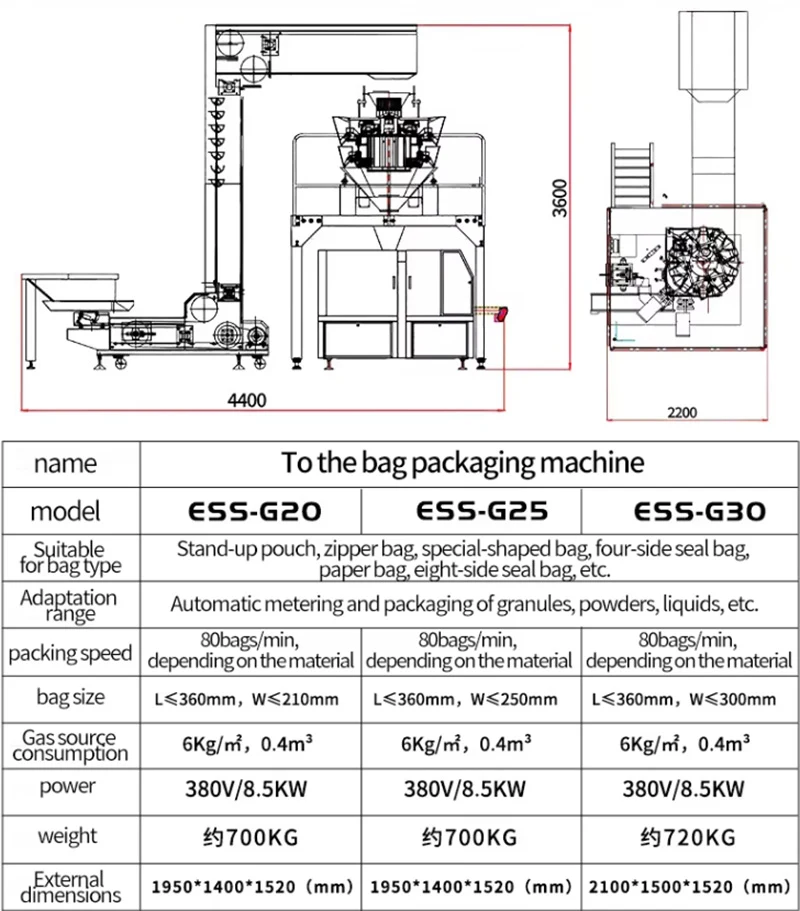

A rotary bag packaging machine is an automated device that achieves continuous packaging through a rotating worktable or multi-station mechanism. Its working principle is as follows: pre-made bags or roll film are positioned by a bag-taking/bag-making device, then pass through feeding, filling, sealing, printing, and sorting stations in sequence with the rotating worktable. Each station operates synchronously to achieve high-speed and precise packaging of materials (granules, powders, liquids,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Rotary Bag Packaging MachineAdvantages

1. Efficient continuous operation: The rotating station design enables a packaging speed of 30–120 bags per minute, increasing efficiency by over 40% compared to linear equipment, suitable for mass production.

2. Multi-station synchronous precision: The feeding system uses screw/weighing metering (accuracy ±0.5%–1%), and the sealing station is equipped with constant-temperature heat sealing or cold pressing to ensure sealing strength and appearance consistency.

3. Flexible bag-type adaptation: Supports pre-made bags (stand-up pouches, zipper bags) and roll film bag-making (three-side seal, back seal). Different specifications (50g–5kg) can be quickly switched by replacing molds.

4. High space utilization: The rotating structure integrates multiple processes within a worktable with a diameter of 1–3 meters, occupying only 60% of the floor space of traditional production lines, ideal for compact workshops.

5. Low loss and stability: Closed material paths reduce leakage, and servo motor drives ensure long-term failure rates <0.3%, with maintenance cycles extended to over 5,000 hours.

Rotary Bag Packaging MachineCharacteristics

1. Modular station design: Feeding, filling, and sealing modules can be independently disassembled for quick maintenance and functional expansion (e.g., adding metal detection or inflatable freshness preservation).

2. Intelligent human-machine interaction: A color touchscreen supports storing 100 sets of process parameters, real-time monitoring of operation data (output, energy consumption, fault codes), and compatibility with Industry 4.0 system data docking.

3. Hygienic-grade materials: Material-contact components use 316L stainless steel or food-grade engineering plastics, complying with FDA and GMP standards. Easy-to-clean designs meet high hygiene requirements in pharmaceutical and food industries.

4. Energy-saving design: Servo motors supply energy on demand, with standby power consumption <50W; waste recycling systems collect cutting residues, increasing packaging material utilization to over 98%.

Rotary Bag Packaging MachineApplication Fields

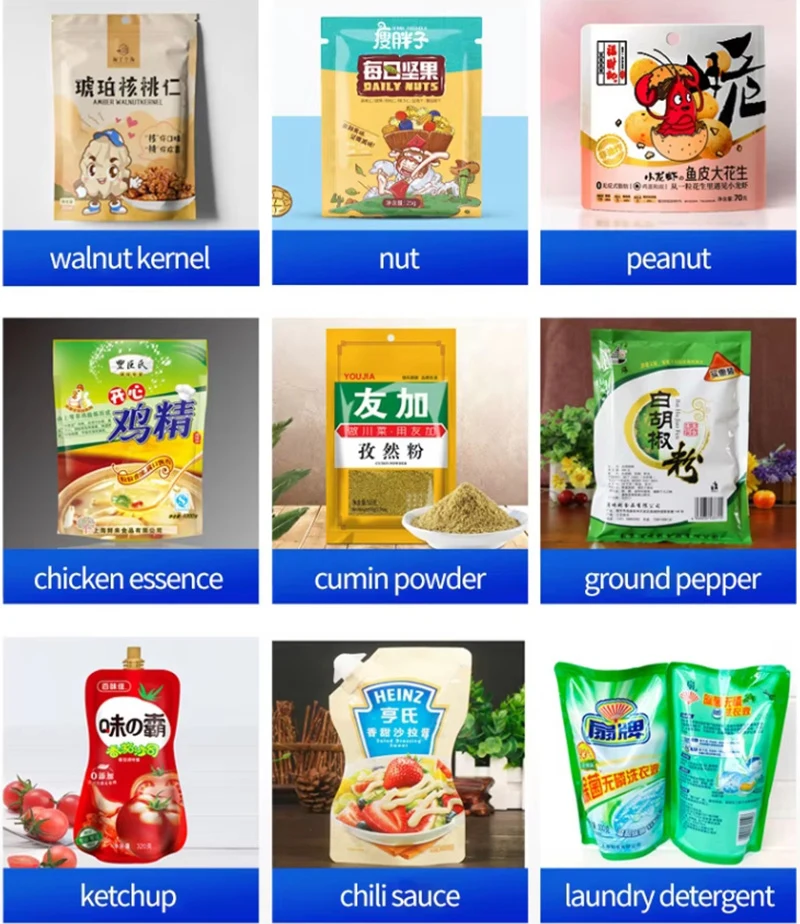

1. Food industry:

- Granules: Nuts, candies, pet food (stand-up pouch packaging);

- Powders: Milk powder, coffee powder (aluminum foil composite film moisture-proof packaging);

- Liquids: Soy sauce, juice (stand-up spout pouch filling).

2. Pharmaceutical industry:

- Aseptic filling of powder drugs and health product granules, supporting aluminum foil bags and polyester bottles, suitable for 100,000-class clean workshops.

3. Chemical industry:

- Leak-proof packaging for pesticide powders and pigment powders (explosion-proof motors optional), compatible with 500g–25kg specifications.

4. Daily necessities industry:

- High-speed packaging of washing powder and liquid detergent (bottle + bag dual mode), completing 80 bags of 2kg liquid detergent per minute.

5. Agricultural products industry:

- Vacuum packaging of rice and grains (extended shelf life), and weighing bag packaging of dried goods (e.g., wood ear, shiitake mushrooms), adapting to e-commerce small packages and supermarket bulk packaging.

Typical case: A condiment enterprise adopted a rotary bag packaging machine production line to achieve co-line production of chili sauce (liquid) and Chinese prickly ash powder (powder). With 15-minute quick model changeover, daily capacity reached 200,000 bags, labor costs decreased by 70%, and packaging loss rate dropped from 3% to 0.8%.

Product Description

Product Inquiry