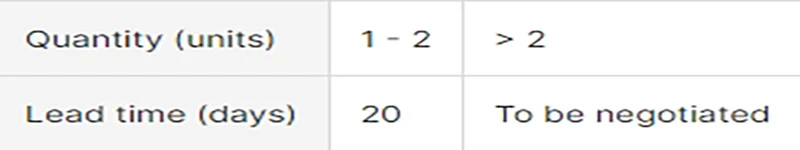

Industrial high - level palletizers are indispensable automated equipment in modern industrial production. Benson's industrial high - level palletizer adopts an advanced PLC control system to achieve intelligent and fully automated operation, accurately and efficiently completing the material palletizing. It can handle a 50 - kg load with ease and can operate stably even in complex and harsh environments such as chemical dust, greatly reducing manual intervention and effectively saving labor

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

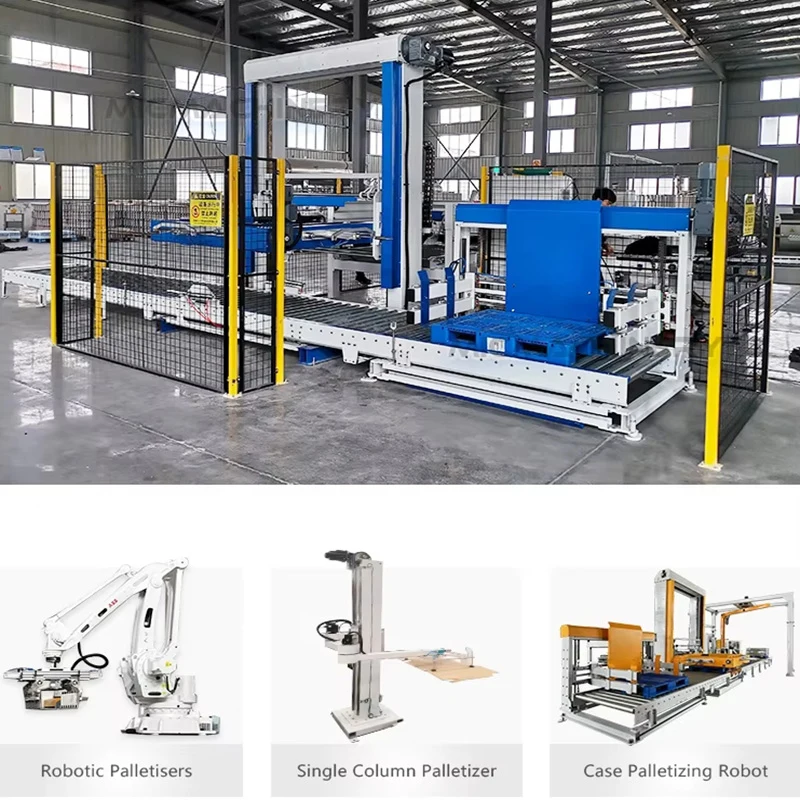

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Lead time

Products Description

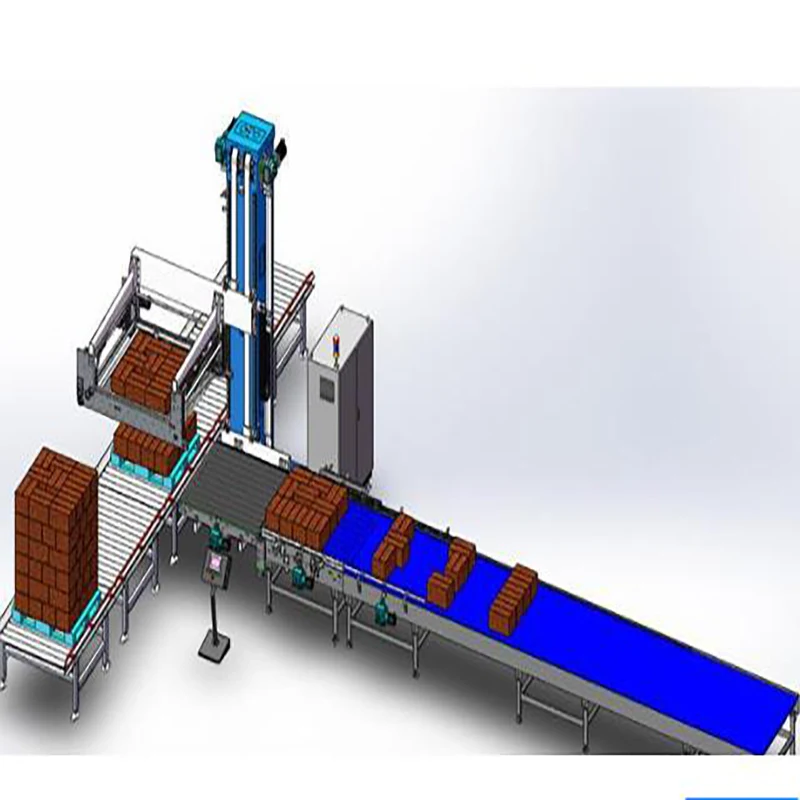

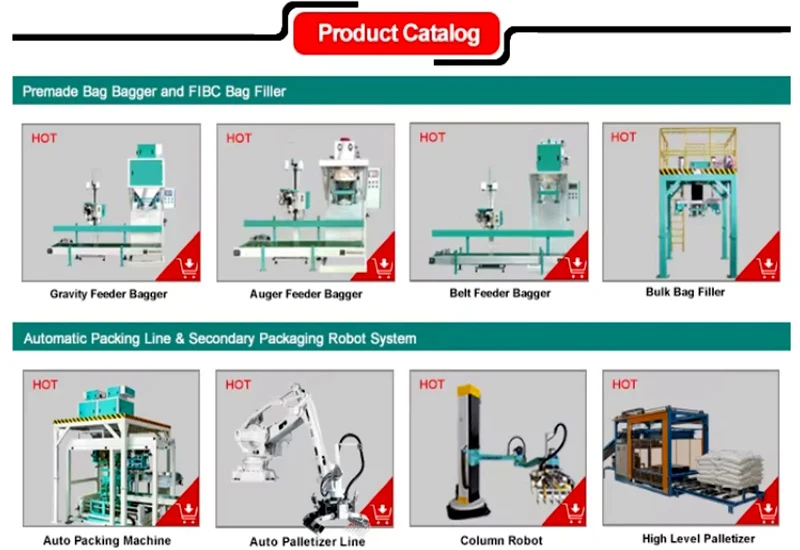

Industrial high-level palletizer

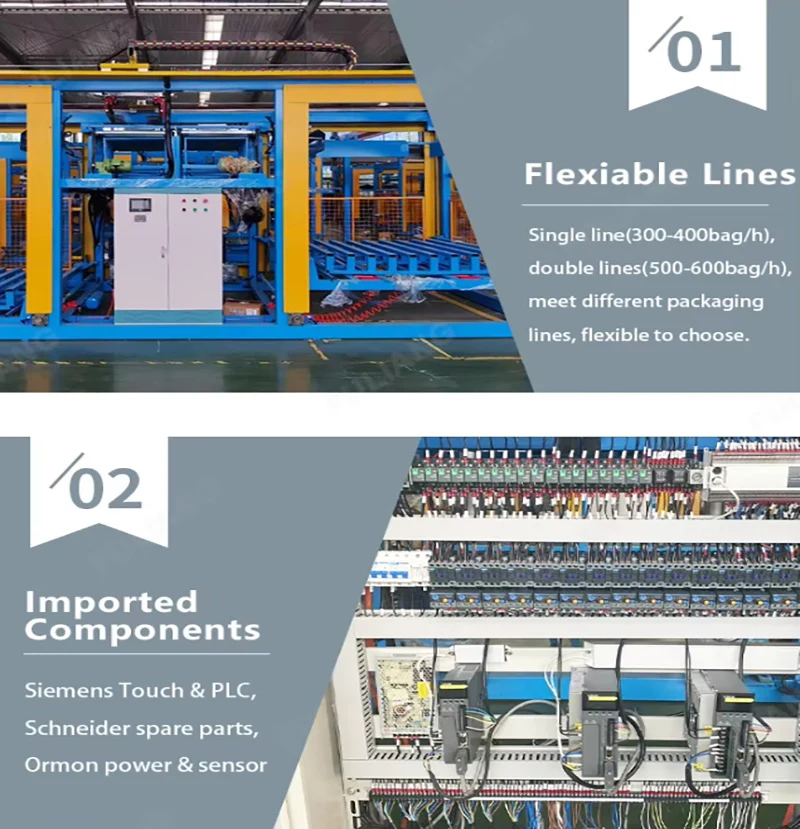

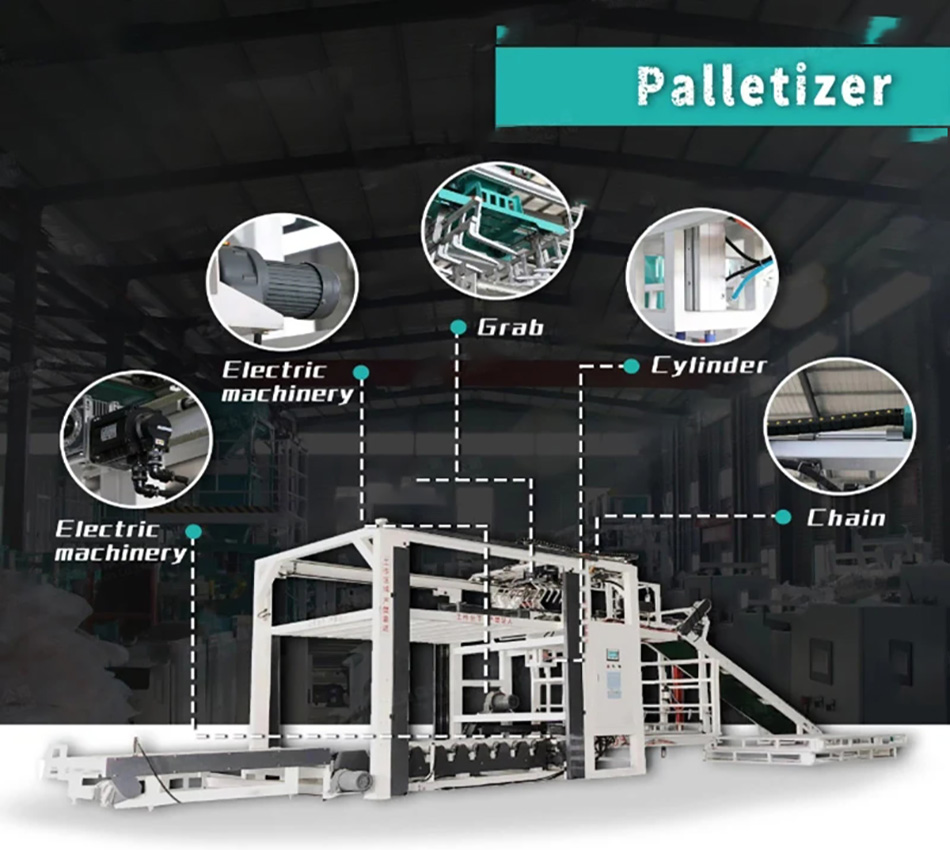

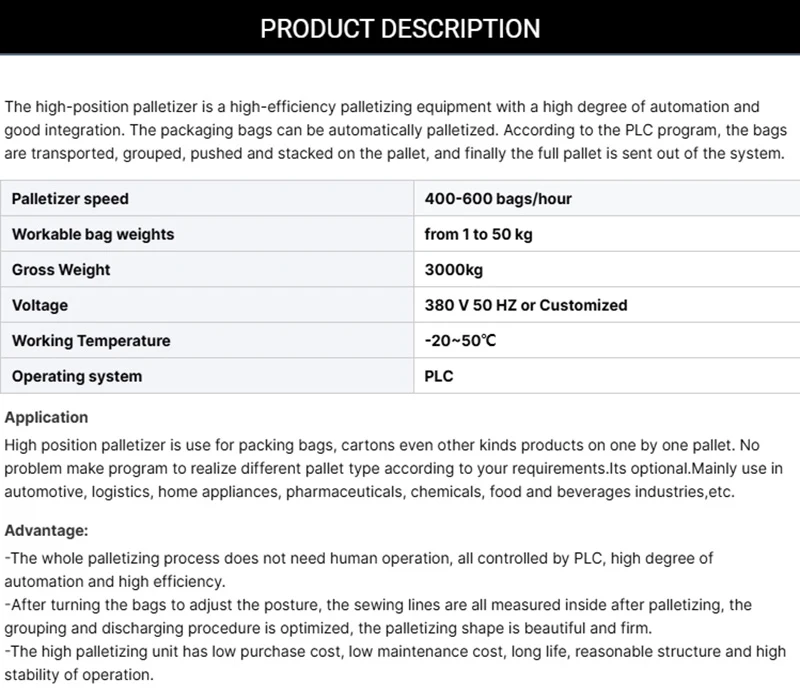

The industrial high-level palletizer is an automated packaging equipment widely used in many industries such as food, beverage, chemical, and building materials. It is mainly used to neatly and automatically stack various finished materials, such as bagged, boxed, and barreled products, on pallets in a specific arrangement and number of layers, facilitating subsequent transportation, storage, and other processes. In terms of structure, the industrial high-level palletizer is mainly composed of components such as the mechanical main body, gripping device, conveying system,controlled by PLC. and control system. The mechanical main body usually adopts a frame structure, which has good stability and rigidity and can withstand large loads. The gripping device can be customized according to the type of materials, such as clamping type, vacuum suction cup type, robotic gripper type, etc., to achieve reliable gripping of materials with different shapes and weights. The conveying system is responsible for accurately transporting the materials to the palletizing position. The control system is the "brain" of the high-level palletizer, generally controlled by a PLC (Programmable Logic Controller). Through pre-written programs, it precisely controls the actions of each component to automate the palletizing process. The industrial high-level palletizer has remarkable advantages. In terms of efficiency, it operates at a high speed and can work continuously, with a palletizing capacity of hundreds or even thousands of pieces per hour. Compared with manual palletizing, it can significantly improve production efficiency and meet the needs of large-scale production. In terms of stability and accuracy, relying on its precise mechanical structure and accurate control system, the high-level palletizer can always maintain a stable working state, palletize materials in the set arrangement and number of layers, resulting in neat and standardized stacking, reducing the risk of product damage caused by human operation errors. From a cost perspective, although there is a certain investment required for equipment procurement and installation in the early stage, long-term use can reduce a large amount of labor costs. At the same time, it reduces labor intensity and improves the working environment for workers. In addition, the high-level palletizer has strong flexibility and adaptability. Through simple parameter adjustment and program modification, it can quickly switch between palletizing operations of different specifications and types of products, meeting the diverse production needs of enterprises.The manufacturer of the palletizer is Benson. It saves labor costs and improves production efficiency.

The working process of an industrial palletizerusually includes core steps such as material conveying, positioning and separation, grasping and lifting, translation and palletizing, and pallet replacement. The specific process is as follows:

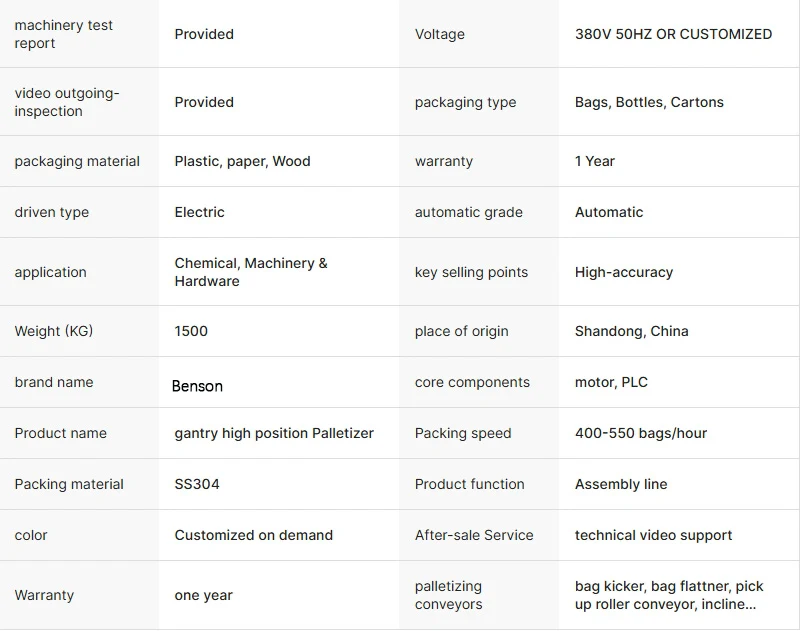

Specification

Customer Sites

Company Profile

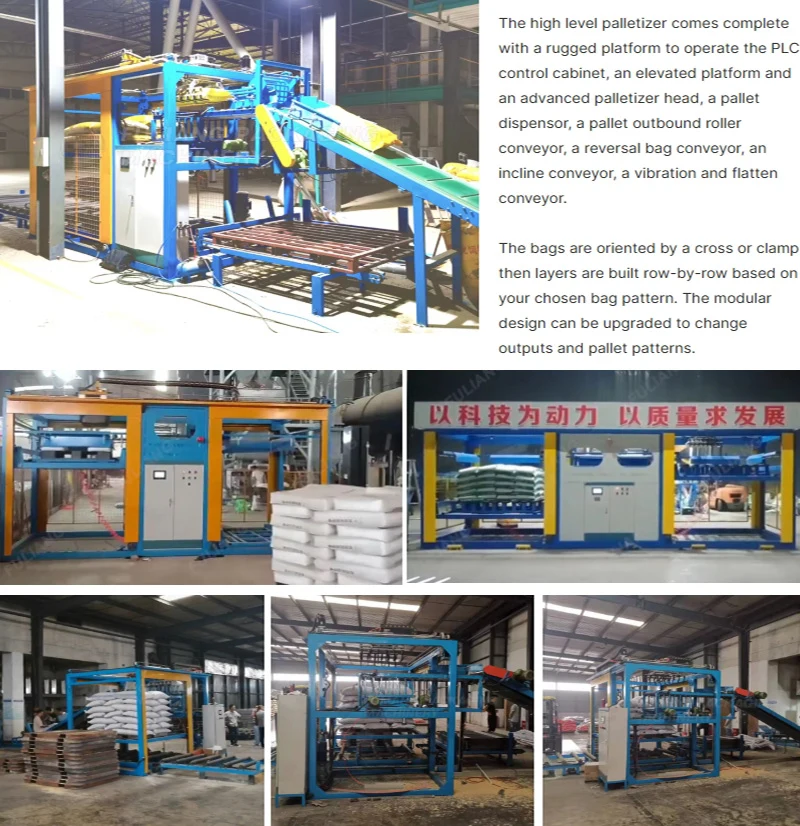

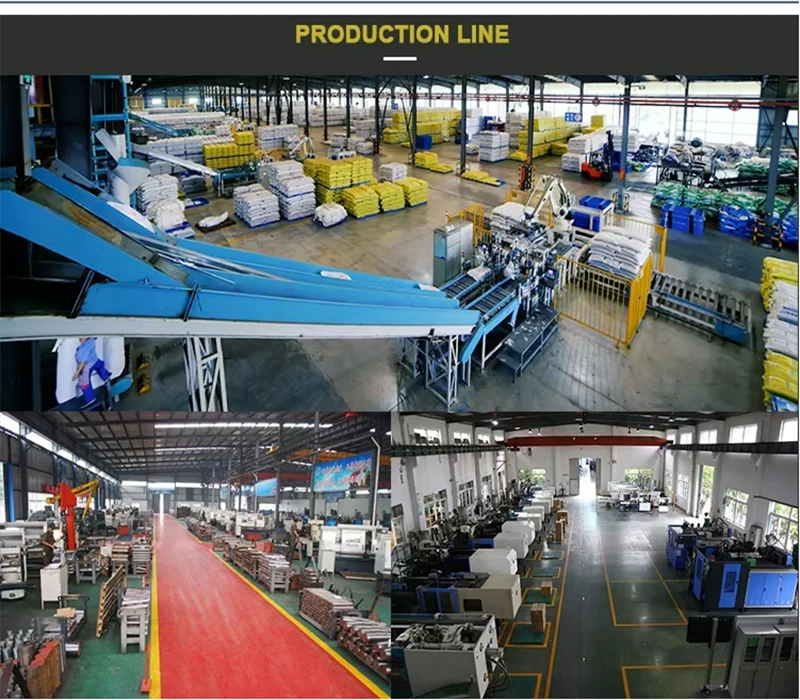

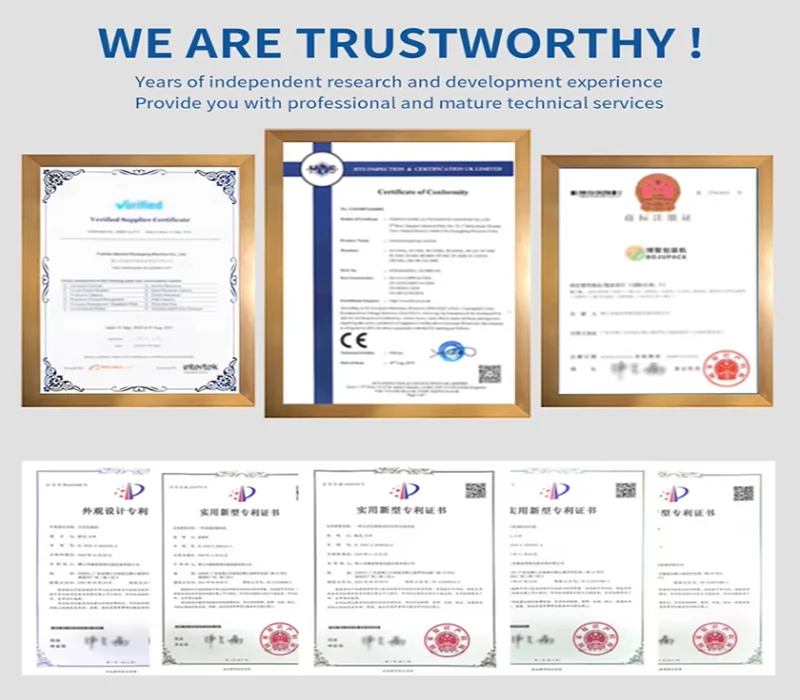

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales.

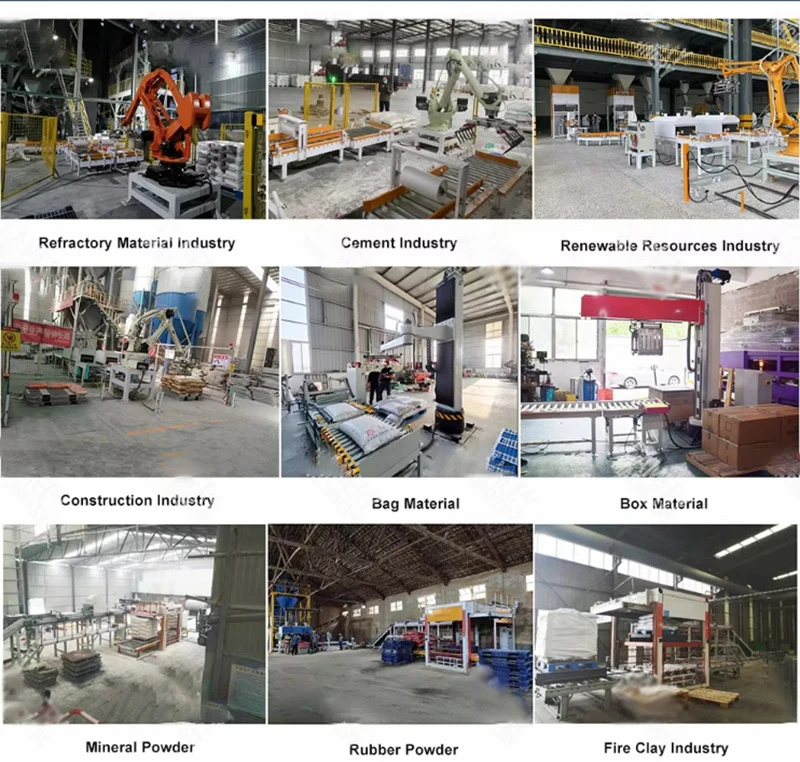

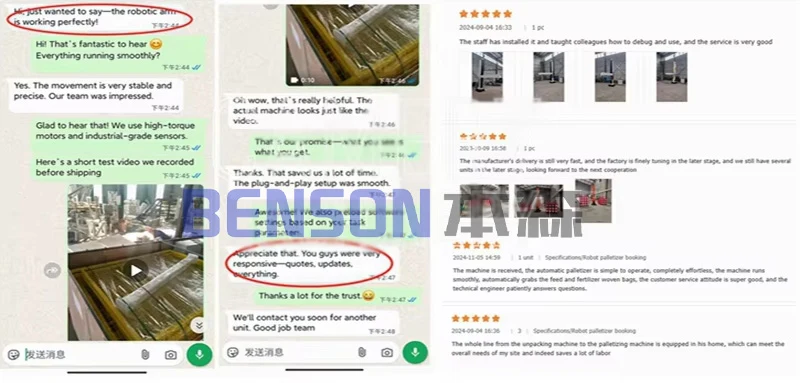

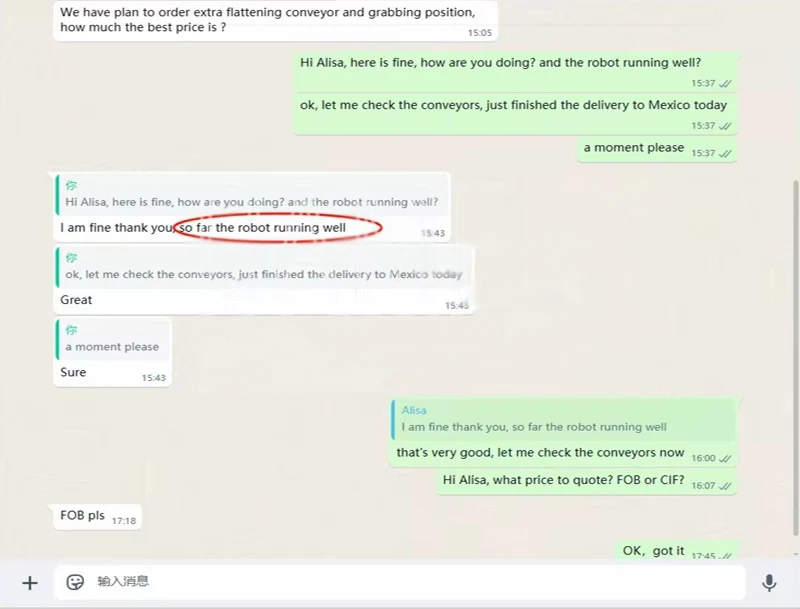

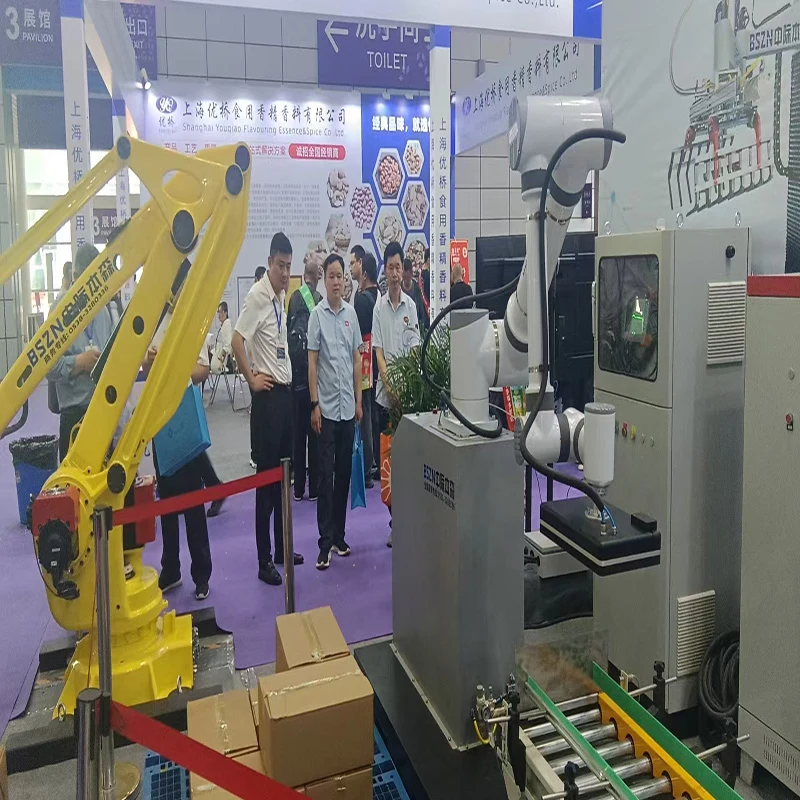

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

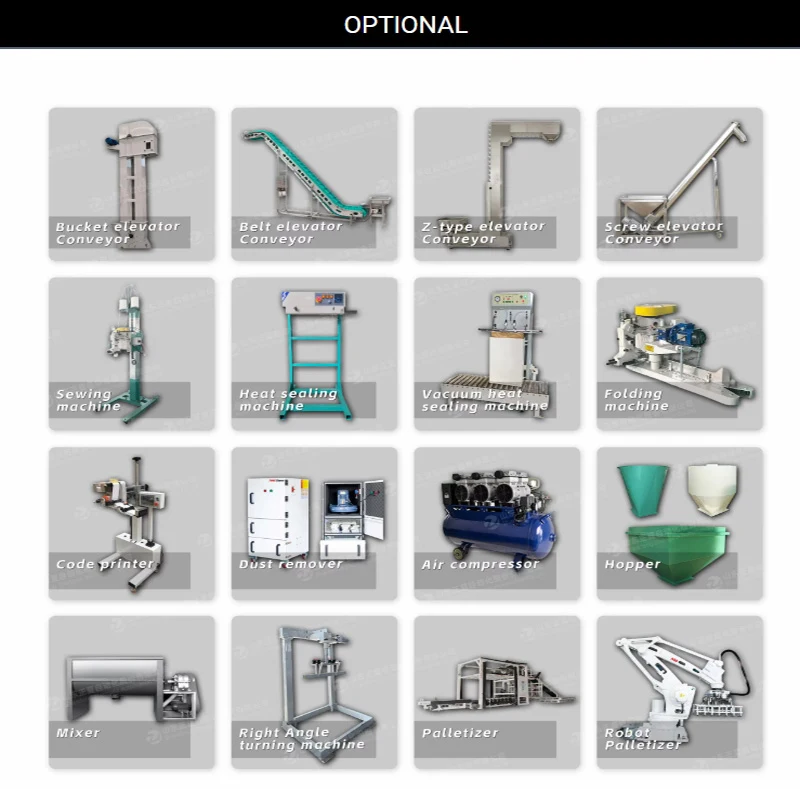

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry