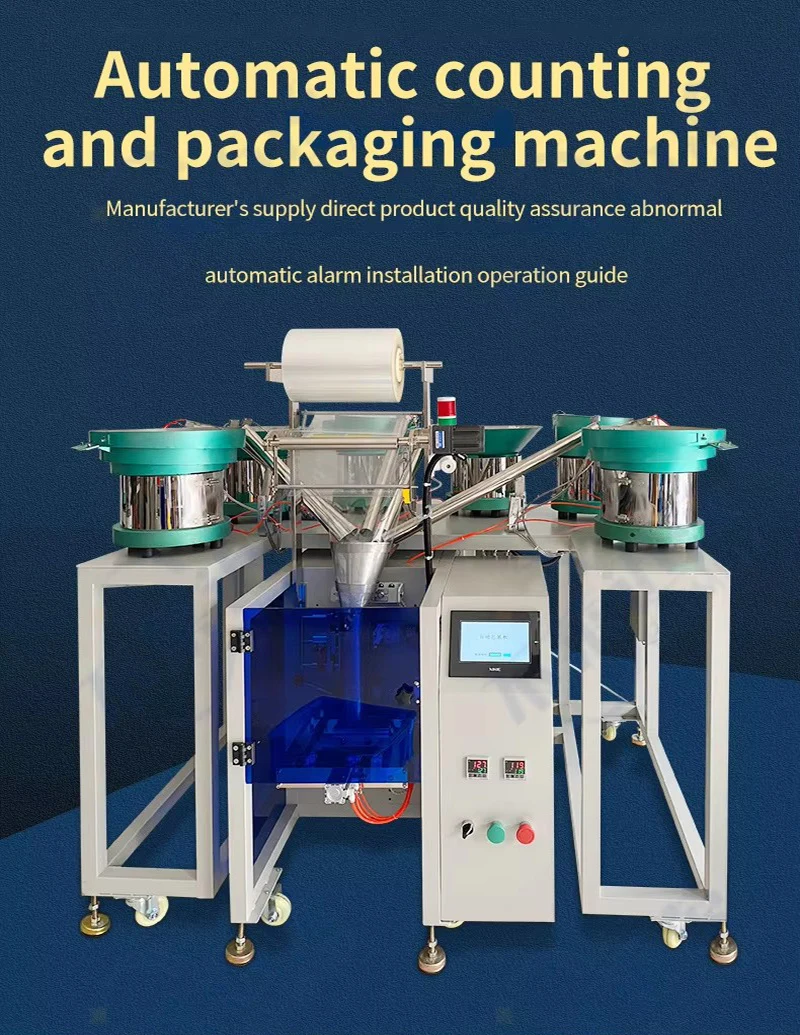

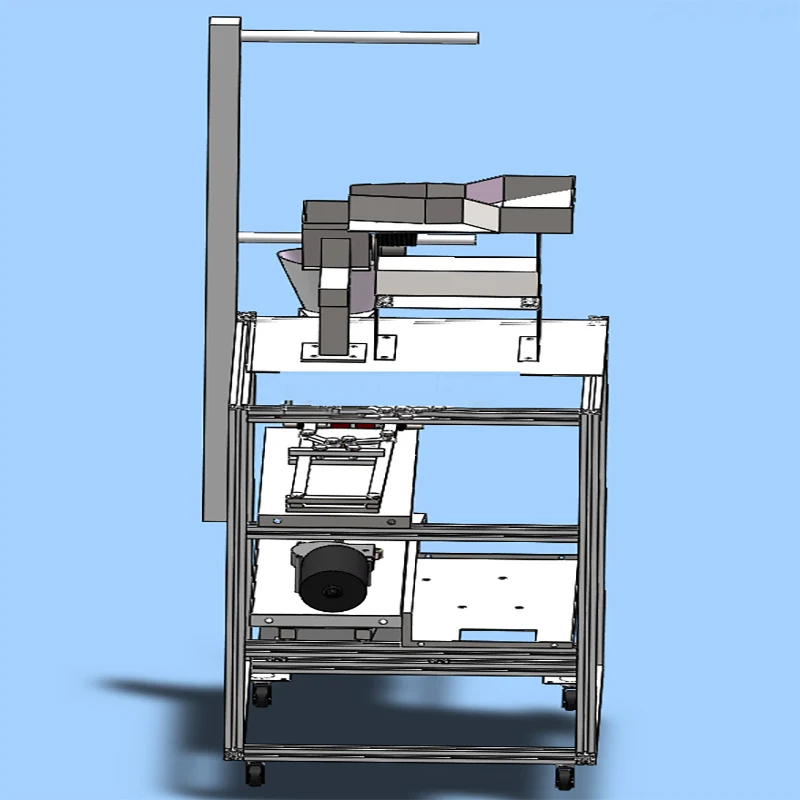

This Automatic Sorting and Screening Disk of Metal Washer Screws and Linear Feeder is an advanced device specifically designed for the efficient processing of metal washers and screws. It can automatically carry out precise sorting and screening of metal washers and screws, effectively identify and separate products that do not meet the specifications, greatly improving the product quality and production efficiency. The linear feeder part adopts advanced technology, which can smoothly and contin

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The following are some advantages of the Automatic Sorting and Screening Disk of Metal Washer Screws and Linear Feeder:

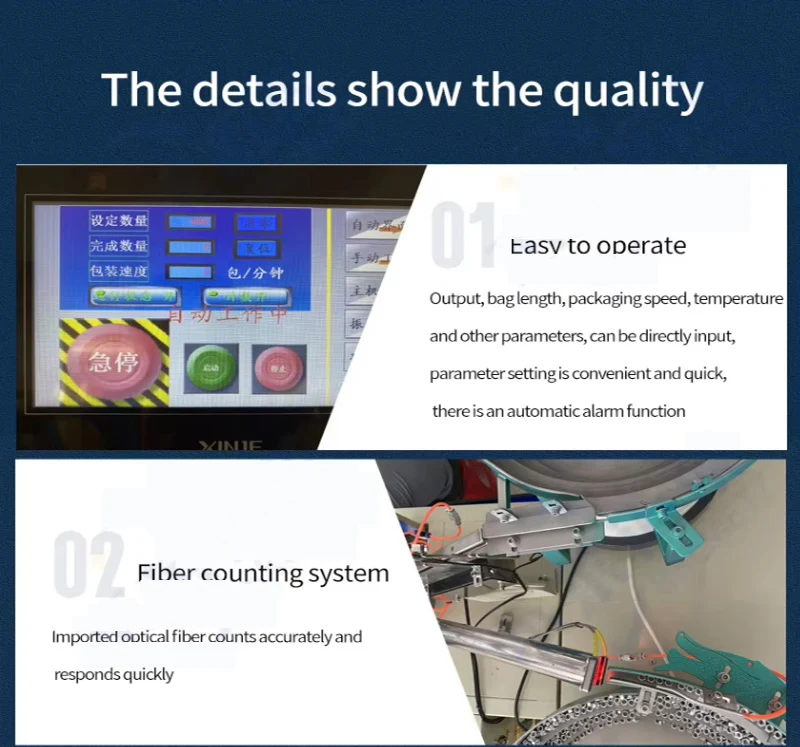

1. Efficient and Precise Sorting: It can quickly and accurately classify and screen metal washers and screws according to specifications, dimensions, shapes, etc., greatly improving the sorting efficiency and accuracy, and reducing the error rate of manual sorting.

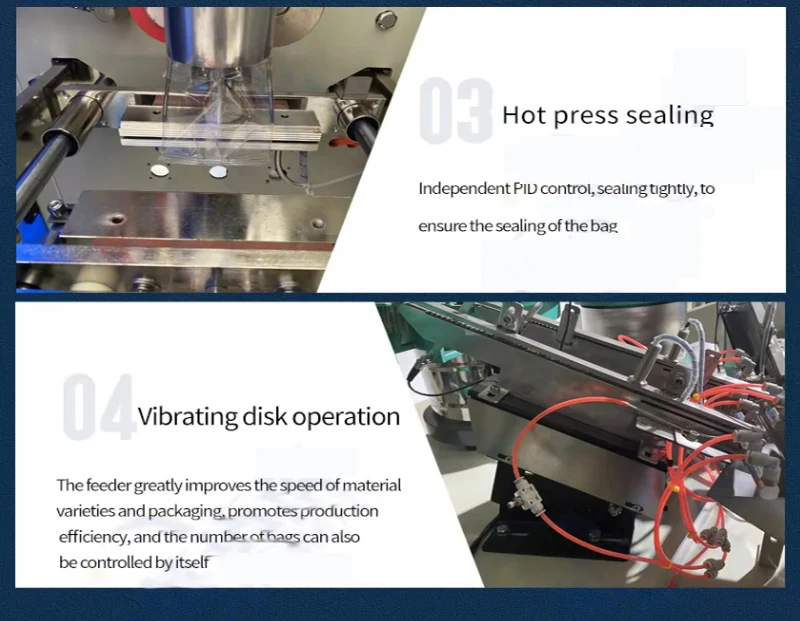

2. Increased Production Efficiency: It operates automatically and provides continuous and stable feeding, reducing the time for manual feeding and sorting. This makes the production process smoother, speeds up the production rhythm, and increases the output per unit of time.

3. Labor Cost Saving: There is no need for a large number of workers to perform cumbersome sorting and feeding work, which reduces the labor cost of enterprises. At the same time, it also reduces the labor intensity caused by manual operation.

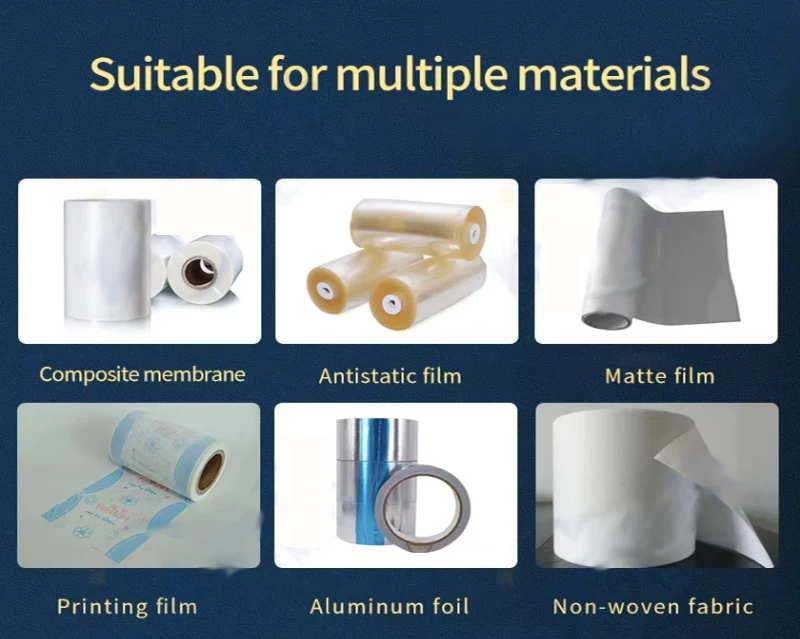

4. Wide Application Range: It can handle various types and specifications of metal washers and screws, meeting different production needs and product changes, and has good versatility and flexibility.

5. Stable and Reliable: The linear feeder works stably, and the material conveying process is smooth, reducing the damage to products caused by collisions, frictions, etc., and ensuring the product quality and the normal operation of the equipment.

6. Improved Automation Level: As an automated device on the production line, it can be integrated with other automated equipment, improving the automation level of the entire production line and making production management more convenient and efficient.

7. Strict Quality Control: Through precise sorting and screening, it can effectively eliminate unqualified products, ensure the consistency and stability of product quality, and enhance the market competitiveness of the enterprise's products.

8. Easy to Operate and Maintain: The operation interface of the equipment is simple and easy to understand, and operators can get started after a short training. The structural design is reasonable, making it convenient for daily inspection, cleaning, maintenance and other maintenance work.

Products Description

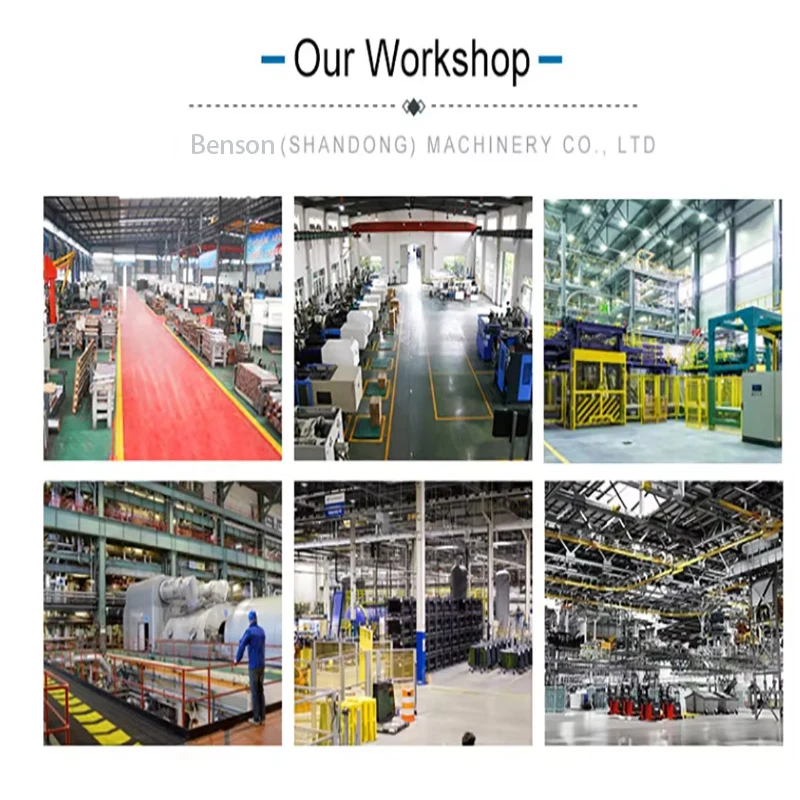

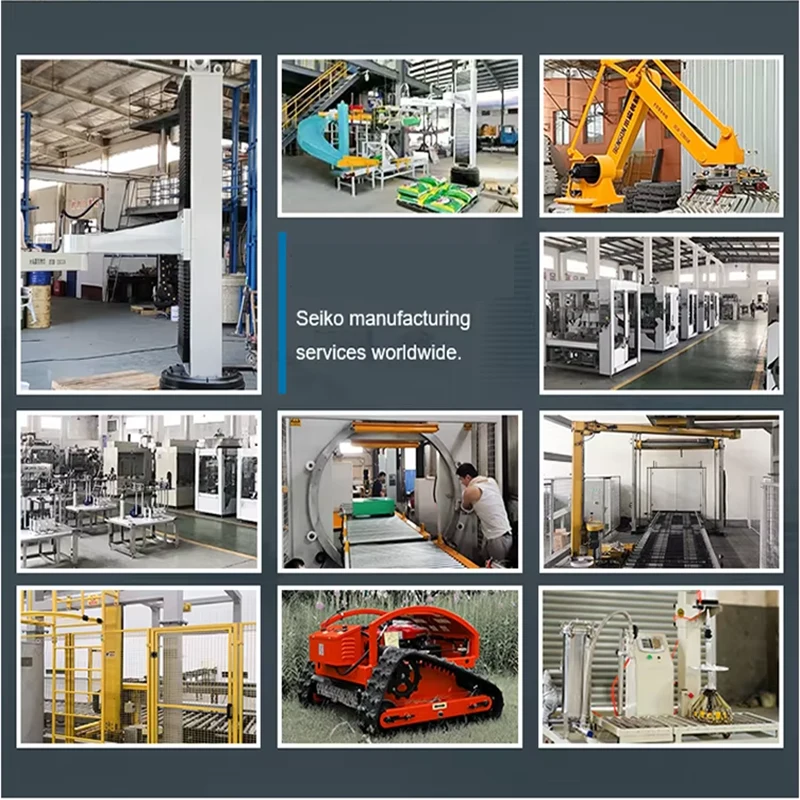

BENSON(Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry