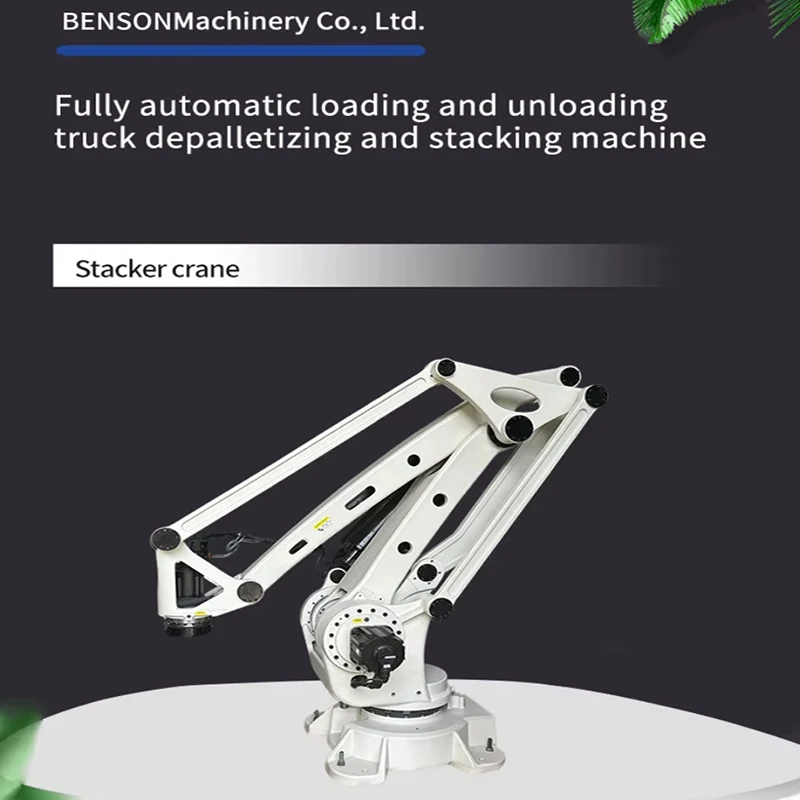

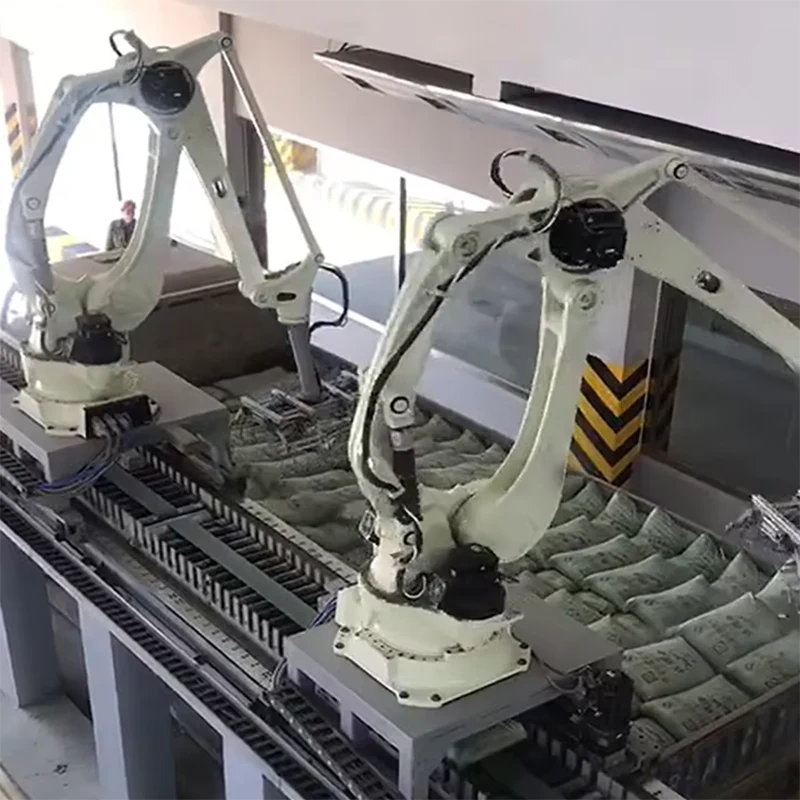

The structure of the new robot palletizer: mainly composed of flattening conveyor, slow stop conveyor, transfer conveyor, pallet warehouse, pallet conveyor, marshalling machine, bag pusher, palletizing device, pallet conveyor and other components.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Working principle of food and beverage carton packaging palletizing robot

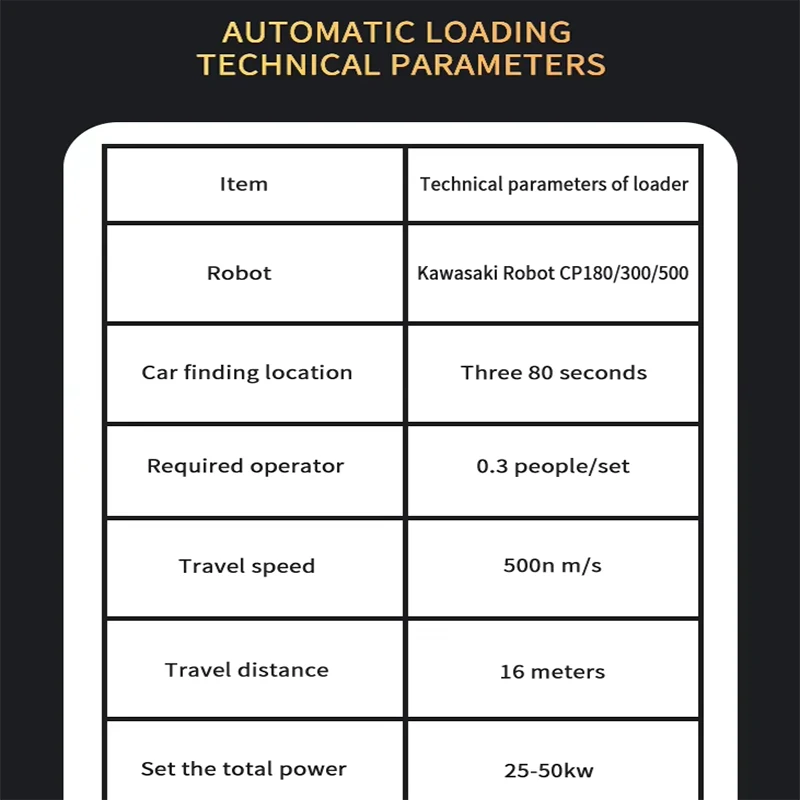

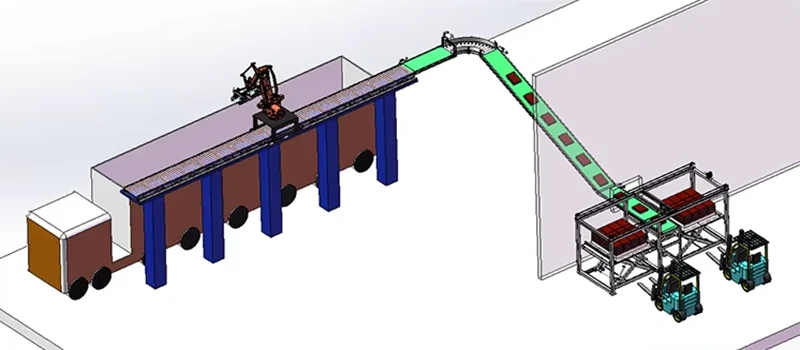

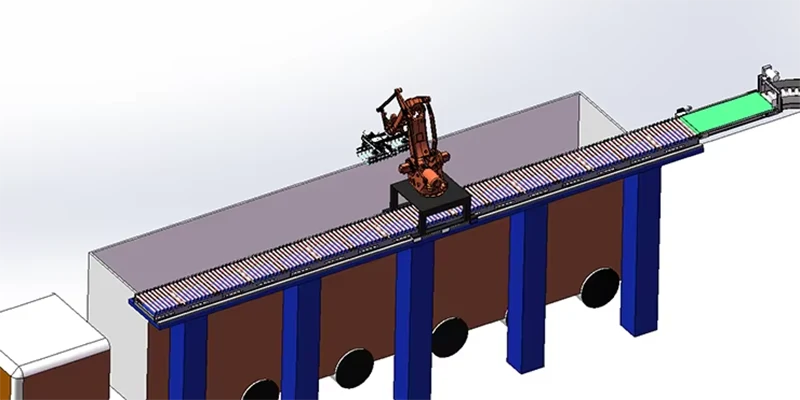

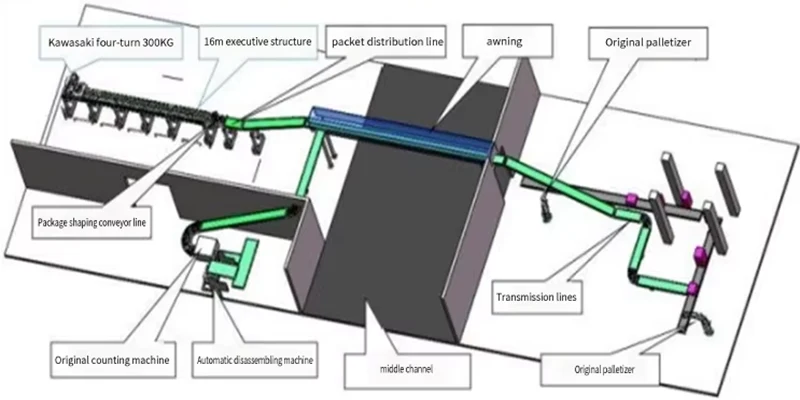

The packaged materials are transported to a specific palletizing area by a conveyor belt. The robot realizes point-to-point linear interpolation through the control system, and uses the coordination of each axis to move the fixture to the top of the material. After receiving the material positioning signal, the fixture descends, clamps the material through the servo motor control, and then transports it to the top of the palletizing position, and accurately places the material in the designated position, and repeats until the whole pallet of materials is palletized.

Structural composition of the new robot palletizer

It is mainly composed of flattening conveyor, slow stop conveyor, transfer conveyor, pallet warehouse, pallet conveyor, marshalling machine, bag pusher, palletizing device, pallet conveyor and other components.

Easy operation and maintenance

- Simple programming operation: some have graphical programming interface and graphical software, which is easy for non-professional users to use.

Excellent performance

- High speed and high efficiency: high rigidity design and vibration suppression control realize high-speed operation and fast production rhythm.

- Wide load range: diverse load capacity to meet the needs of different industries. - Large working range: The working radius and stacking height are increased to expand the working coverage.

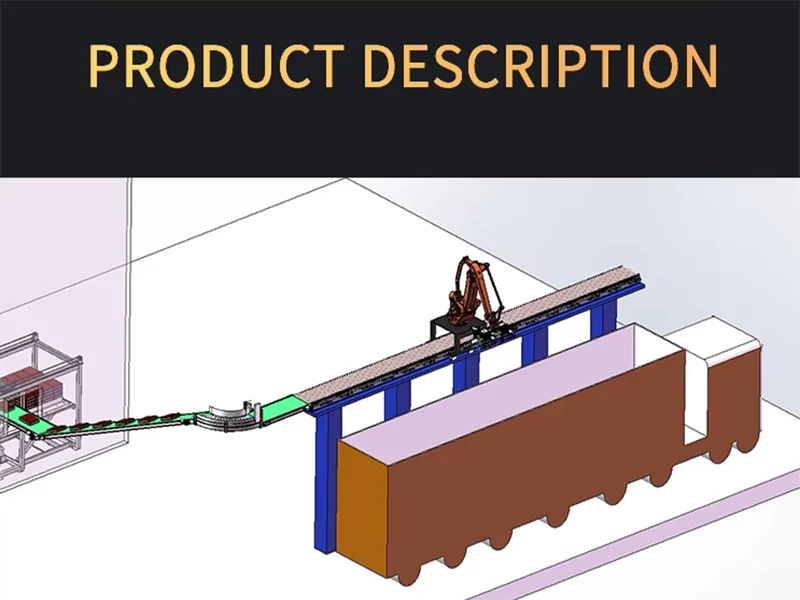

Products Description

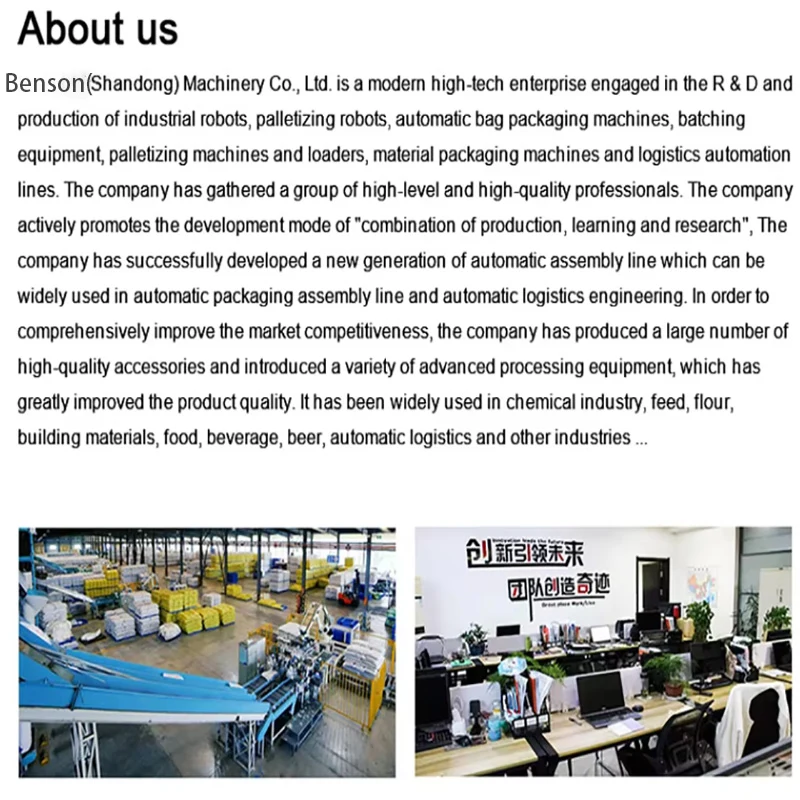

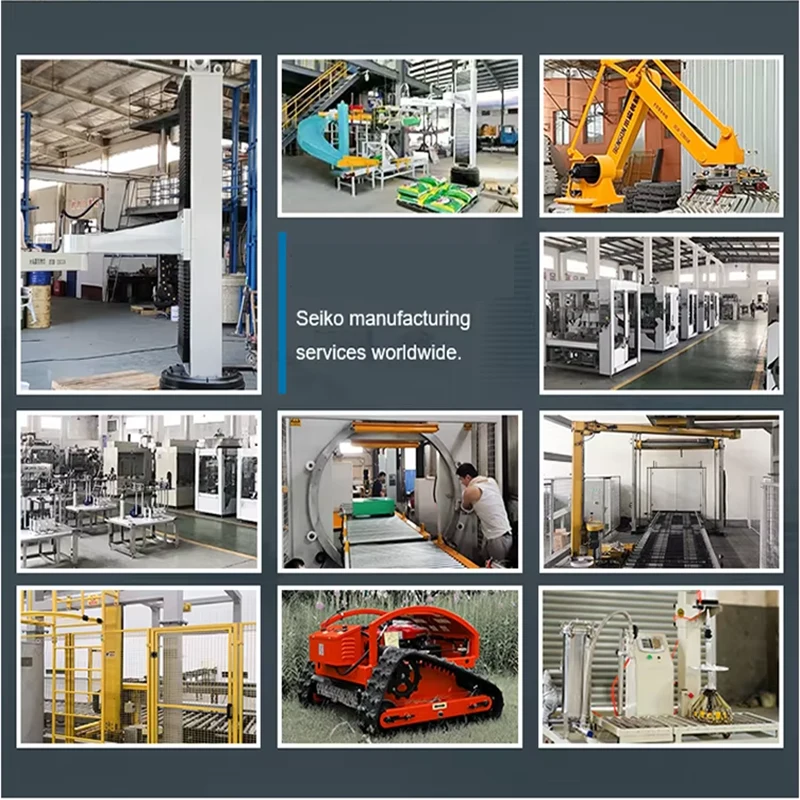

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

Product Inquiry