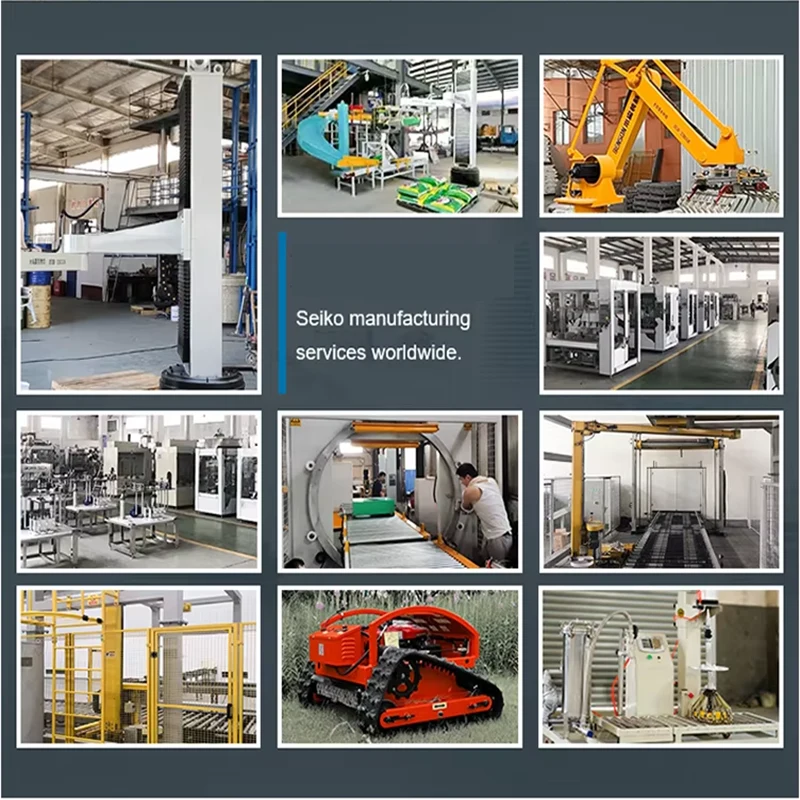

Corrugated cardboard loading articulated robot palletizer is an intelligent equipment developed specifically for packaging materials such as corrugated cardboard, core cardboard and cartons. It integrates advanced robot technology and automatic control technology, and can accurately and efficiently complete the grabbing, handling and palletizing of cardboard and cartons. It is widely used in carton factories, logistics warehousing, e-commerce sorting centers and other scenarios.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

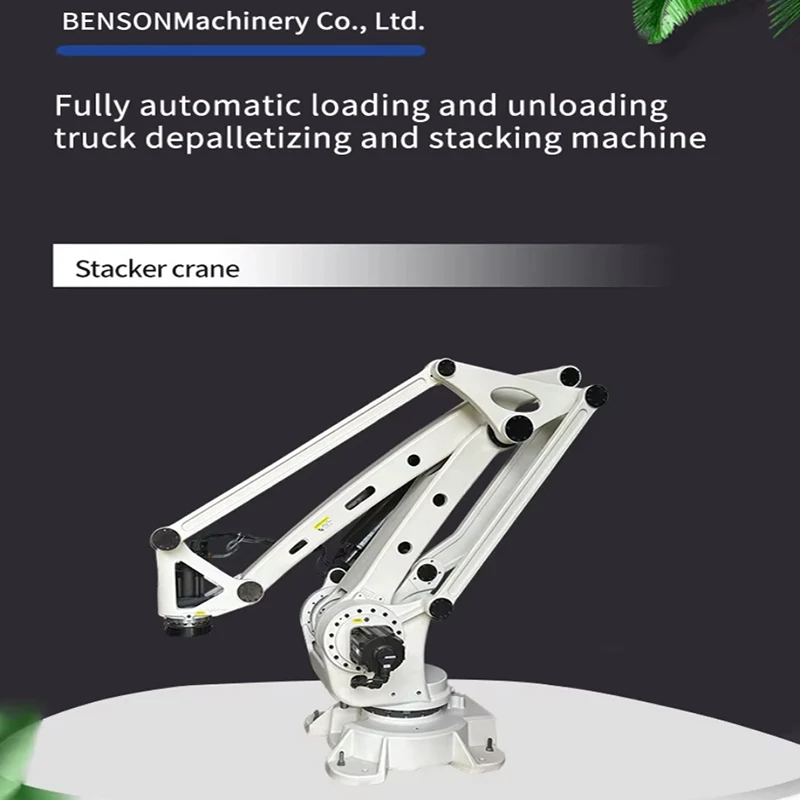

Corrugated cardboard loading articulated robot palletizer: efficient and intelligent packaging logistics solution

Product Overview

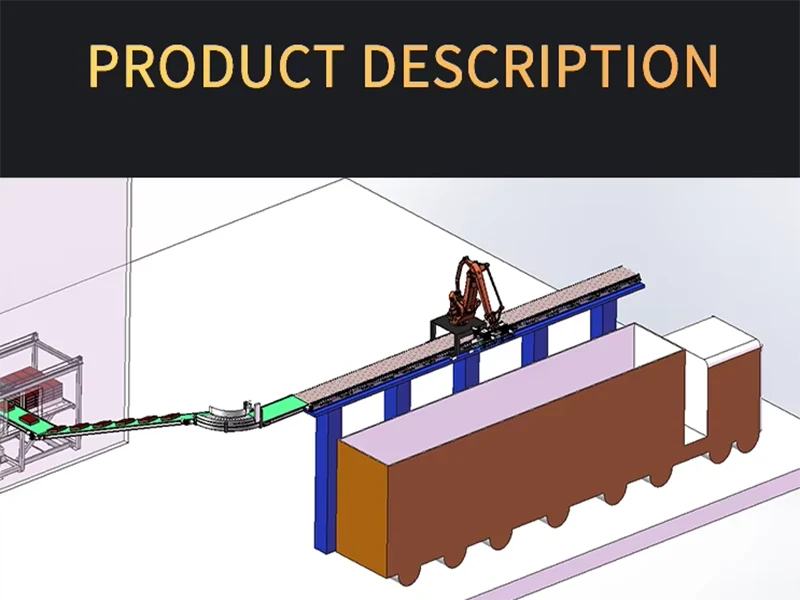

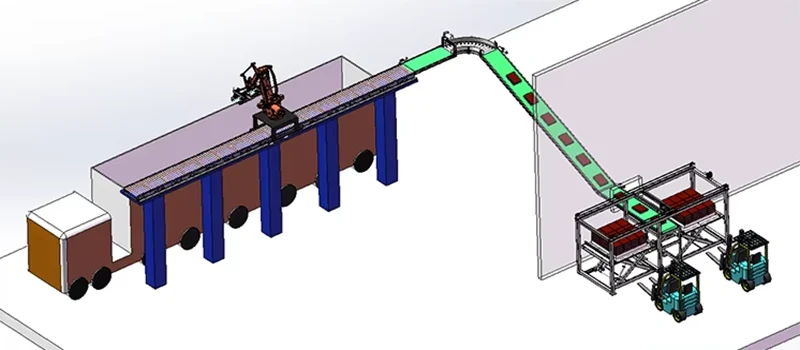

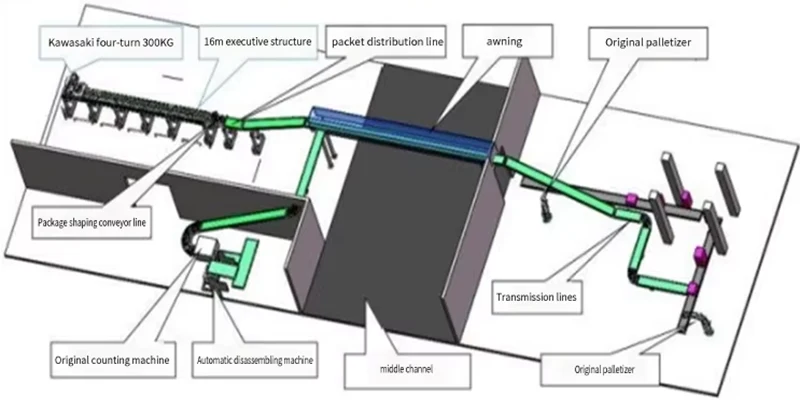

Corrugated cardboard loading articulated robot palletizer is an intelligent device developed specifically for packaging materials such as corrugated cardboard, core cardboard and cartons. It integrates advanced robot technology and automatic control technology, and can accurately and efficiently complete the grabbing, handling and palletizing of cardboard and cartons. It is widely used in carton factories, logistics warehousing, e-commerce sorting centers and other scenarios.

Core advantages

Efficient and stable: fast running speed, the maximum palletizing speed can reach [X] boxes/hour, and it can operate stably for 24 hours continuously. Compared with traditional manual palletizing, the efficiency is increased by 3-5 times, meeting the needs of large-scale production and rapid delivery of enterprises.

Flexible adaptation: supports palletizing tasks of various specifications of corrugated cardboard and cartons. Through simple program settings and mechanical adjustments, it can adapt to products of different sizes, weights and shapes. At the same time, it can customize exclusive palletizing solutions according to customer needs.

Safe and reliable: Equipped with multiple safety protection devices, such as light curtain sensors, emergency stop buttons, anti-collision devices, etc., it can effectively prevent operators from accidentally touching the equipment and ensure the safety of people and machines; the equipment uses high-strength materials and high-quality components, and has undergone rigorous testing and verification, with a low failure rate and easy maintenance.

Intelligent management: Equipped with an intelligent control system, it supports seamless connection with enterprise ERP, WMS and other management systems, realizes real-time monitoring, statistics and analysis of palletizing data, and facilitates production scheduling and resource optimization for enterprises.

Workflow of automatic loading robot for core cardboard sheets

Conveying and detection: Corrugated cardboard or cartons are transmitted to the working area of the palletizer through the conveyor line, and the sensors on the conveyor line automatically detect the arrival and size information of the product.

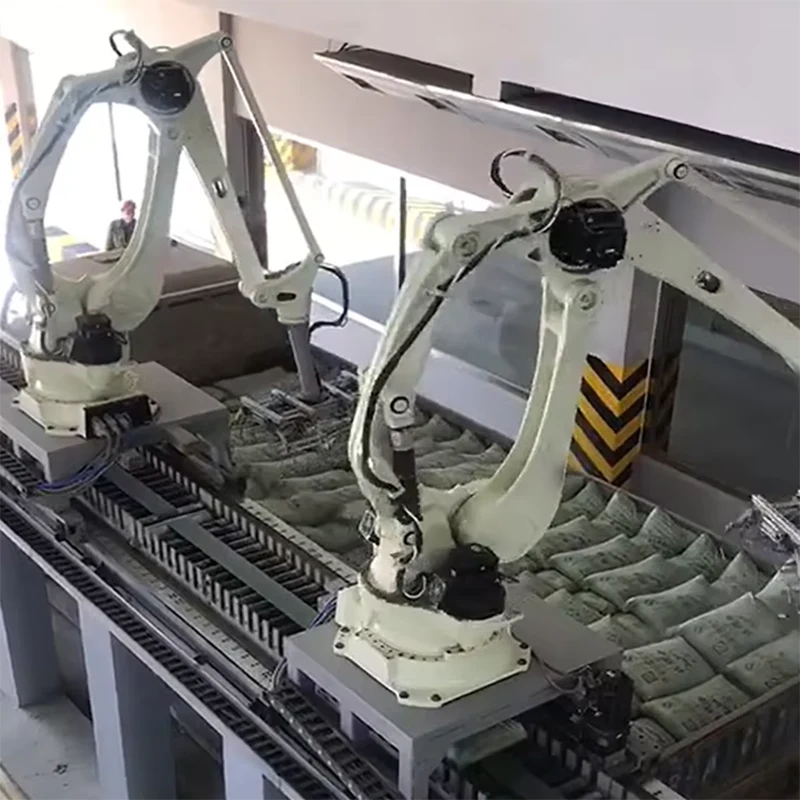

Visual recognition: The high-definition visual camera carried by the robot takes pictures of the product, and quickly calculates the position, angle and posture information of the product through the image recognition algorithm.

Precise grasping: The articulated robot adjusts the posture of the robotic arm according to the data provided by the visual system, and uses the end effector such as vacuum suction cups or grippers to accurately grasp the product.

Palletizing: The robot places the products layer by layer, column by column, and row by row on the pallet or designated area according to the preset palletizing program to complete the palletizing task.

Palletizing completed: When a pallet is palletized, the system automatically sends a prompt signal, and the forklift or AGV trolley transports the full pallet of products away, and replaces the new pallet to continue the operation.

After-sales service

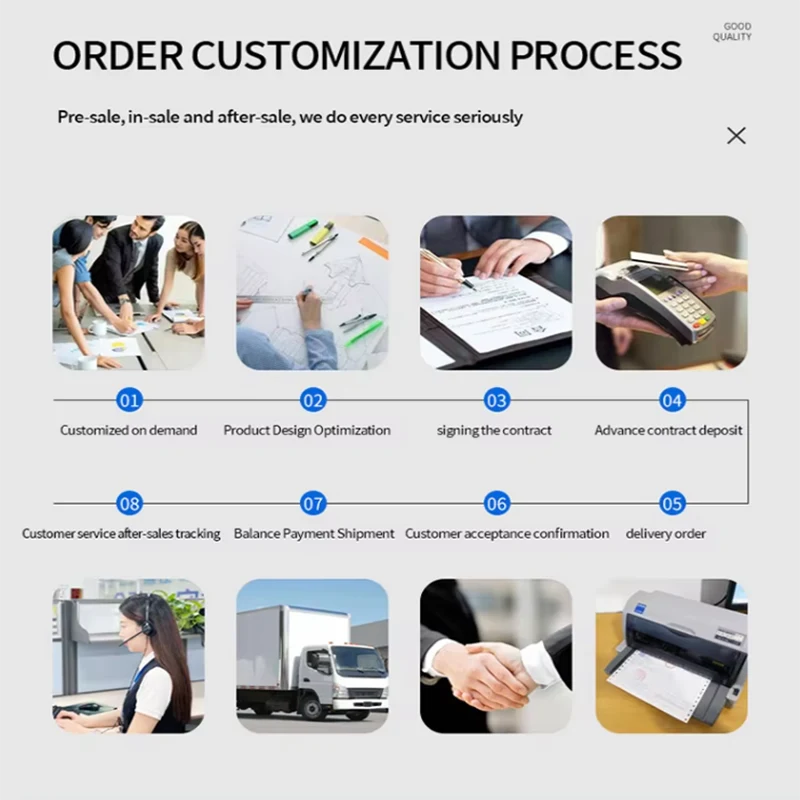

We provide a full range of after-sales services, including equipment installation and commissioning, operation training, regular maintenance, 24-hour technical support, etc., to ensure that your equipment always maintains the best operating condition. The professional after-sales team will respond to your needs quickly and solve any problems encountered during the use of the equipment, so that you have no worries.

Products Description

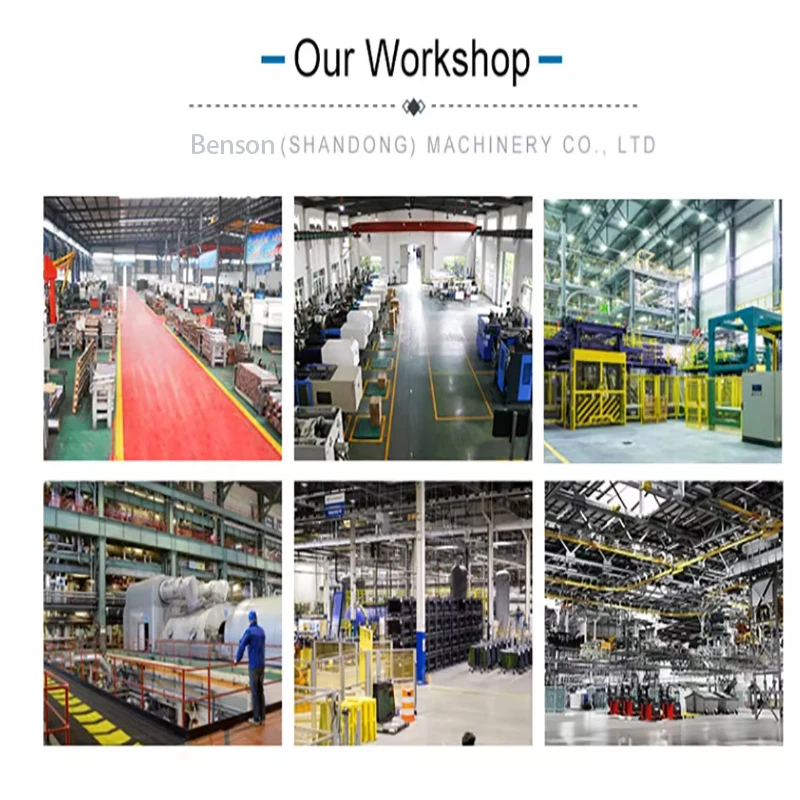

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry