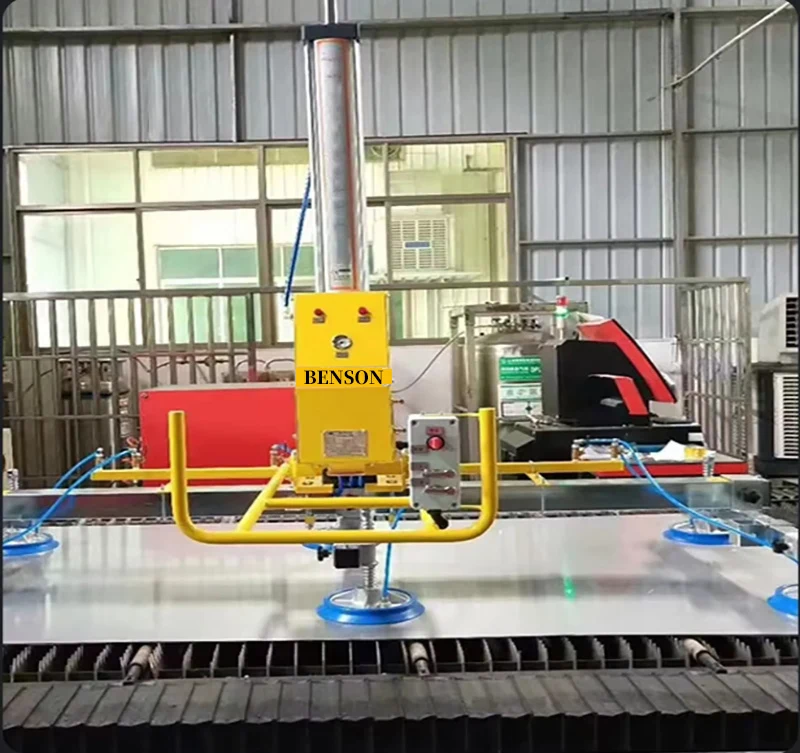

Working Principle

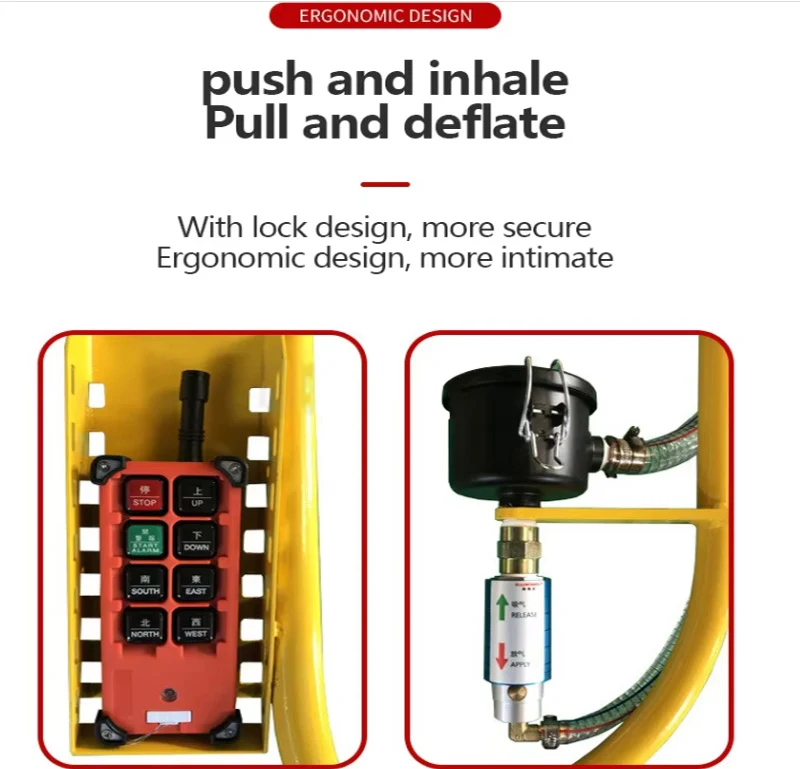

It relies on a vacuum pump or a vacuum generator to create a vacuum, which forms a pressure difference between the suction cup and the surface of the thin plate, thereby adsorbing the thin plate. When it is necessary to release the thin plate, air is allowed to enter the suction cup by controlling the valve, eliminating the vacuum state, and the thin plate can then be detached from the suction cup.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

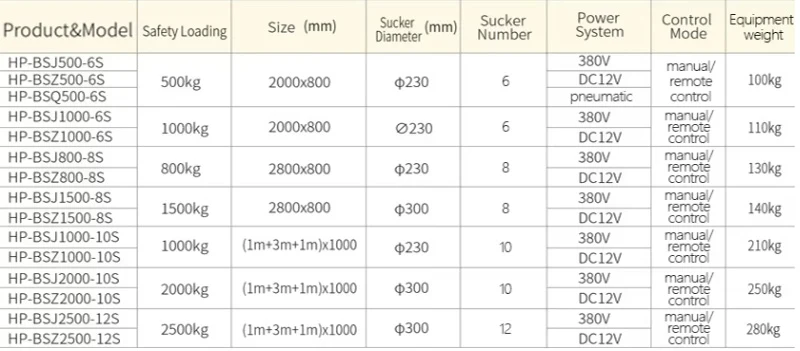

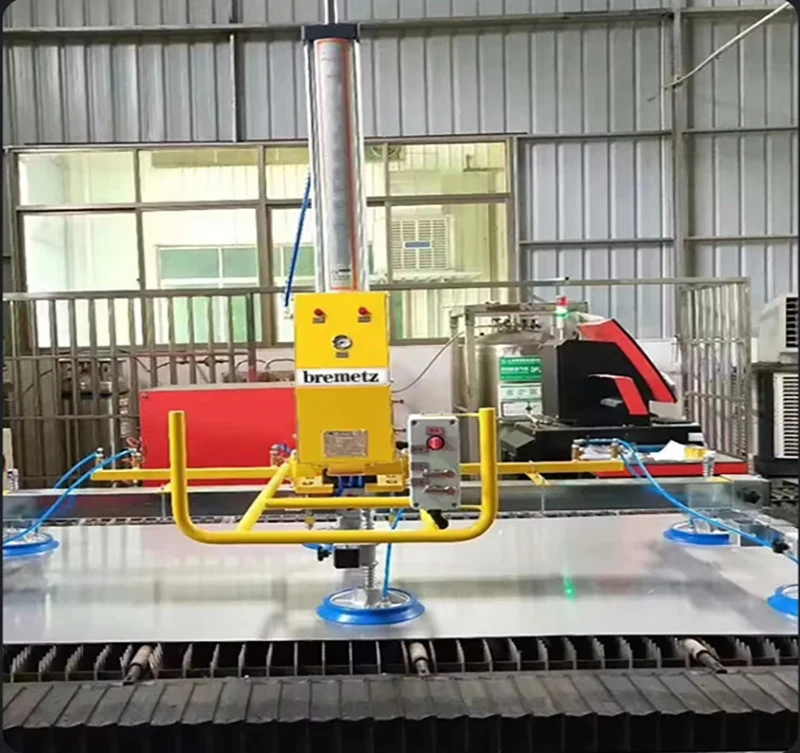

Industrial thin - plate vacuum lifterStructural Composition

- Suction Cup: Made of materials such as rubber, it has good sealing and wear - resistance properties, and can closely adhere to the surface of the thin plate to ensure the adsorption effect. Common shapes include circular, rectangular, etc., and they can be selected according to the size and shape of the thin plate.

- Vacuum Pump or Vacuum Generator: A vacuum pump can continuously pump air to maintain a vacuum and is often used in situations where a large degree of vacuum and air - extraction volume are required; a vacuum generator uses the energy of compressed air to generate a vacuum and has the advantages of simple structure and low cost.

- Control System: It includes vacuum pressure sensors, control valves, operation buttons, etc., which are used to monitor the vacuum degree, control the adsorption and release of the suction cup, and realize the automated operation of the equipment.

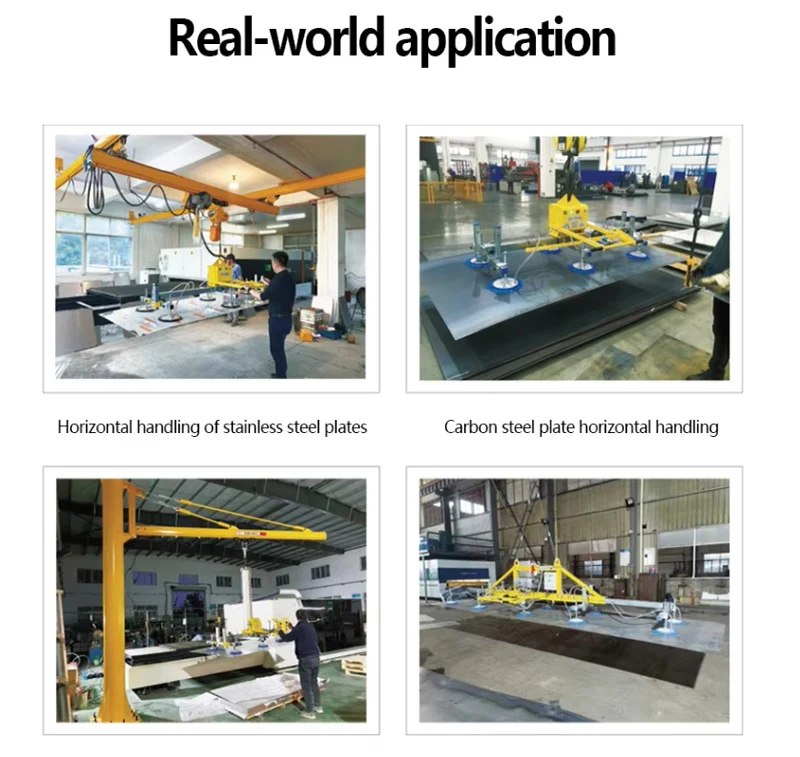

- Robotic Arm or Hanger: Used to support and move the suction cup assembly, it can realize the handling of thin plates at different positions. Common structures include cantilever - type and gantry - type.

Industrial thin - plate vacuum lifterPerformance Characteristics

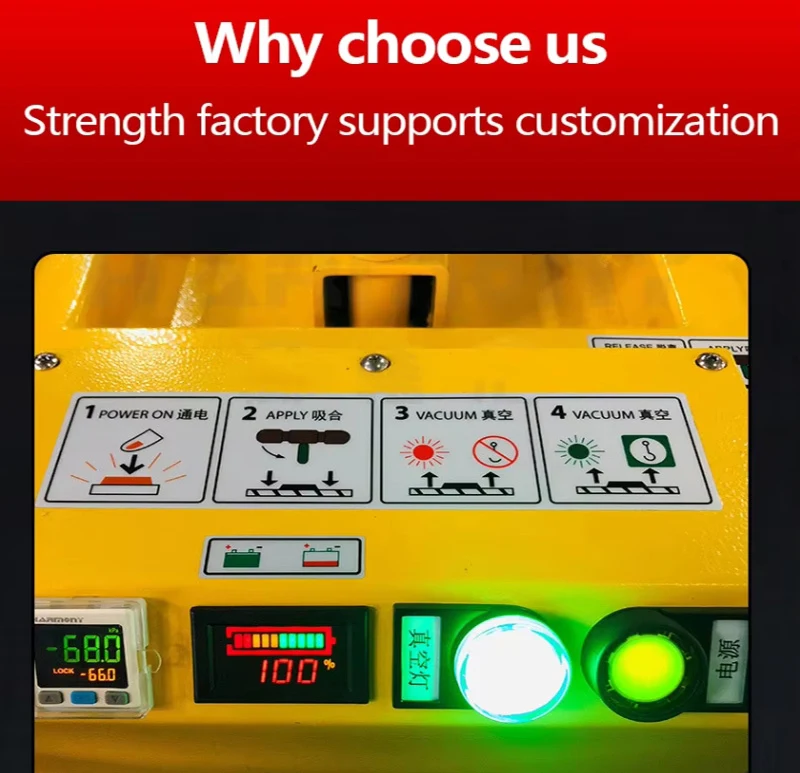

- High - efficiency: It can quickly complete the adsorption and release actions of thin plates. When coordinated with an automated production line, it can significantly improve production efficiency and reduce manual handling time.

- Safety: It is equipped with multiple safety protection measures, such as vacuum pressure monitoring and alarm. When the vacuum degree is insufficient, it will give a timely reminder to prevent the thin plate from falling; some are also equipped with backup power supplies or energy - storage devices, which can still maintain a vacuum for a short time in case of sudden power outages, ensuring safety.

- Precision: It can accurately control the adsorption position. When combined with a visual recognition system, it can accurately grasp the thin plate and achieve high - precision placement, meeting the requirements of processes with high positioning requirements for thin - plate handling.

- Non - damage: The vacuum adsorption method avoids the clamping and scratching of the thin - plate surface by traditional fixtures, and is suitable for thin plates with high surface - quality requirements, such as stainless - steel thin plates and aluminum plates.

Product Description

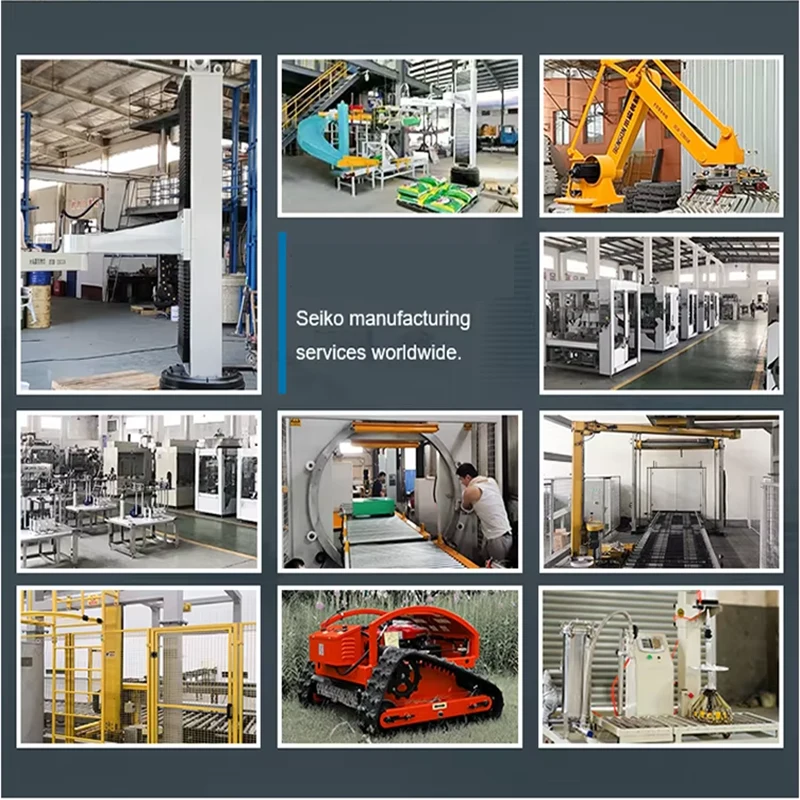

BENSON (Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON(Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry