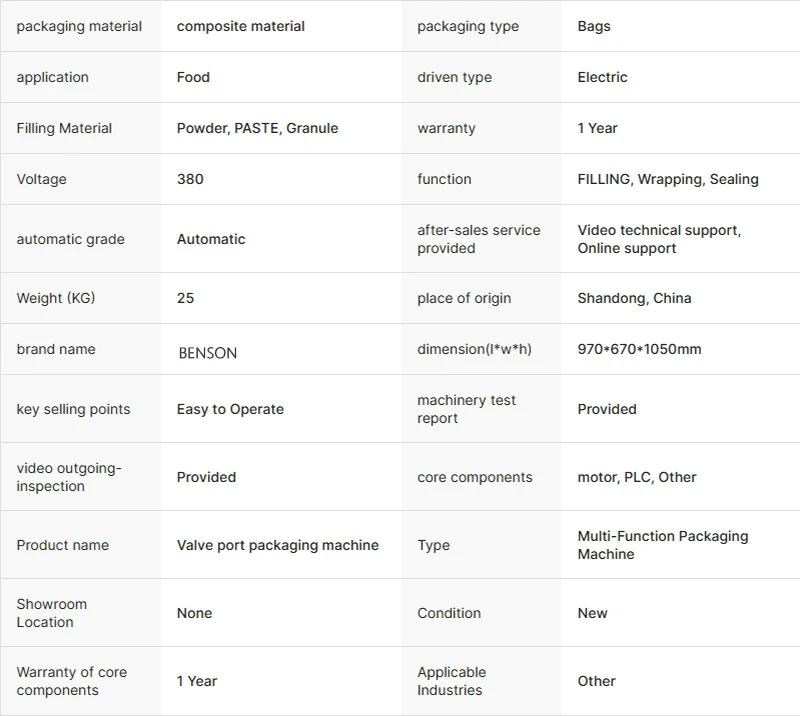

Lead time

BensonSmall Granule Dry Powder Packaging Machine Core Advantages

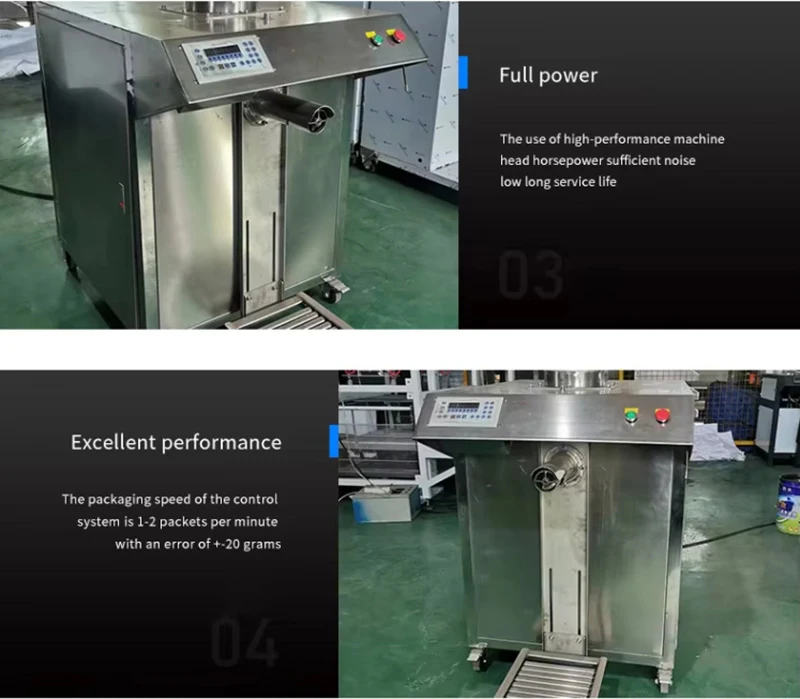

1. High-Precision Metering: Equipped with advanced weighing sensors and intelligent control systems, the metering accuracy reaches ±0.5%–±1%, ensuring uniform weight per bag, reducing material waste, and enhancing product quality and corporate reputation.

2. Efficient Production: With a packaging speed of 30–60 bags per minute, it significantly improves production efficiency compared to manual packaging, meets large-scale production needs, and reduces unit labor costs.

3. Flexible Customization: Parameters such as packaging weight, bag size, and packaging form can be flexibly adjusted according to material properties, packaging specifications, and production requirements, adapting to diverse market demands.

4. Strong Stability: Made with high-quality mechanical components and electrical parts, the equipment operates stably with low failure rates, simple maintenance, and long continuous operation capability, ensuring production continuity.

5. Hygienic and Environmentally Friendly: The entire equipment uses food-grade or hygienic-standard materials with good sealing, effectively preventing dust leakage during packaging, reducing environmental pollution, and avoiding material contamination, complying with hygiene standards for food and pharmaceutical industries.

Benson Small Granule Dry Powder Packaging MachineNotable Features

1. Intelligent Control: Equipped with a PLC (Programmable Logic Controller) and touchscreen human-machine interface, it is easy to operate. Staff can quickly set parameters, monitor equipment status, and use fault self-diagnosis and alarm functions for timely problem-solving.

2. Good Compatibility: Suitable for various small particle dry powder materials, such as food powders (milk powder, coffee powder, seasonings), chemical powders (putty powder, tile adhesive, coating powder), and pharmaceutical powders, with wide application across industries.

3. High Automation: From material conveying, metering, bag-making, filling, sealing to finished product output, the entire process requires minimal manual intervention, reducing human impact on packaging quality and improving efficiency and consistency.

4. Safety Protection: Multiple safety devices such as emergency stop buttons, protective barriers, and photoelectric sensors are installed to effectively prevent operator injuries during operation and ensure production safety.

BensonSmall Granule Dry Powder Packaging MachineWide Applications

1. Food Industry: Used for packaging small particle dry food powders like milk powder, protein powder, starch, sugar powder, and seasonings (e.g., Chinese prickly ash powder, cumin powder, five-spice powder), meeting food hygiene and precision metering requirements while extending shelf life.

2. Chemical Industry: Suitable for packaging chemical products such as putty powder, tile adhesive, coating powder, plastic particles, rubber additives, and pesticide powders, addressing special packaging needs like moisture and oxidation resistance for different materials.

3. Pharmaceutical Industry: Enables precise packaging of medicinal powders and health product powders, ensuring accurate dosage while complying with strict hygiene and quality standards in pharmaceutical production.

4. Building Materials Industry: Plays a key role in packaging dry mortars, masonry mortars, and plastering mortars, improving packaging efficiency, reducing labor intensity, and supporting large-scale production for building material enterprises.

5. Other Industries: Also applicable to fields like feed (premixes, fish feed powder) and electronics (electronic powders), enabling efficient and precise packaging of various small particle dry powder materials.

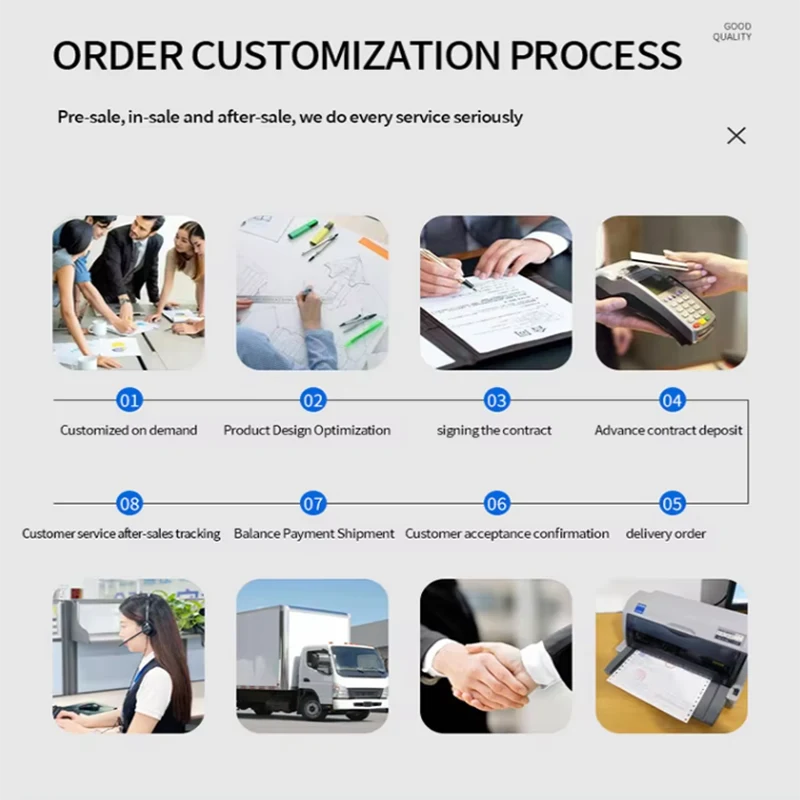

Products Description

Product Inquiry