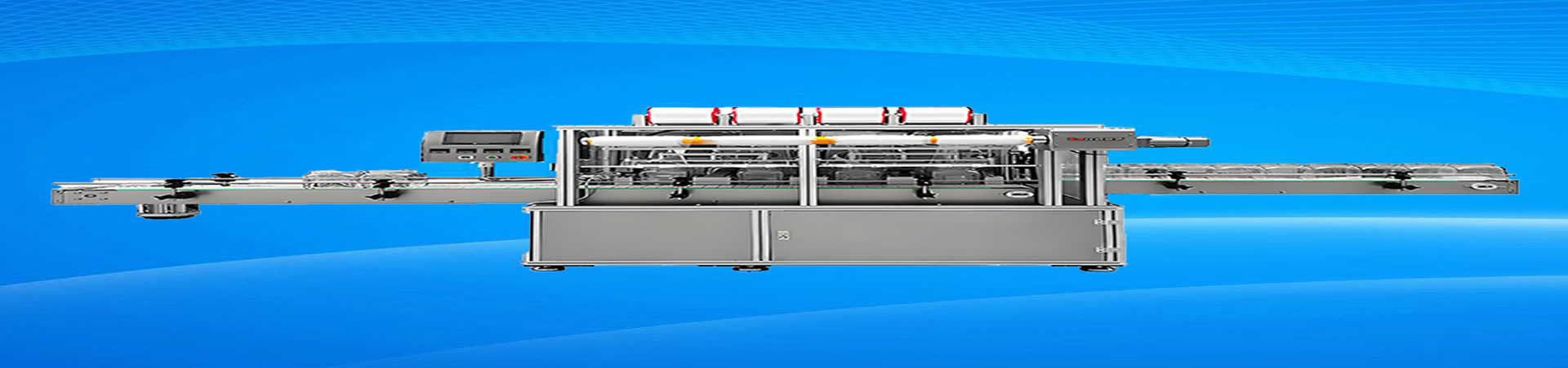

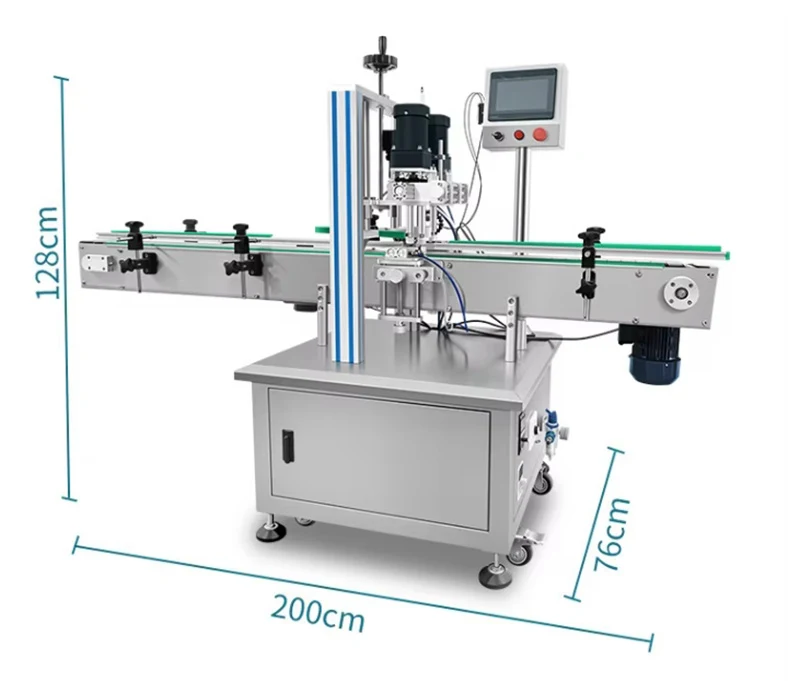

Equipment Description

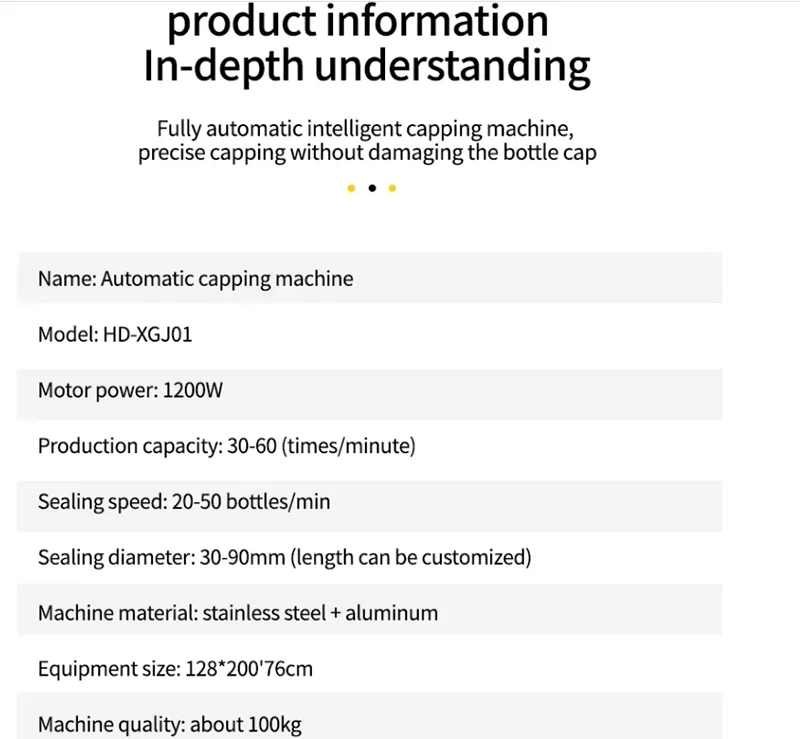

The high-speed capping machine for pump heads of plastic and glass bottles is a highly automated packaging equipment, specifically designed for the rapid and precise capping operation of pump head caps on plastic and glass bottles. This equipment is generally composed of core components such as the bottle feeding system, pump head feeding system, capping execution mechanism, transmission system, and control system.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

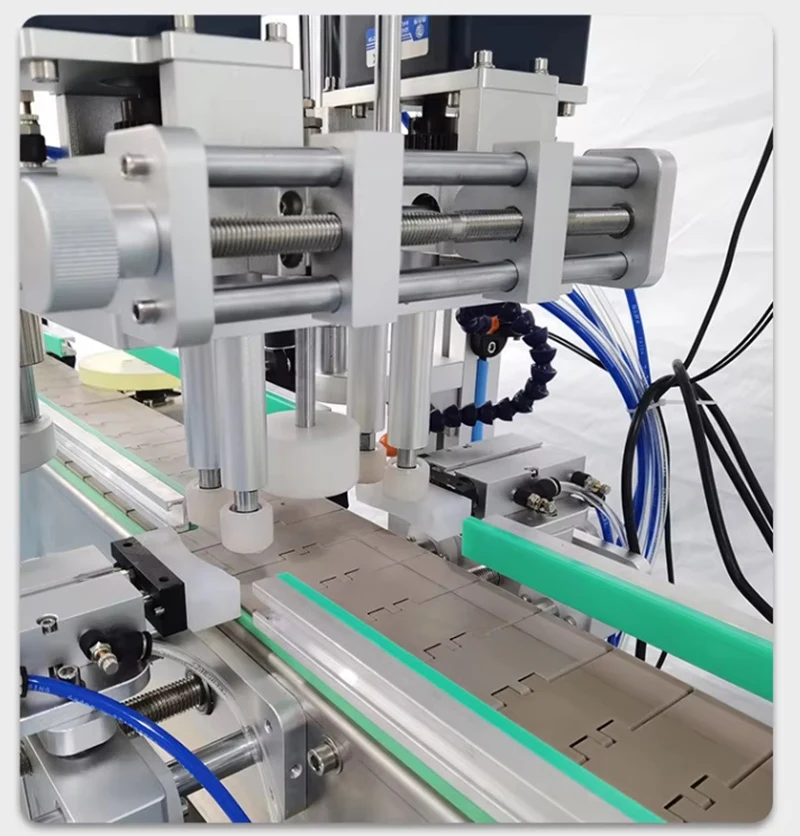

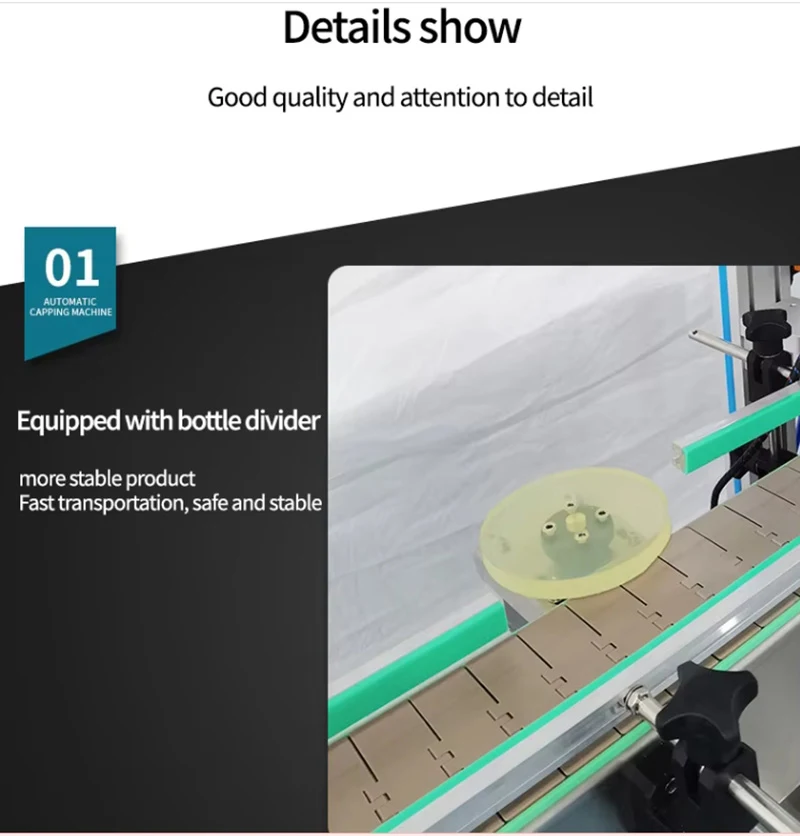

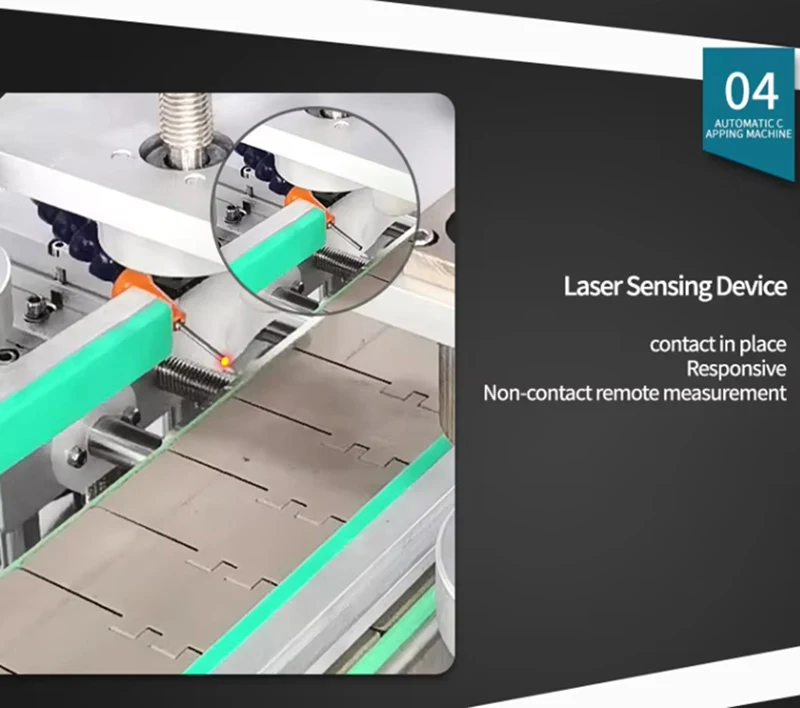

- Bottle Feeding System: Structures such as chain plates, screws, or star wheels are adopted to orderly and stably convey the bottles to the capping station, ensuring that the spacing between the bottles is uniform and facilitating subsequent precise operations.

- Pump Head Feeding System: Through devices such as vibration plates and conveyor belts, the pump heads are sorted and oriented, and are conveyed to the position to be capped at a stable speed, ensuring the continuity of pump head supply.

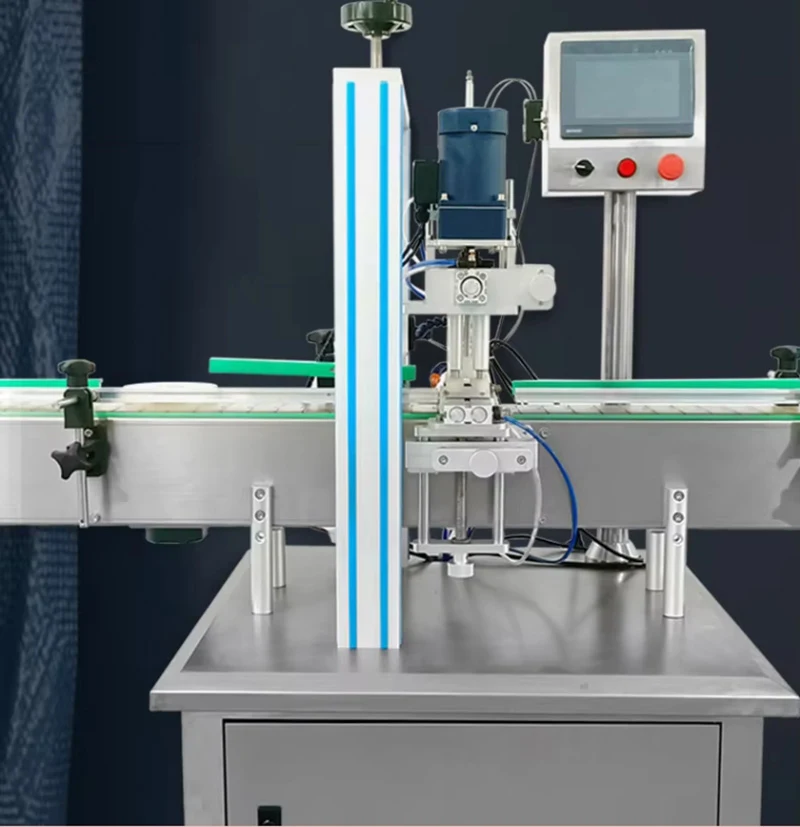

- Capping Execution Mechanism: Equipped with high-precision robotic arms or capping heads, driven by servo motors or pneumatic components, it can achieve actions such as grabbing, placing, screwing, or pressing the pump heads. It can accurately control the capping force and torque, ensuring a tight and firm cap.

- Transmission System: Transmission methods such as gears, chains, or synchronous belts are mostly used to provide stable power transmission for all components of the equipment, ensuring the stability and reliability of the equipment operation.

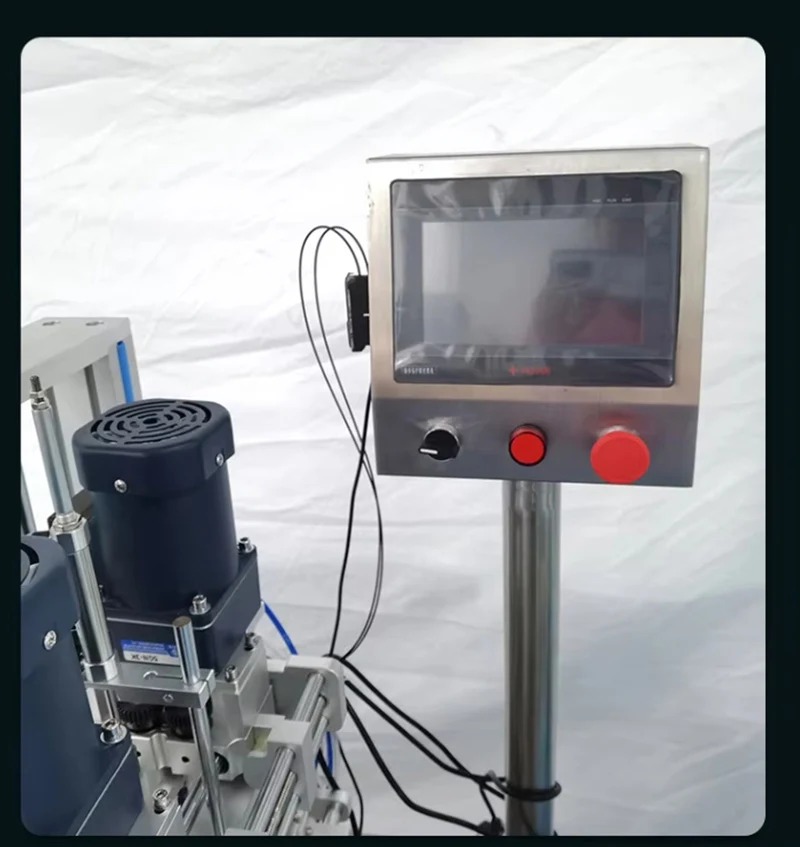

- Control System: Integrated with PLC (Programmable Logic Controller) and a touch screen human-machine interface, it can achieve precise setting and adjustment of equipment operation parameters (such as capping speed, torque size, bottle feeding rate, etc.), and also has functions such as fault diagnosis and alarm prompts, making it easy to operate and maintain.

High-speed capping machine for pump heads of plastic and glass bottles Core Advantages

1. High Efficiency and Speed: Relying on advanced mechanical structures and automated control systems, its capping speed far exceeds that of traditional manual or semi-automatic equipment. The processing capacity per hour can reach thousands or even tens of thousands of bottles, greatly improving production efficiency and meeting the needs of large-scale industrial production.

2. Precision and Stability: It can accurately control the capping force and position, ensuring that each pump head is capped according to a consistent standard, effectively reducing the defective rate and ensuring the stability of product packaging quality.

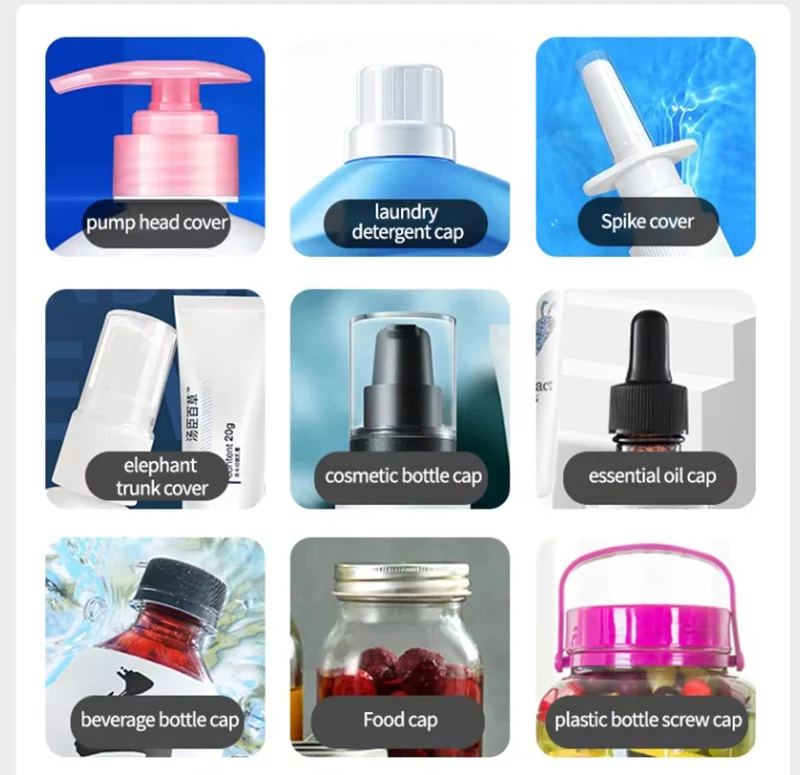

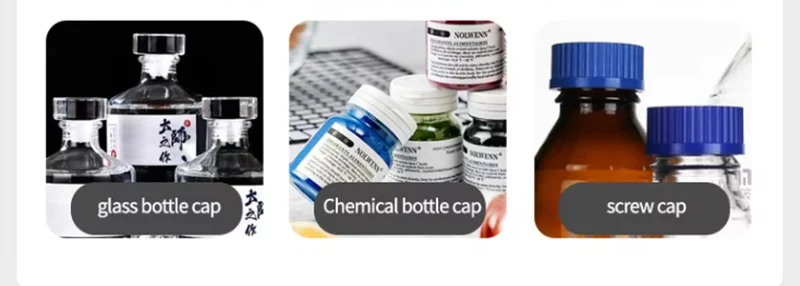

3. Strong Compatibility: By simply adjusting the equipment parameters and replacing a small number of molds, it can adapt to plastic and glass bottles of different specifications and shapes, as well as various types of pump head caps, and is widely used in the packaging production of industries such as daily chemicals, pharmaceuticals, and food.

4. Labor Cost Saving: The highly automated operation mode reduces the dependence on manual labor, reduces the errors caused by manual operation and labor costs, and also improves the safety of the production process.

5. Intelligent and Convenient: With an intuitive human-machine interaction interface, it is easy to operate and understand, and the staff can quickly get started. It has data recording and analysis functions, which is convenient for monitoring and optimizing the production process and realizing intelligent production management.

High-speed capping machine for pump heads of plastic and glass bottlesApplication Areas

1. Daily Chemical Industry: It is often used for capping the pump heads of plastic or glass bottle packaging for products such as shampoo, shower gel, hand sanitizer, and skin care products, ensuring that the products will not leak during storage and transportation and improving product quality and user experience.

2. Pharmaceutical Industry: It is suitable for the pump head packaging of medicinal plastic bottles and glass bottles, such as externally applied drugs, oral liquids, etc., meeting the strict requirements of pharmaceutical products for packaging sealing and sterility and ensuring the quality and safety of drugs.

3. Food Industry: It can be used for the packaging of foods such as edible oil, sauce, honey, etc., ensuring that the food is not contaminated during storage and use, extending the shelf life, and being convenient for consumers to use.

Product Inquiry