The intelligent high - level palletizing machine equipment is an important device on the modern industrial automated production line. It integrates advanced sensing technology, robot control algorithms, and artificial intelligence systems, enabling it to accurately and efficiently stack products neatly on pallets. During operation, it quickly locates products through the visual recognition system and, in conjunction with a high - speed and stable robotic arm, can achieve thepalletizing operation

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

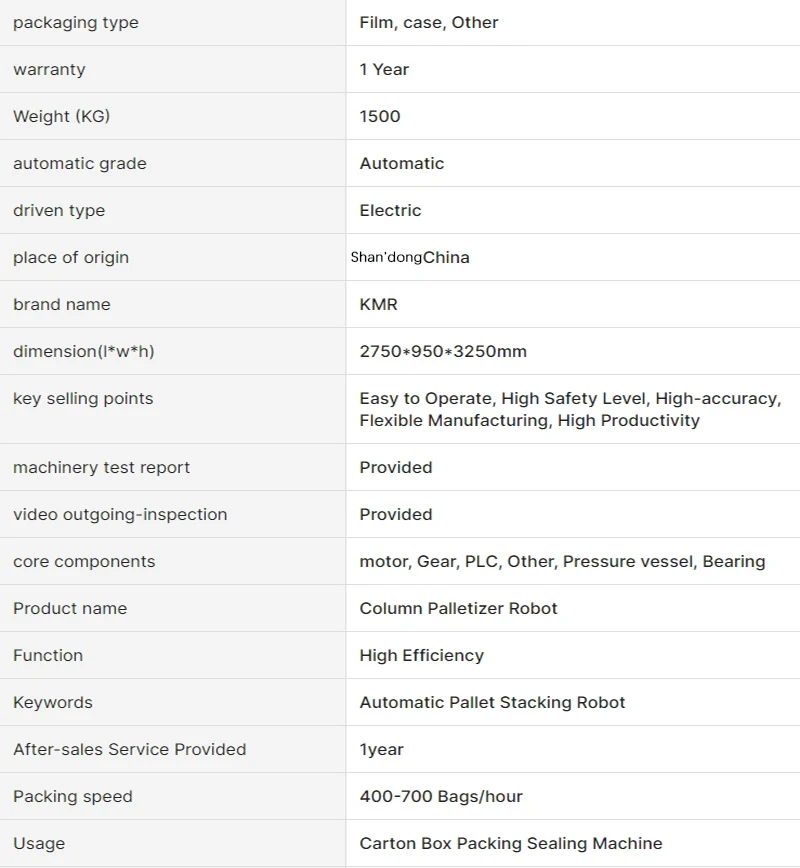

Products Description

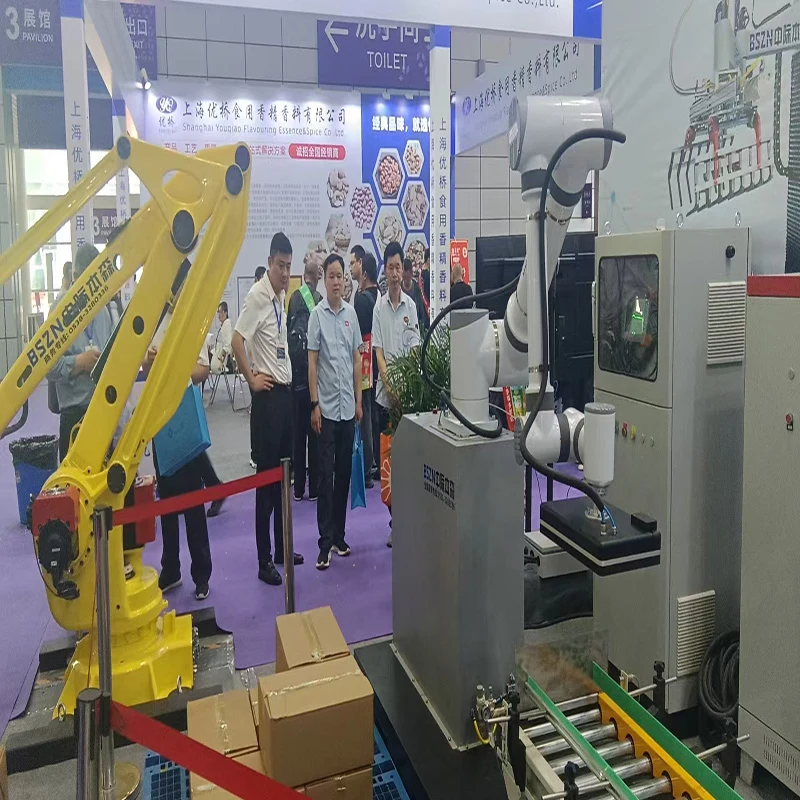

Intelligent high - level palletizing machine equipment

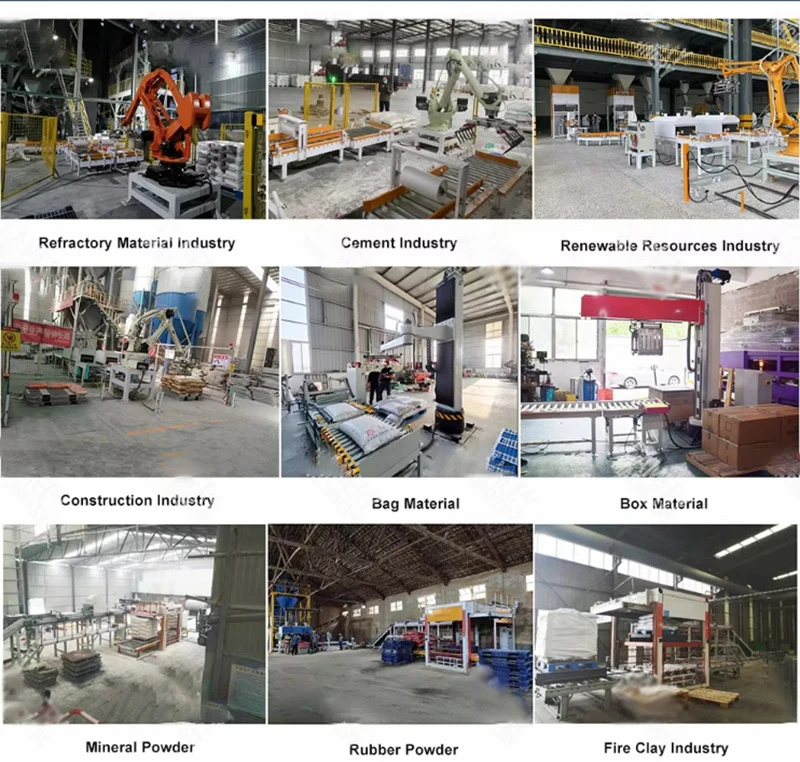

As a core automated equipment in the Industry 4.0 era, the intelligent high - level palletizer is built on a high - strength gantry truss structure. With a four - axis servo drive system, it achieves millimeter - level precise positioning. The maximum running speed reaches 300 times per hour, and the single - cycle operation beat is compressed to 12 seconds. The front end of the equipment integrates an AI vision sorting system, equipped with deep - learning algorithms. It can complete the identification and analysis of the size, material, and placement angle of incoming materials within 0.5 seconds. Combined with an adaptive flexible gripper and a vacuum negative - pressure adsorption device, it can achieve non - destructive grasping of more than 10 types of material forms such as cartons, plastic packages, and barrels. Its digital control system supports 3D stack pattern simulation modeling. Users can quickly configure more than 30 standard stack patterns through the HMI human - machine interaction interface and also be compatible with custom layout editing. The built - in IoT module supports remote operation and maintenance and real - time upload of production data. Together with the fault predictive maintenance system, it effectively ensures that the overall OEE efficiency of the equipment reaches over 95%. This equipment is widely used in the post - packaging processes of industries such as food and beverage, new energy materials, and pharmaceutical and chemical industries. A single device can replace 8 - 10 workers, significantly improving the intelligent level and operational efficiency of the production line.

Customer Sites

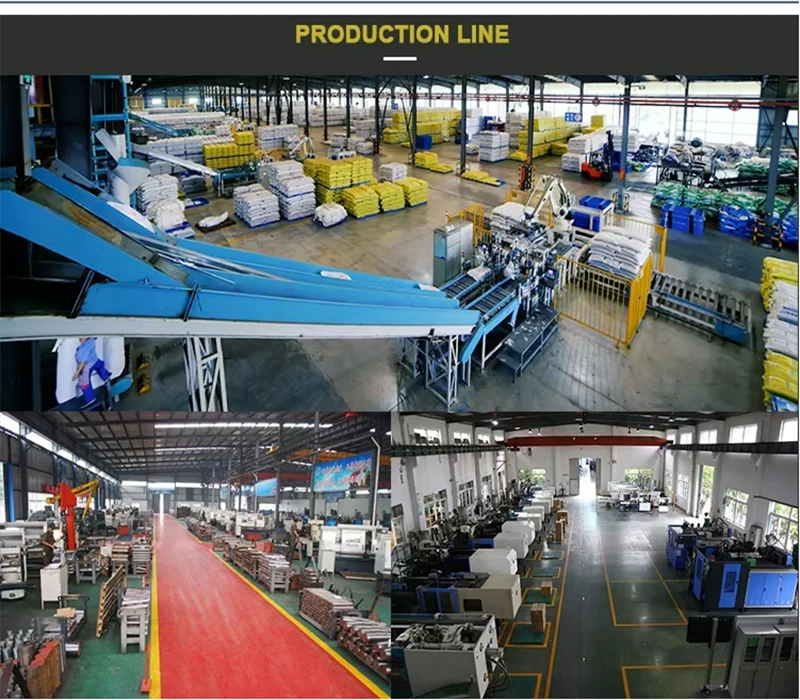

Company Profile

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, produ

ction and sales.

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machin

e, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other i

ndustries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries includ

ing United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solu

tion with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced dome

stic and foreign client.

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

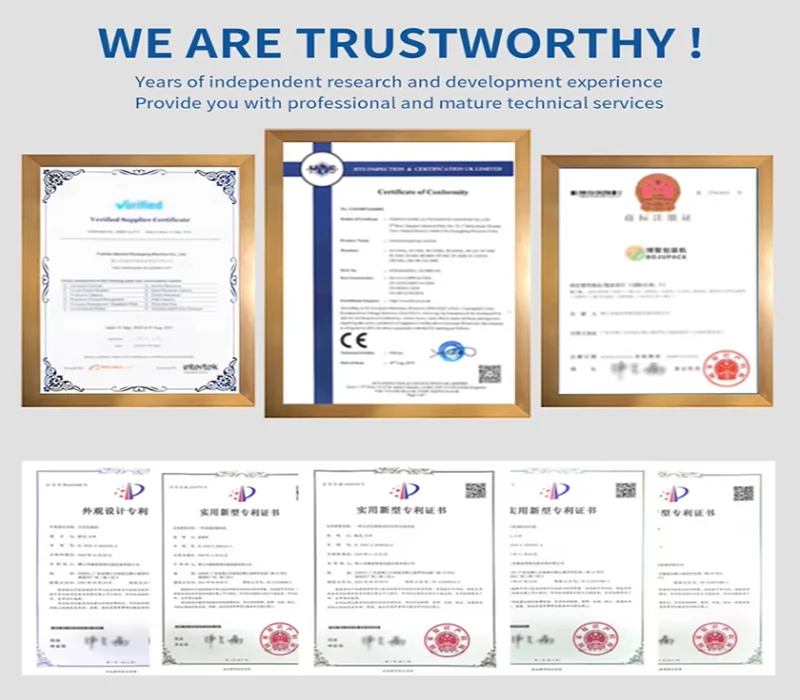

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

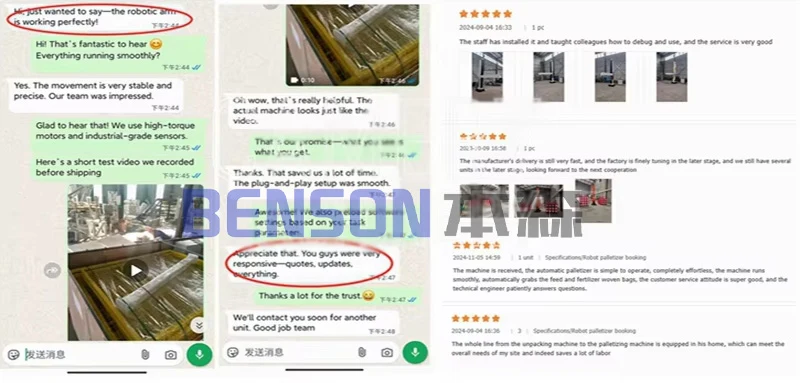

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry