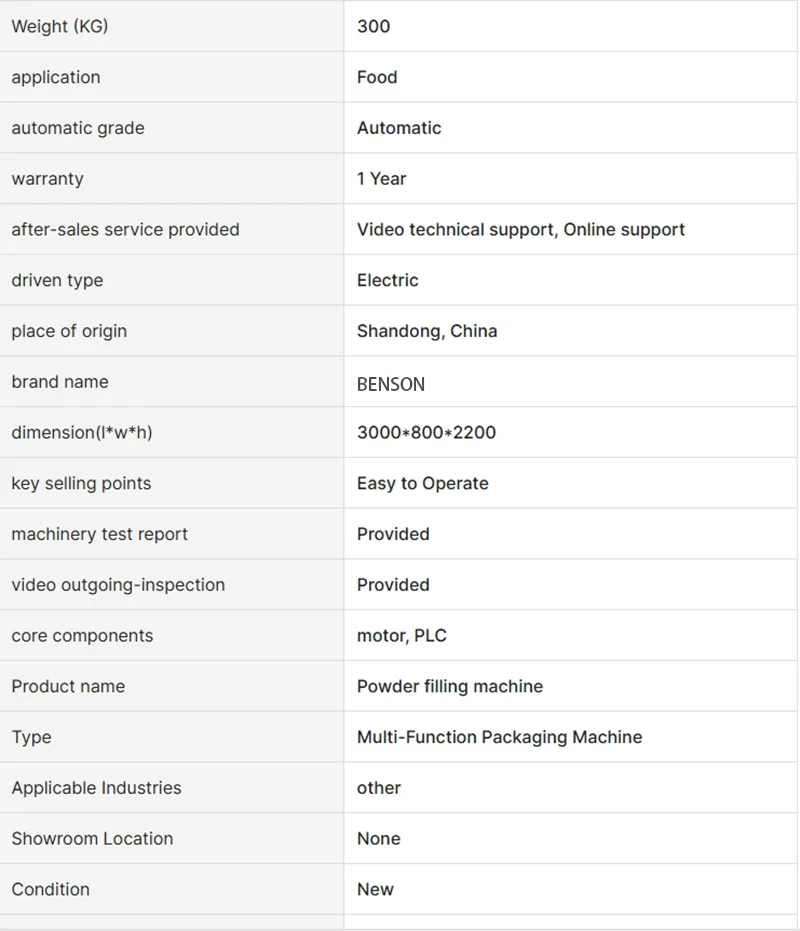

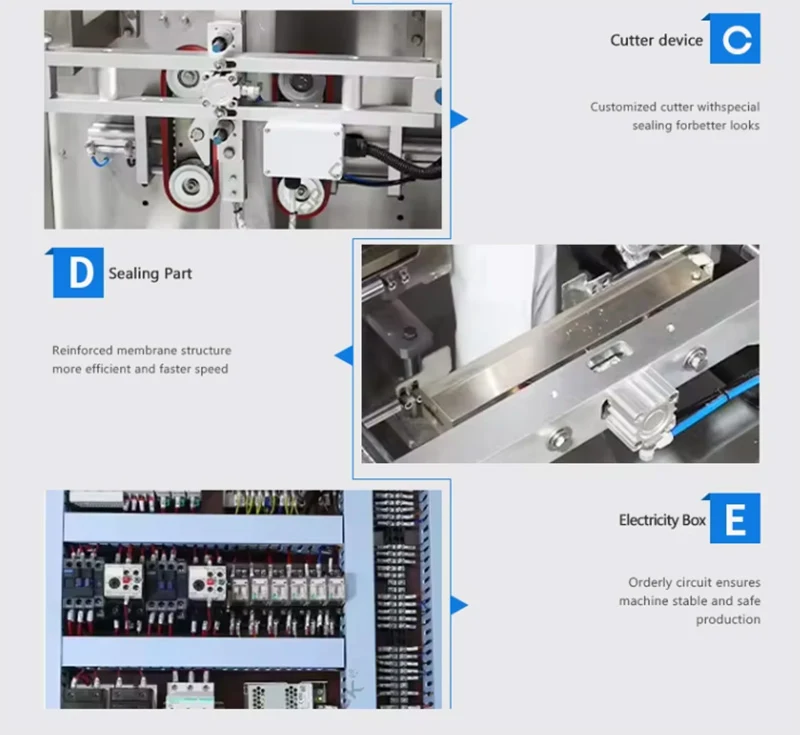

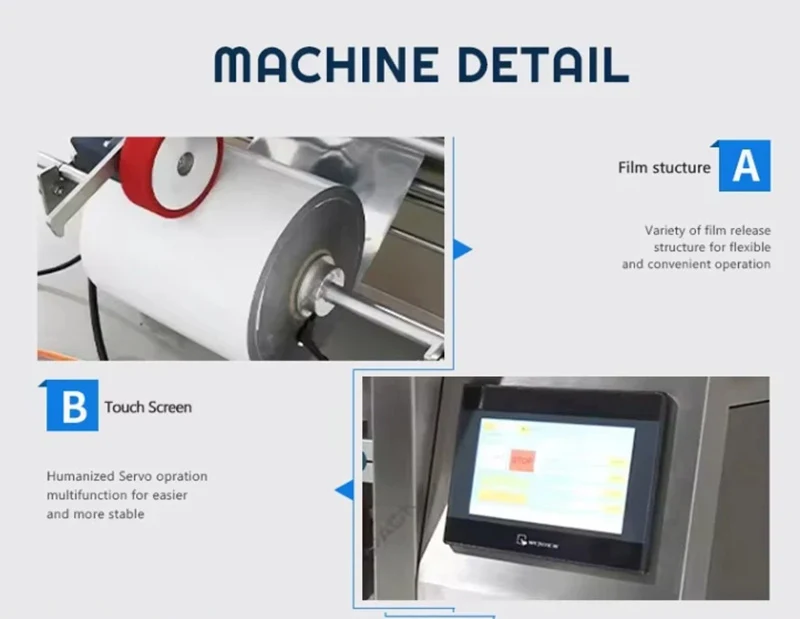

The "Small Multi-functional Automatic Packaging Machine with PLC Core Components" is a compact packaging device with the Programmable Logic Controller (PLC) as its core control unit. Relying on its high stability, flexible programming, and powerful logical processing capabilities, the PLC precisely regulates all aspects of the packaging process, including material transportation, metering and filling, sealing, labeling, etc. This device integrates multiple functions, can adapt to the packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Core components of PLC: Small multi-functional automatic packaging machineAdvantages

1. Precise and Efficient: The PLC enables automated control, reducing manual intervention. It has high packaging accuracy and speed, effectively improving production efficiency and reducing the error rate.

2. Strong Flexibility: It supports personalized programming and can quickly switch packaging modes to meet the packaging needs of different products (such as food, daily necessities, electronic products, etc.), flexibly handling small-batch and multi-variety production.

3. Stable and Reliable: The core components of the PLC have strong anti-interference ability, stable operation, a low failure rate, and low maintenance costs, ensuring long-term continuous operation of the equipment.

4. Easy to Operate: Equipped with an intuitive Human-Machine Interface (HMI), operators can get started without complex training, and the operation is convenient.

5. Space-friendly: The miniaturized design saves workshop space, is easy to install and deploy, and is especially suitable for production environments with limited space.

Core components of PLC: Small multi-functional automatic packaging machineApplication Areas

1. Food Industry: Used for the quantitative packaging and sealing of foods such as candies, biscuits, nuts, seasonings, etc.

2. Daily Necessities Industry: Suitable for the packaging of daily necessities such as cosmetics, detergents, paper towels, etc., ensuring hygiene and aesthetics.

3. Pharmaceutical Industry: Meets the aseptic packaging requirements of drugs and health products, complies with GMP standards, and ensures product safety.

4. Electronic Products: Conducts moisture-proof and anti-static packaging for small electronic components and accessories to protect product quality.

5. Chemical Industry: Achieves precise metering and sealed packaging of granular and powdered chemical raw materials.

Core components of PLC: Small multi-functional automatic packaging machineFeatures

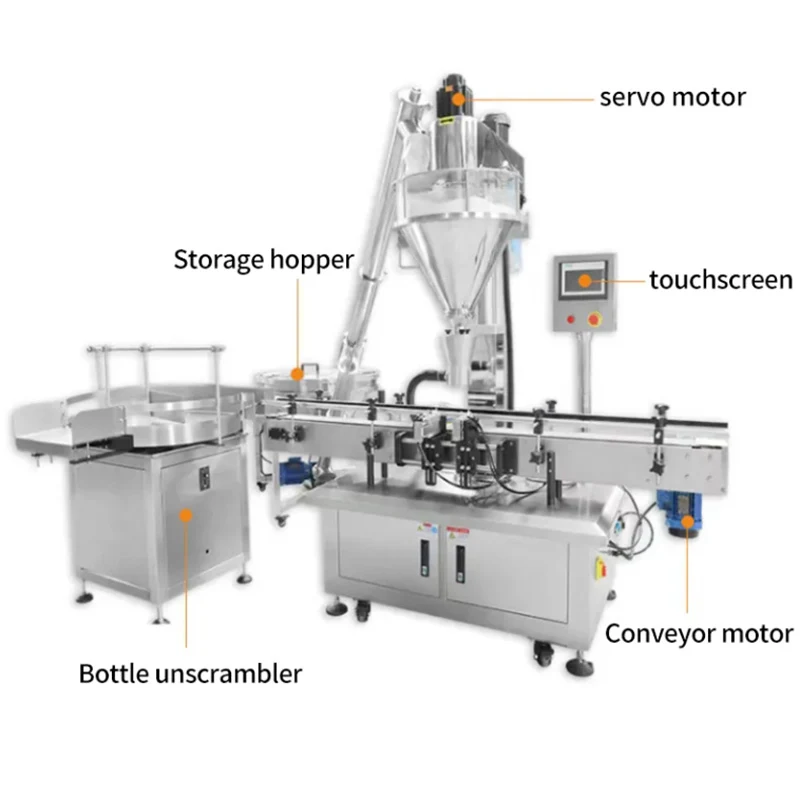

1. Multi-functional Integration: Integrates multiple functions such as metering, filling, sealing, batch number printing, labeling, etc., and completes the entire packaging process in one stop.

2. Modular Design: Each functional module can be independently disassembled, replaced, or upgraded, facilitating equipment maintenance and function expansion.

3. Intelligent Monitoring: Built-in sensors monitor the packaging process in real time, automatically alarm and stop the machine to handle abnormalities, ensuring production safety.

4. Energy-saving and Environment-friendly: Optimizes the energy management system, reduces energy consumption, and at the same time adopts environmentally friendly materials and processes, conforming to the concept of sustainable development.

5. High Compatibility: Can be seamlessly connected with other equipment on the production line (such as filling machines, palletizers), and constructs an automated production system.

Product Inquiry