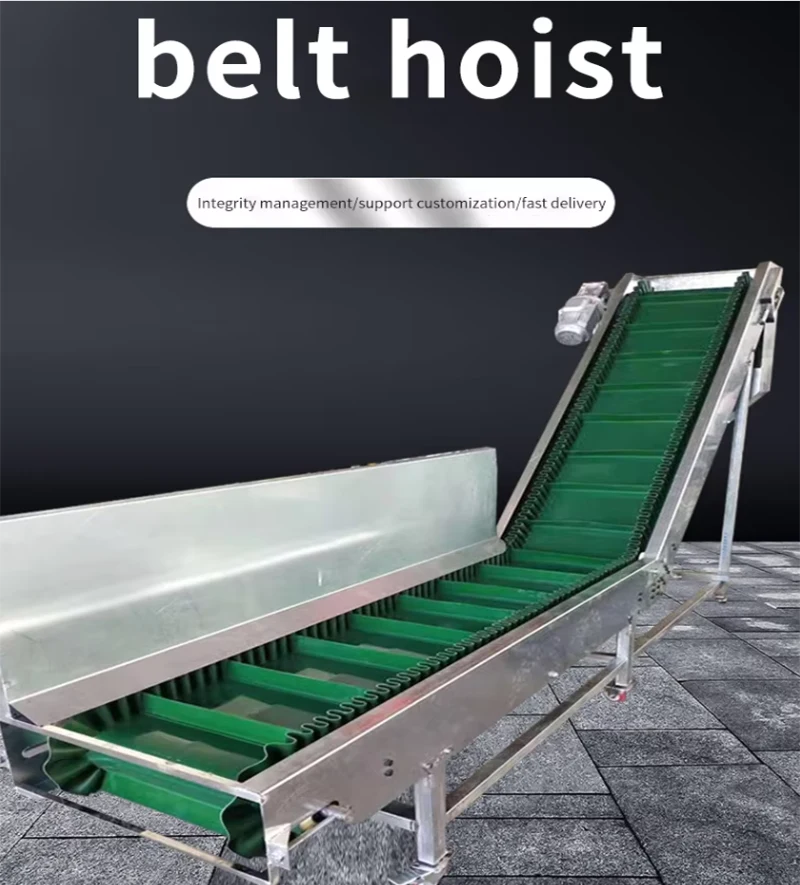

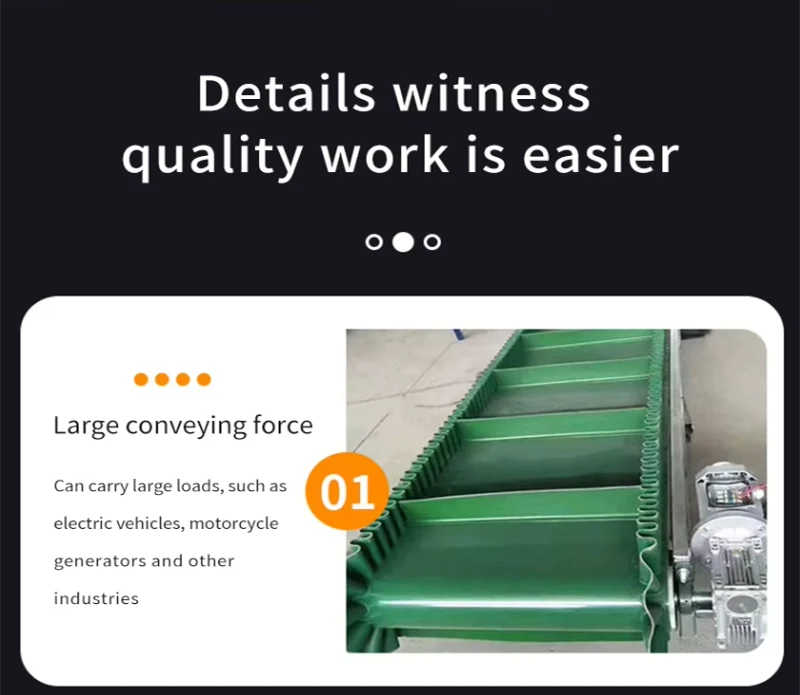

Breaking the traditional linear transportation mode, the innovative Z-type three-dimensional layout can flexibly switch the transportation path in the vertical and horizontal directions, and only requires a very small footprint to achieve multi-level and long-distance lifting and transfer of materials. Compared with traditional conveying equipment, it is particularly suitable for production scenarios with limited plant height and tight ground space.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

New automatic Z-belt conveyor - an innovative choice for efficient space utilization and intelligent transportation

Core technical highlights of the new automatic Z-belt conveyor

Intelligent drive, precise and efficient

Equipped with servo motor + PLC control system, it supports fully automated operation and can automatically start and stop and adjust the conveying speed (range 0.1-2m/s) according to the production rhythm. The built-in high-precision sensor monitors the belt tension, running speed and material distribution status in real time. When there are abnormalities such as blockage and offset, the system immediately triggers an audible and visual alarm and automatically shuts down to avoid material spillage and equipment damage, ensuring production continuity and safety. At the same time, it supports seamless docking with the enterprise MES system to achieve data interoperability and remote monitoring and management.

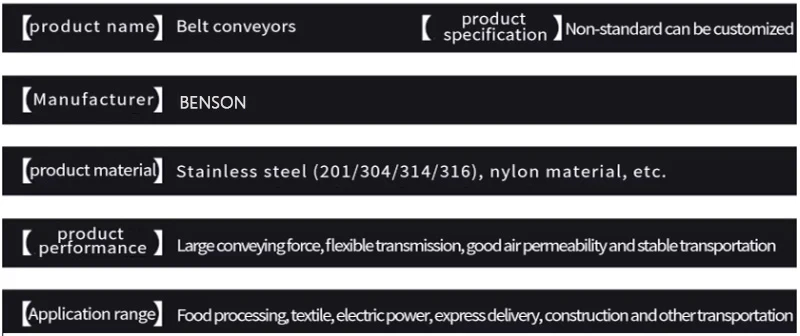

Modular design, flexible customization

Adopting a modular assembly structure, the conveying unit, steering module, drive device, etc. can be combined as needed. According to the material characteristics (granules, powders, packaged finished products, etc.), you can choose a variety of belt materials such as food-grade PU, wear-resistant rubber, anti-static PVC, etc.; the conveying height, angle, width and inlet and outlet positions can be customized to meet the differentiated needs of multiple industries such as food processing, electronic assembly, pharmaceutical packaging, logistics sorting, etc., and quickly complete the production line upgrade and transformation.

Excellent performance advantages of the new automatic Z-type belt conveyor

- Stable and durable: The frame is made of high-strength carbon steel/stainless steel, rust-proof treated, with wear-resistant rollers and reinforced belts, the continuous operation life exceeds 50,000 hours, and the maintenance cycle is extended by 30%.

- Low noise and energy saving: Optimized transmission system design, operating noise is less than 65dB; frequency conversion energy-saving technology reduces energy consumption by 25%, in line with green production standards.

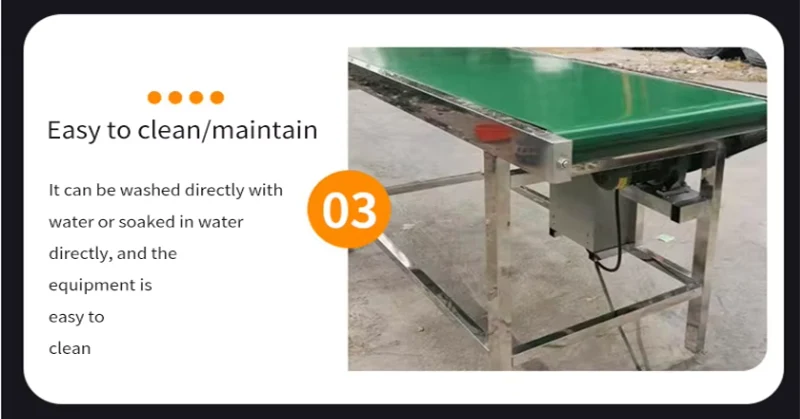

- Clean and convenient: open structure design, easy for daily cleaning and maintenance; quick-detachable belt design makes replacement and maintenance easier, greatly shortening downtime.

Diverse application scenarios

- Food and beverage industry: used for multi-layer sorting and vertical lifting of cakes and bottled drinks, food-grade materials ensure hygiene and safety, and avoid cross contamination.

- Electronic manufacturing industry: realize the smooth transportation of precision components and semi-finished products, anti-static belts effectively protect sensitive electronic components, and high-precision positioning ensures assembly accuracy.

- Pharmaceutical industry: meet the clean transportation needs of drugs and medical devices, meet GMP standards, and customize dust-free transportation environment.

- Logistics and warehousing industry: efficiently complete the three-dimensional sorting and inter-floor transfer of packages, work with AGV and sorting robots to improve the level of warehousing automation.

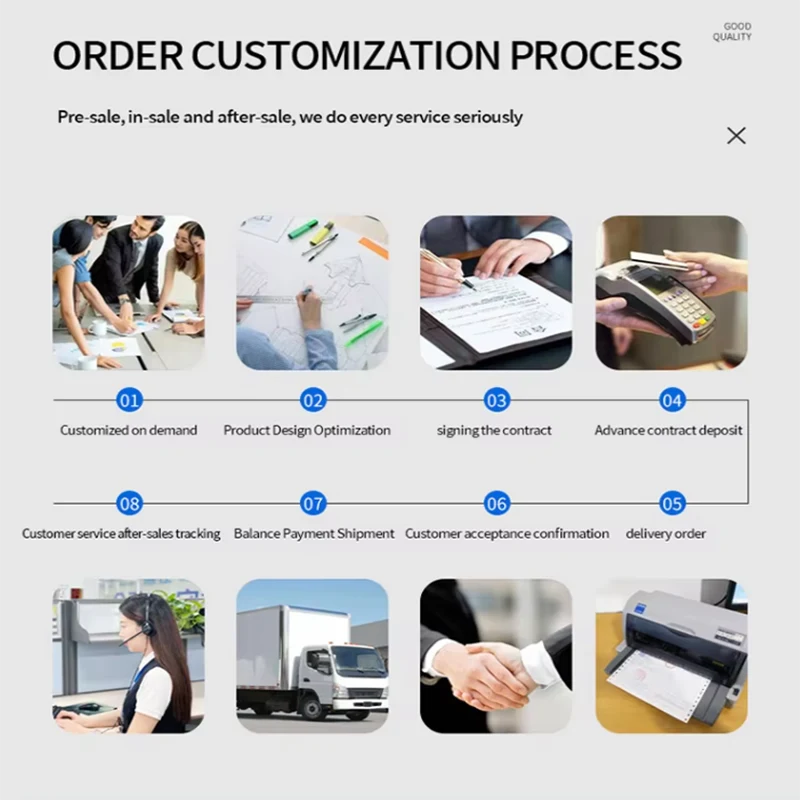

Full-cycle service guarantee

We provide one-stop service from demand analysis, solution design, installation and commissioning to lifelong after-sales. The professional technical team responds online 24 hours a day, 7 days a week, and regularly visits for maintenance to ensure that the equipment always maintains the best operating condition. It has helped many companies achieve both transportation efficiency and production capacity.

Choose a new automatic Z-type belt conveyor to drive production upgrades with innovative technology and open up a new future of cost reduction and efficiency improvement! Contact us now to get exclusive solutions and unlock new experiences in intelligent transportation!

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry