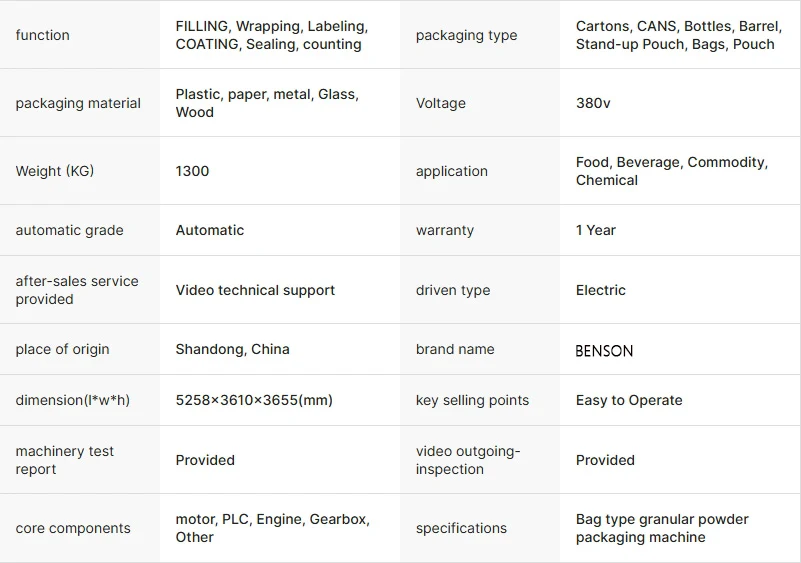

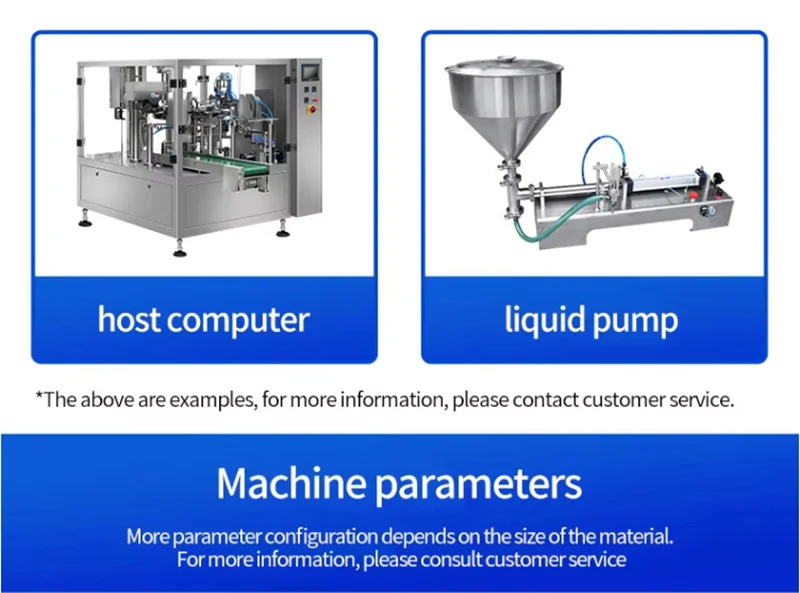

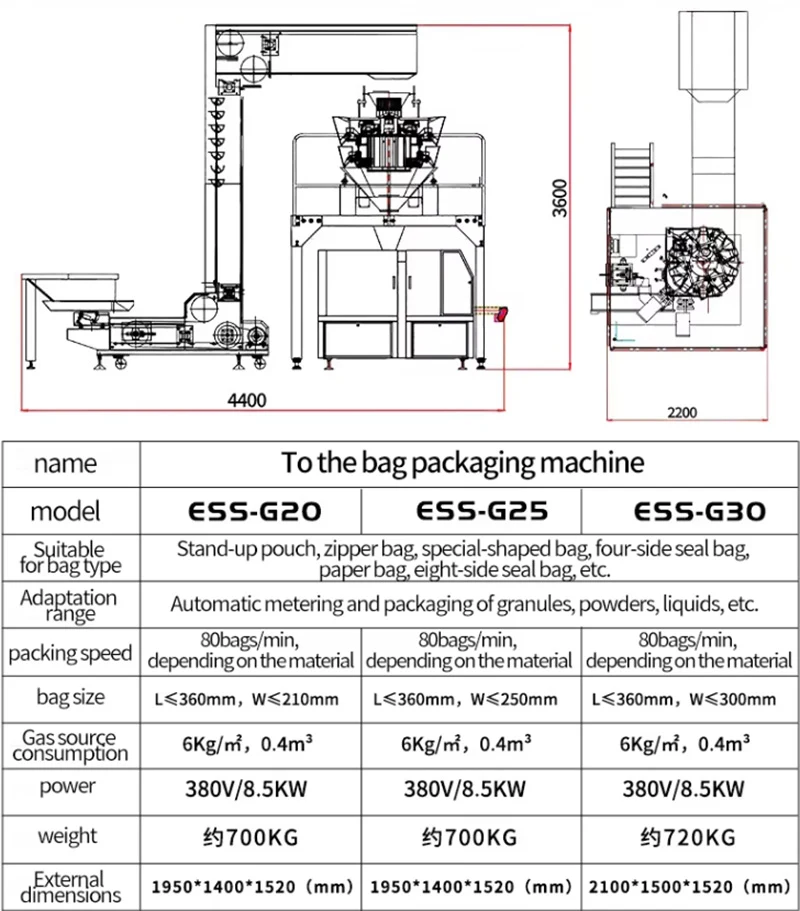

A rotary bag packaging machine is an advanced packaging equipment that utilizes a rotating mechanism to complete the packaging process. It generally consists of key components such as a feeding system, bag - forming device (for pre - made bags, this step is skipped), filling mechanism, sealing unit, and control system. The machine operates by continuously rotating the worktable or relevant components, enabling multiple processes like bag feeding, product filling, metering, sealing, and cutting

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Rotary bag packaging machineAdvantages

1. High - efficiency:With its continuous rotary operation mode, the rotary bag packaging machine can quickly complete a series of packaging processes. It can significantly increase production output compared to traditional linear packaging machines, meeting the mass - production needs of enterprises, especially for products with large - scale packaging requirements.

2. High precision:Equipped with advanced control systems and precise metering devices, it can accurately control the filling volume of products, reducing material waste and ensuring the consistency of each package. The sealing process also achieves high - quality seals, minimizing the occurrence of leakage or damage to packages.

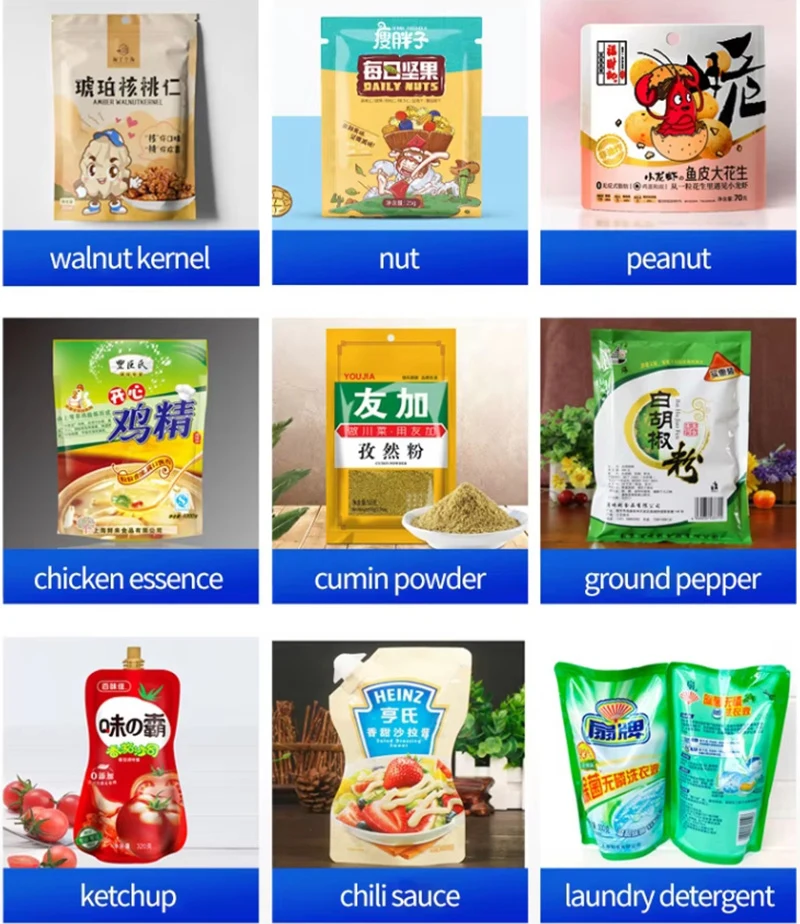

3. Flexibility:It can adapt to various types of bags, including flat - bottom bags, stand - up pouches, and side - gusset bags, and can handle different sizes and specifications of bags by adjusting relevant parameters. At the same time, it is suitable for packaging a wide range of products, from granular, powdery, to liquid materials.

4. Stable performance:The mechanical structure of the rotary design is relatively stable, with fewer moving parts in the overall transmission process, reducing the probability of mechanical failures and maintenance frequency. This helps to ensure long - term stable operation of the production line and reduces production interruptions caused by equipment failures.

5. Space - saving:The rotary layout allows multiple packaging functions to be integrated into a relatively compact space. Compared with linear packaging systems that require a long production line, it occupies less floor space, which is very beneficial for factories with limited space.

Rotary bag packaging machineCharacteristics

1. Automated operation:From bag feeding, filling, sealing to finished product output, the entire process can be automatically completed under the control of the program, reducing the need for manual intervention and improving production efficiency while also reducing labor costs.

2. Intelligent control:Adopts intelligent control systems, which can be easily operated through touch - screen interfaces. Operators can set various packaging parameters, monitor the operation status of the machine in real - time, and quickly adjust and troubleshoot problems when abnormal situations occur.

3. Hygienic design:In order to meet the requirements of food, pharmaceutical, and other industries for product hygiene, the machine is usually made of food - grade stainless steel and other materials that are easy to clean, and its structural design also facilitates cleaning and disinfection to prevent product contamination.

4. Good compatibility:It can be easily integrated with other production equipment, such as conveyor lines, weighing machines, and labeling machines, to form a complete automated production and packaging line, realizing seamless connection of the entire production process.

Rotary bag packaging machineApplications

1. Food industry:It is widely used for packaging various foods, such as grains (rice, wheat, etc.), snacks (chips, nuts), powdered foods (milk powder, coffee powder), and liquid foods (juices, sauces). Whether it is for retail - sized packages or large - volume bulk packages, the rotary bag packaging machine can meet the needs.

2. Chemical industry:Used to package chemical raw materials, fertilizers, pesticides, etc. For granular chemical raw materials, it can accurately control the filling amount; for powdery pesticides, it can ensure reliable sealing to prevent leakage and volatilization of harmful substances.

3. Pharmaceutical industry:Suitable for packaging pharmaceutical products, including powders, granules, and small - volume liquid medicines. The hygienic and precise characteristics of the machine meet the strict requirements of the pharmaceutical industry for product packaging in terms of quality and safety.

4. Agricultural products industry:Can be used to package agricultural products like seeds, dried fruits, and grains. It helps to protect agricultural products from moisture, insects, and damage during storage and transportation, and also facilitates product sales through standardized packaging.

5. Daily necessities industry:For packaging products such as laundry powder, washing liquid, and seasonings, it can complete high - speed and high - quality packaging operations, improving production efficiency and product competitiveness in the market.

Product Inquiry