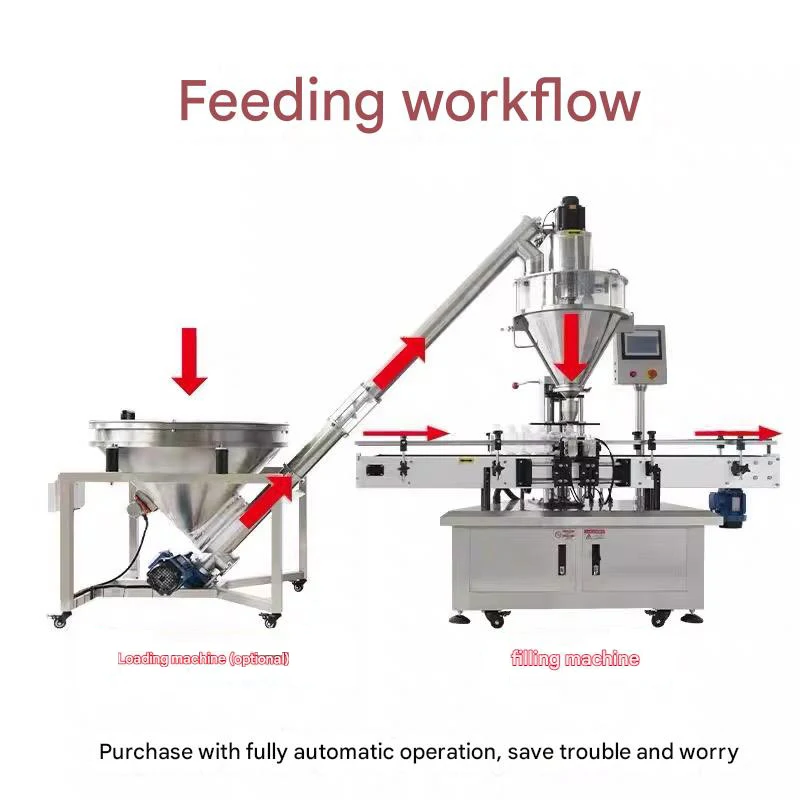

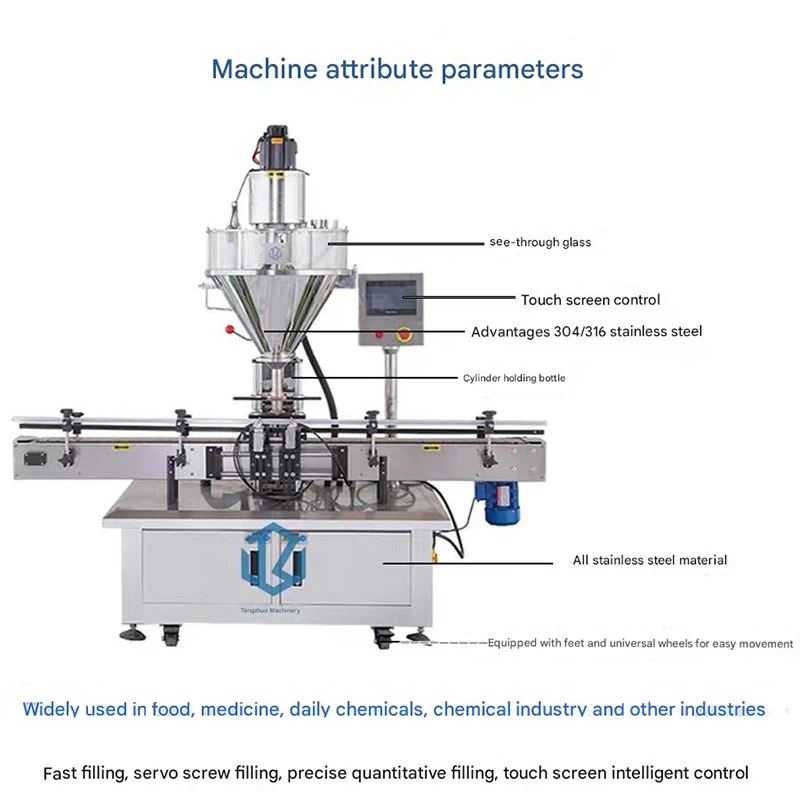

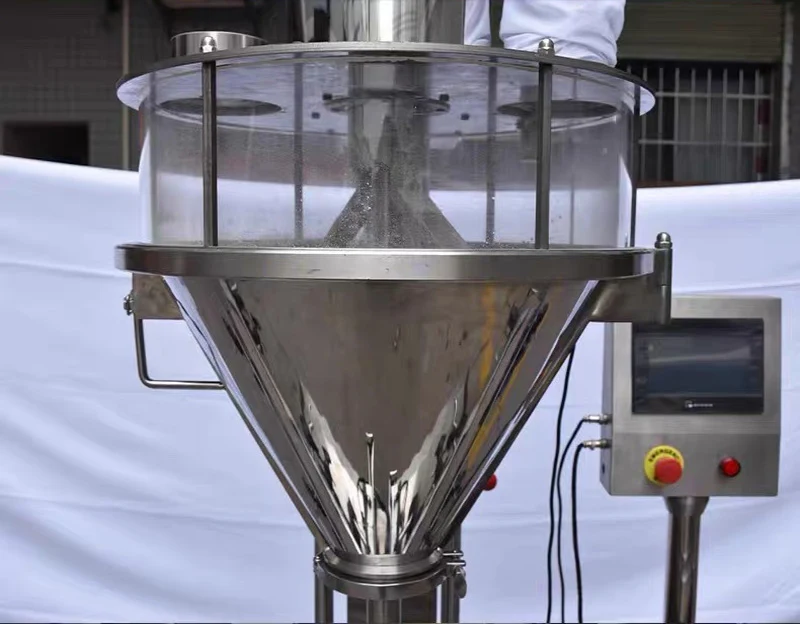

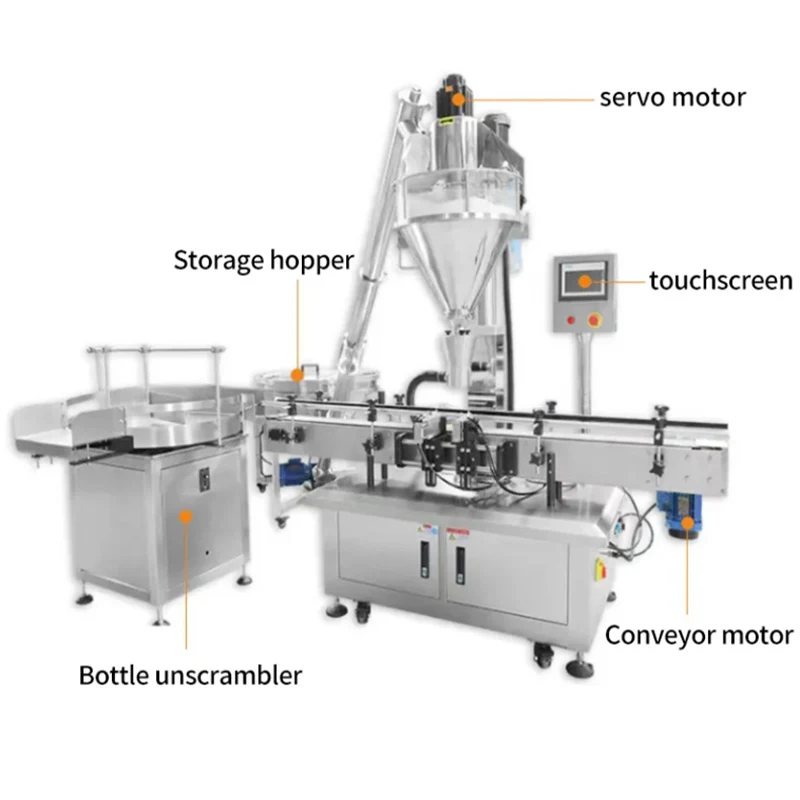

The Powder Filling Machine is specialized industrial equipment designed to accurately measure and dispense powdered materials into various packaging containers. It integrates mechanical, electrical, and pneumatic technologies to ensure consistent and reliable filling operations. Whether handling fine powders like pharmaceutical ingredients, food additives, or industrial powders such as chemicals and pigments, this machine can adapt to different powder characteristics, including particle size,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Powder Filling MachineAdvantages

1. High Precision: Utilizes advanced weighing sensors and control systems to achieve accurate powder measurement, reducing material waste and ensuring product consistency. Deviation rates can be minimized to meet strict industry standards.

2. High Efficiency: Automated operation significantly improves production speed, capable of handling a large number of packaging containers per minute, which greatly increases output and meets mass production demands.

3. Flexibility: Equipped with adjustable components, it can accommodate various packaging sizes, shapes, and materials, from small sachets and bottles to large bags and drums. It can also be customized to handle different types of powders with varying physical properties.

4. Hygienic Design: Constructed from food-grade or corrosion-resistant materials, the machine is easy to clean and prevents cross-contamination, making it suitable for industries with strict hygiene requirements, such as food and pharmaceuticals.

5. Low Maintenance: With a modular structure and high-quality components, the machine requires minimal maintenance. Its durable design reduces the frequency of breakdowns, ensuring long-term stable operation and saving maintenance costs.

Powder Filling MachineApplications

1. Food Industry: Used for filling spices, coffee powder, milk powder, flour, and other food powders, ensuring accurate portion control and maintaining product quality and freshness.

2. Pharmaceutical Industry: Essential for filling pharmaceutical powders for capsules, tablets, and other solid dosage forms, complying with strict GMP (Good Manufacturing Practice) standards to ensure product safety and efficacy.

3. Chemical Industry: Applied to fill industrial chemicals, pigments, dyes, and other powder materials, meeting the needs of different chemical production and packaging processes.

4. Cosmetics Industry: Suitable for filling cosmetic powders like face powder, eye shadow powder, and other powdered beauty products, ensuring precise filling and product uniformity.

5. Agricultural Industry: Used to fill powdered fertilizers, pesticides, and feed additives, helping to improve the efficiency and accuracy of agricultural production.

Powder Filling MachineFeatures

1. Intelligent Control System: Equipped with a PLC (Programmable Logic Controller) and a touch - screen interface, allowing operators to easily set parameters, monitor the filling process, and adjust the machine according to different production requirements.

2. Dust - Prevention Design: Incorporates dust collection and sealing devices to prevent powder leakage and dust飞扬 during the filling process, creating a clean working environment and protecting operators' health.

3. Automatic Error Detection: Can detect common issues such as abnormal weighing values, blockages, or low powder levels in real - time, and automatically stop the operation while issuing an alarm to facilitate quick troubleshooting.

4. Gentle Handling: Designed to minimize powder degradation or segregation during the filling process, especially important for sensitive powders that require careful handling to maintain their properties.

5. Energy - Saving: Optimized power consumption through efficient motor control and energy - saving technologies, reducing overall production costs while maintaining high - performance operation.

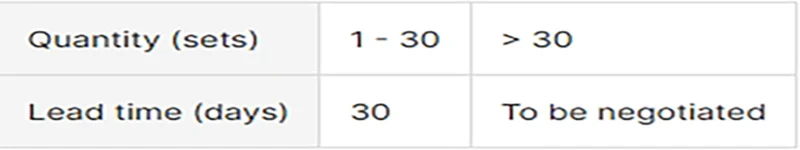

Lead time

Products Description

Product Inquiry