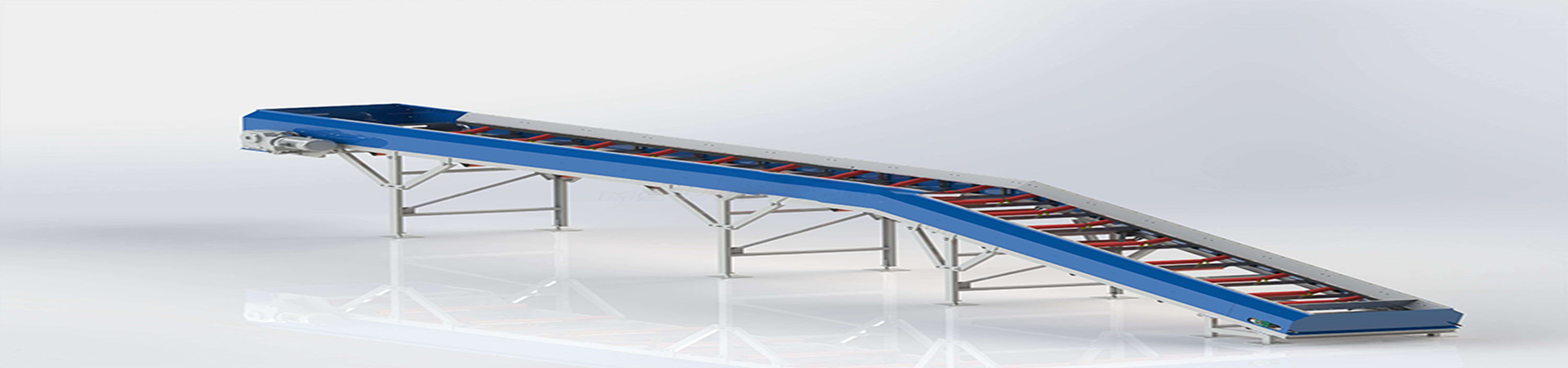

Self-supporting roller conveyor is a type of roller conveyor.

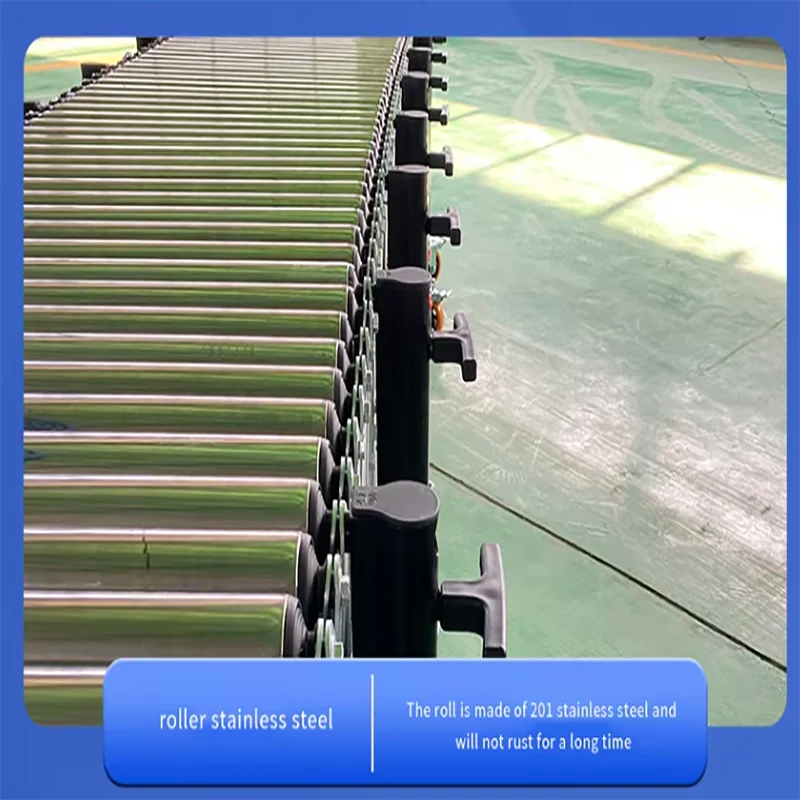

- Frame: Self-supporting roller conveyors are usually made of carbon steel spraying, stainless steel or aluminum profiles. Carbon steel spraying has low cost and certain protection capabilities; stainless steel is corrosion-resistant and suitable for industries with high hygiene requirements such as food and medicine; aluminum profiles are light in weight, beautiful in appearance, and easy to install.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

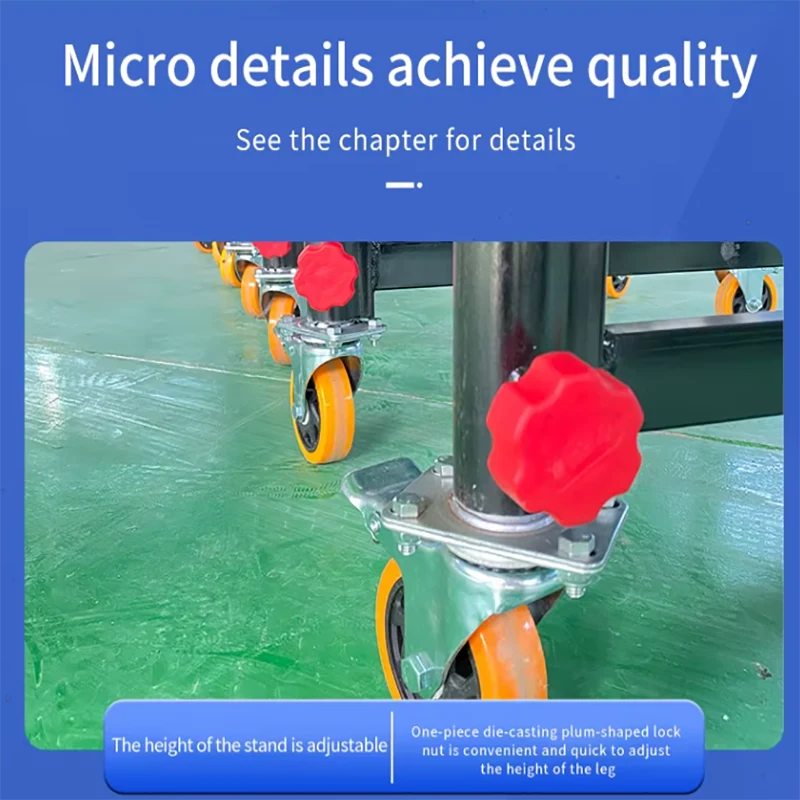

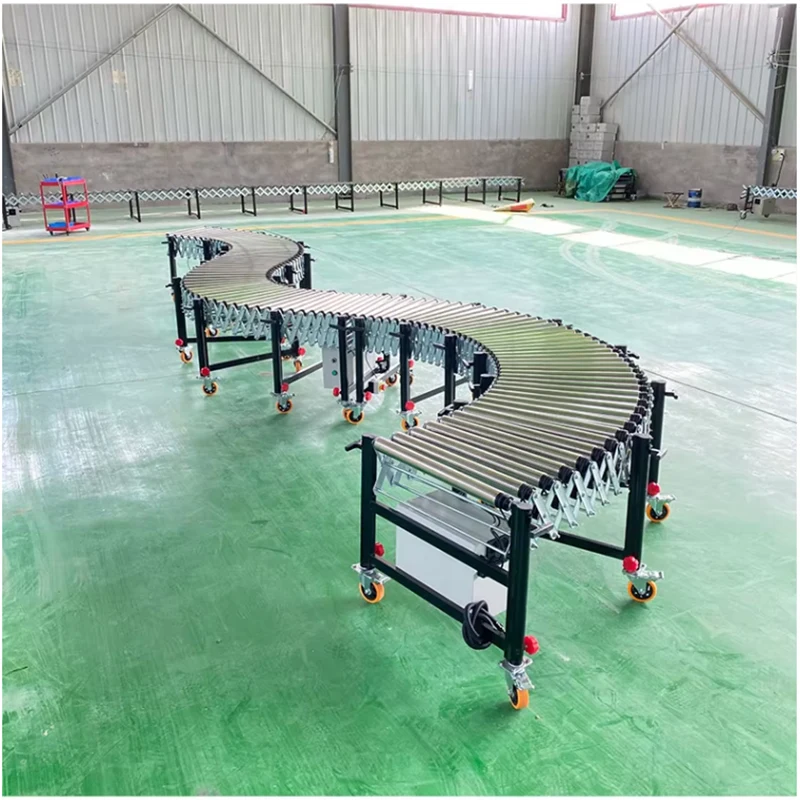

Customizable Size: With a customizable size, users can select the appropriate dimensions to suit their specific production needs, making it an ideal solution for various production line configurations.

Free replacement parts

Free replacement parts

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

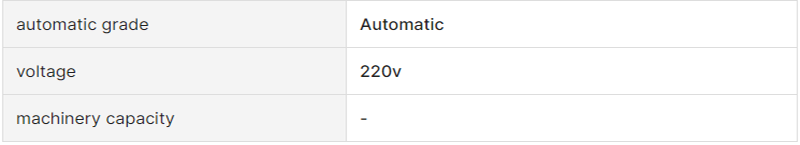

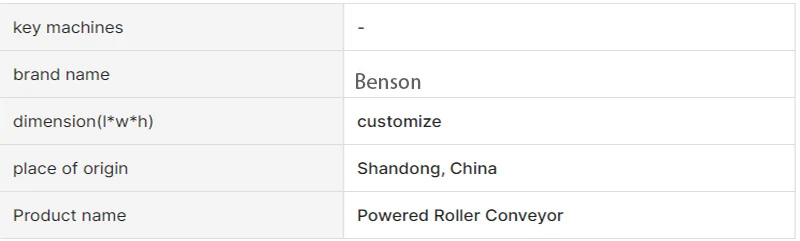

Key attributes

Industry-specific attributes

Other attributes

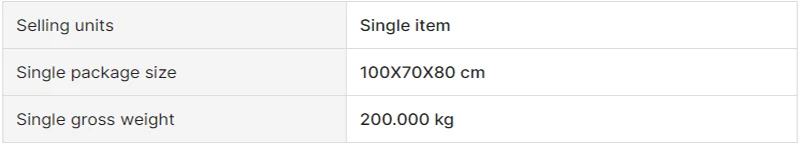

Packaging and delivery

Lead time

Working principle of self-supporting roller conveyor for corrugated paper

- Unpowered type: Relying on the weight of the object itself or external thrust to move on the roller. For example, in gravity applications, a certain inclination angle is used to make the object slide down the roller under the action of gravity.

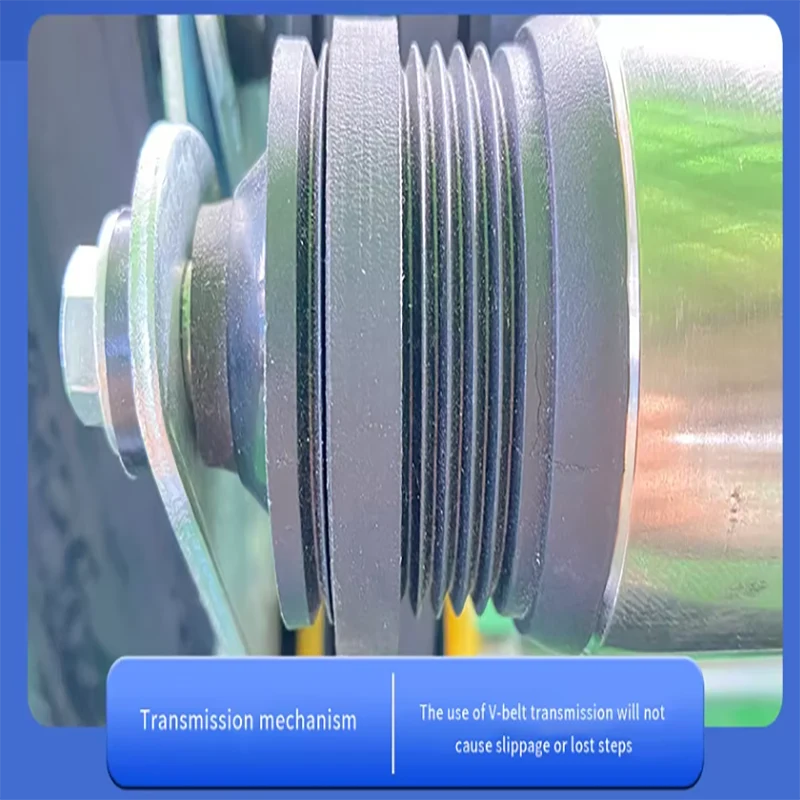

- Power type: The roller is rotated by the drive device, and the friction between the roller and the object is used to drive the object forward. The conveying speed can be set according to needs. Some also have frequency conversion speed regulation and stepless speed change functions, which can flexibly adjust the conveying rate.

Technical parameters of self-supporting roller conveyor for corrugated paper

- Conveying capacity: depends on the roller load capacity, spacing, weight and size of the conveyed items. The load capacity of roller units of different specifications is different. For example, a roller with a diameter of 38mm may carry 45kg, and a roller with a diameter of 50mm may carry 55kg.

- Conveying speed: The speed range of the powered self-supporting roller conveyor is generally 0-30m/min. The specific speed depends on the actual production needs and equipment configuration.

- Dimensions: The length and width of the line can be customized according to the customer's process requirements. Common standard roller line widths are 200mm, 300mm, 400mm, 500mm, 1200mm, etc.; the standard turning radius of the turning roller line is 300mm, 600mm, 900mm, 1200mm, etc., which can also be specially customized.

Exhibition

Product Inquiry