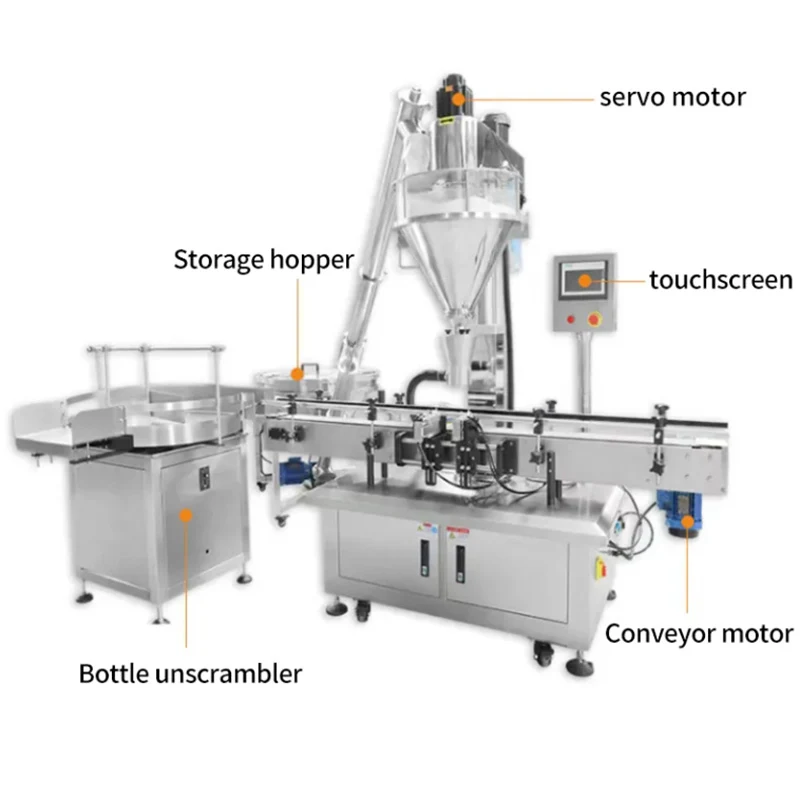

The powder distribution machinery talcum powder filling machine is a specialized piece of equipment designed for the accurate and efficient filling of talcum powder. It integrates advanced powder distribution technology with precise metering systems. The machine typically consists of components such as a powder storage hopper, a conveying mechanism, a filling head, and a control system. The powder storage hopper holds the talcum powder, and the conveying mechanism transports it to the filling

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Powder Distribution Machinery: Talcum Powder Filling MachineAdvantages

1. High Precision:Utilizes advanced sensors and control algorithms to achieve extremely accurate filling volumes, minimizing product waste and ensuring product quality consistency. Deviation from the set filling amount can be controlled within a very narrow range, meeting strict production requirements.

2. High Efficiency:Capable of continuous high - speed operation, significantly increasing production capacity. It can handle a large number of containers in a short time, reducing production time and labor costs, which is suitable for mass production environments.

3. Automation:Fully automated operation reduces the need for manual intervention, improving production efficiency and reducing human - error - related filling inaccuracies. The control system can be programmed to adjust filling parameters according to different production needs, and it can also monitor the operation status in real - time and give alarms in case of malfunctions.

4. Dust - Control Design:Features special dust - prevention structures, such as sealed chambers and dust - extraction devices. This helps to minimize talcum powder dust diffusion during the filling process, creating a cleaner and safer working environment while also reducing powder loss.

5. Flexibility:Can be easily adjusted to fill different container sizes and shapes, from small bottles to large industrial - sized containers. Additionally, it can adapt to different production batches, whether for small - scale custom production or large - scale commercial production.

Powder Distribution Machinery: Talcum Powder Filling MachineApplications

1. Cosmetics Industry:Widely used for filling talcum powder products like body powder, baby powder, and face powder into various packaging containers, such as plastic bottles, cardboard boxes with shaker lids, and sachets. These products are popular personal care items, and the accurate filling provided by the machine is crucial for maintaining brand quality and consumer satisfaction.

2. Pharmaceutical Industry:Used for filling talcum powder - based pharmaceutical products, such as certain topical powders for medical treatment. In the pharmaceutical field, strict hygiene and precision requirements are necessary, and this filling machine can meet these standards to ensure the safety and efficacy of the products.

3. Industrial Manufacturing:In industries where talcum powder is used as a lubricant, release agent, or filler, such as in the rubber, plastic, and ceramic manufacturing processes. The machine can accurately fill talcum powder into containers used in the production line, ensuring the proper proportion of additives in the manufacturing process.

4. Chemical Industry:For the production and packaging of talcum powder - related chemical products, including some chemical raw materials or intermediate products that use talcum powder as an ingredient. The high - precision filling function helps to control the quality of chemical products.

Powder Distribution Machinery: Talcum Powder Filling MachineCharacteristics

1. Robust Construction:Built with high - quality materials and a sturdy structure to withstand the rigors of continuous operation and the abrasion caused by talcum powder. This ensures long - term reliable performance and a relatively long service life.

2. Easy Maintenance:Designed with a modular structure, making component replacement and maintenance simple. Quick - release connections and accessible parts allow maintenance personnel to clean and repair the machine efficiently, reducing downtime and maintenance costs.

3. Hygienic Design:In compliance with strict hygiene standards, especially important for applications in the cosmetics and pharmaceutical industries. The surfaces in contact with talcum powder are smooth and easy to clean, preventing powder residue accumulation and the growth of bacteria or contaminants.

4. Intelligent Control:Equipped with an intelligent control panel that enables operators to easily set filling parameters, monitor production data, and adjust the machine's operation. Some advanced models may also support data logging and communication with other production systems for better production management and quality control.

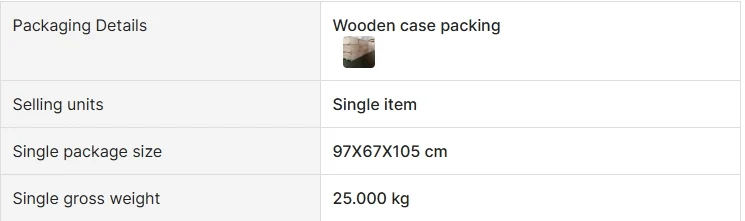

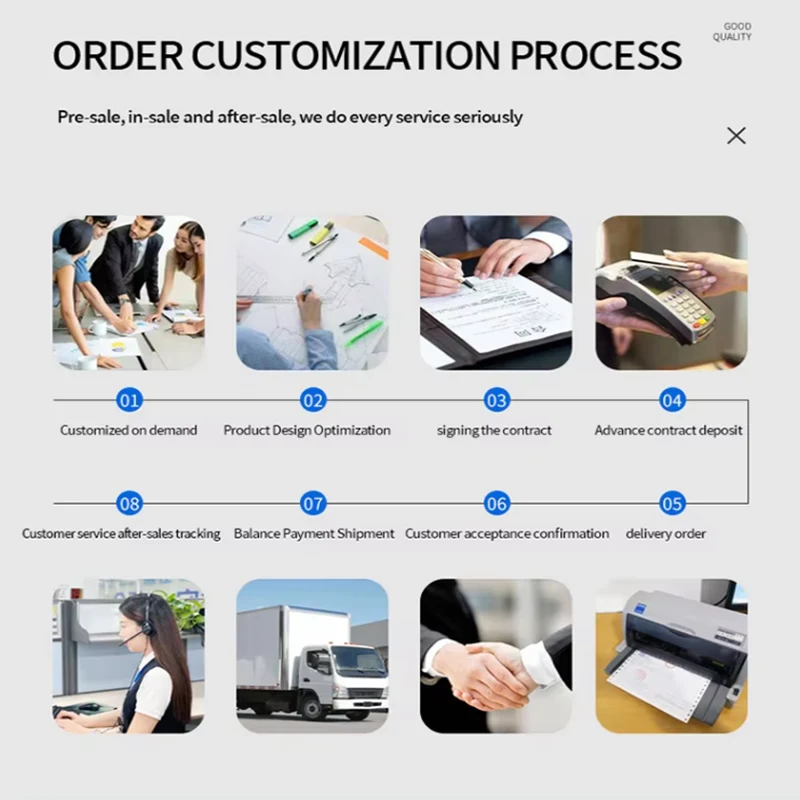

Products Description

Product Inquiry