Fully automatic corrugated cardboard palletizer is an intelligent equipment designed for corrugated cardboard production, warehousing and logistics. It aims to replace traditional manual palletizing operations and realize efficient, accurate and stable cardboard palletizing processes. It is widely used in carton factories, packaging material companies, etc., helping companies improve production efficiency and reduce labor costs.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

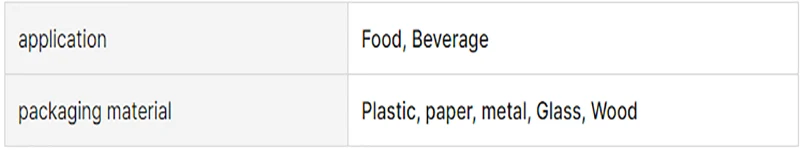

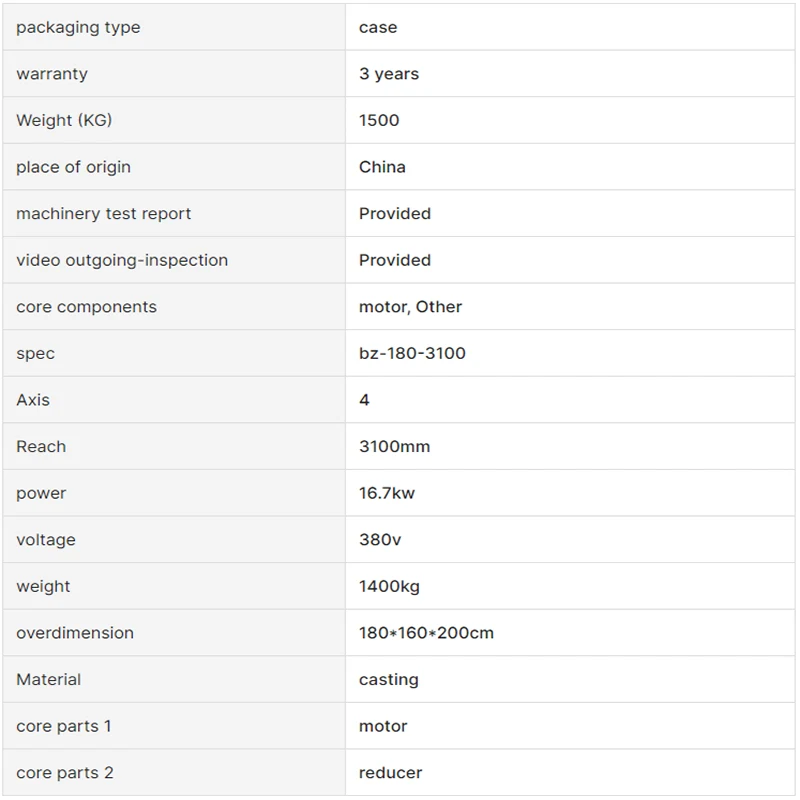

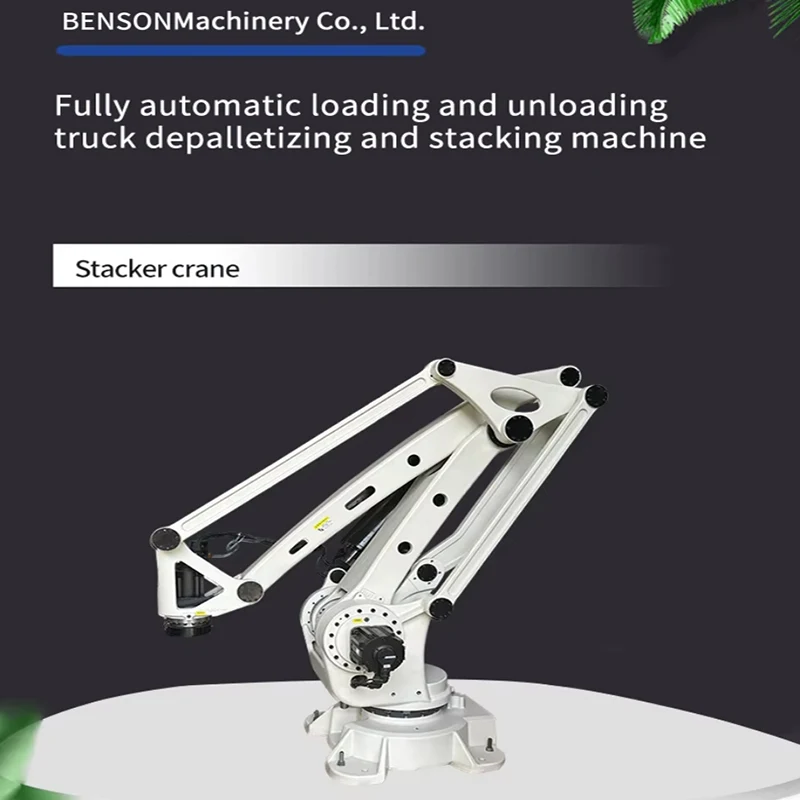

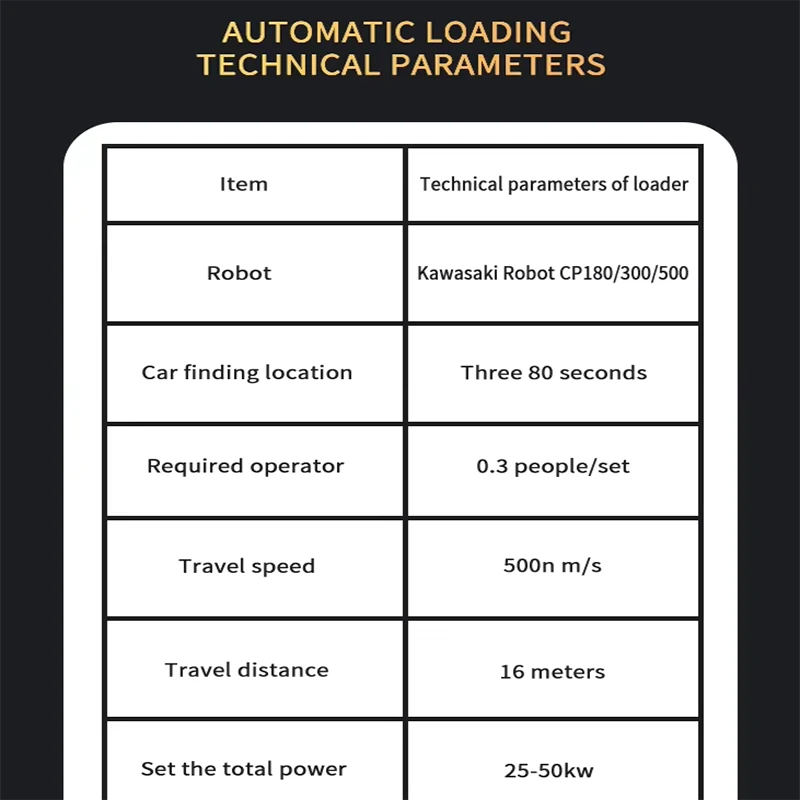

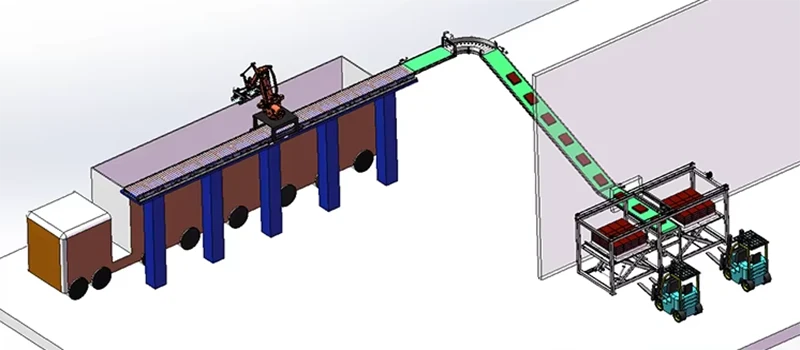

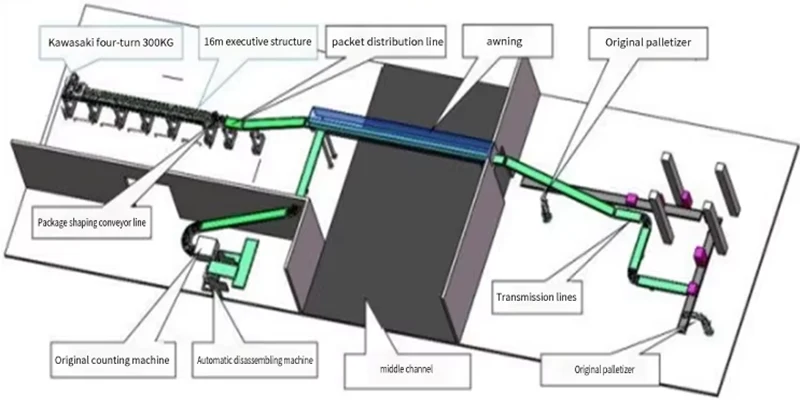

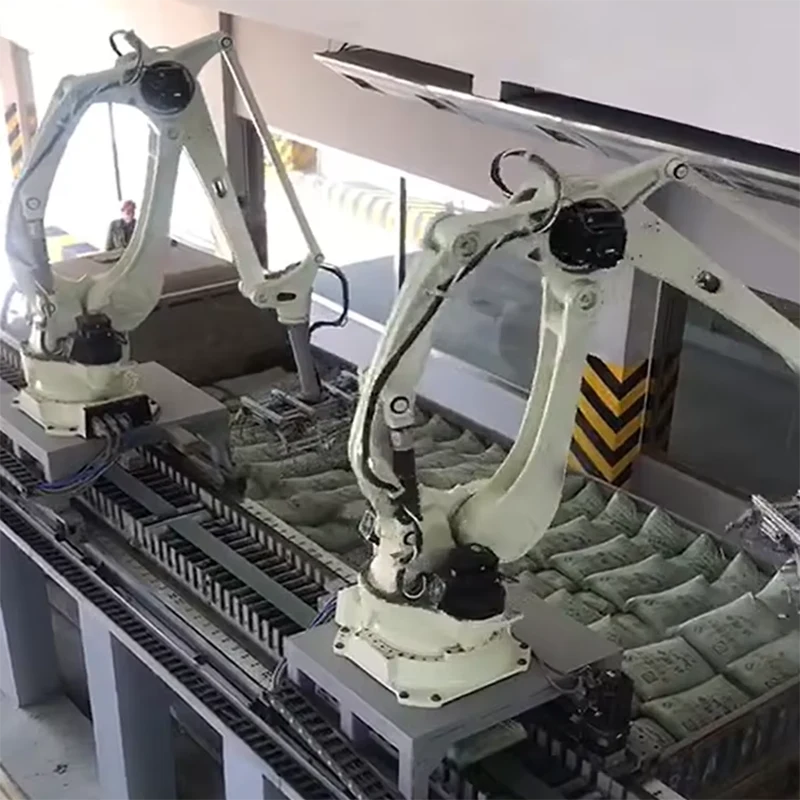

Feature highlights: This robotic palletizer is designed for handling corrugated cardboard cores and paper for the food, beverage, glass and wood industries. It has a working radius of 3,100 mm, 16.7 kW of power and four-axis control to ensure efficient operation. The machine is made of high-quality casting materials and comes with a three-year warranty. It supports a variety of packaging materials, including metal, wood, plastic, glass and paper. Mechanical test reports and video factory inspections are also provided to ensure quality.

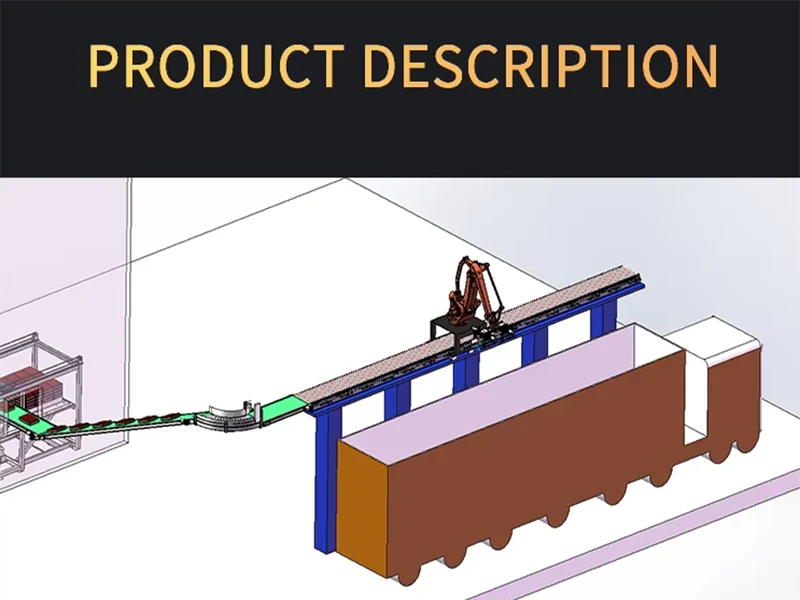

Products Description

Core advantages of fully automatic corrugated paper palletizer

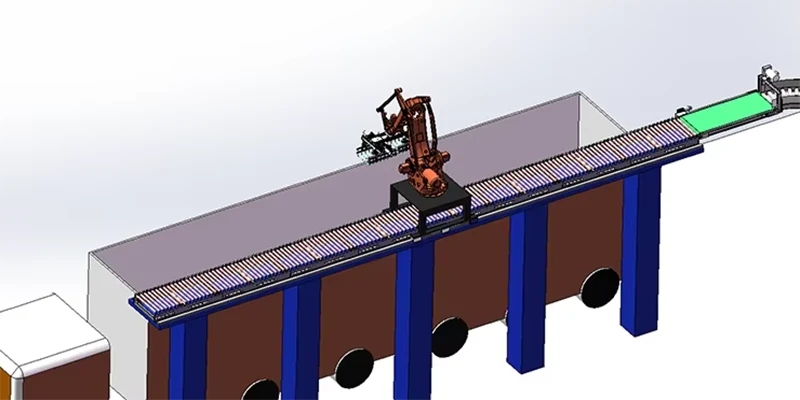

1. Efficient operation: using advanced servo drive system and high-speed motion control algorithm, greatly shortening the production cycle, meeting the rapid palletizing needs of large quantities of cardboard.

2. Accurate positioning: equipped with high-precision sensors and visual recognition systems, it can quickly identify the size, position and posture of the cardboard, ensure that the cardboard is neatly stacked, and reduce the risk of handling damage caused by irregular stacking.

3. Flexible adaptation: compatible with corrugated cardboard and core cardboard of various specifications and sizes, supporting custom stacking settings, whether standard size or special specifications, can quickly adjust parameters to meet diversified production needs.

4. Stable and reliable: the whole machine is made of high-strength steel and high-quality components, and has undergone strict quality inspection and performance testing. It has excellent fatigue and wear resistance, can operate continuously and stably for 24 hours, and reduce the equipment failure rate.

5. Safety and environmental protection: equipped with complete safety protection devices, including light curtain sensors, emergency stop buttons, safety fences, etc., to effectively ensure the safety of operators; at the same time, the equipment runs with low noise and low energy consumption, meeting green production standards.

Key technologies of high-speed core cardboard robot

1. Intelligent control system: integrated PLC programmable controller and touch screen human-machine interface, easy and intuitive operation, support one-button start, parameter setting, fault diagnosis and other functions, even non-professionals can quickly get started.

2. Visual recognition technology: through high-definition industrial camera to collect cardboard images in real time, combined with deep learning algorithm, automatically identify cardboard specifications, defects and stacking status, realize intelligent and unmanned palletizing operation.

3. Vacuum adsorption gripper: adopts efficient vacuum suction cup design, strong and stable adsorption force, can automatically adjust the suction force according to the material and size of the cardboard, to ensure that the cardboard is not damaged or slipped during the grabbing process.

4. Modular design: each functional unit of the equipment adopts modular structure, which is convenient for installation, debugging, maintenance and upgrading. It can be flexibly combined and configured according to the actual needs of the enterprise to reduce the later operating costs.

Application scenarios

1. Corrugated cardboard production workshop: At the end of the cardboard production line, quickly complete the stacking and sorting of the cardboard that has just come off the line, and seamlessly connect the subsequent packaging and warehousing processes.

2. Warehousing and logistics center: Efficiently stack the cardboard that is temporarily stored or waiting to be shipped, optimize the utilization rate of storage space, and facilitate the loading and unloading operations of forklifts and other handling equipment.

3. Carton processing enterprises: Meet the palletizing needs of corrugated cardboard of different order specifications, and provide efficient and orderly raw material preparation for carton production.

After-sales service

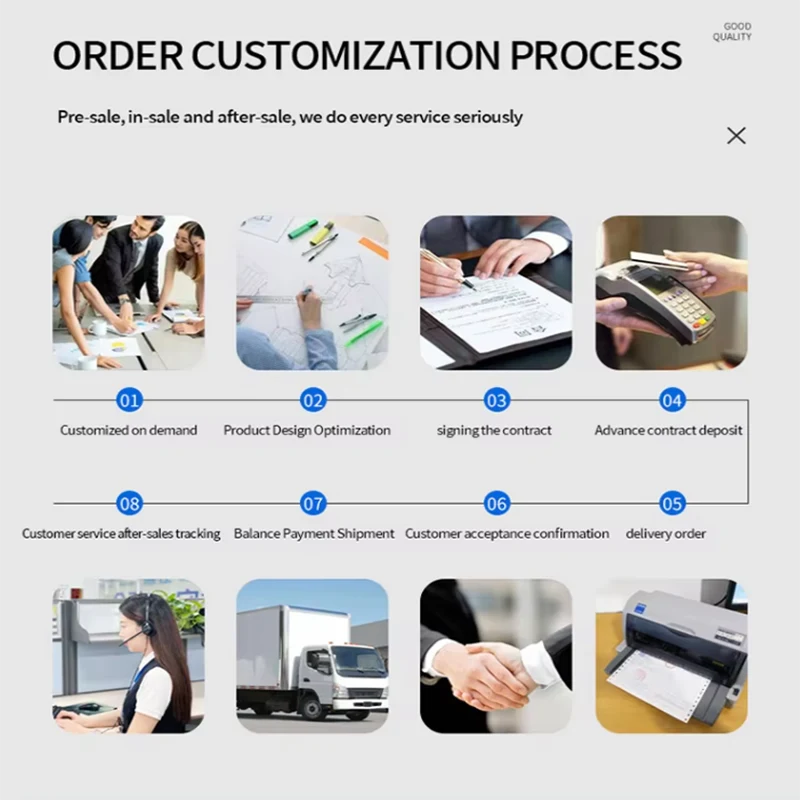

1. Installation and commissioning: Professional technical teams provide on-site installation and commissioning services to ensure that the equipment is quickly put into use, and provide free technical training for operators.

2. Warranty service: The whole machine provides a one-year warranty period. During the warranty period, equipment failures caused by non-human factors will be repaired or replaced free of charge.

3. Regular maintenance: Provide regular equipment inspection and maintenance services to extend the service life of the equipment and ensure long-term stable operation of the equipment.

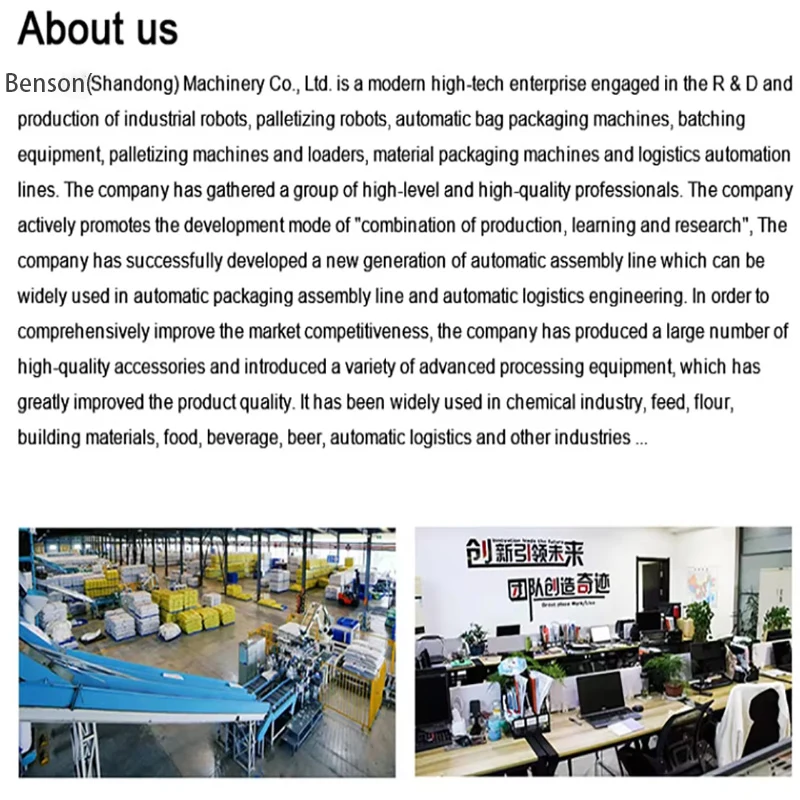

Company Profile

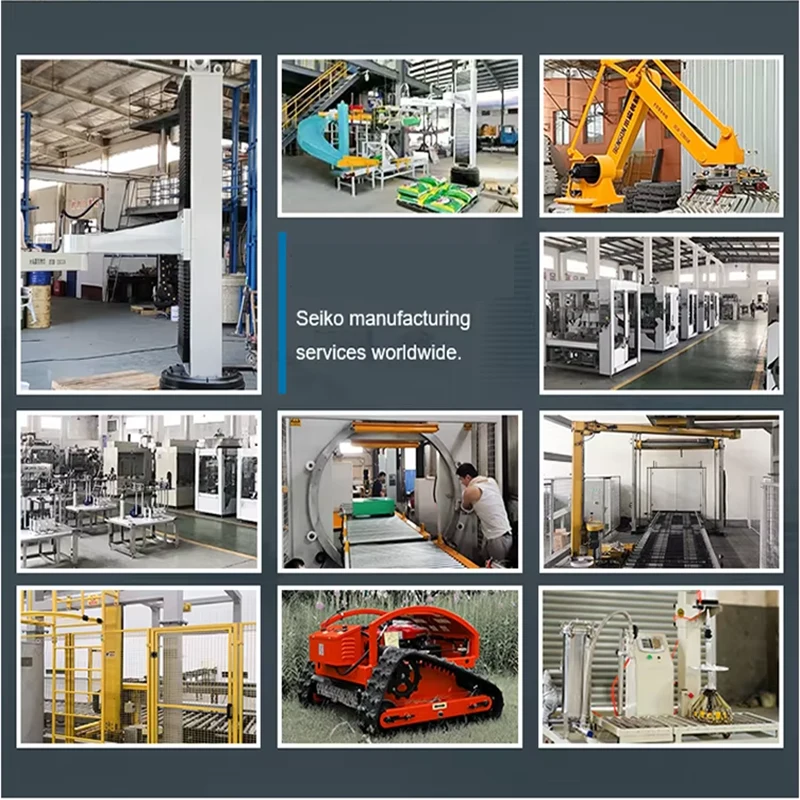

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and wechat.

Product Inquiry