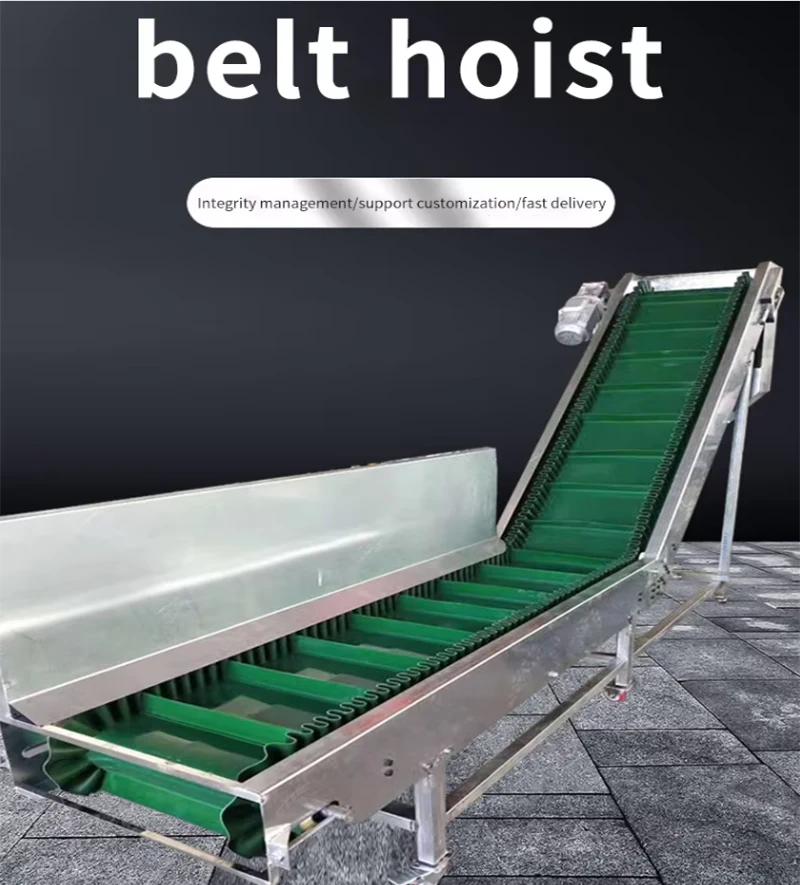

Inclined elevator: an innovative tool for industrial vertical transportation

In modern industrial production and logistics operations, efficient vertical transportation of materials is a key link to ensure smooth processes. Inclined elevators, as a unique transportation equipment, have become the ideal choice for many companies due to their excellent performance and wide applicability.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Inclined lifts are flexible and adaptable

- Flexible angle adjustment: The tilt angle can be freely adjusted within a large angle range (such as 15° - 75°, etc., depending on the product), which can meet the needs of different working scenarios and sites. Whether it is a construction site with special terrain requirements or a warehouse with complex internal structure, it can adapt to different material conveying angles without the need to customize equipment for specific angles.

- Good site adaptability: Compared with traditional vertical lifts, its inclined conveying method has more advantages in space utilization. It can cleverly use irregular areas such as slope space and corner space in the building for installation and operation. For places with limited space, it can effectively save floor space and improve site utilization.

Inclined lifts can transport efficiently

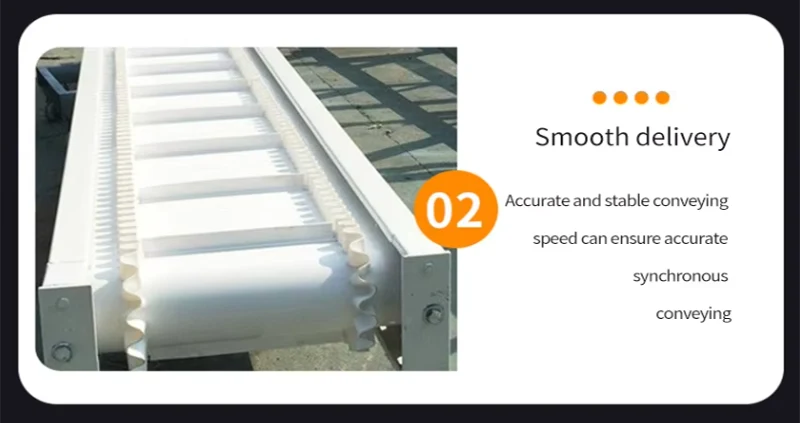

- Fast transportation: With a high operating speed, it can complete the vertical or inclined lifting and transportation of materials in a short time. In some logistics sorting centers, goods can be quickly lifted from lower floors to the sorting area, speeding up the flow of goods and improving overall logistics efficiency.

- Continuous operation capability: It can realize continuous and uninterrupted material transportation, and can be closely connected with production lines, storage systems, etc., to form an efficient and automated material transportation process, meet the needs of large-scale production and logistics operations, and reduce the waiting time for goods.

Inclined elevators are safe and reliable

- Multiple safety protections: Equipped with complete safety devices, such as anti-fall devices, overload protection devices, speed limiters, etc., it can quickly brake in emergencies to ensure the safety of personnel and goods. In addition, some advanced inclined elevators also have fault warning functions, which can detect potential problems of equipment in advance and avoid accidents.

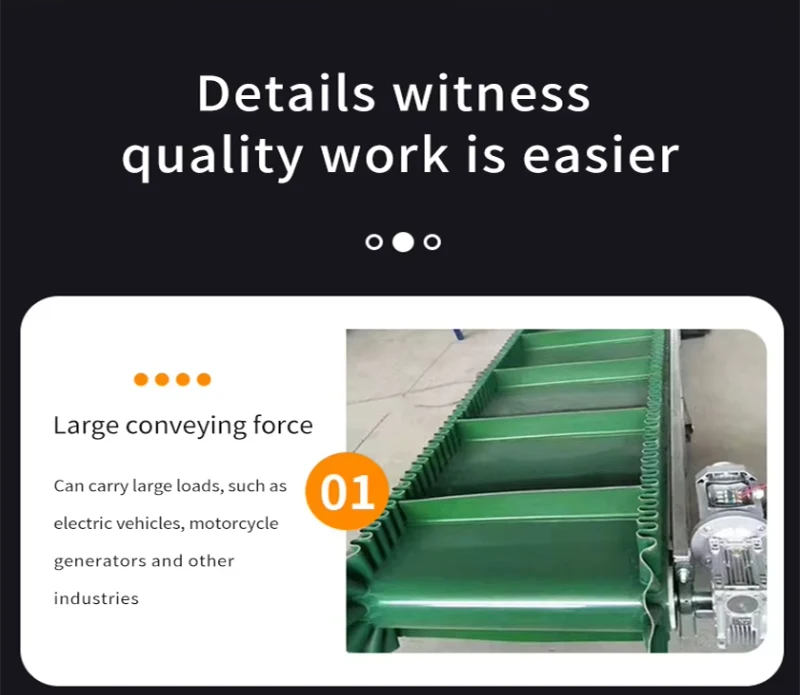

- Stable structural design: It adopts high-strength materials and sturdy structural design, which can withstand large loads, remain stable even when running in an inclined state, reduce shaking and vibration, and ensure the safety and integrity of materials during transportation.

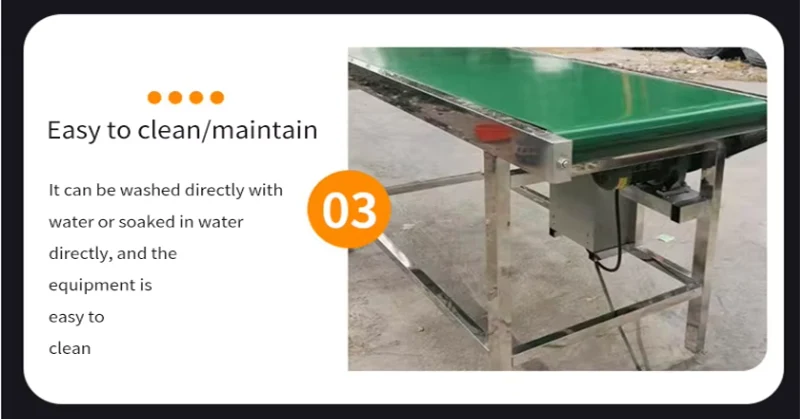

Ingenious craftsmanship of inclined lift, worry-free maintenance

- Lubrication-free design: The rollers and back wheels of the lift adopt lubrication-free bearings, which do not require regular oiling and maintenance, reducing maintenance workload and costs, while avoiding equipment failures caused by lubrication problems and ensuring the continuity of equipment operation.

- No debugging feature: The rollers and back wheels are equipped with anti-loosening card plates, which will not loosen during use, and no repeated debugging is required. After installation, it can run stably, providing users with a worry-free and labor-saving experience.

- Long-term anti-corrosion process: Up to 95% of the parts are hot-dip galvanized, and the cage and drive part adopt electrophoresis + paint process to achieve comprehensive anti-corrosion of the internal and external cavities, effectively extending the service life of the equipment, reducing the frequency of equipment updates, and reducing the long-term operating costs of the enterprise.

Inclined lifts are widely used

- Bridge construction: In bridge construction, inclined lifts can run along inclined piers or bridge structures, making it convenient for construction workers to go up and down, and efficiently transport building materials. For example, they have performed well in major projects such as the Pingtan Strait Railway Bridge and the Chaoma Railway Bridge, helping to promote efficient bridge construction.

-Warehouse logistics scenarios: The inclined lift can easily handle the handling of goods between different floors or shelves in the warehouse, quickly lift the goods from the ground to the specified height, improve the utilization rate of storage space, and optimize the logistics storage and sorting process.

-Factory production link: It is suitable for material transfer between different height stations of the production line within the factory, ensuring the continuity of the production process, improving the overall production efficiency, and meeting the diversified production needs of various manufacturing companies.

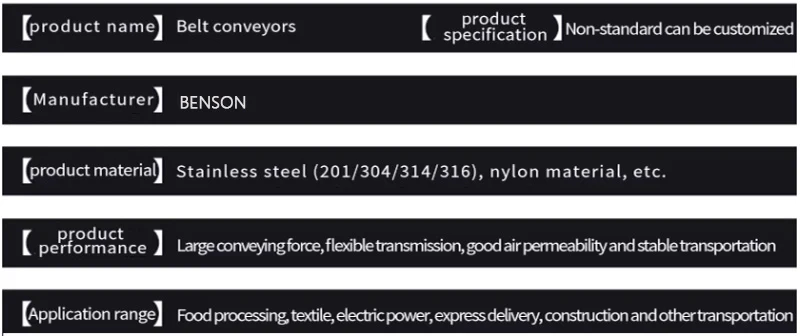

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry