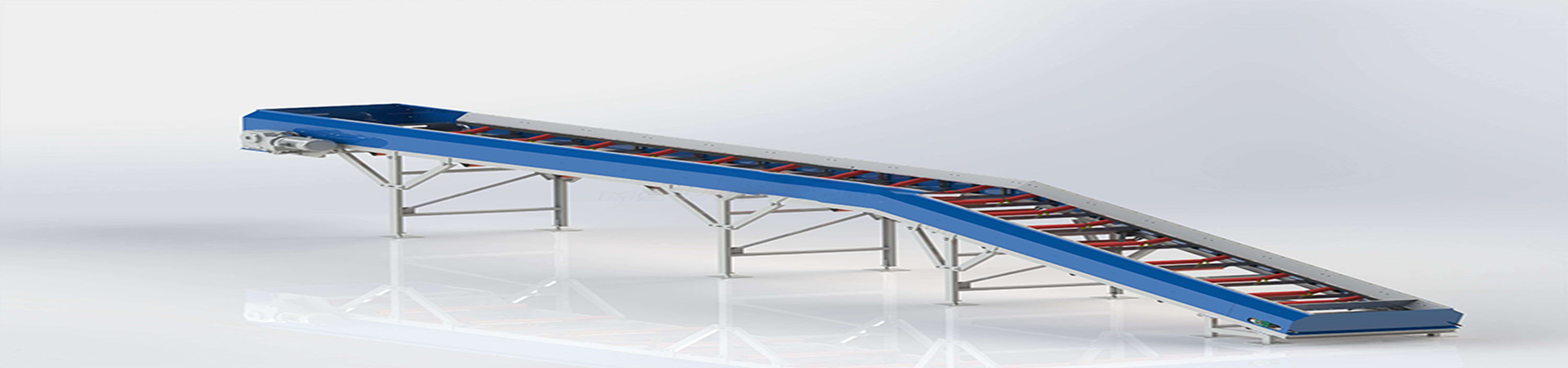

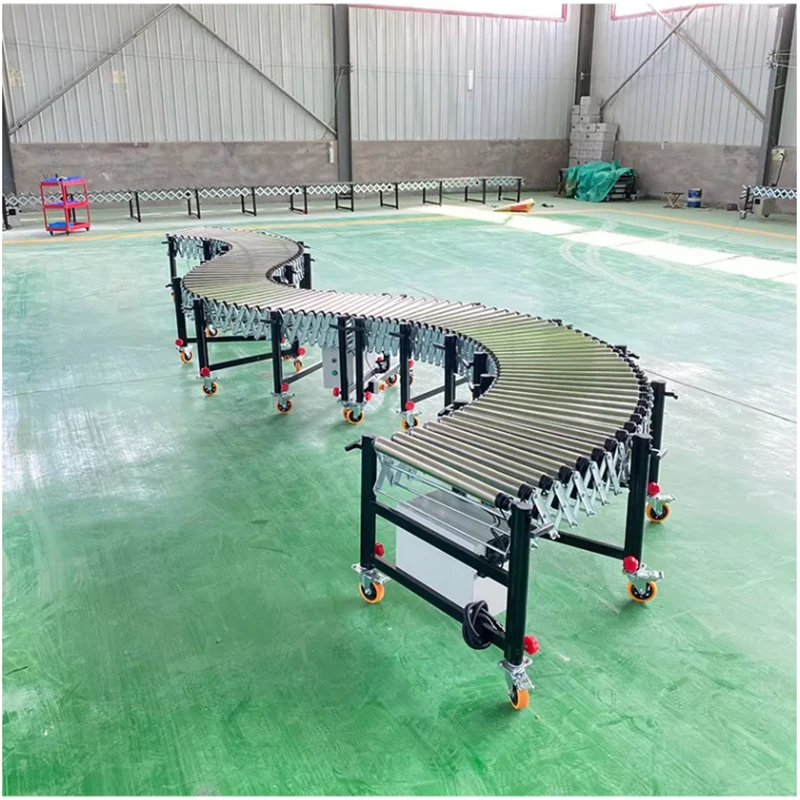

Stainless steel conveyor roller conveyors can be closely connected with each process of the production line to form a highly automated, stable and reliable material conveying system, effectively improving the efficiency and continuity of industrial production and reducing labor costs and labor intensity.Industrial conveyor roller conveyor is an efficient material transfer equipment specially designed for industrial production scenarios. It is widely used in many industrial fields such as machine

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

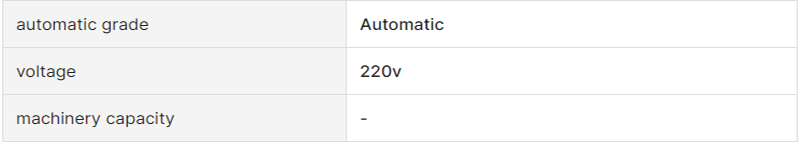

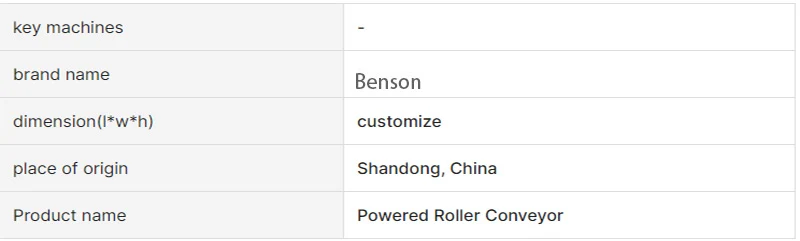

Key attributes

Industry-specific attributes

Performance characteristics of automated conveyor roller conveyor:

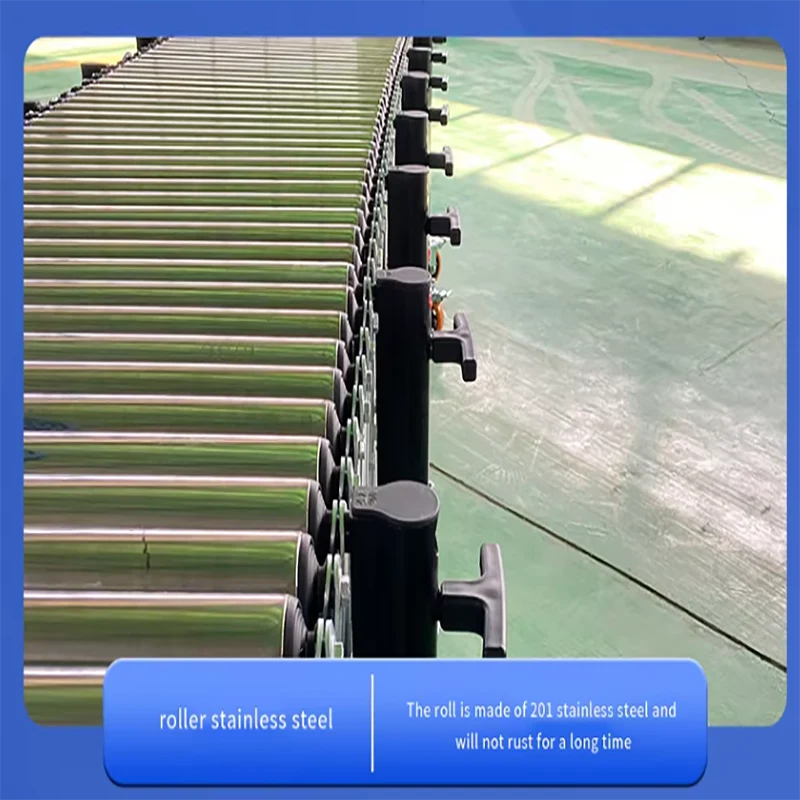

- Strong load capacity of automated conveyor roller conveyor: It usually adopts high-strength alloy steel rollers and sturdy frame structure, which can bear the transportation of materials of different weight levels, such as in some large factories, it can carry heavier mechanical parts.

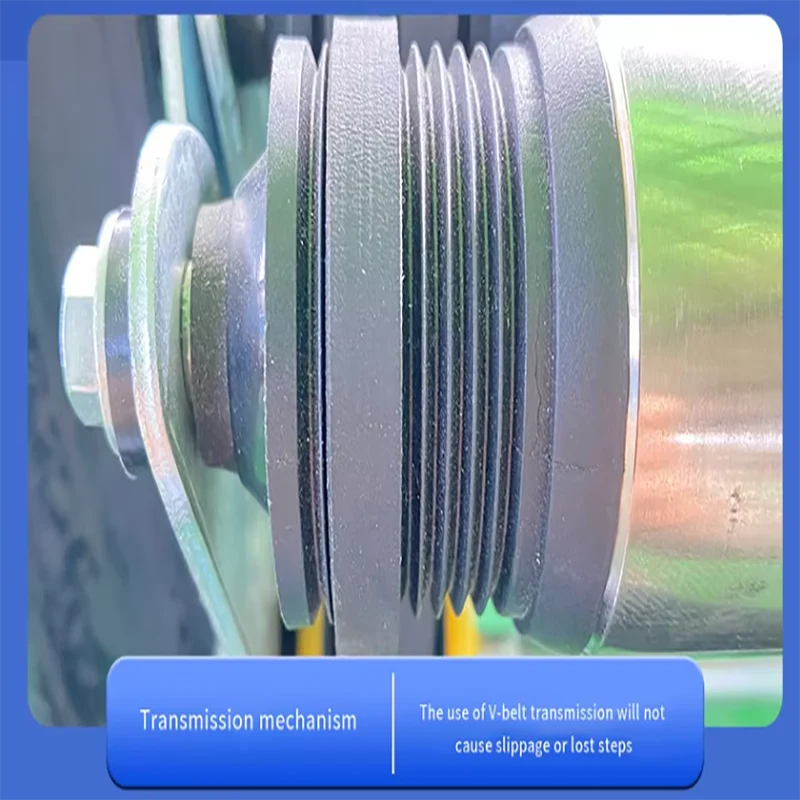

- Efficient and stable operation: Equipped with high-quality drive motors and precision transmission systems, it runs smoothly, with uniform and adjustable speed, such as on the production line of electronics factories, it can convey products according to the production rhythm.

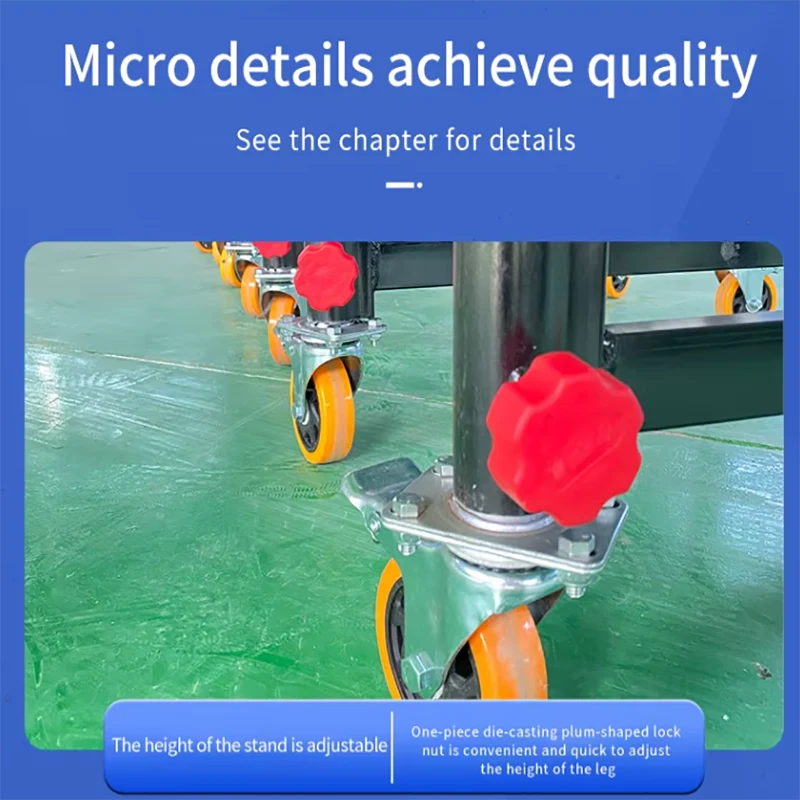

- Highly flexible customization: The roller spacing, conveyor length, width, height, etc. can be customized according to different production needs, and different roller materials can be selected. For example, stainless steel may be selected in food factories.

Technical parameters of automated conveyor roller conveyor:

- Conveying speed: Generally variable frequency adjustable within a certain range to adapt to different production rhythms.

- Maximum load per meter: There are specific load values according to different models.

- Roller diameter: There are many specifications to choose from.

Application scenarios of automated conveyor roller conveyors: widely used in machinery manufacturing, electronics, chemicals, building materials and other industries, used for parts transportation in automobile assembly workshops, and used for electronic product production process transportation in electronics factories.

After-sales service of automated conveyor roller conveyors: usually provide professional installation and commissioning, perfect quality assurance system, rapid response mechanism and regular maintenance services to ensure long-term and stable operation of the equipment.

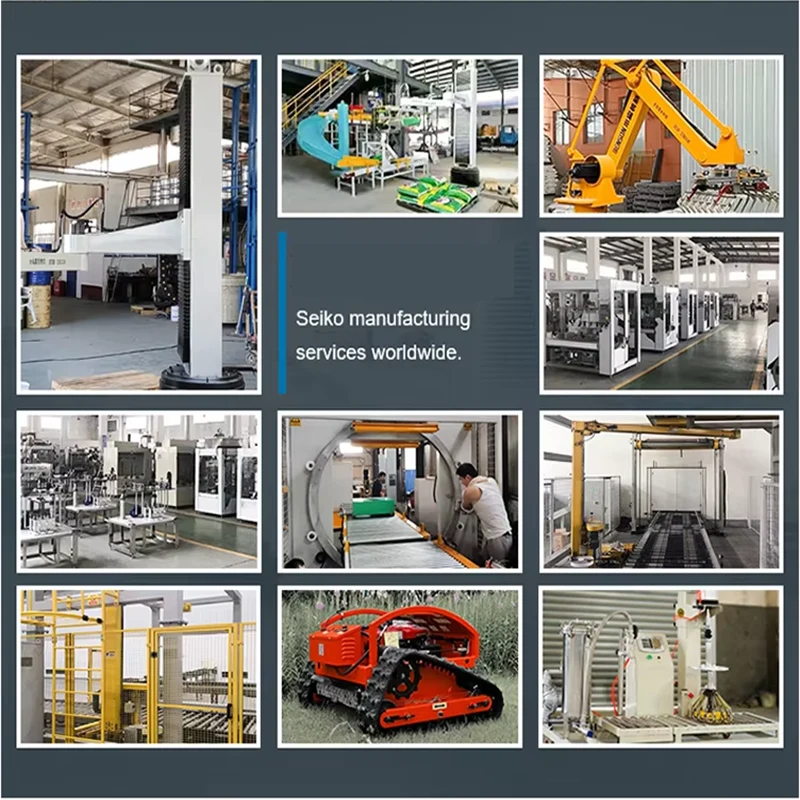

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bomei (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry