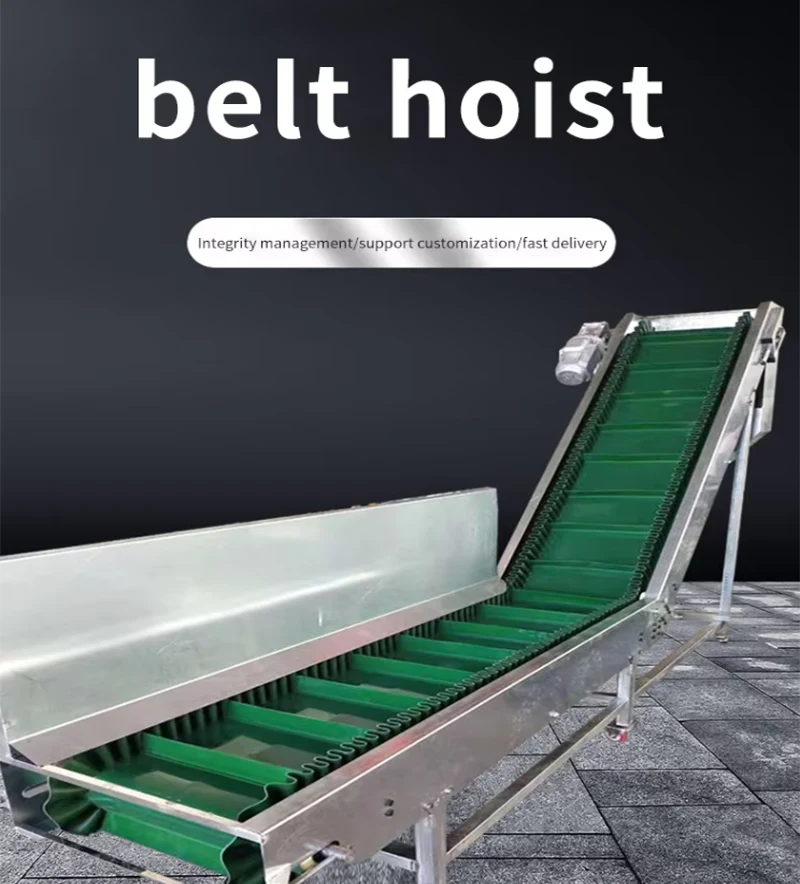

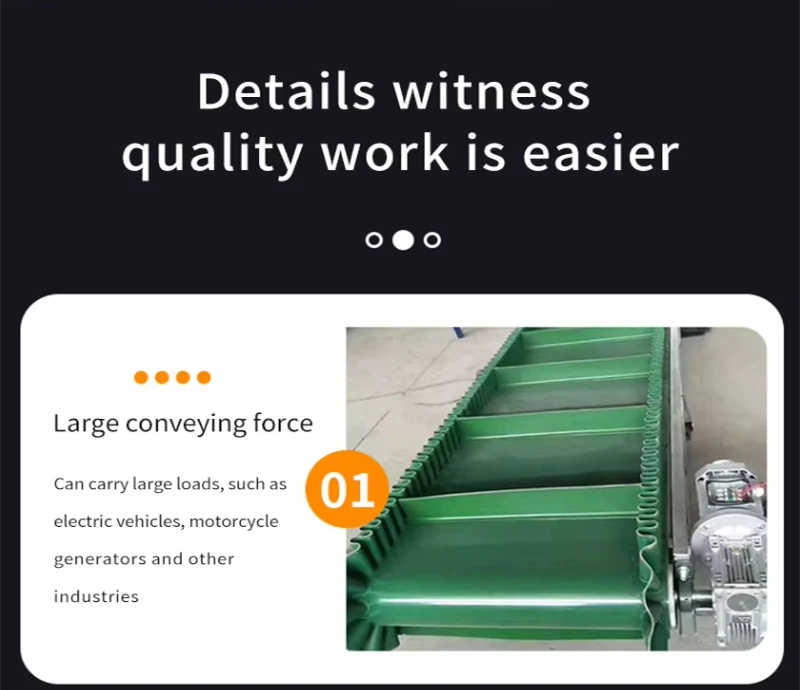

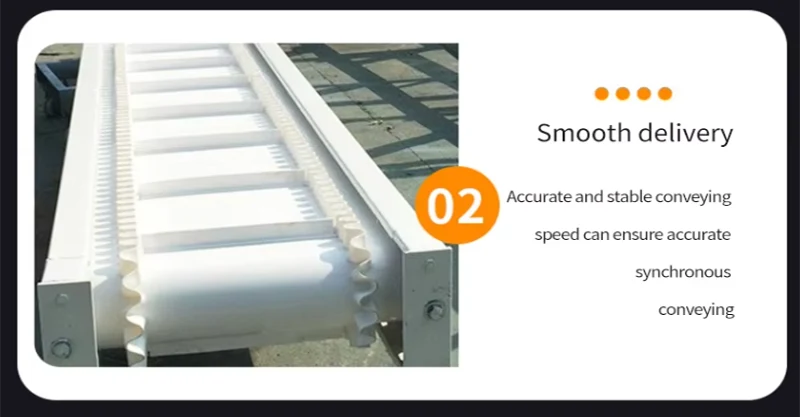

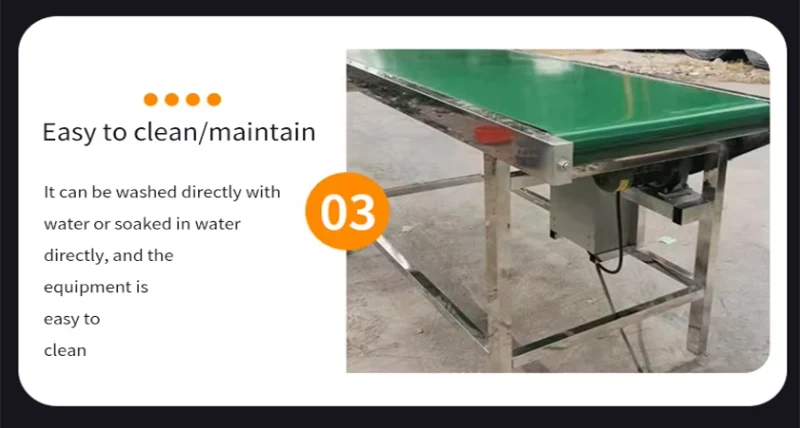

Incline conveyor uses conveyor belts, chain plates, rollers and other components as main load-bearing components, and drives the conveyor carrier through the motor-driven transmission device. Its inclination angle can be flexibly adjusted according to actual needs, generally between 0°-90°, and a larger inclination model can be customized under special working conditions. In order to ensure stable material transportation,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

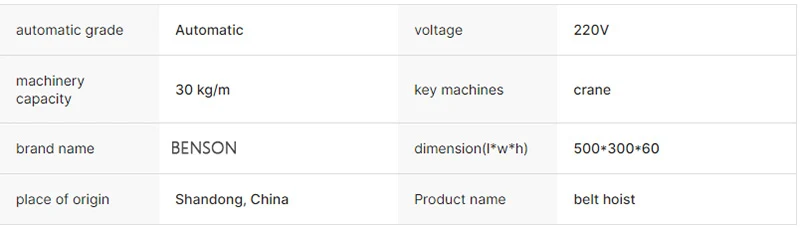

Key attributes

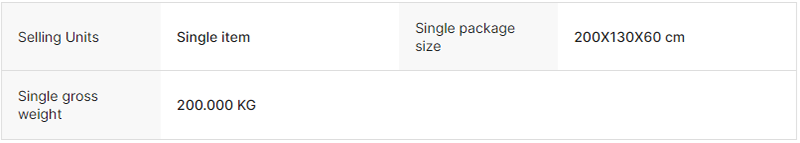

Packaging and delivery

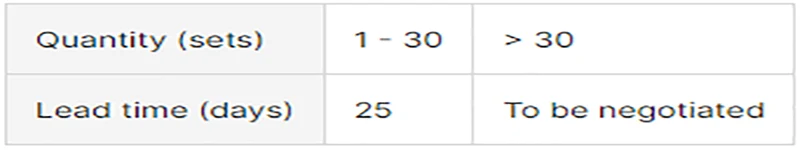

Lead time

Product descriptions from the supplier

Inclined conveyor: efficient material conveying solution

Diversified types and advantages of inclined conveyor

- Belt inclined conveyor: It uses high-strength rubber or PU belts, which have the characteristics of smooth operation, low noise and flat conveying surface. It is suitable for granular, powdered and small packaging materials, such as food, medicine, electronic components, etc., and is widely used in food processing and e-commerce sorting.

- Chain plate inclined conveyor: It uses metal chain plates as the conveying medium, with strong bearing capacity, high temperature resistance and wear resistance. It is suitable for conveying materials with large weight, large volume or irregular surface, such as mechanical parts, stone, building materials, etc., which are commonly used in heavy industry and mining industry.

- Roller inclined conveyor: It relies on the rotation of the roller to realize material conveying. It is suitable for conveying boxed or palletized goods with flat and regular bottom. It is often used in logistics warehousing and express sorting centers, and can be seamlessly connected with the automated sorting system.

Widely used in the field

1. Food and beverage industry: In biscuit and candy production lines, the slope conveyor can smoothly transport the baked products to the packaging link; in fruit and vegetable processing, it can realize the automatic connection of raw material cleaning, sorting and basket loading, which meets the food-grade hygiene standards.

2. Logistics and warehousing industry: In e-commerce warehouses and logistics centers, the slope conveyor is used for the efficient transfer of goods from the sorting area to the loading area, and forms a three-dimensional conveying network with other conveying equipment to improve the utilization rate of storage space and the efficiency of cargo handling.

3. Chemical and building materials industry: For powdery or blocky materials such as chemical raw materials, cement, sand and gravel, chain plate or trough belt-type slope conveyor can operate stably under harsh working conditions, with anti-corrosion and anti-dust leakage design to ensure production safety and environmental protection requirements.

4. Electronics and light industry: With its low friction and anti-static characteristics, belt-type slope conveyor is often used in electronic product assembly lines to achieve accurate transportation of precision parts and avoid product damage.

Customized service and after-sales guarantee

We provide a full range of customized slope conveyor services, and tailor-make the best solution according to the customer's material characteristics (weight, size, shape), conveying volume requirements, installation space and budget. From equipment selection, drawing design to production installation, commissioning and maintenance, we are equipped with a professional technical team to follow up throughout the process. At the same time, the perfect after-sales service system ensures that when the equipment fails, engineers can respond quickly, provide repair, maintenance and operator training services, minimize downtime, and escort the company's production.

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry