Pallet machine flexible collaborative robot: a new smart partner for industrial automation

Under the wave of Industry 4.0 and intelligent manufacturing, the production model is changing from traditional large-scale and standardized to small batch and multi-variety. In order to adapt to this trend, the pallet machine flexible collaborative robot we launched integrates high flexibility, intelligence and safety, and has become a key force in promoting the efficient development of modern industry.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Excellent flexible adaptability

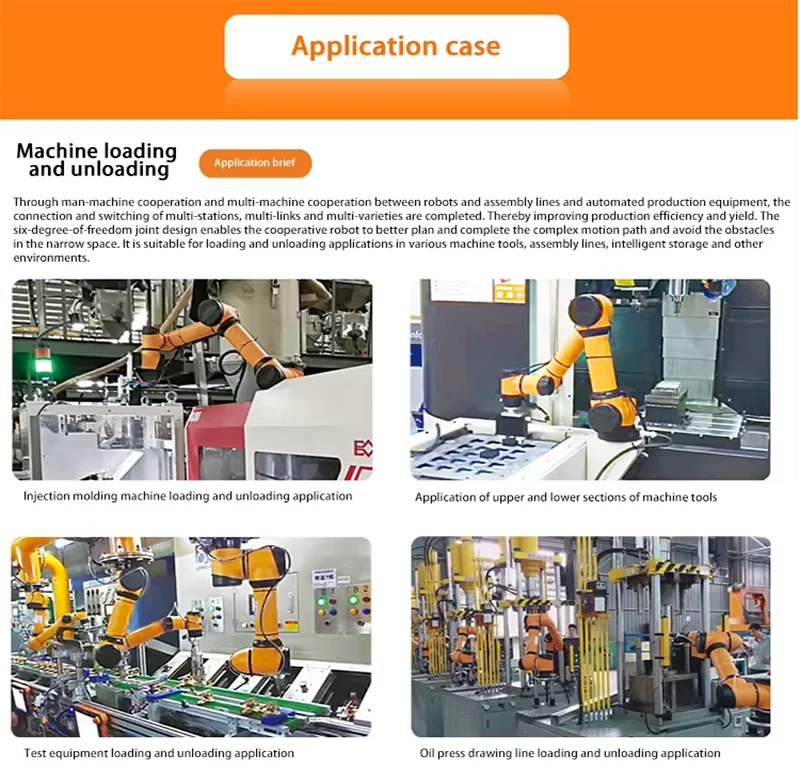

Traditional pallet handling equipment can only handle pallets and goods of specific specifications, but our pallet machine flexible collaborative robot completely breaks this limitation. It is equipped with advanced visual recognition system and intelligent algorithm, which can quickly and accurately identify pallets and goods of various sizes and shapes. Whether it is a standard industrial pallet or a non-standard pallet designed for special products, it can flexibly respond and easily complete tasks such as handling, stacking, and depalletizing. In small-batch, multi-variety production scenarios, there is no need to frequently change equipment or perform complex debugging, and the operation mode can be quickly switched, which greatly improves production efficiency, reduces production costs, and brings unprecedented production flexibility to enterprises.

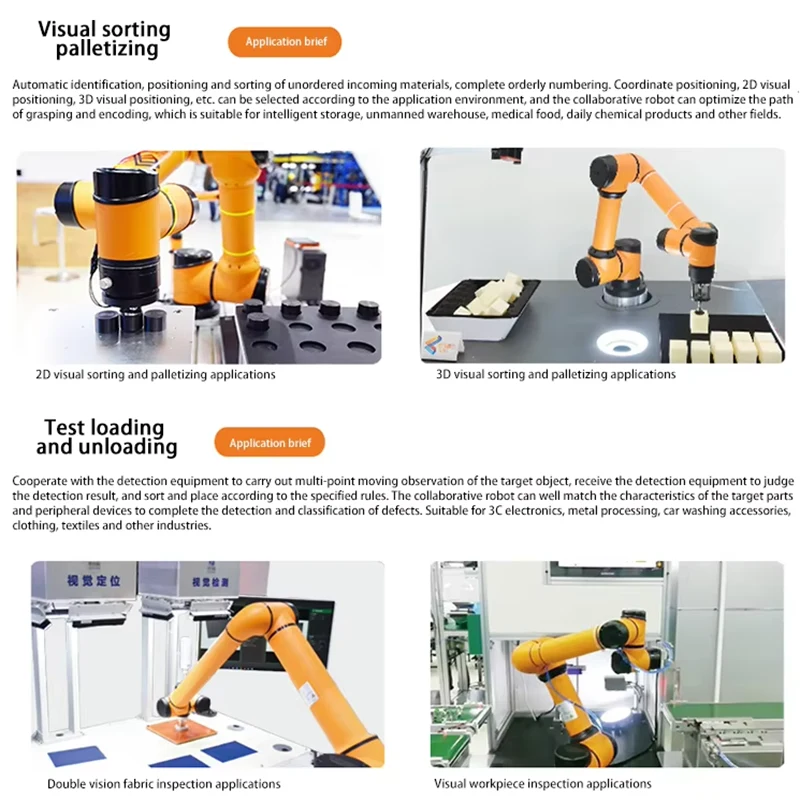

Highly intelligent and precise operation

This robot is equipped with an advanced 3D vision system, just like having a pair of "fire eyes and golden eyes", which can quickly and accurately identify the position, posture and stacking of pallets and goods, and the repeat positioning accuracy can reach ±[X]mm. Whether on a high-speed production line or in a complex storage environment, it can achieve efficient grabbing, handling and placement of pallets and goods with precise positioning and stable operation, effectively avoiding damage to goods or production stagnation caused by operational errors, and ensuring the stability and efficiency of the production process. At the same time, its intelligent algorithm can also make autonomous decisions and optimizations based on real-time working conditions to further improve operating efficiency and quality.

Safe collaboration, human-machine friendly

Safety is the top priority of industrial production. Our pallet machine flexible collaborative robot strictly follows international safety standards and is equipped with multiple safety protection mechanisms. The advanced collision detection system can monitor the surrounding environment in real time. Once it detects the risk of collision with people or other objects, it will immediately stop the action to ensure the safety of personnel. In addition, it supports human-machine collaboration mode and can work with workers in the same work area to complete production tasks together. In the process of human-machine collaboration, the robot can respond promptly to the actions and instructions of the personnel to achieve efficient cooperation, which not only improves the overall production efficiency but also creates a safe working environment.

Convenient programming and rapid deployment

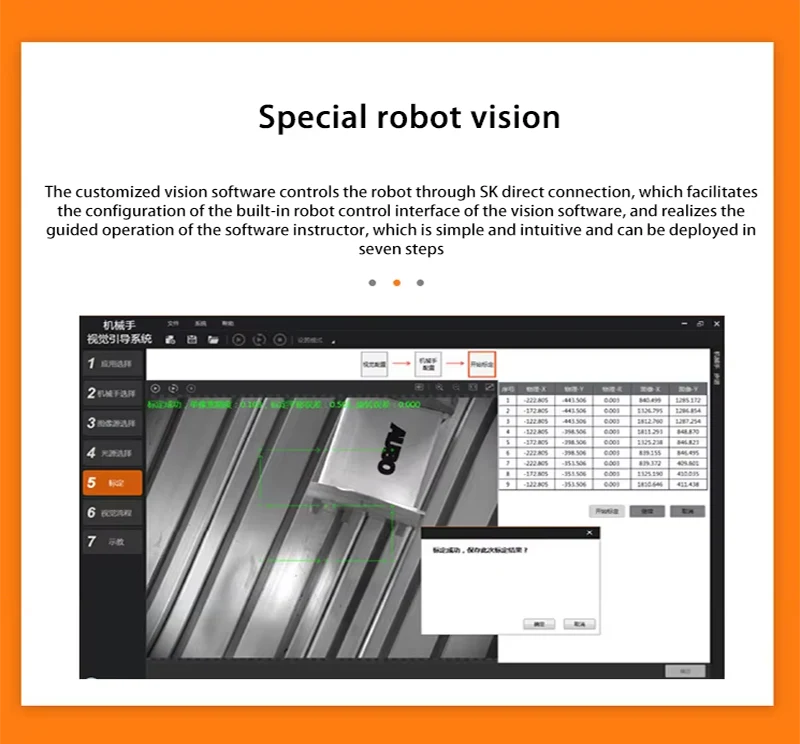

In order to lower the user's usage threshold and implementation cost, our robot adopts an intuitive graphical programming interface, which is easy to operate. Ordinary employees can start operating after a short training, which greatly shortens the programming time and the learning cost of operators. At the same time, the robot has the characteristics of rapid deployment, which can be installed, debugged and put into use in a short time, quickly creating value for the enterprise. In addition, it also supports remote monitoring and maintenance. Through the Internet, technicians can obtain the robot's operating status, fault information, etc. in real time, and perform remote diagnosis and repair, further improving the availability and maintenance efficiency of the equipment.

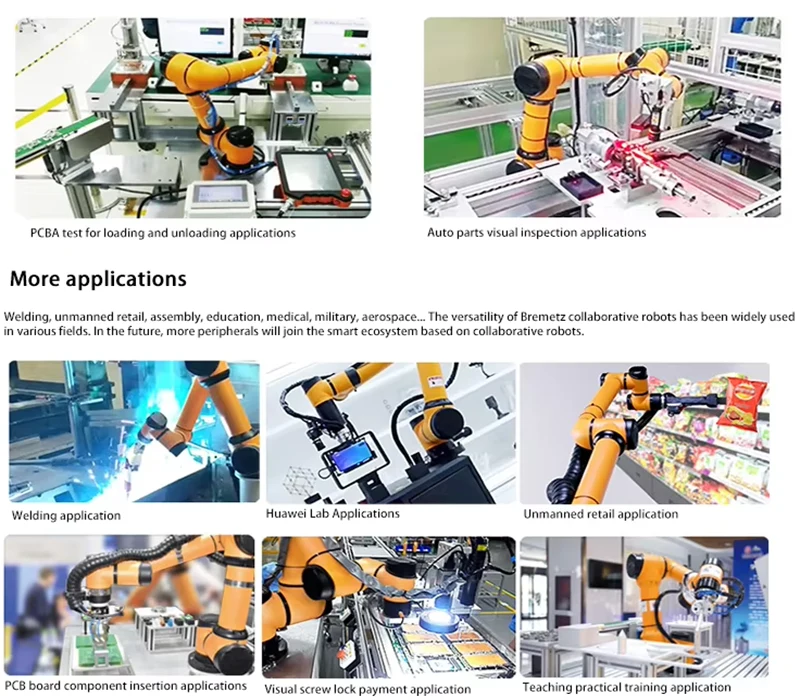

Wide range of application scenarios

Logistics and warehousing: In large warehouses and logistics centers, robots can undertake the warehousing, outbound, handling and stacking of pallet goods. Quickly and accurately move goods from the storage area to the sorting area or delivery area, improve the utilization rate of storage space and logistics operation efficiency, reduce labor costs, and reduce the risk of damage to goods, ensuring the safe and timely delivery of goods.

Manufacturing production line: On the production line of manufacturing enterprises, complete the pallet handling tasks of raw materials, semi-finished products and finished products. Closely cooperate with production equipment to realize the automated distribution of materials and the automated offline of products, improve the automation level and production efficiency of the production line, reduce the impact of human factors on production, and help enterprises achieve lean production.

E-commerce and express delivery industry: Aiming at the characteristics of large order volume, wide variety of goods and high delivery timeliness requirements in the e-commerce and express delivery industries, the sorting, packaging and pallet handling of goods are completed efficiently. During shopping peaks such as "Double Eleven" and "618", a large number of orders can be processed in a short time to ensure timely and accurate delivery of goods and improve customer satisfaction.

Product Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been used, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in machinery manufacturing, automation equipment manufacturing, automated production lines, automated production lines, etc. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

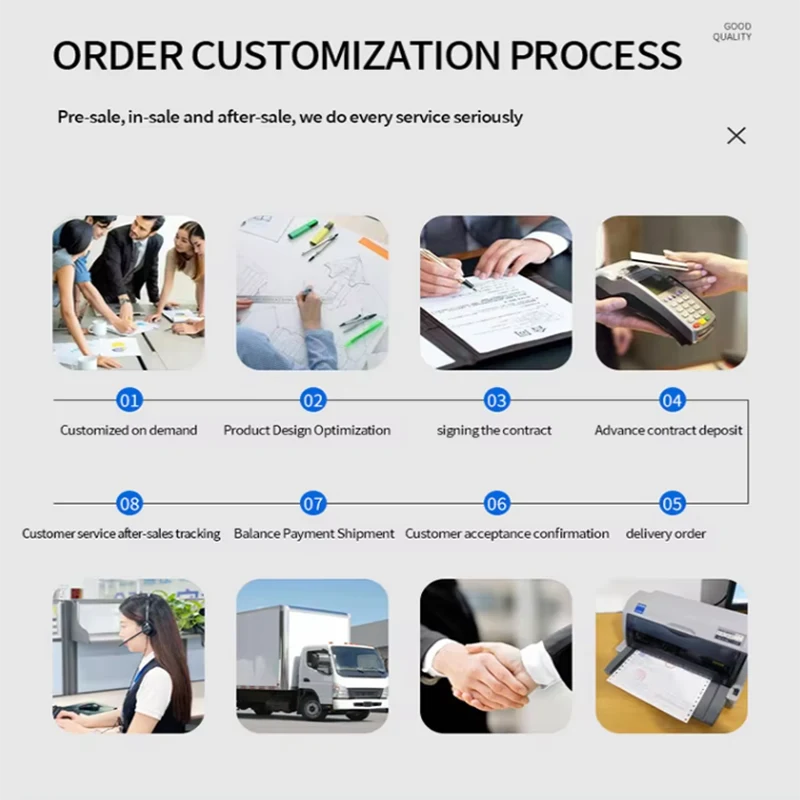

Product Inquiry