Fully automatic stainless steel screw conveyor: a hygienic and efficient intelligent conveying expert

The fully automatic stainless steel screw conveyor uses high-quality stainless steel as the core material and integrates intelligent control technology. It is the preferred equipment for conveying powdered and granular materials in the food, medicine, chemical and other industries. With excellent corrosion resistance, stable automation performance and clean production characteristics,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

- Fully automatic stainless steel screw conveyor is made of stainless steel: the whole machine is made of 304/316L food-grade stainless steel, which has excellent corrosion resistance and rust resistance, can resist acid and alkali environment and humid working conditions, ensure that the material is transported without pollution throughout the process, and meet the strict hygiene standards of food, medicine and other industries; the surface is mirror polished, smooth and without dead corners, effectively avoiding material residue and facilitating cleaning and disinfection.

- Precision screw conveying system: The screw shaft and blades are integrally formed, and high strength and sealing are ensured by laser welding technology; according to different material characteristics (such as fluidity and viscosity), variable pitch and variable diameter blades can be customized to optimize the conveying efficiency and prevent material blockage or adhesion. The spiral blade edge has a smooth transition to reduce the extrusion and crushing of the material and ensure the integrity of the material.

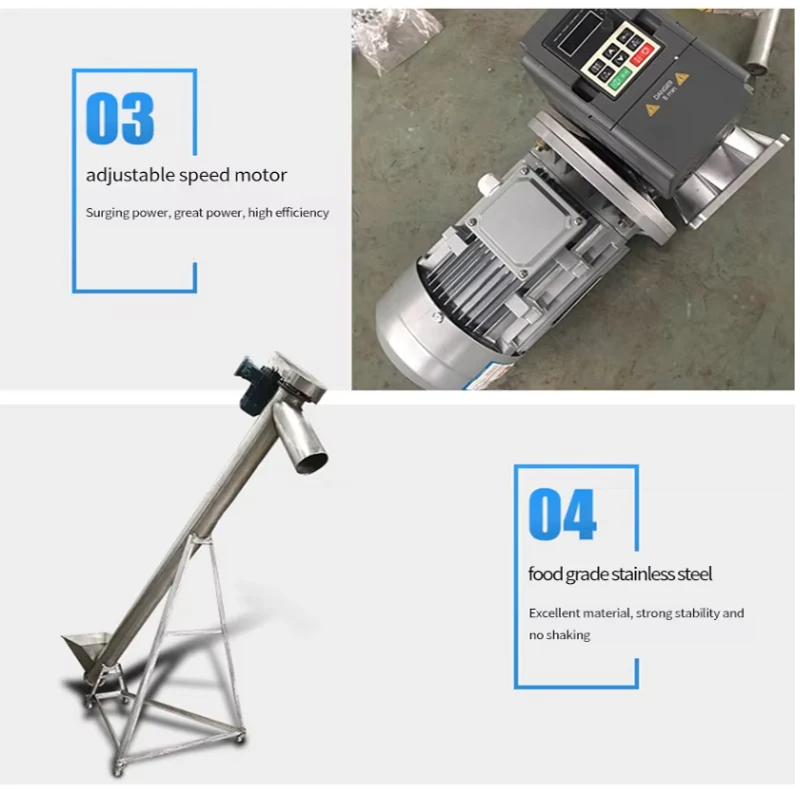

- Intelligent drive and control system: equipped with servo motor and high-precision frequency converter, it can achieve 0-100% stepless speed regulation, and can accurately control the conveying volume according to production needs; integrated PLC intelligent control system, supports remote control, fault diagnosis and data recording functions, monitors the equipment operation status in real time through touch screen or central control platform, automatically adjusts the conveying parameters, and realizes unmanned intelligent operation.

Core competitive advantages of fully automatic stainless steel screw conveyor

- Clean and safe conveying: all stainless steel material and sealing design, eliminate metal pollution and bacteria breeding risks from the source, comply with HACCP, GMP and other international certification standards, especially suitable for the conveying of food additives, pharmaceutical raw materials, fine chemicals and other materials with high cleanliness requirements.

- Efficient and energy-saving operation: the optimized spiral structure and power system are combined to save more than 30% energy compared with traditional conveying equipment; continuous and stable conveying capacity, the maximum conveying volume can reach 50m³/h, meeting the efficient operation needs of large-scale production lines.

- Intelligent operation and maintenance management: built-in vibration, temperature, blockage and other sensors, real-time monitoring of equipment operation data, once an abnormality occurs, immediately trigger the sound and light alarm and automatically shut down, and simultaneously push the fault information to the management terminal; modular design makes it easy to replace wearing parts, greatly shortening the maintenance time.

- Flexible customization scheme: supports horizontal, inclined, vertical and other conveying methods, can be customized according to the plant space layout and production process, different pipe diameters (100-600mm), lengths (1-30 meters) and interface forms of equipment, seamless connection mixers, packaging machines, silos and other upstream and downstream equipment, to create personalized conveying solutions.

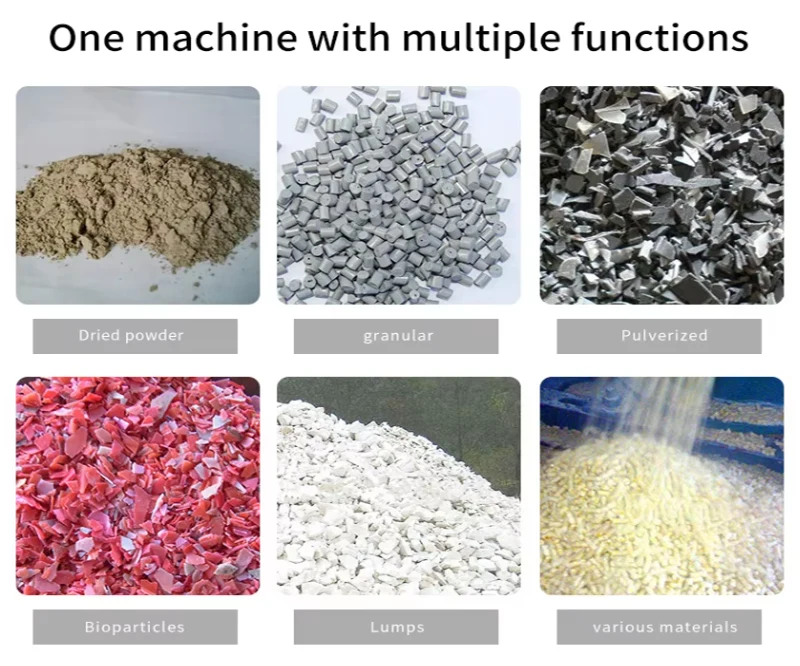

Fully automatic stainless steel screw conveyor wide application scenarios

- Food processing field: suitable for the conveying of materials such as flour, starch, powdered sugar, grain particles, etc., in bakeries, biscuit factories, and condiment production lines, to ensure the safe and efficient circulation of food raw materials and help clean production.

- Pharmaceutical production industry: meet the aseptic conveying requirements of materials such as pharmaceutical particles, capsules, powder preparations, avoid cross contamination, and provide reliable guarantee for the automated production of pharmaceutical companies.

- Fine chemical industry: used to transport chemical raw materials such as pigments, dyes, and resin powders. Its corrosion resistance ensures stable operation of the equipment in complex chemical environments and reduces maintenance costs.

- Environmental protection and new energy: In the transportation of special materials such as lithium battery negative electrode materials and sludge dehydrated materials, it effectively copes with the transportation challenges of highly abrasive and highly viscous materials with its wear resistance and sealing advantages.

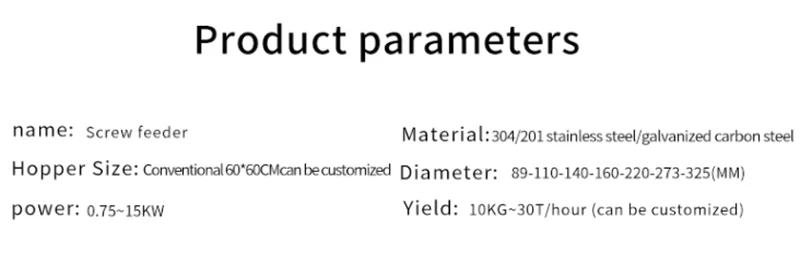

Products Description

Company Profile

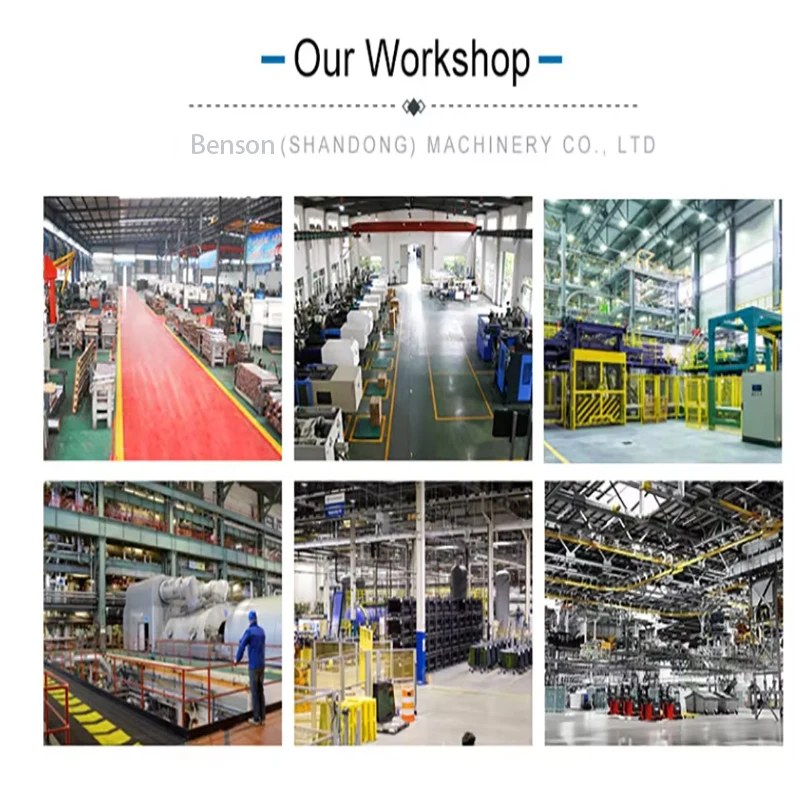

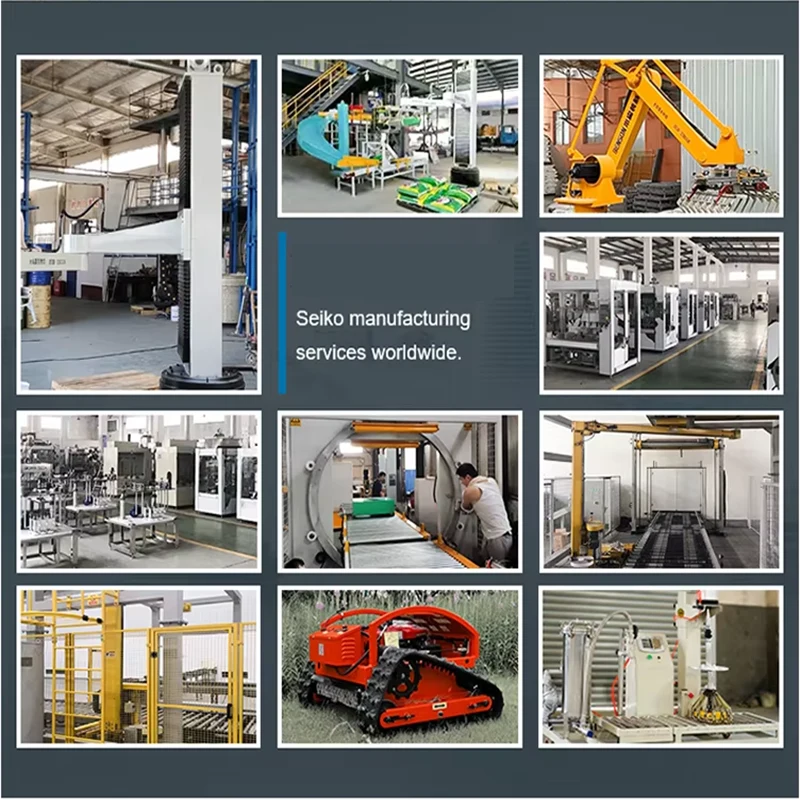

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry