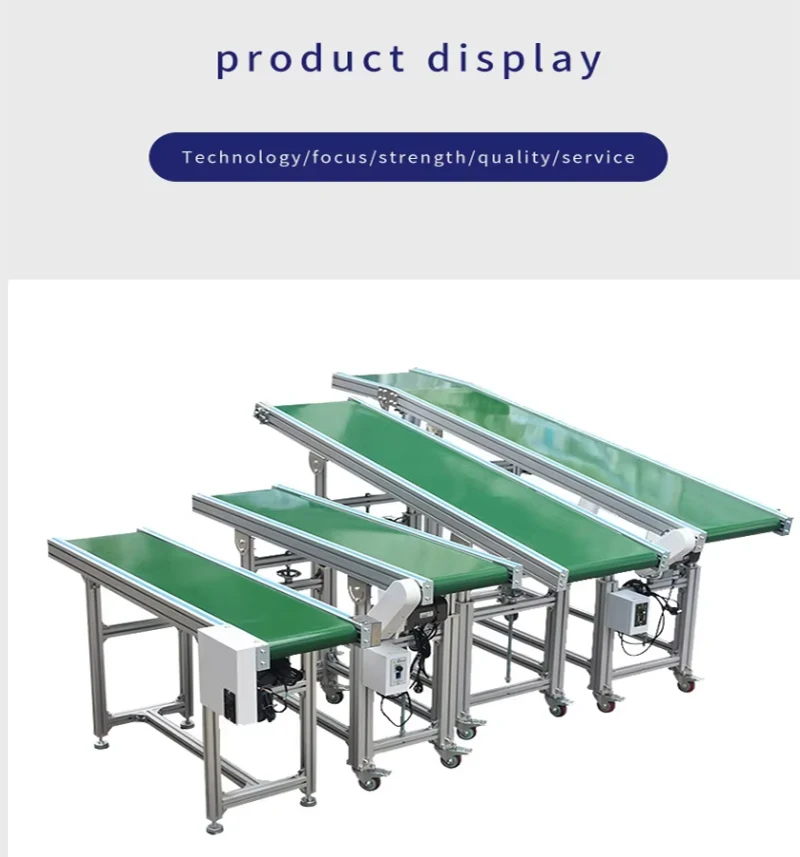

PVC belt aluminum frame conveyor - efficient and durable modern material conveying solution

Against the background of growing demand for industrial automation and refined production, PVC belt aluminum frame conveyor has become the preferred equipment for food, electronics, medicine and other industries with its lightweight design, excellent corrosion resistance and stable transmission performance.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

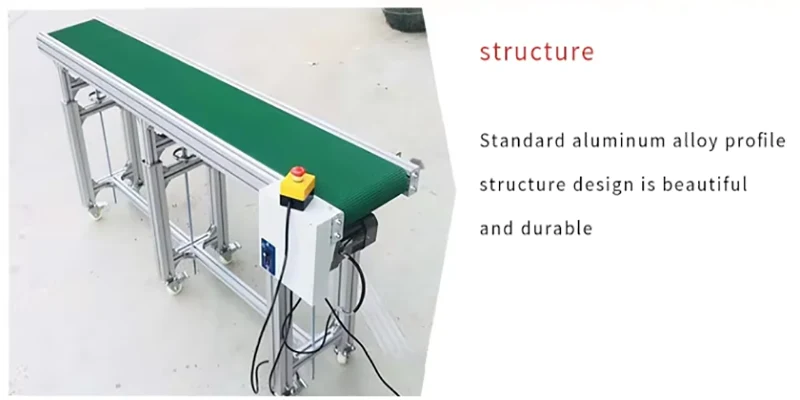

Core structure and innovative design of PVC belt aluminum frame conveyor

1. High-strength aluminum alloy frame: Made of 6061/T6 industrial-grade aluminum alloy, it is precision-processed and anodized, with high strength, lightweight and corrosion resistance. Compared with traditional steel frames, it is 40% lighter and can adapt to complex environments such as humidity, acid and alkali, effectively extending the service life of the equipment.

2. High-quality PVC conveyor belt: Made of food-grade, anti-static or wear-resistant PVC material, the surface is flat and non-slip, with the advantages of tear resistance, wear resistance and easy cleaning; different colors such as green and white can be customized according to needs to meet the hygiene and safety standards of food, electronics and other industries.

3. Modular assembly design: The aluminum frame adopts a snap-on or bolted connection structure, which supports quick disassembly and assembly, and is easy to transport, install and maintain later; the conveying length, width and angle can be flexibly adjusted to adapt to various production scenarios.

PVC belt aluminum frame conveyor excellent performance advantages

- Efficient and stable transmission: equipped with variable frequency speed regulation motor and high-precision roller, it can achieve 0.1-5m/s stepless speed regulation to ensure smooth material transportation; precision bearing and low friction roller design can reduce running resistance and save more than 20% energy consumption.

- Corrosion-resistant and easy to maintain: both aluminum alloy frame and PVC belt are corrosion-resistant, and are not afraid of moisture and slightly acidic and alkaline environment; open structure design makes belt replacement and component maintenance more convenient, and maintenance costs are reduced by 30%.

- Safe and environmentally friendly design: standard safety devices such as guardrails and emergency stop switches to ensure the safety of operators; PVC material has no odor and pollution, complies with international environmental protection and safety certifications such as RoHS and FDA, and is suitable for high-demand industries such as food and medicine.

PVC belt aluminum frame conveyor multiple application scenarios

- Food industry: used for sorting, packaging and transportation of bread, candy, fruits and vegetables, etc. Food-grade PVC belts ensure that materials are pollution-free and meet hygiene standards.

- Electronics industry: Smooth transmission of precision electronic components, anti-static PVC belts effectively avoid static damage to products and improve production yield.

- Pharmaceutical industry: Clean transportation of drugs and medical devices, white food-grade PVC and rust-proof aluminum frames meet GMP specifications.

- Light industrial manufacturing: Assembly and packaging line transportation of daily necessities, stationery, toys and other products, lightweight design reduces equipment operation load.

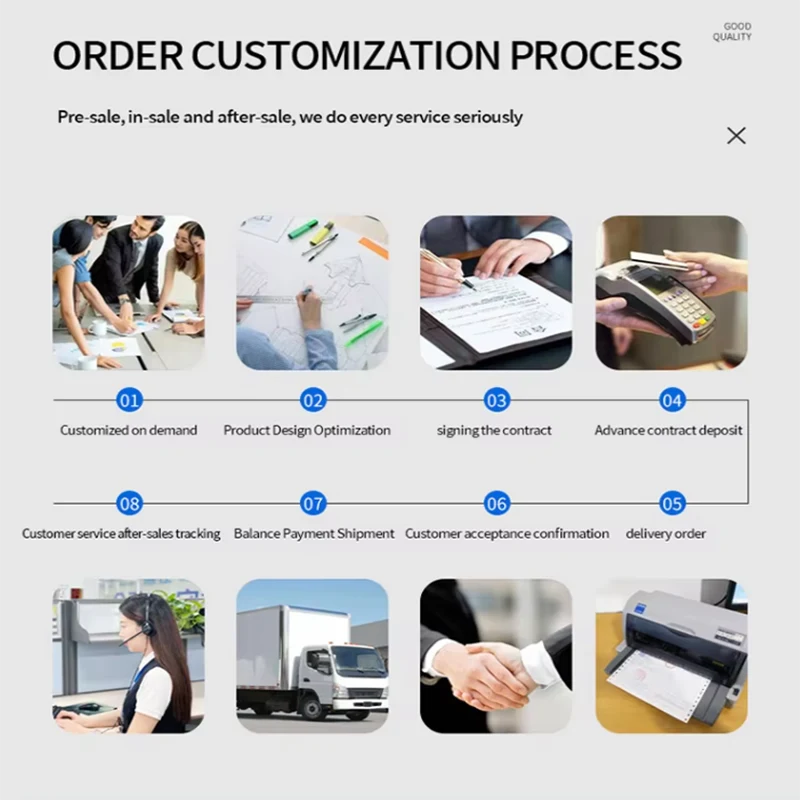

Customized service and support

We provide full-process customized services and flexibly adjust according to customer needs:

- Size customization: Free selection of conveying length, width and height to adapt to different production line layouts.

- Function upgrade: Integrated scanning, weighing, sorting, climbing and other modules to achieve seamless connection of automated production.

- After-sales guarantee: Professional team provides installation and commissioning, operation training and 24-hour response service to ensure efficient operation of equipment.

Choose PVC belt aluminum frame conveyor to inject efficiency and stability into your production line with innovative design and reliable quality!

Products Description

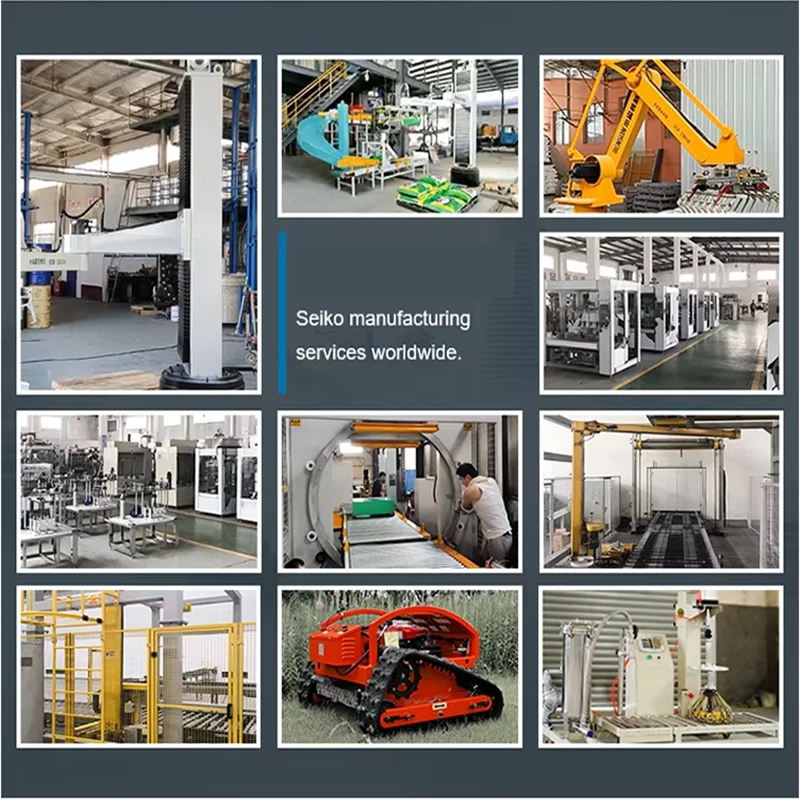

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry