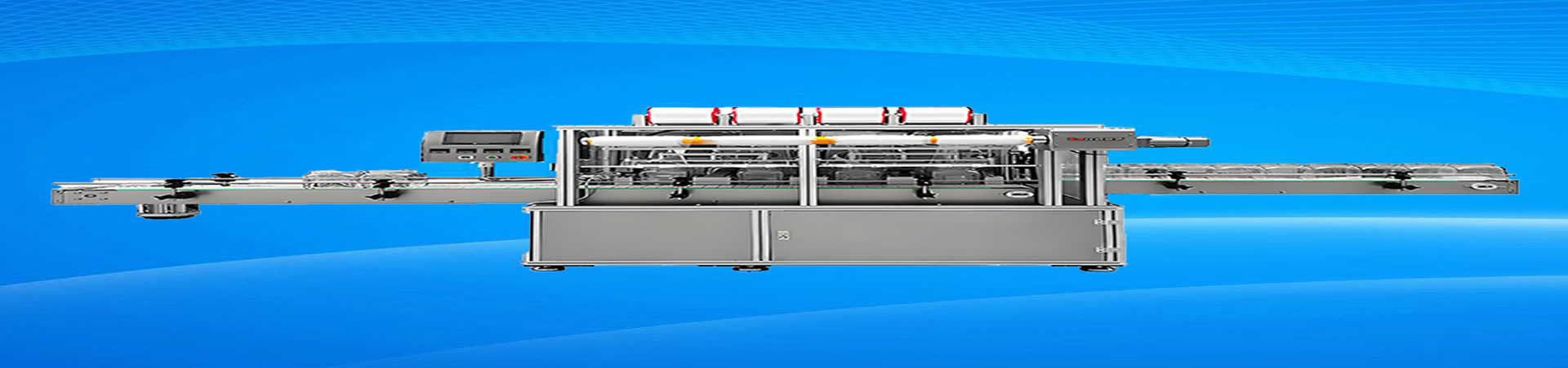

The new automatic electric track paper flow sealing machine represents a cutting - edge innovation in the packaging machinery field. It combines advanced automation technology with efficient electric operation, providing a seamless and high - speed packaging solution for various paper - based products. This machine is equipped with an intelligent control system that enables fully automatic operation. From feeding the paper materials onto the track to the final sealing process, it can complete

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

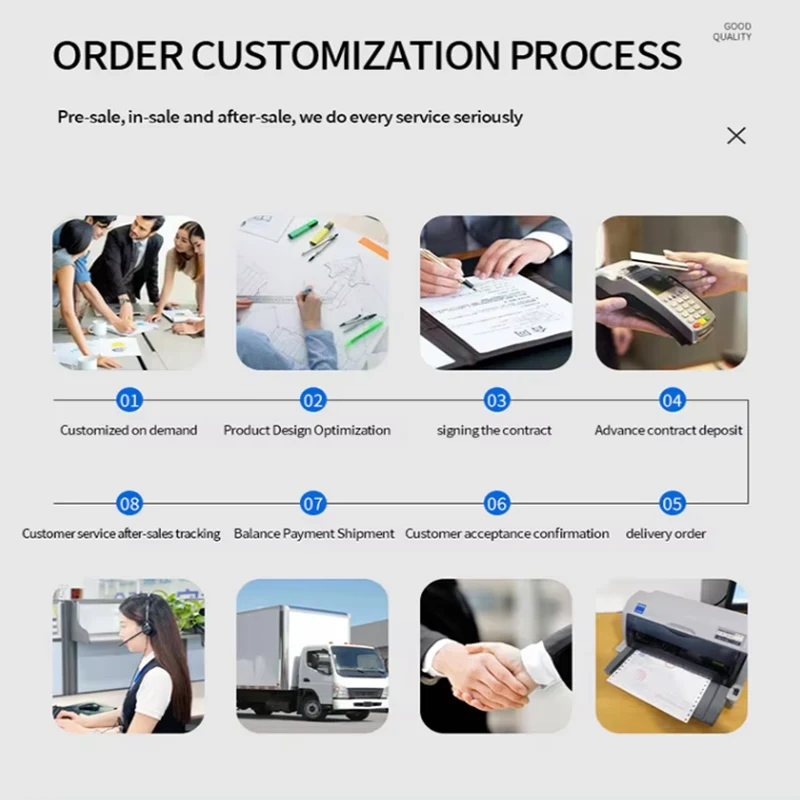

The new automatic electric track paper flow sealing machine represents a cutting - edge innovation in the packaging machinery field. It combines advanced automation technology with efficient electric operation, providing a seamless and high - speed packaging solution for various paper - based products.

Key Features

1. Automated Operation

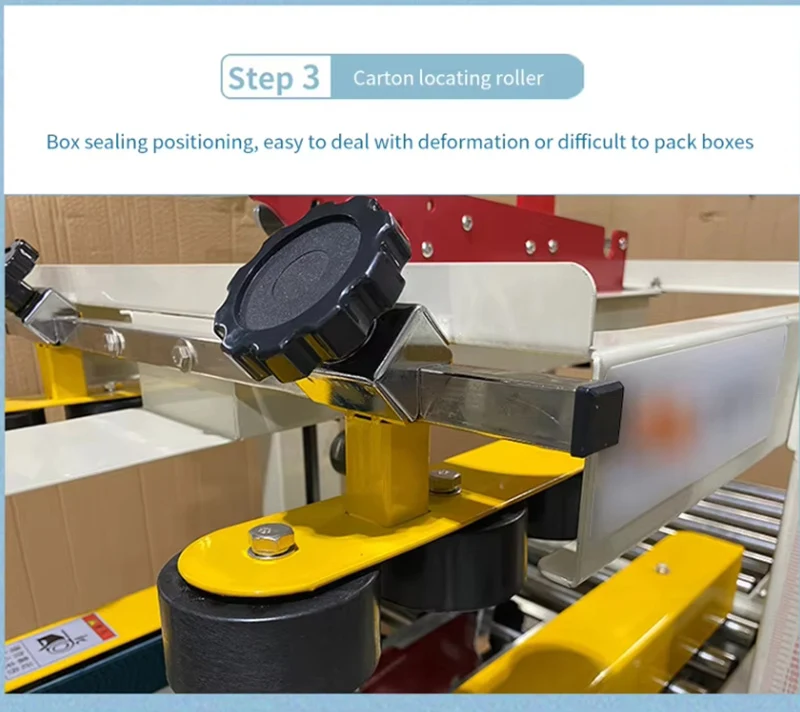

This machine is equipped with an intelligent control system that enables fully automatic operation. From feeding the paper materials onto the track to the final sealing process, it can complete the entire workflow without extensive manual intervention. Sensors and programmable logic controllers (PLCs) monitor and adjust each step, ensuring accurate paper alignment and consistent sealing quality. This automation significantly reduces labor costs and human error, improving overall production efficiency.

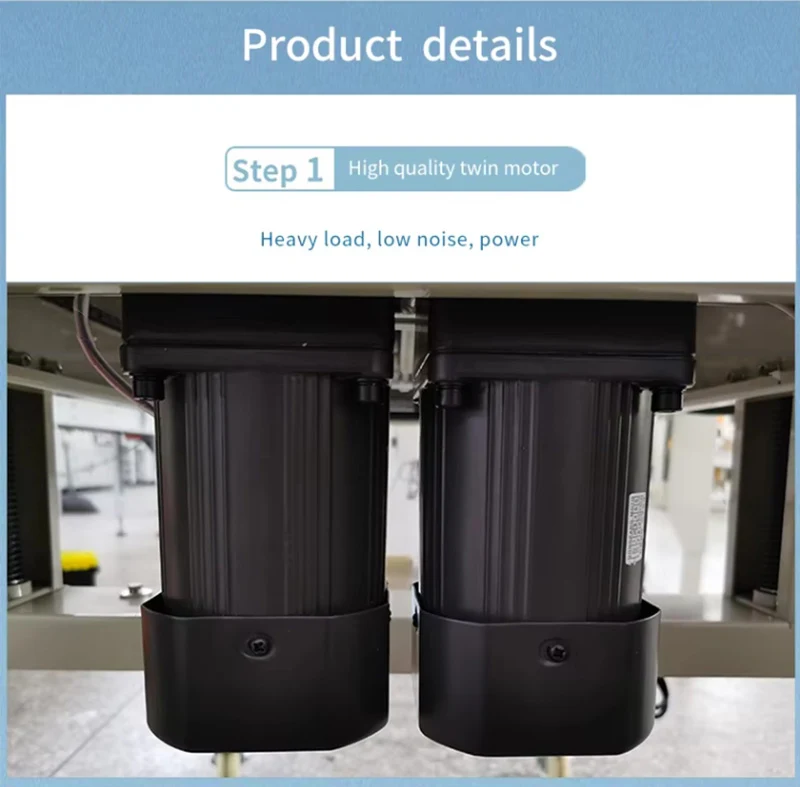

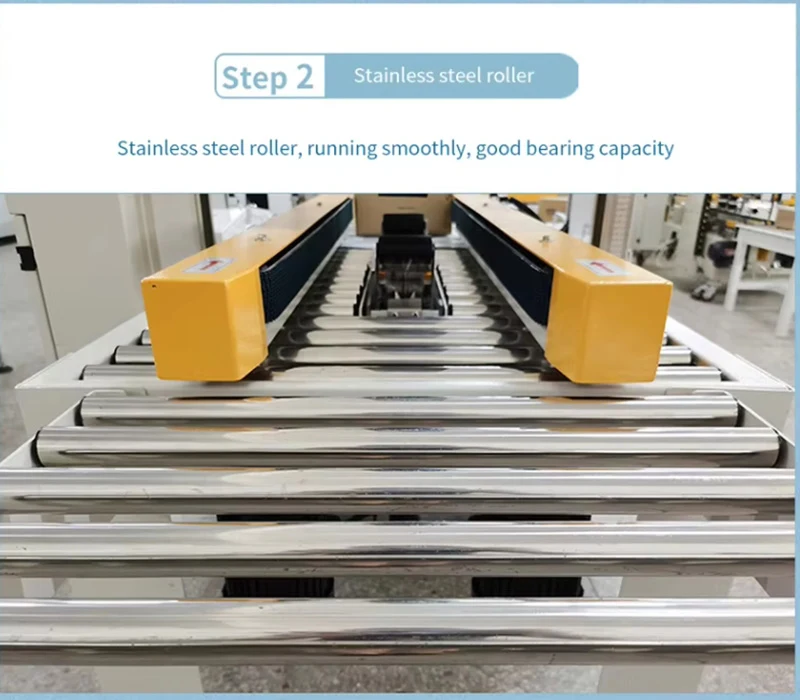

2. Electric - Driven Track

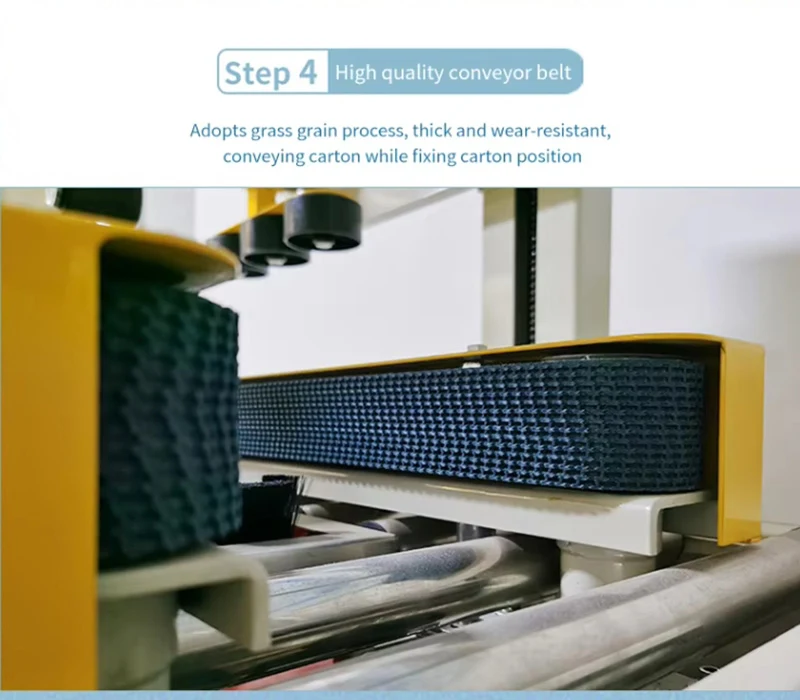

The electric - powered track mechanism is the core of this sealing machine. It provides stable and smooth movement of the paper products during the sealing process. The adjustable speed feature of the track allows users to customize the production rate according to their specific needs, whether it's for small - batch, high - precision work or large - scale mass production. The electric drive also ensures low noise operation and energy - saving performance, making it an environmentally friendly choice.

3. Precise Sealing Technology

The sealing system of the machine utilizes advanced heat - sealing or ultrasonic - sealing techniques, depending on the model. It can create strong, air - tight seals on a wide range of paper materials, including coated paper, kraft paper, and specialty papers. The sealing width and temperature can be precisely adjusted, guaranteeing a perfect seal for different product sizes and paper thicknesses. This precision not only enhances the product's appearance but also provides excellent protection, preventing moisture, dust, and damage during storage and transportation.

4. User - Friendly Design

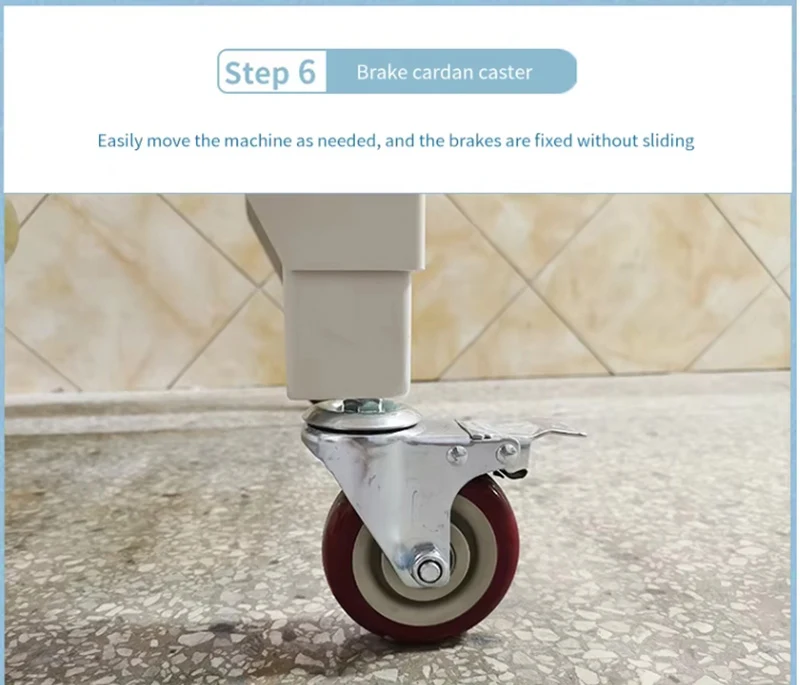

Designed with user convenience in mind, the machine features an intuitive control panel. Operators can easily set parameters such as sealing time, temperature, and track speed through the touch - screen interface. The machine also has a modular structure, which makes it easy to install, maintain, and replace parts. Additionally, safety features such as emergency stop buttons and protective covers are integrated to ensure the safety of operators during use.

New automatic electric track paper flow sealing machineVersatile Applications

This automatic electric track paper flow sealing machine is suitable for a variety of industries. In the food industry, it can be used to package paper - wrapped snacks, baked goods, and confectionery, keeping the products fresh and hygienic. In the stationery and printing industries, it is ideal for sealing notebooks, brochures, and printed materials, presenting them in an attractive and professional manner. It also has applications in the pharmaceutical and cosmetics industries, where it can package paper - based product inserts, manuals, and promotional materials.

In conclusion, the new automatic electric track paper flow sealing machine offers a reliable, efficient, and versatile packaging solution. Its combination of advanced technology, user - friendly design, and wide - ranging applications makes it an essential asset for any business looking to improve its packaging process and enhance product quality.

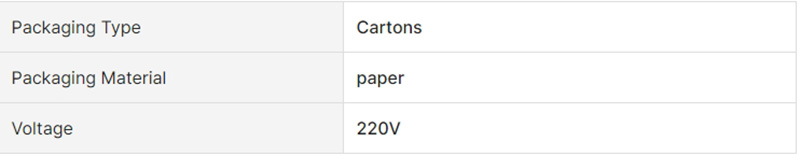

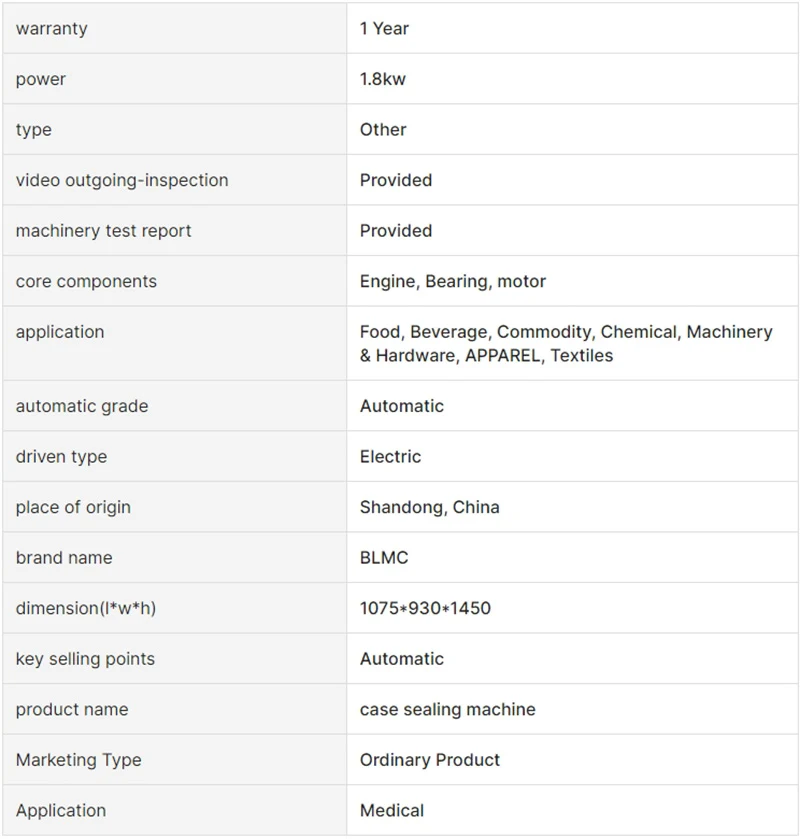

Other attributes

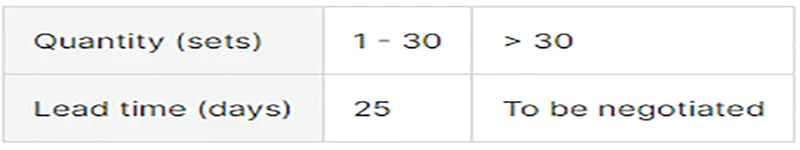

Lead time

Product Inquiry