Carton palletizing machine: efficient and intelligent core equipment for logistics and warehousing

In the field of modern logistics and industrial production, carton palletizing machine has become a key equipment for improving work efficiency and reducing labor costs with its excellent automation and intelligent characteristics. Whether it is food and beverage, electronic appliances, or pharmaceutical and daily chemical industries, carton palletizing machine plays an indispensable role.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The carton palletizing machine integrates advanced technologies such as mechanical transmission, sensor detection, electrical control and intelligent algorithms to achieve full-process automation from carton grabbing, handling to palletizing, replacing the traditional manual palletizing method, greatly improving production efficiency and palletizing quality.

Core advantages of carton palletizing machine

Efficient and stable: The equipment runs fast and can complete the palletizing task of hundreds or even thousands of boxes per hour. Compared with manual palletizing, the efficiency is improved several times. At the same time, the precise mechanical structure and stable control system ensure that the palletizing process is smooth and orderly, avoiding damage and collapse of cartons and ensuring the safety of goods.

Flexible customization: The palletizing mode can be flexibly adjusted according to different carton sizes, weights and palletizing requirements, and supports multiple arrangement methods (such as determinant, staggered, etc.) and palletizing layer settings. Whether it is a standard specification carton or a carton of special shape and size, perfect palletizing can be achieved.

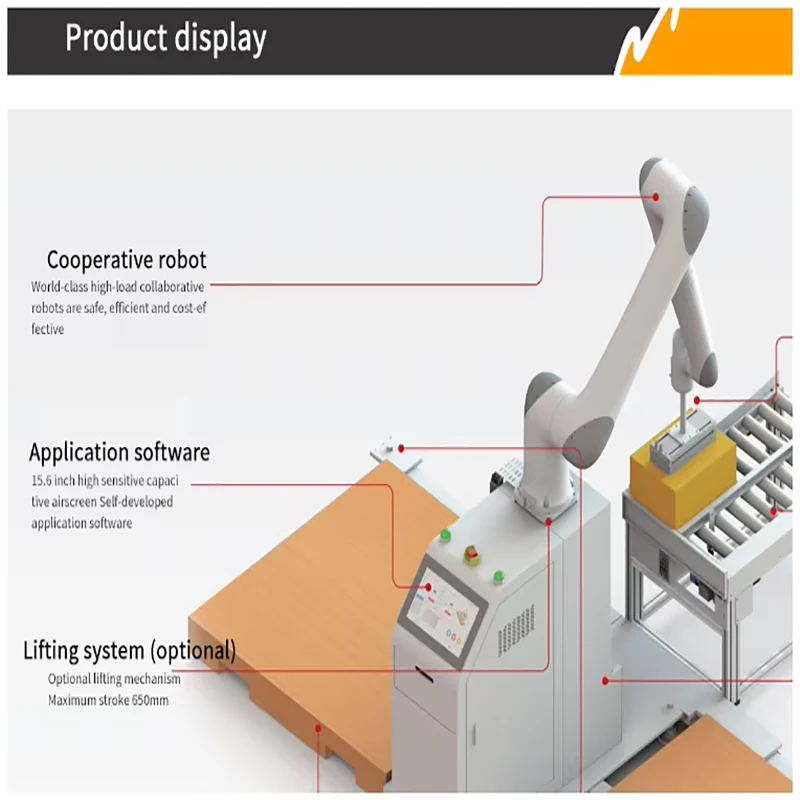

Intelligent operation: It adopts advanced PLC control system and touch screen human-computer interaction interface, which is simple and convenient to operate. The operator only needs to enter the relevant parameters on the touch screen, and the equipment can automatically complete the palletizing operation. In addition, the equipment also has a fault self-diagnosis function, which can quickly locate and display fault information, so that maintenance personnel can handle it in time and reduce downtime.

Cost saving: Automated palletizing reduces dependence on manual labor, reduces labor costs and management costs. At the same time, a reasonable palletizing method can make full use of pallets and storage space, improve space utilization, and further reduce the operating costs of enterprises.

Safe and reliable: Equipped with complete safety protection devices, such as photoelectric sensors, safety fences, emergency stop buttons, etc., it effectively prevents operators from accidentally touching the equipment and ensures personnel safety. The equipment operates stably and reliably, has a long maintenance cycle and a long service life, providing guarantees for the long-term and stable production of enterprises.

Workflow of carton palletizing machine

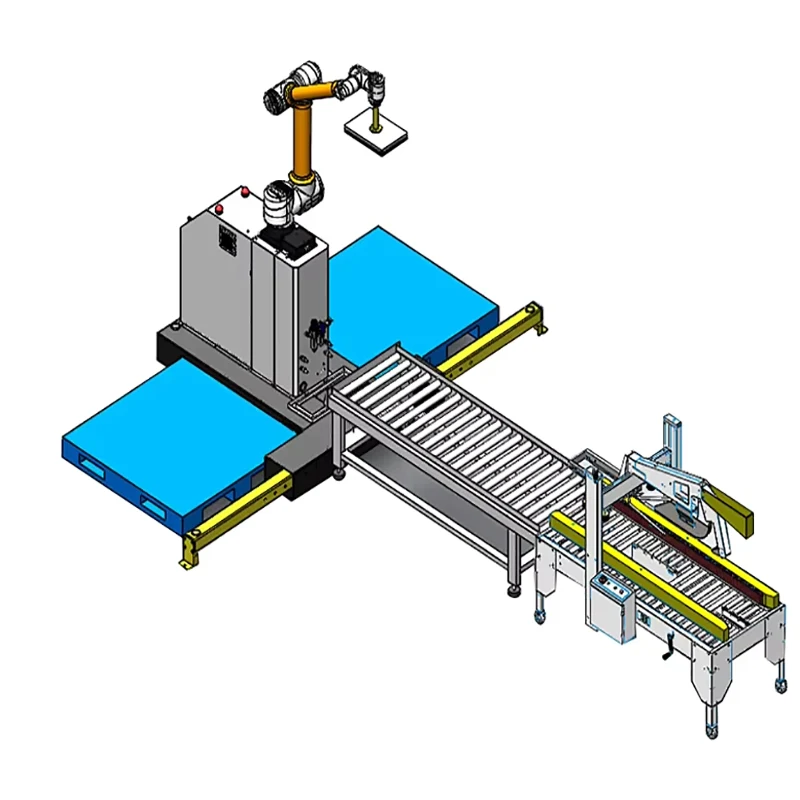

Carton conveying: The cartons on the production line are transported to the grabbing station of the carton palletizing machine in an orderly manner through conveying equipment such as belt conveyors and roller conveyors.

Carton grabbing: The grabbing device (such as vacuum suction cup, clamping gripper, etc.) installed on the robot arm can accurately grab single or multiple cartons according to the type and characteristics of the cartons. The vacuum suction cup is suitable for cartons with flat surfaces, and the cartons are adsorbed by generating vacuum suction; the clamping gripper is suitable for heavier or irregularly shaped cartons, and is grabbed by mechanical clamping.

Handling and palletizing: After grabbing the carton, the robot arm moves the carton to the top of the pallet according to the preset trajectory, and accurately places the carton at the designated position on the pallet according to the set palletizing mode. After completing one layer of palletizing, the pallet automatically descends to a certain height to facilitate the next layer of palletizing until the set number of palletizing layers is reached.

Pallet output: The pallet after palletizing is transported to the designated area through the conveyor line, waiting for the forklift or other handling equipment to transfer it to the warehouse or transport vehicle.

Application scenarios of carton palletizing pallet machine

Food and beverage industry: suitable for palletizing of various food packaging boxes and beverage cartons, such as instant noodle boxes, bottled beverage boxes, canned beer boxes, etc., to meet the food industry's requirements for hygienic, efficient and stable production.

Electronic and electrical industry: can palletize electronic equipment packaging boxes and home appliance cartons to ensure that the products are not damaged during the palletizing process, and to ensure product quality and packaging integrity.

Pharmaceutical and daily chemical industry: plays an important role in the palletizing of pharmaceutical product packaging boxes and daily chemical product cartons, strictly follows the production specifications and hygiene standards of the pharmaceutical industry, and provides reliable guarantees for the storage and transportation of medicines and daily chemical products.

Logistics and warehousing industry: as an important equipment for logistics centers and warehouses, it can quickly and efficiently palletize a large number of carton goods, improve cargo turnover efficiency, and optimize warehousing management.

Products Description

Company Profile

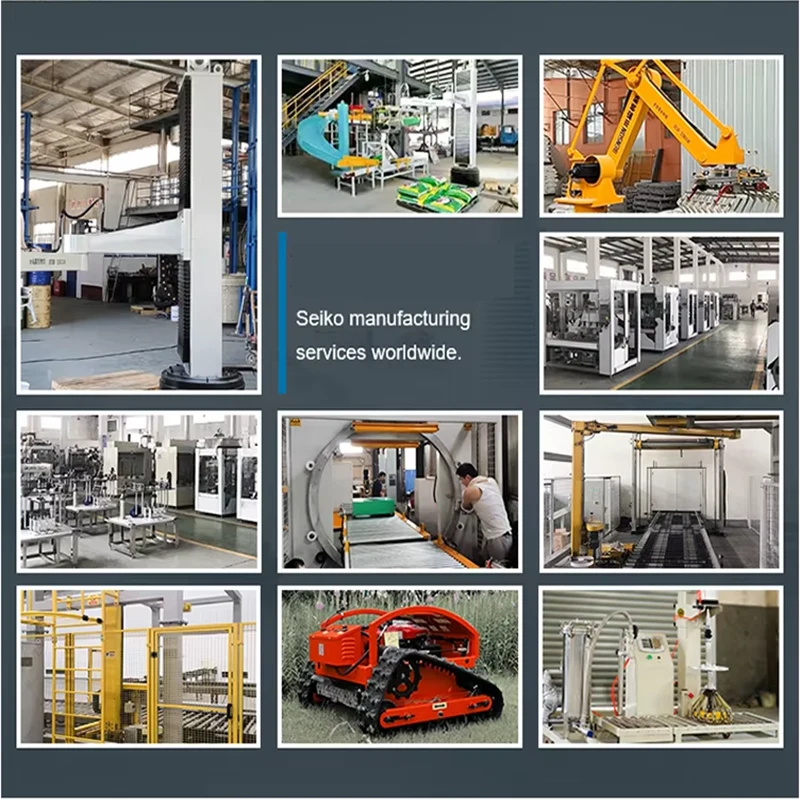

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

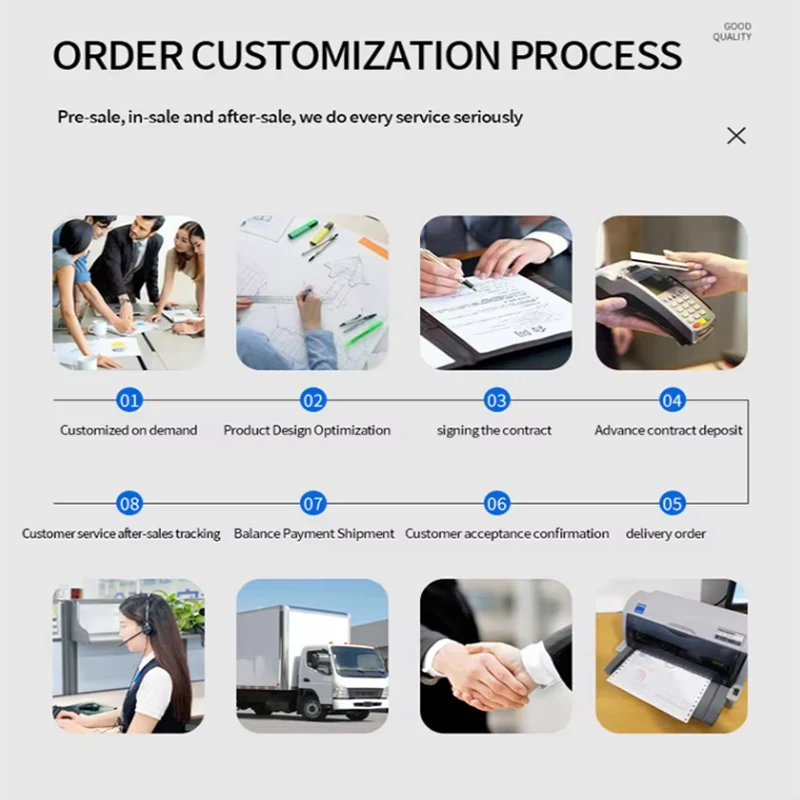

Product Inquiry