The gravity valve cement powder filling machine is a device that achieves automatic filling of cement powder using the principle of gravity. It controls material flow through a gravity valve to accurately convey cement powder from the storage bin into packaging containers (such as paper bags and plastic woven bags). Integrated with weighing sensors and a control system, the equipment enables quantitative filling, suitable for large-scale powder packaging in cement production, warehousing,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

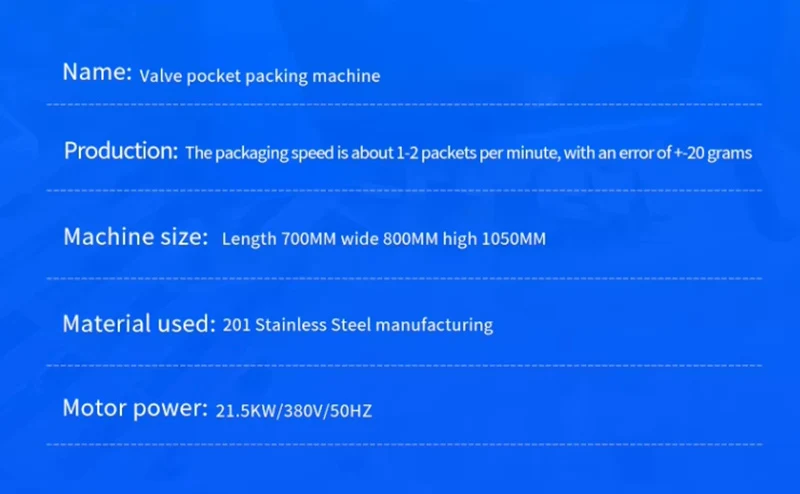

Gravity valve cement powder filling machineAdvantages

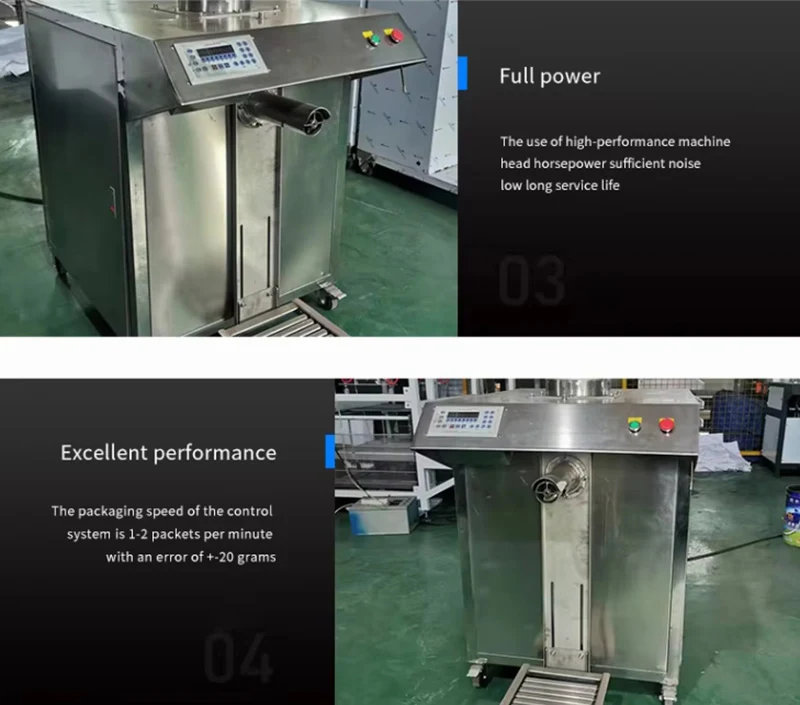

1. High Efficiency and Energy Saving: Utilizing gravity-driven self-flow filling requires no additional power to drive material flow, resulting in low energy consumption. Combined with continuous operation, it can complete 300-600 bags of filling per hour, significantly improving production efficiency.

2. Precise Metering: High-precision weighing modules monitor filling weight in real time, with errors controlled within ±0.5%, ensuring consistent weight for each bag of cement powder and reducing material waste and manual rechecking costs.

3. Dust-Proof and Environmentally Friendly: The gravity valve is equipped with a sealed discharge port and a negative pressure dust collection system, effectively suppressing dust overflow during filling, reducing dust concentration in the working environment, and complying with environmental standards and occupational health requirements.

4. Easy Operation: The intelligent control system supports one-click start/stop and parameter presetting. Operators can quickly adjust parameters such as filling weight and valve opening/closing speed via a touchscreen, lowering the threshold for manual operation.

Gravity valve cement powder filling machineApplications

1. Cement Production Industry: Used for packaging various cement powders such as ordinary Portland cement, slag cement, and fly ash cement, meeting the market’s demand for standardized bagged cement in the building materials industry.

2. Concrete Batching Plants: Provides precise filling of bulk or bagged cement powder for batching plants, ensuring accurate cement metering in concrete production and enhancing concrete quality stability.

3. Warehousing and Logistics: Suitable for the transfer and warehousing of cement powder, quickly repackaging bulk cement powder into bagged products for easy transportation, reducing loss and pollution risks during logistics.

4. Special Building Materials Production: Can be extended to fill similar powder materials such as gypsum powder and mineral powder, meeting the versatility needs of special building materials enterprises for powder packaging equipment.

Gravity valve cement powder filling machineCharacteristics

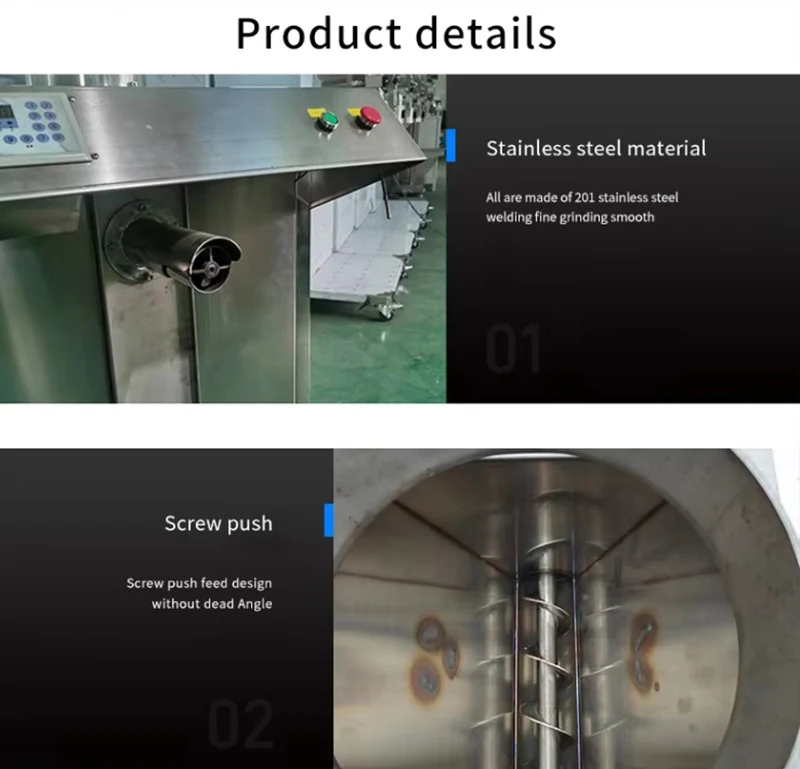

1. Gravity-Driven Structure: Adopts a non-powered gravity filling mode with a simple and reliable structure, low maintenance costs, and is particularly suitable for free-flowing powder materials like cement powder.

2. Intelligent Control System: Integrates a PLC programmable controller and weighing instrument, supporting real-time data monitoring, production report generation, and fault self-diagnosis for easy production management and quality traceability.

3. Modular Design: Key components (such as gravity valves and weighing platforms) use modular assembly, supporting quick disassembly and maintenance, reducing equipment downtime, and adapting to 24-hour continuous production.

4. Multiple Sealing Protections: Silicone sealing rings and pneumatic clamping devices are used at the interface between the discharge port and packaging bag to ensure no dust leakage during filling and prevent external moisture from entering the bag.

5. Highly Compatible Packaging: Can adapt to packaging bags of different specifications (5-50kg). By adjusting the valve opening and filling speed, it meets the needs of different packaging weights and material characteristics.

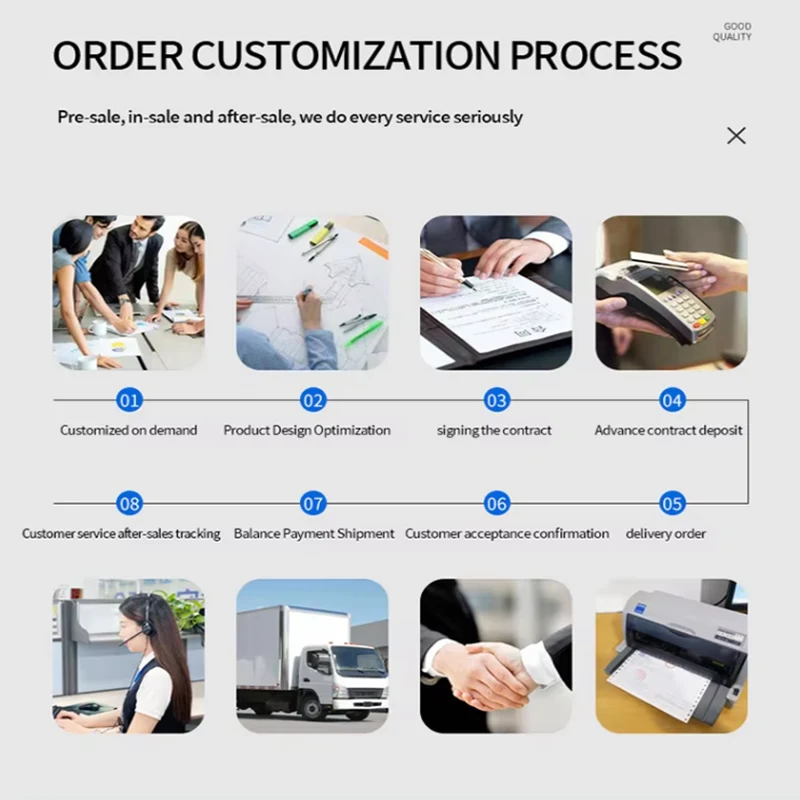

Product Inquiry