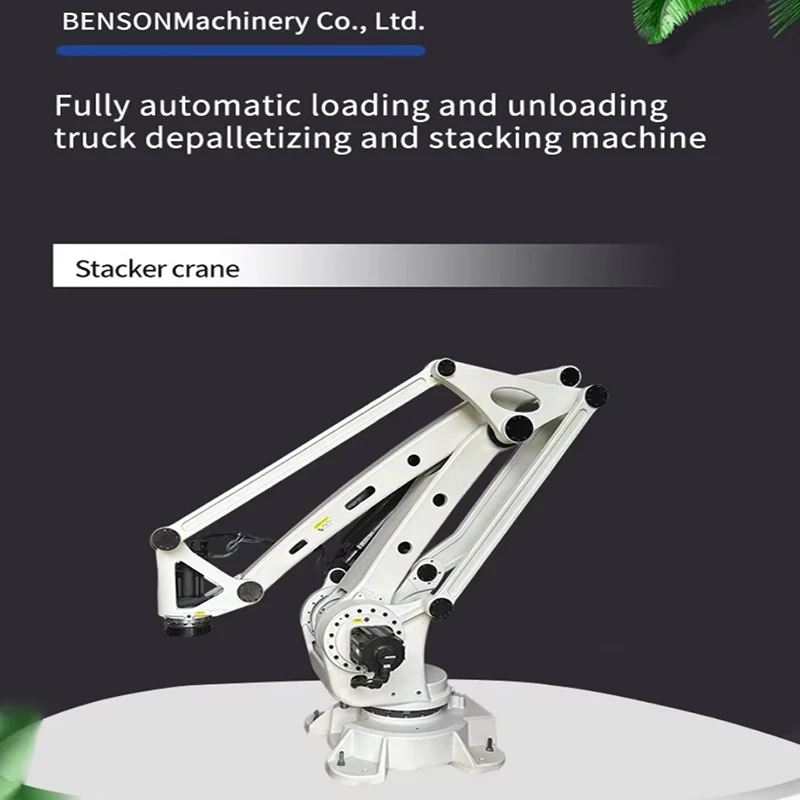

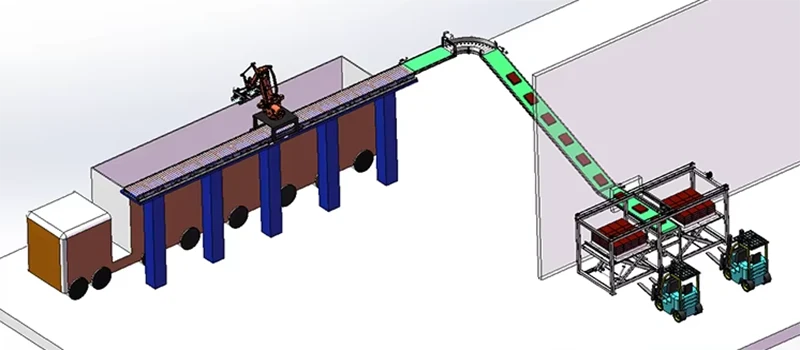

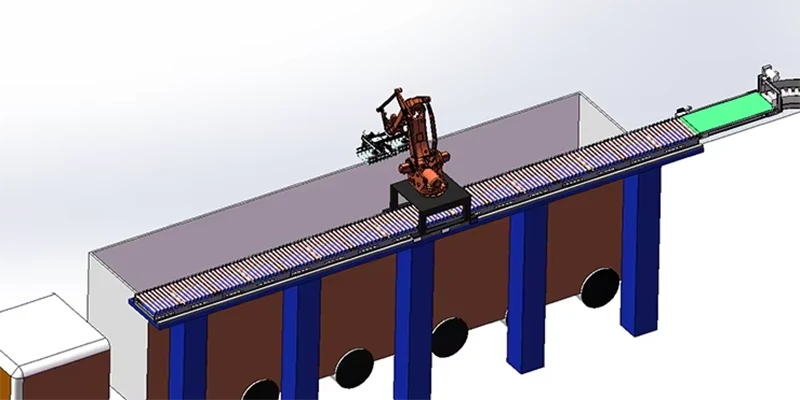

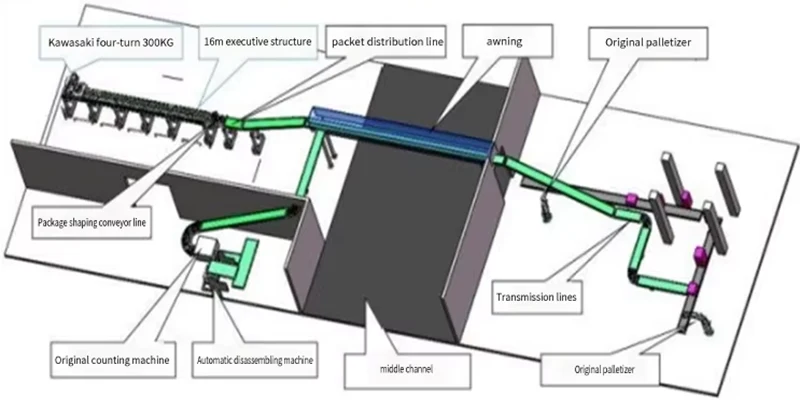

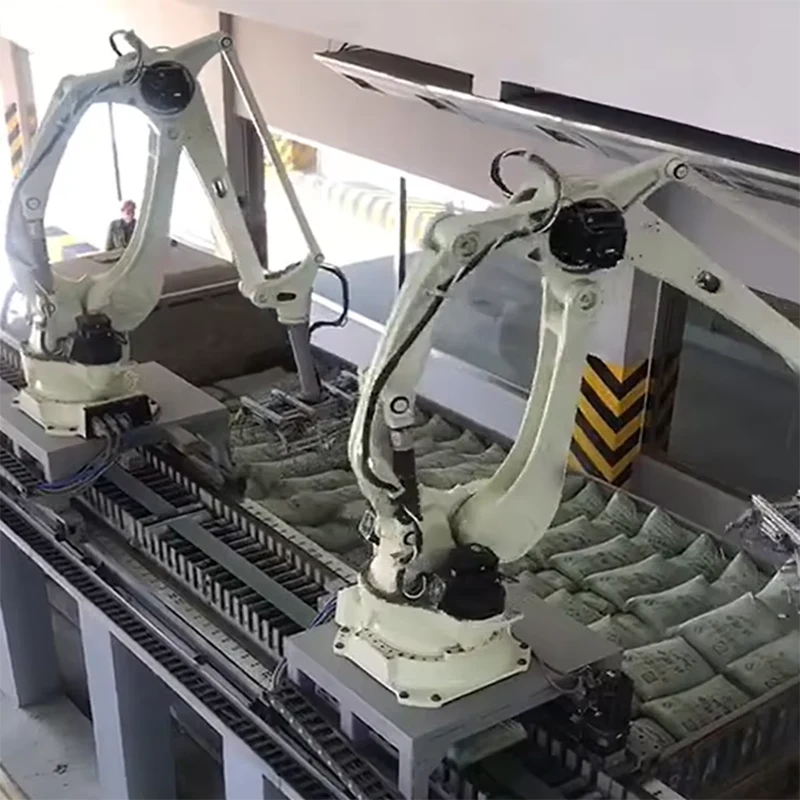

- The box-loading and palletizing robot has a wide range of motion: the large arm span can cover a large working space, meet the needs of diverse production layouts, and can complete tasks such as handling and palletizing in a large area; the 6-degree-of-freedom flexible joint design can achieve all-round motion and cope with complex position grasping.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

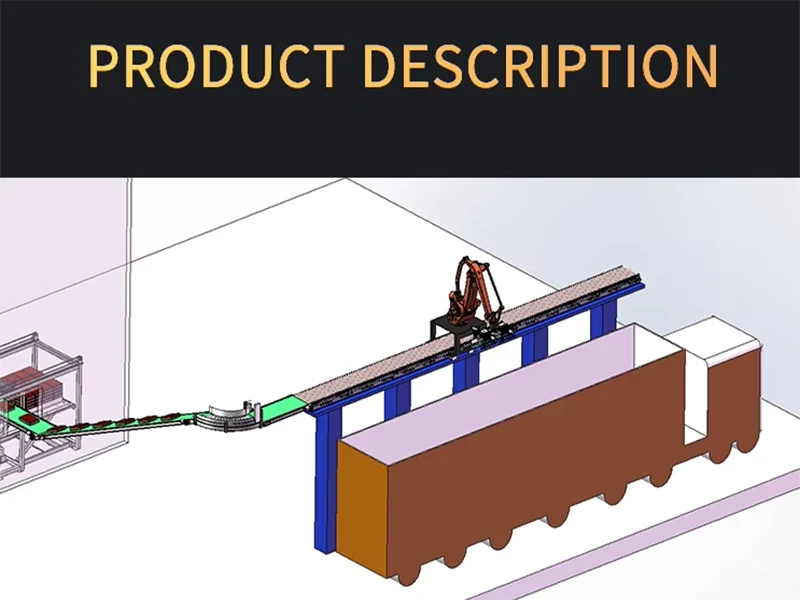

Products Description

- High production efficiency: high repetition accuracy, accurate and consistent operation, and reduced defective rate; fast handling speed, shortened operation cycle; continuous and stable operation, low failure rate for long-term high-intensity work.

- Advanced technology: The intelligent control system integrates artificial intelligence and other technologies to optimize the motion path in real time; the high-performance drive system provides powerful and stable power output; equipped with a variety of sensors, such as vision and force sensors, to ensure precise operation.

- Strong versatility: It can be used for various work scenarios such as handling, welding, palletizing, picking up, assembling, grinding, cutting, etc., and is suitable for many industries such as automobile manufacturing, mechanical processing, logistics and warehousing.

- Low cost: The program can repeat the action, which can reduce labor and time costs in large-scale production.

- Application scenarios: cargo handling and palletizing in the logistics and warehousing industry; welding operations in the automobile manufacturing, mechanical processing and other industries; picking up and assembling parts on the production line, etc.

Benson 180 joint palletizing robot

- Basic information: Designed for automated palletizing operations, the joints have a 180-degree working range and high flexibility.

- Product Features

- High efficiency: fast palletizing speed, such as up to 700 bags/hour, improves production efficiency.

- Strong stability: stable operation, and can ensure palletizing accuracy and stability even at high speed.

- Wide applicability: suitable for palletizing of various materials such as powder, granular, and boxed, covering flour, feed, chemicals, beer and beverages and other industries.

- Energy-saving design: operating power of 5kW, high energy efficiency.

- Intelligent operation: adopts intelligent management system, simple operation process, easy to use, can reduce labor costs and labor intensity.

- Flexible structure: may be equipped with special clamps such as claw finger type, adapt to packaging of different shapes and materials, and ensure compact and neat palletizing.

- Application scenario: mainly used for efficient and accurate palletizing of various materials on industrial production lines, and can be combined with fully automatic carton sealing machines, balers, etc. to form a complete production line.

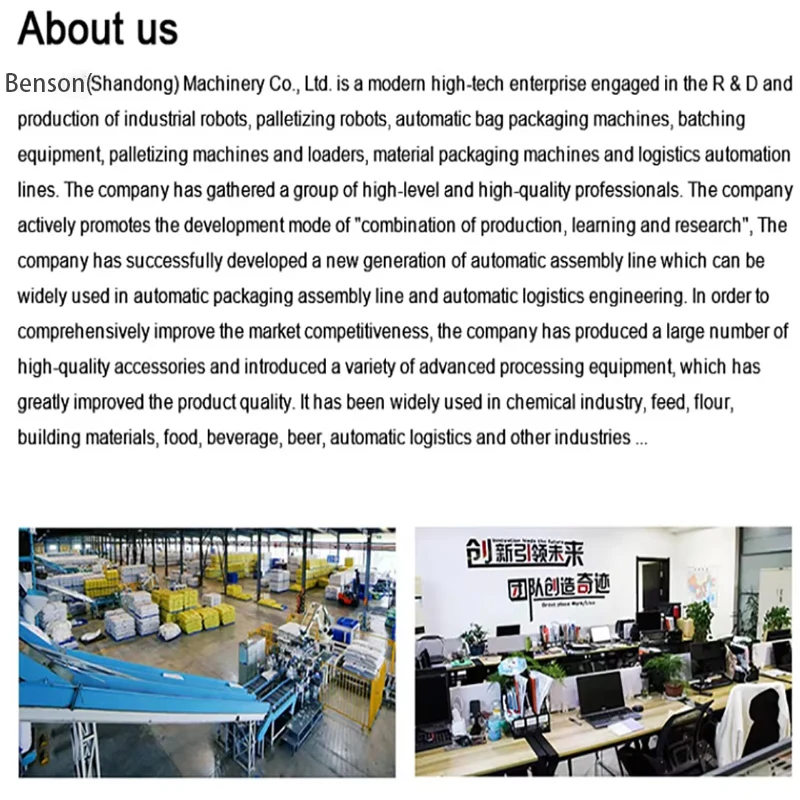

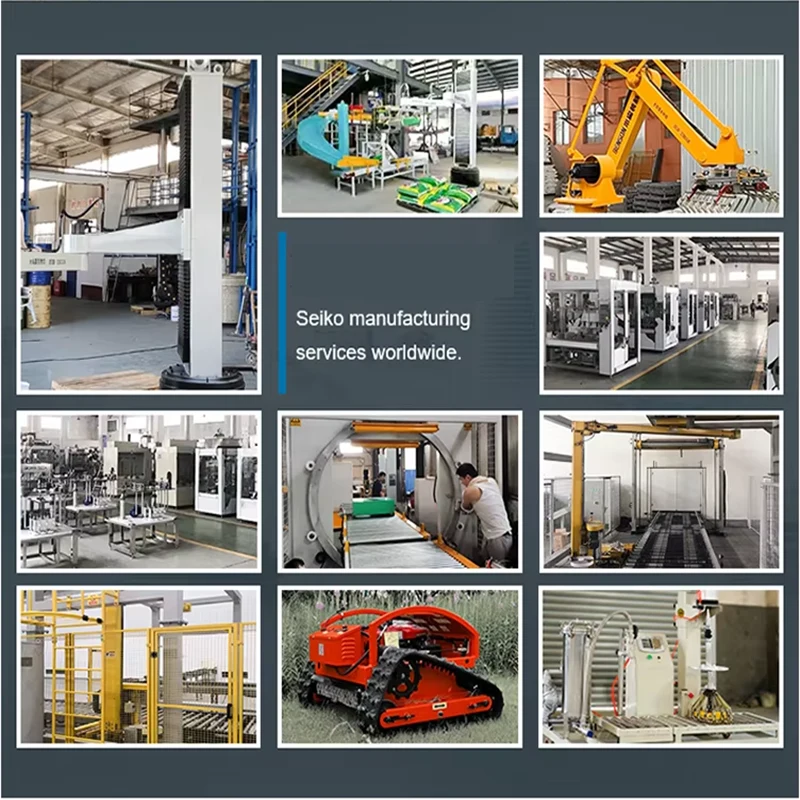

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

Product Inquiry