The semi-automatic weighing scale packaging machine is an industrial equipment that integrates weighing and packaging functions. It combines manual operation with automated control, enabling operators to complete the processes of feeding, precise weighing through the built-in weighing scale, and packaging. After manually placing items on the weighing scale, the machine automatically measures the weight. Once the set weight is reached, the machine initiates the packaging process,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

which may include bagging, sealing, and labeling. This equipment bridges the gap between fully manual and fully automatic machines, offering a cost-effective and flexible solution for various production needs.

Semi-automatic weighing scale packaging machine Advantages

1. Cost - effectiveness:Compared to fully automatic packaging systems, semi-automatic weighing scale packaging machines are more affordable in terms of initial investment. They are an ideal choice for small and medium-sized enterprises or businesses with limited budgets, helping them achieve a certain level of automation without a large capital outlay.

2. Flexibility:It can handle a wide variety of products with different shapes, sizes, and weights. Operators can easily adjust parameters such as packaging weight, bag size, and sealing methods according to specific product requirements, making it suitable for both batch production and customized packaging tasks.

3. Ease of operation and maintenance:With a relatively simple structure, it is easy for operators to learn and master its operation. Additionally, maintenance procedures are less complex, reducing downtime and maintenance costs. Fewer components mean lower risks of mechanical failures, and common issues can often be resolved by in-house staff without the need for highly specialized technicians.

4. Accuracy:Equipped with high-precision weighing sensors, the machine can achieve accurate weight measurement, ensuring that each package meets the specified weight requirements. This not only improves product quality consistency but also helps avoid product waste caused by overfilling or underfilling.

Semi-automatic weighing scale packaging machineApplications

1. Food industry:It is widely used for packaging various food products, such as snacks (chips, nuts), grains (rice, wheat), dried fruits, and candies. Whether it's small retail packages or large bulk packages for wholesale, this machine can handle the weighing and packaging efficiently while meeting food hygiene standards.

2. Agriculture and animal husbandry:In the agricultural sector, it can be used to package seeds, fertilizers, and agricultural by-products. For the animal husbandry industry, it is suitable for packaging pet food, livestock feed, ensuring accurate portioning for different feeding needs.

3. Chemical industry:Used to package various chemical raw materials, additives, and finished products. The machine can be customized with anti-corrosion materials and explosion-proof designs to meet the safety requirements of handling potentially hazardous chemical substances.

4. E-commerce and logistics:As e-commerce grows, it is applied to package small items for shipping, like small electronics, handicrafts, and accessories. It helps streamline the packaging process, ensuring accurate weight measurement for shipping cost calculations.

Semi-automatic weighing scale packaging machine Features

1. Semi-automatic operation mode:The combination of manual and automatic functions gives operators control over the production process, allowing for real-time adjustments and monitoring. For example, operators can manually place irregularly shaped items on the weighing scale and start the automatic weighing and packaging process, ensuring that each package is handled properly.

2. High - precision weighing system:Advanced weighing sensors and intelligent control algorithms ensure accurate weight measurement within a narrow error range. The machine can quickly and accurately display the weight of items, and automatically stop feeding once the preset weight is reached, guaranteeing the consistency of package weight.

3. Adjustable packaging parameters:Parameters such as packaging speed, bag length, sealing temperature, and vacuum degree (if applicable) can be easily adjusted through the control panel. This adaptability allows the machine to meet diverse packaging requirements, from simple plastic bag packaging to more complex vacuum-sealed packaging.

4. Compact and space-saving design:Its relatively small footprint makes it suitable for installation in factories or workshops with limited space. Despite its compact size, it maintains high productivity and performance, optimizing the use of production space.

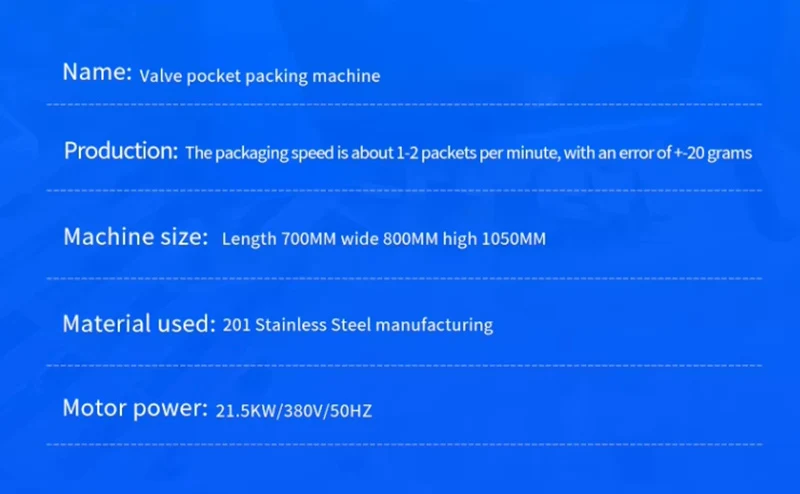

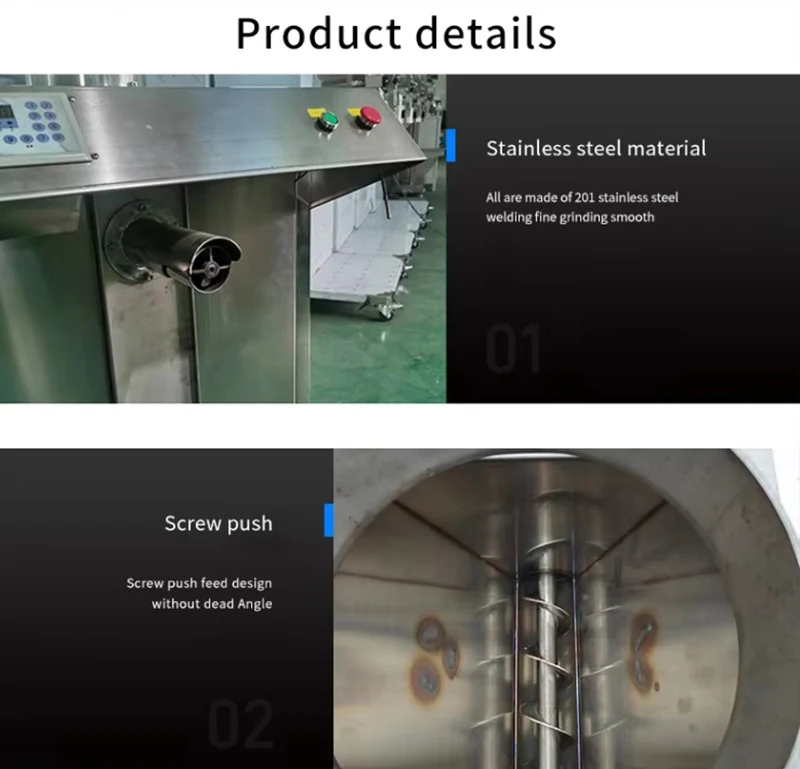

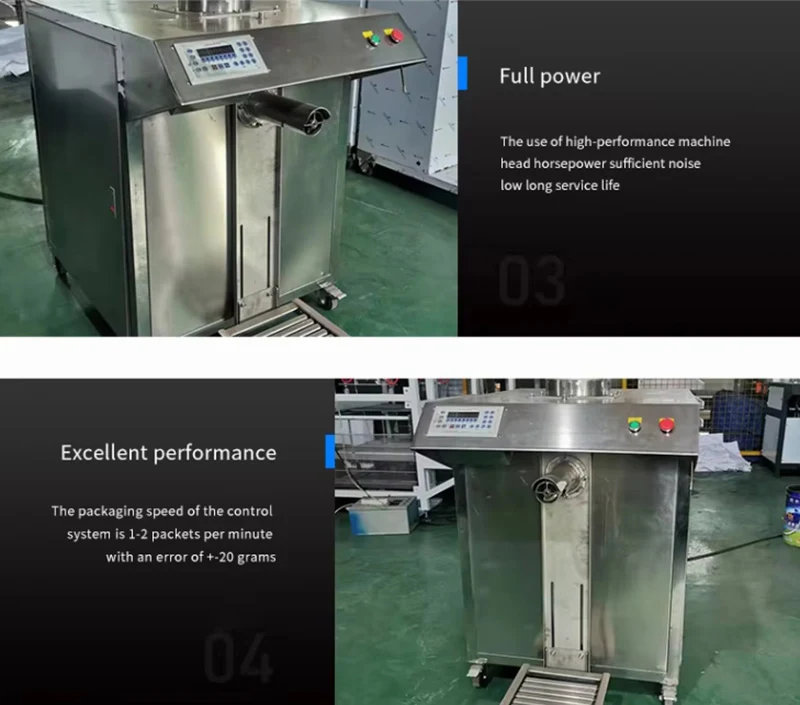

Products Description

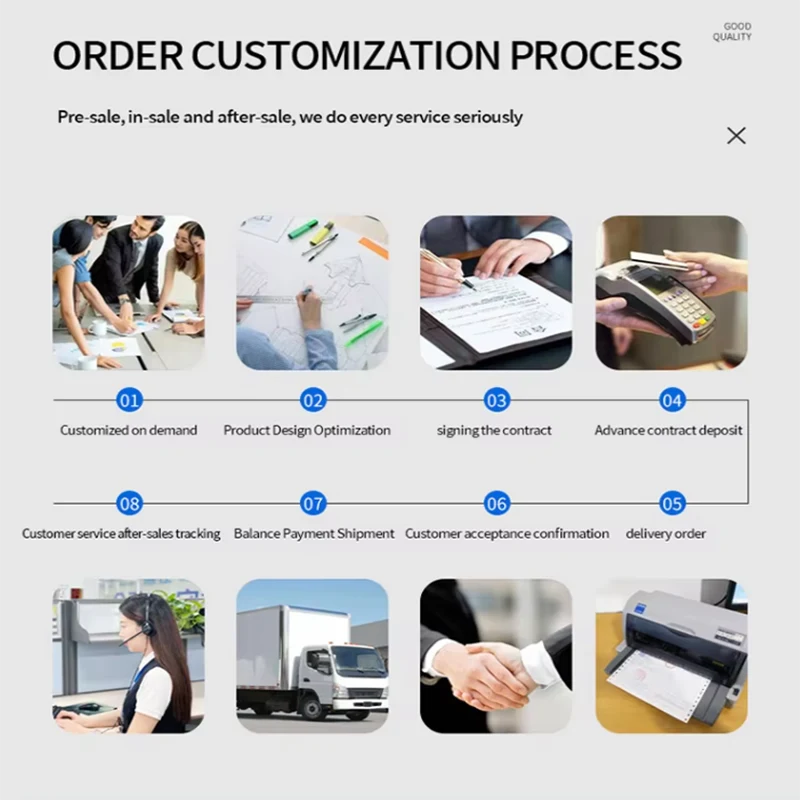

Product Inquiry