Logistics sorting belt conveyor: the core hub of efficient logistics

Logistics sorting belt conveyor is the core equipment for modern logistics industry to realize automated and intelligent sorting operations. With its high efficiency, stability and flexibility, it has become a key tool for optimizing sorting processes in e-commerce, express delivery, warehousing and other fields.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Core functions and advantages of logistics sorting belt conveyor

1. High-speed and accurate sorting: Equipped with advanced sensors and intelligent control systems, it can quickly identify information such as package size, weight, destination, etc., and cooperate with high-precision sorting algorithms to achieve accurate diversion of multiple pieces of goods per second, with a sorting accuracy rate of up to 99.9%, greatly reducing the error and efficiency loss of manual operation.

2. Strong environmental adaptability: It adopts wear-resistant, anti-slip, and anti-static high-quality belt materials, such as rubber, PVC, PU, etc., which can adapt to complex working environments such as humidity and dust; it supports wide temperature operation from -20℃ to 60℃ to ensure stable operation in different regions and climatic conditions.

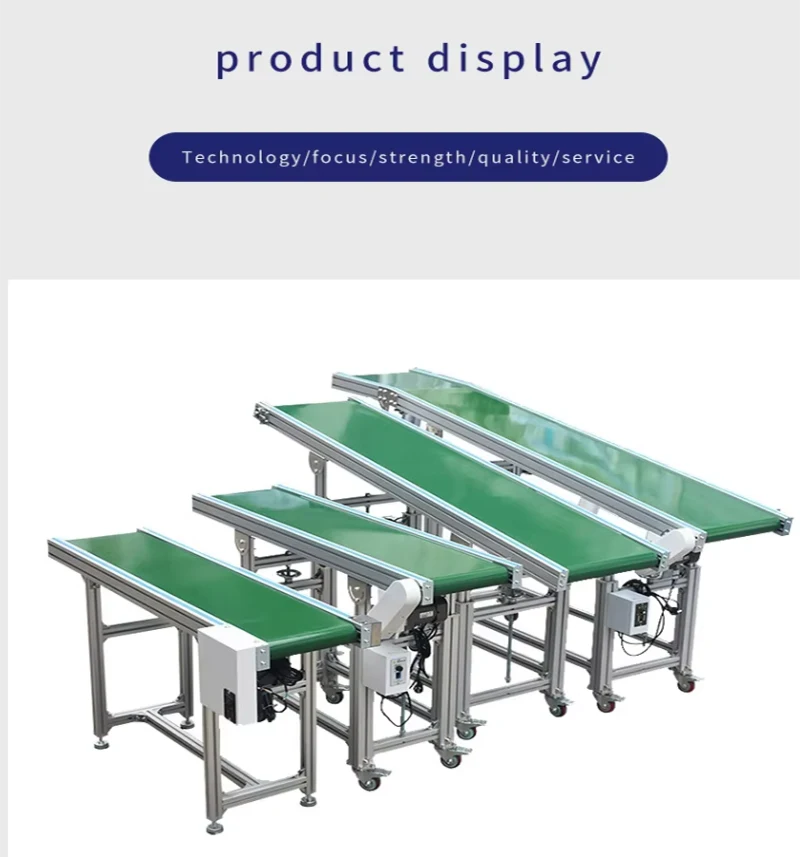

3. Flexible customization scheme: It can customize diversified conveying routes such as straight line, curve, slope, etc. according to site space, cargo type and sorting requirements; it supports single-level or multi-level sorting combinations, and is suitable for different scale scenarios from small and medium-sized warehouses to large logistics centers.

4. Strong compatibility and scalability: seamlessly connect upstream and downstream equipment such as code scanning equipment, weighing instruments, automatic sorting robots, etc. to form a complete intelligent sorting system; support modular design, which is convenient for later equipment upgrades and function expansion to meet the needs of corporate business growth.

5. Safe and energy-saving design: equipped with emergency stop button, anti-deviation device, overload protection system, all-round protection of equipment and personal safety; energy-saving drive motor and intelligent speed regulation technology are adopted to maintain efficient operation under low energy consumption state and reduce operating costs.

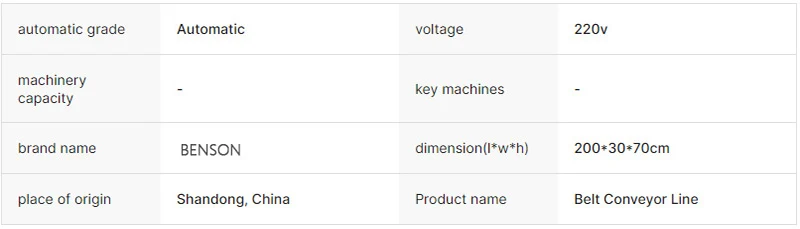

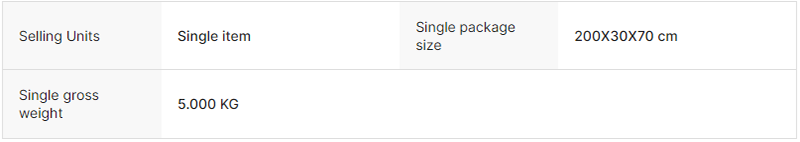

Core parameters of logistics sorting belt conveyor

Project Parameter details

Conveying speed: 0.5-2.5m/s adjustable to meet the efficiency requirements of different sorting scenarios

Belt width: 200-2000mm optional, suitable for full-size goods from small packages to large boxes

Maximum load: 50-300kg per meter, heavy-duty type can be customized to 500kg

Drive power: 1.5-7.5kW, intelligent frequency conversion control, energy consumption can be adjusted on demand

Sorting accuracy: ±5mm, higher accuracy can be achieved with visual recognition system

Working voltage: AC 220V/380V, 50/60Hz

Core technology and configuration of logistics sorting belt conveyor

Belt material

- PVC belt: economical and durable, suitable for ordinary goods, anti-static treatment, anti-slip texture design on the surface

- PU belt: food-grade material, wear-resistant and oil-resistant, suitable for the pharmaceutical and food industries

- Rubber belt: high elasticity, tear resistance, suitable for heavy loads and rough goods

Logistics sorting belt conveyor drive system

Imported servo motor + high-precision reducer combination, smooth start and stop without impact; equipped with overload protection device, automatic shutdown alarm in case of abnormality.

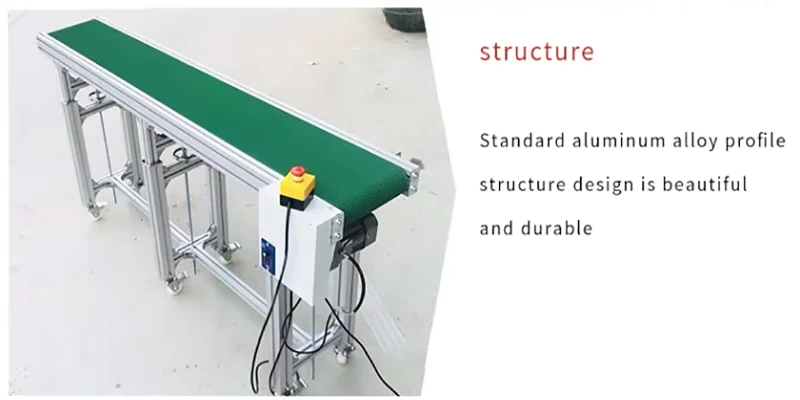

Logistics sorting belt conveyor structure design

Modular design of logistics sorting belt conveyor

The body adopts aluminum profile frame + carbon steel bracket structure, and each component is modularly assembled to support rapid installation and debugging on site; it can flexibly combine straight, curved, climbing and other conveying routes according to the site.

Logistics sorting belt conveyor sorting device

- Swing arm sorting: response speed <0.5 seconds, suitable for high-speed sorting of small and medium-sized goods

- Push block sorting: large thrust design, suitable for heavy goods sorting

- Inclined wheel sorting: silent operation, suitable for express parcel intensive sorting

Adaptation scheme for application scenarios of logistics sorting belt conveyor

Scenario type Key points of customized scheme

E-commerce warehousing Multi-sorting port design, equipped with automatic code scanning system, can process up to 15,000 pieces per hour

Express distribution center Long-distance continuous transportation, the minimum curve radius can reach 600mm, suitable for narrow site layout

Food processing All stainless steel racks, food-grade belts, in line with GMP hygiene standards

Manufacturing Precise rhythm matching with production lines, supporting integrated operation of workpiece positioning and sorting

Service guarantee

Pre-sales service: professional team provides free site survey and customized three-dimensional design plan

In-sales service: nationwide on-site installation and commissioning, and provides operation training

After-sales service:

- Warranty period: 1 year for the whole machine, 2 years for core components

- Response time: technical support within 24 hours, on-site service within 48 hours

- Regular maintenance: provide annual equipment inspection and maintenance services

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry