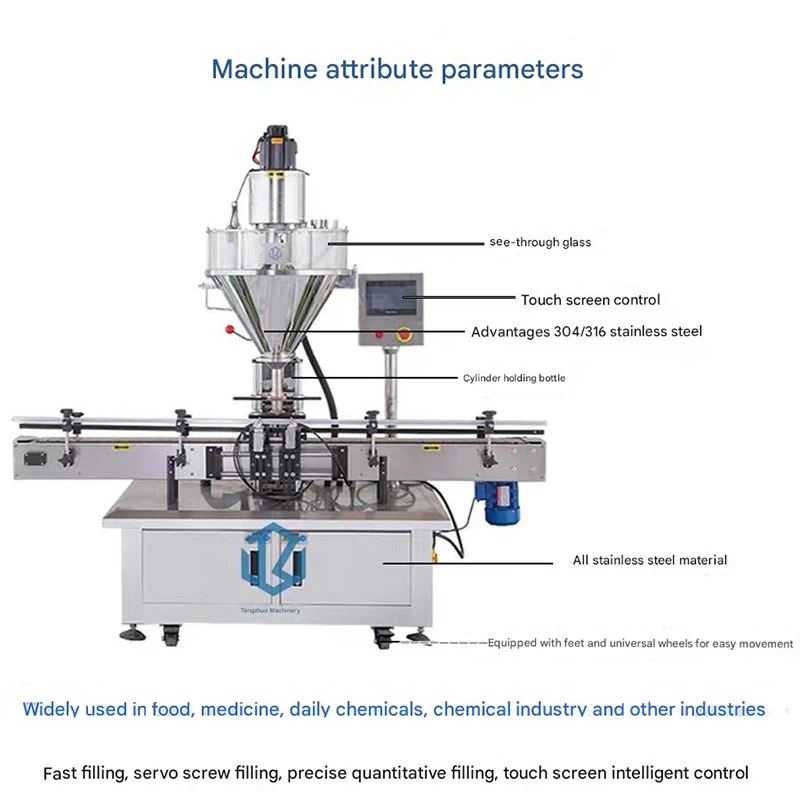

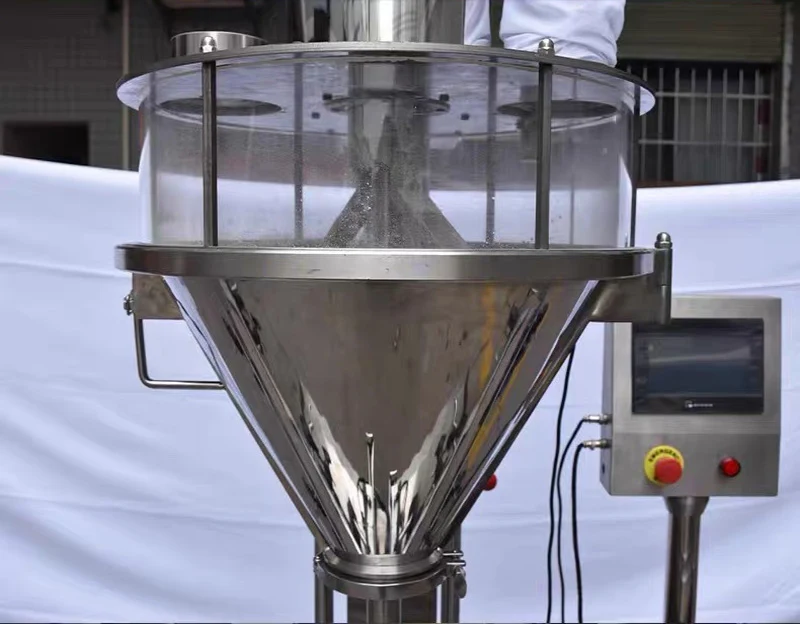

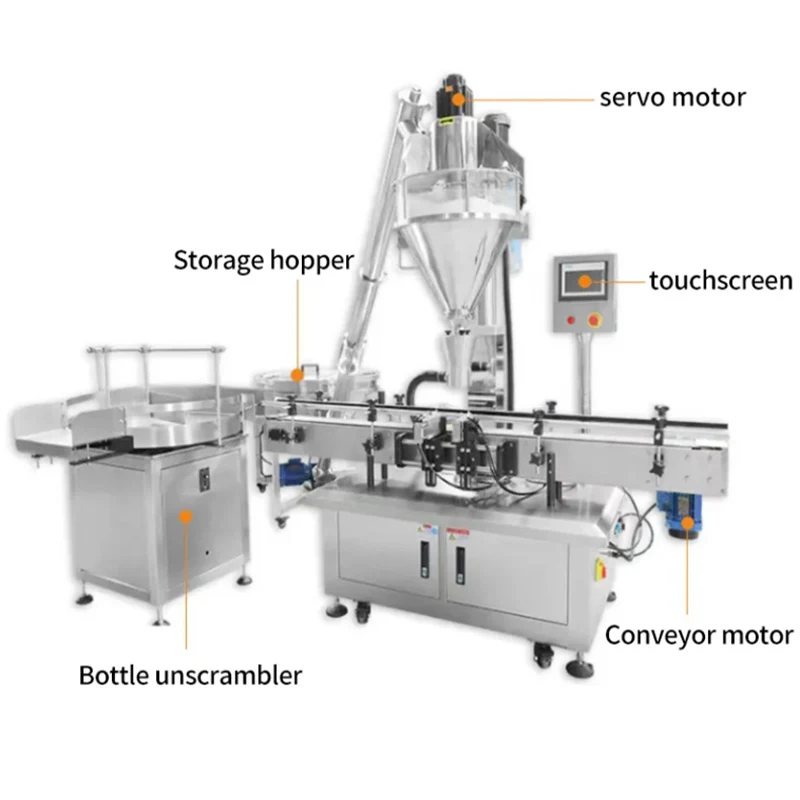

The cumin barbecue powder filling machine is an automated packaging device specially designed for powdery food seasonings like cumin barbecue powder, primarily used for quantitative filling and packaging of powdery materials. The equipment uses a servo motor or stepper motor as the power source, paired with a high-precision screw metering device or gravitational metering system, and precisely controls the filling process through a PLC control system.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

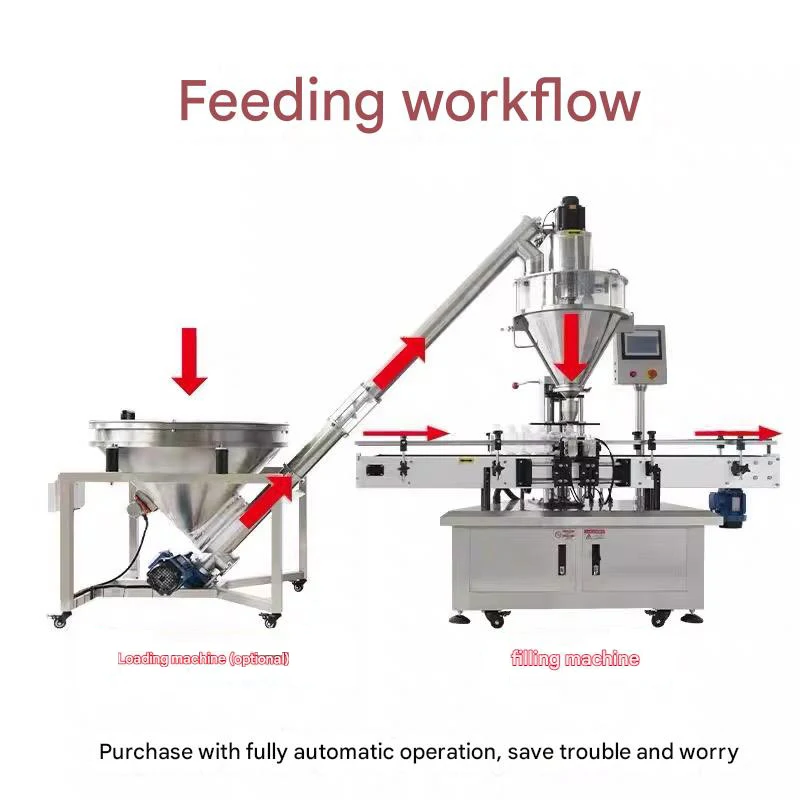

During operation, powdery materials are transported from the storage hopper to the metering device. After precise weighing or volumetric measurement, they are filled into pre-made packaging bags, bottles, or cans through a feeding tube, and can simultaneously complete processes such as sealing and labeling. It is suitable for small-to-medium batch or large-scale production scenarios.

Cumin barbecue powder filling machine Advantages

1. High-Precision Metering: Using technologies such as screw(screw dosing) and electronic weighing, filling accuracy can reach ±0.5%-1%, avoiding errors and material waste in manual filling, especially suitable for high-value seasoning powders.

2. High Efficiency and Stability: Capable of completing 20-60 filling operations per minute (depending on packaging specifications), with high automation to reduce manual intervention, improve production efficiency, and suit continuous production.

3. Dust-Proof and Leak-Proof Design: A fully enclosed filling channel with a dust removal device effectively prevents powder spillage and dust, maintaining a clean production environment. A drip-proof feeding nozzle avoids material residue and packaging contamination.

4. Flexible and Adjustable: Supports multiple packaging specifications (e.g., 50g, 100g, 500g). Filling volume can be quickly switched via parameter settings or replacing the metering screw, adapting to different brands and types of powdery seasonings.

5. Low Maintenance Cost: Key components (e.g., screws, seals) are made of wear-resistant stainless steel, corrosion-resistant and easy to disassemble for cleaning, reducing wear and tear and extending equipment lifespan.

Cumin barbecue powder filling machineApplications

1. Condiment Industry:

- Main products: Cumin barbecue powder, chili powder, Sichuan pepper powder, five-spice powder, and other powdery compound seasonings.

- Packaging forms: Plastic bags, aluminum foil bags, glass bottles, metal cans, etc., suitable for household and commercial catering packaging.

2. Food Processing Industry:

- Used for filling powdery seasonings in pre-made meals and barbecue ingredient processing plants, such as marinades and seasoning packets.

3. E-Commerce and Retail Sector:

- Meets small-specification packaging needs for e-commerce (e.g., 10g portable packs) and large-specification products for supermarket shelves (e.g., 1kg family packs).

Cumin barbecue powder filling machineFeatures

1. Intelligent Operation: An intuitive touchscreen interface supports storage of multiple formulas, allowing one-click switching of filling parameters for different products, reducing professional requirements for operators.

2. Hygienic and Compliant: Components in contact with materials use food-grade 304 stainless steel or food-grade plastic, complying with food hygiene standards such as FDA and GB 14881. They support quick disassembly and cleaning to meet high-frequency production hygiene needs.

3. Safety Protection: Equipped with overload protection and a fault alarm system, automatically stopping operation in case of blockages, missing bags, or other anomalies to prevent equipment damage and material waste.

4. Integrated Design: Can be linked with upstream material mixers and downstream sealing machines, cartoners, etc., to form a fully automated production line, enhancing overall production efficiency.

Products Description

Product Inquiry